In the world of paints and coatings, decision-makers often grapple with continuous advancements and material choices. Among these innovations, zirconium silicate has emerged as a game-changer. It addresses concerns such as durability, environmental impacts, and overall performance in various applications. This article will explore how zirconium silicate influences the future of coatings, providing insights valuable to purchasing managers and industry leaders. With a focus on practicality and innovation, we aim to offer credible solutions that enhance product formulations and meet the demands of today’s market.

How is Zirconium Silicate Relevant to Coatings?

Zirconium silicate stands out as an essential ingredient in modern coatings. Its unique chemical composition provides significant advantages, including enhanced durability and improved performance.

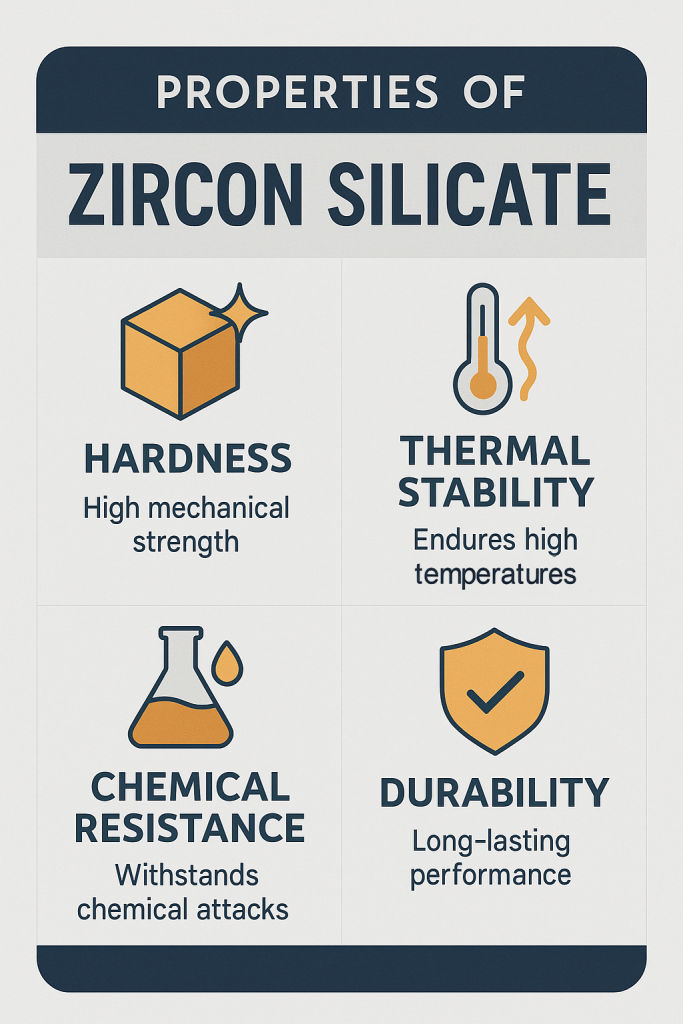

The key properties of this material include:

- Chemical Resistance: It withstands harsh chemicals, making it ideal for industrial applications where exposure to aggressive agents is common.

- Thermal Stability: This enables coatings to maintain integrity and performance under high temperatures, making them suitable for various environments.

- Mechanical Strength: Enhanced hardness contributes to better resistance against scratches and wear, ensuring a longer lifespan for coated products.

These qualities make zirconium silicate suitable for a wide array of applications, spanning industrial to decorative coatings.

The benefits are clear: using this material reinforces paint formulations, resulting in a finish that can withstand even the harshest of environmental conditions.

Here’s the point: manufacturers see lower costs in maintenance and repairs, which enhances overall client satisfaction. This economic advantage cannot be overlooked, especially in sectors where budgets are tight.

Moreover, discussions about zirconium silicate’s role in coatings often reflect growing concerns about environmental impacts. Coatings containing this material tend to have a longer lifespan, thus reducing waste caused by frequent reapplications. As companies focus on corporate social responsibility, the sustainability aspect of this ingredient plays a pivotal role in decision-making.

In essence, this silicate creates coatings that are not only high in performance but also beneficial from a sustainability perspective. As such, its relevance in the coating industry continues to grow, prompting companies to rethink their material choices.

This image illustrates the key properties of zirconium silicate, highlighting its strength and chemical resistance.

What Innovations in Zirconium Silicate Are Changing Paints?

Recent technological breakthroughs have transformed how zirconium silicate integrates into paint formulations. These advancements allow for improved application methods and better end-product quality.

