Tailored particle size, purity, and composition to match your exact process requirements

We produce Zirconia, zirconium silicate, and composite beads with precise roundness and strength.

Receive SDS, COA, and application guidance from our experienced material engineers

Launch confidently with our support for pilot runs and sample orders starting at 100kg.

Most orders ship within 7–14 days. We handle export documents for US, EU, SEA, and Africa.

Offer your brand on a reliable supply base. We help resellers and distributors grow.

We specialize in the research, development, production and sales of new zirconium products. Our main products include zirconium oxide powder, zirconium silicate powder, zircon powder, zircon sand, ceramic structural parts (zirconia beads, zirconium silicate beads, water slides, zirconium aluminum composite beads, etc.), etc., with a total of more than 40 specifications. We have been rated as national famous and high-quality products, with a market share increasing year by year, and are well received by customers.

Since its establishment, the company has continued to build a good independent brand with first-class product quality and after-sales service, maintaining its leading position in China’s zirconium industry, and striving to become a trustworthy partner for users. Relying on a complete industrial chain, relying on technological innovation and strong technical strength, we work hard and develop continuously. The company has become a domestic professional manufacturer of zirconium materials and products, providing customers with high-quality products and winning wide praise from customers at home and abroad.

We have a leading R&D, production and after-sales service team, constantly improves and perfects the production line, optimizes the production process, and builds a series of complete industry industrial chains from R&D, production, quality inspection, channels, services, etc. The company currently has more than 100 employees.

The company is a national high-tech enterprise and a strategic new industry in Shandong Province. It is a high-tech sunrise industry integrating raw material import, processing and application advocated by the national macro-control.

Since its establishment, the company has won many honors such as the top ten famous brands of casting materials in China, the member of China Building Sanitary Ceramics Association, the famous brand award of China coating raw and auxiliary materials, and the gold award of China zirconium industry science and technology content.

The company takes scientific and technological innovation as the leading factor. In order to further improve the training of technical talents and break through technical bottlenecks, it has successively formed technical alliances with relevant scientific research institutions such as Australia, Japan, Shanghai Institute of Silicon of Chinese Academy of Sciences, China University of Geosciences, provincial research and development centers, Tsinghua University, Shandong University of Science and Technology, etc., and built a national large-scale and advanced equipment zirconium silicate, nano-composite zirconium oxide powder and zirconium oxide grinding medium research and development and production center, which has developed into the largest zirconium material production base in mainland China.

Zirconia powder is used to manufacture various structural ceramics, electronic ceramics, bioceramics, advanced refractory materials, optical communication devices, oxygen sensors, high-grade ceramic colorants, etc.

Zirconia Beads are suitable for various sand mills, stirring ball mills, drum ball mills, etc. It can be used for dispersing and grinding electronic slurries, ceramic powders, magnetic materials, battery raw materials, rare earth materials, non-metallic minerals, pigments, oils, inks, polymer fibers, heavy calcium, titanium dioxide, pesticides, food, pharmaceutical raw materials.

Compared with traditional grinding media, zirconium oxide grinding media has unparalleled grinding efficiency such as high density, high hardness, high toughness and low wear.

Ceramic glaze

As an emulsifier, it is used in various types of ceramic glazes, such as floor tiles, large rock slabs and other building ceramics, toilets, wash basins and other sanitary ware, export coffee cups, dishes, tableware and other daily ceramics, coarse ceramic utensils, special porcelain, etc., and can also be used in the ceramic stick and brake pad industry.

Plastic industry

Used in epoxy resin formulations, sealing resins, fillers for silicone, vinyl resins and resins to increase heat resistance and improve resistance insulation value, and fillers that require inertness, fineness, whiteness and chemical resistance.

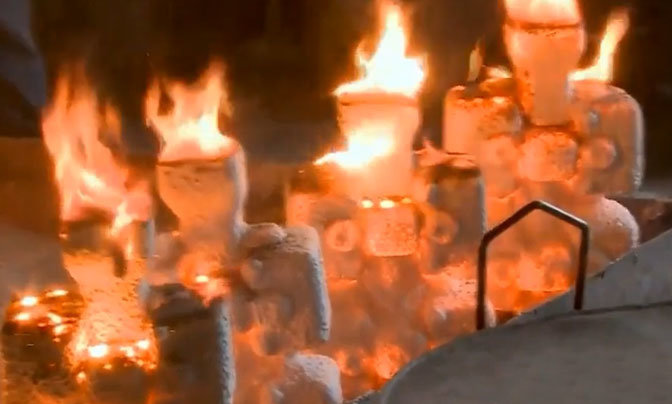

Refractory materials

Casting high refractory materials are used in glass melting furnaces; heat-resistant porcelain; sandblasting of refractory castings; sandblasting of refractory boards: special refractory porcelain; refractory cement.

Our Zirconium Silicate Beads are made of imported Australian zircon sand, which is finely ground and rolled into billets, sintered to fix the phase. They have low abrasion (ppm level) and minimal wear on equipment, and are very high-quality grinding media.

They are widely used in the dispersion and grinding of medium-hardness particles in slurries with a low to medium viscosity range. For example, ultra-fine grinding of products such as calcium carbonate, zirconium silicate, kaolin, titanium dioxide, coatings, paints, and inks.

Zircon sand is commonly used in the manufacture of refractory materials (called zirconium refractory materials, such as zirconium corundum bricks, diamond refractory fibers), casting sand in the foundry industry, and in the manufacture of ceramic enamels. It is also used in the production of glass, metal (sponge zirconium) and zirconium compounds (zirconium dioxide, zirconium oxychloride, sodium zirconate, potassium fluorozirconate, zirconium sulfate, etc.).

Zircon powder is used in stainless steel precision casting, casting coatings, and glass fiber manufacturing industries. Zircon powder is used as a main material in the ceramic industry and is also used for glazing to increase the wear resistance and surface finish of the finished ceramics. Zircon powder has special uses in many chemical industries, including cosmetics, instrument corrosion protection, leather making, and fiber.

It can be customized and applied in biomedical field, mining and metallurgical equipment field, electronic equipment field, chemical and petroleum equipment field, zirconia bearing ball blank, valve ball field, military equipment field, papermaking dehydration original field, health care ball field, textile and other mechanical equipment field, valve pump facility field, and other fields.

1. Precision Ceramics Manufacturing