Manufacturers are now exploring modified versions, which enhance dispersion within paints. This innovation results in smoother application and improved texture in finished products.

Companies have also started utilizing advanced processing techniques. Processes like nanotechnology enable the creation of extremely fine particles, which can further enhance functionality in coatings.

The compatibility between zirconium silicate and various binder systems is an aspect worth noting. This compatibility gives formulators more flexibility, allowing them to create customized solutions tailored to specific market needs.

For example, some manufacturers have developed environmentally friendly paints that safely incorporate zirconium. This not only reduces harmful emissions but also appeals to an increasingly eco-conscious consumer base.

Here’s a compelling statistic: coatings using this material can improve longevity by up to 30%. This impressive figure highlights the cost-effectiveness associated with this solution. Additionally, these changes align with a shift toward high-performance and eco-friendly formulations in the paint industry.

The following table illustrates some of the latest innovations in this material and their applications:

| Innovation | Description | Application |

|---|---|---|

| Modified Zirconium Silicate | Enhances dispersion and texture | Custom paint formulations |

| Nano-Zirconium Silicate | Provides improved UV resistance | Exterior coatings |

| Hybrid Systems | Integrates zirconium with other materials | Specialty industrial applications |

These innovations clarify how zirconium silicate adapts to meet modern demands and can shape future formulations significantly. A continuous focus on innovation will undoubtedly keep companies ahead of the curve.

This image showcases various innovations in coatings that incorporate zirconium silicate technology.

Why Choose Zirconium Silicate in Modern Coating Formulations?

Choosing this silicate for paint and coating formulations offers numerous advantages for manufacturers. This versatile material plays a crucial role in enhancing the quality and performance of various products.

One of the standout benefits is its durability. Coatings formulated with it exhibit superior resistance to environmental stressors. This includes exposure to heat, humidity, and harsh chemicals, making these coatings preferred choices in many industries.

Another point worth noting is its eco-friendliness. As businesses strive for sustainability, products containing zirconium provide a route to reduce environmental impact. Longer-lasting coatings mean less frequent replacements, a benefit that collectively contributes to reducing landfill waste.

Consider the following benefits of incorporating zirconium silicate into coatings:

- Cost-Effectiveness: Lower maintenance and replacement costs lead to substantial savings over time.

- Market Appeal: Decreasing environmental footprints aligns with consumer preferences, increasing marketability.

- High Performance: Delivering enhanced durability fulfills consumer demand for robust products.

Here’s a compelling statistic: coatings using this ingredient can improve longevity by up to 30%. This impressive figure highlights the cost-effectiveness associated with this material. By focusing on long-term benefits, companies can strategically position themselves in the market.

For organizations wanting to remain competitive, the choice of zirconium silicate marks a strategic advantage. Not only does it align with current trends toward sustainability, but it also promotes the production of high-quality, reliable coatings.

How Does Zirconium Silicate Improve Performance?

The performance enhancements offered by this material are noteworthy, impacting various aspects of coating products.

Primarily, it enhances durability and prolongs the life of coatings. This silicate allows for better adhesion to substrates, ensuring that the coatings stay intact even in the toughest conditions.

Furthermore, coatings featuring this additive provide significant chemical resistance. This capability protects against acids, bases, and corrosive environmental pollutants. As a result, facilities utilizing these coatings often see longer intervals between reapplications, which is a key consideration for operations management.

Layering coatings that incorporate zirconium can further improve overall performance. For instance, when applied over an initial layer that acts as a primer, the final finish can become even more resilient against wear and environmental factors.

To understand the performance characteristics more clearly, consider the following table comparing standard coatings with those incorporating zirconium:

| Property | Standard Coating | Coating with Zirconium Silicate |

|---|---|---|

| Adhesion to substrate | Moderate | High |

| Chemical resistance | Low | High |

| Longevity | 5 years | 10+ years |

| Surface hardness | Moderate | High |

These performance improvements are compelling reasons to consider zirconium silicate in paint formulations. Superior standards lead to satisfied clients, minimizing complaints regarding operational environments.

This image compares the performance characteristics of standard coatings versus those with zirconium silicate.

What Applications Utilize Zirconium Silicate in Coatings?

Zirconium silicate finds applications across various industries, illustrating its versatility and utility in coatings.

In industrial settings, it is frequently adopted in protective coatings for machinery and equipment. These applications rely on high durability and resistance to corrosion. The material is particularly valuable in manufacturing environments where equipment is exposed to moisture and harsh cleaning agents.

In residential segments, coatings featuring this additive deliver aesthetically pleasing finishes that endure over time. Exterior coatings often witness significant performance rises through its inclusion. For example, houses painted with high-quality exterior paint containing zirconium show less fading and peeling compared to those using standard alternatives.

Here’s an illustrative example from the automotive sector: cars that utilize coatings with this additive often exhibit enhanced paint longevity and gloss. These traits appeal to manufacturers aiming to exceed expectations in quality and durability for consumers.

The following table showcases different industry applications and the benefits of this material in each:

| Industry | Application | Benefits |

|---|---|---|

| Industrial | Protective coatings | High durability and chemical resistance |

| Automotive | External paint | Enhanced gloss and longevity |

| Residential | Wall finishes | Aesthetically pleasing, long-lasting |

| Marine | Boat coatings | Strong moisture and UV resistance |

| Aerospace | Aircraft coatings | High-performance under extreme conditions |

These applications signify how zirconium plays a pivotal role in effectively addressing the unique needs of various markets. Understanding this adaptability is crucial for decision-makers focusing on product development.

How Can Businesses Integrate Zirconium Silicate?

Integrating this silicate into existing product lines requires careful planning and consideration. Here are some essential steps for businesses looking to adopt this material successfully.

- Assess Current Formulations: Companies must thoroughly analyze how the additive will interact with existing components. Testing sample batches before full-scale production offers a practical approach to prevent costly rollbacks.

- Establish Supplier Relationships: Building partnerships with reliable zirconium suppliers is crucial. Suppliers can provide insights into product quality, consistency, and material handling.

- Train Staff Members: It’s vital that formulation teams understand how to use zirconium effectively. This knowledge ensures they can harness its potential properly, maximizing benefits in the formulation process.

- Evaluate Cost Implications: While initial costs may appear higher, the long-term return on investment can be significant. Businesses might find that improved product longevity justifies the initial expenditures.

The following table provides a summary of steps for effective integration of zirconium into formulations:

| Step | Action Needed |

|---|---|

| Assess current formulations | Analyze compatibility with existing product components. |

| Establish supplier ties | Partner with trusted zirconium suppliers and understand their offerings. |

| Train staff | Educate formulation teams on optimizing zirconium usage. |

| Evaluate costs | Consider ROI against initial investment and long-term benefits. |

Successful integration leads to enhanced product quality, solidifying a competitive edge in the marketplace, ultimately supporting business growth.

What Challenges Are Associated with Zirconium Silicate?

While this silicate presents numerous benefits, challenges exist that manufacturers should acknowledge.

One significant concern is the sourcing of high-quality zirconium, as variability in purity can affect coating performance. Companies must ensure they select reputable suppliers who meet established quality standards.

Another issue arises with compatibility among ingredients. Formulators should carefully consider how zirconium interacts with other components in the formulation. Poor compatibility might lead to unfavorable reactions, undermining the intended benefits.

In addition, costs can pose challenges. Although the long-term benefits are promising, initial investment costs for high-quality zirconium may deter some businesses.

Mitigating these challenges requires careful planning and communication with suppliers. Companies might consider creating comprehensive checklists for evaluating potential zirconium suppliers and developing pilot programs for testing compatibility before full-scale implementation.

The following table summarizes some of the challenges and mitigation strategies:

| Challenge | Mitigation Strategy |

|---|---|

| Sourcing quality material | Partner with trusted suppliers with a solid track record. |

| Compatibility concerns | Conduct rigorous formulation testing with various combinations. |

| Initial investment costs | Evaluate long-term ROI, considering phased implementation for better cash flow management. |

Adapting to these challenges is vital for successfully leveraging zirconium in coatings while maintaining product integrity and performance.

How Do Regulations Impact Zirconium Silicate Use?

Regulatory considerations play a significant role in the use of this material within coatings. Environmental protection laws often dictate the types of materials that can be used in products.

It is crucial for companies to stay informed about relevant regulations within their regions. Compliance with laws relating to hazardous materials ensures avoidance of fines and reputational damage. Moreover, many companies must also consider labeling requirements for end products that include chemicals.

Manufacturers may also need to provide safety data sheets and other documentation that demonstrate adherence to safety and environmental standards, which are increasingly scrutinized in today’s market.

To simplify adherence to regulations, here’s a practical approach: companies should conduct regular reviews of regulatory changes. Collaborating with legal teams ensures that every product stays compliant. Establishing strong relationships with regulatory agencies can also provide insights into impending changes, helping organizations prepare ahead of time.

The following table lists critical regulations impacting the use of zirconium in coatings:

| Regulation | Impact on Use |

|---|---|

| EPA Regulations | Standardizes safety and environmental impact assessments for product formulations. |

| OSHA Standards | Governs workplace safety and handling requirements for employees interacting with the material. |

| REACH Compliance | Requires manufacturers to register substances used in coatings, increasing accountability. |

Understanding these regulations helps manufacturers navigate compliance complexities, ultimately ensuring a successful market presence while fostering consumer trust.

What are the Future Trends in Coatings with Zirconium Silicate?

Looking ahead, several trends signal the future direction of coatings containing zirconium. One significant trend includes an increasing emphasis on sustainability as industries shift toward greener practices.

Manufacturers are focusing on reducing their overall carbon footprint. Products that utilize zirconium align with this goal, producing coatings that promote longer life spans, thus minimizing waste and resource utilization.

Moreover, advancements in nanotechnology are expected to open new frontiers for applications in this area. Utilizing nanoparticle-sized zirconium can boost functionality in coatings, enhancing properties like adhesion, UV resistance, and overall durability.

An interesting development is the increasing demand for high-performance coatings. As businesses seek innovative solutions to meet evolving consumer preferences, formulations incorporating zirconium will likely become more prevalent.

Additionally, the rise of digital tools in formulation development can streamline processes. As technology is embraced within the industry, how companies manage their product offerings will evolve, leading to greater efficiencies.

The following table displays anticipated future trends related to zirconium in coatings:

| Trend | Potential Impact |

|---|---|

| Sustainability focus | A higher demand for eco-friendly coatings that align with consumer preferences. |

| Nanotechnology advancements | Enhanced performance characteristics and new applications in various sectors. |

| Digital formulation tools | Streamlined processes leading to expedited innovation and quicker time-to-market. |

These trends highlight how zirconium will continue to shape the coatings industry moving forward, driving innovation and sustainability simultaneously.

How to Choose the Right Supplier for Zirconium Silicate?

Selecting the right supplier for zirconium is crucial for a successful production outcome. Start by evaluating the supplier’s reputation, checking reviews, case studies, and industry standing.

Next, examine the quality of zirconium offered. Request product samples and conduct thorough tests to ensure they meet or exceed your specifications, as performance consistency is key.

After establishing the quality, assess the supplier’s ability to ensure timely deliveries and a consistent supply. Delays in obtaining necessary materials can adversely affect production schedules, which can lead to dissatisfaction among clients and stakeholders.

Moreover, consider whether the supplier offers comprehensive technical support. Having access to knowledgeable representatives can facilitate smoother integration of zirconium into formulations, ensuring that your team maximizes its potential.

Lastly, pricing plays a role in supplier selection but should not be the only factor. The overall value, including quality assurances, service reliability, and responsiveness, often outweighs short-term savings.

Here’s a table summarizing critical factors to consider when choosing a supplier:

| Selection Factor | Consideration |

|---|---|

| Reputation | Look for extensive reviews and industry recognition. |

| Product quality | Request samples and conduct tests to verify quality. |

| Reliability | Ensure the supplier can consistently provide timely deliveries. |

| Technical support | Access to knowledgeable representatives for product optimization. |

| Pricing | Compare the overall value, including quality and services, not just costs. |

Choosing the right supplier sets the foundation for successful product development and market competitiveness, ultimately enhancing customer satisfaction.

Conclusion

In this comprehensive examination of zirconium’s impact on the coatings industry, we explored its relevance, innovations, and the performance enhancements it brings. Notably, adopting this additive can improve durability and sustainability while also aligning with market trends. Organizations can significantly boost their competitive edge by making informed decisions about material choices. Global Industry stands ready to assist you in navigating these innovations, ensuring your formulations are effective and forward-thinking. For personalized advice on implementing zirconium in your product lines, reach out to us today. Your path to improved coatings begins here.

FAQ Section

Q1: What makes zirconium silicate a valuable ingredient in coatings? Zirconium silicate enhances durability, improves resistance, and offers superior performance compared to traditional materials.

Q2: Can zirconium silicate be used in all coating types? Yes, it can be incorporated into various formulations, including industrial, residential, and specialty coatings.

Q3: What are the cost implications of using zirconium silicate? Initial costs may be higher, but the long-term benefits often lead to cost savings due to enhanced performance and durability.

Q4: How does zirconium silicate affect environmental impact? It can reduce the environmental impact of coatings by improving their longevity and reducing the need for frequent reapplication.

Q5: What should companies consider before switching to zirconium silicate? Consider factors such as formulation adjustments, supplier capabilities, and regulatory compliance.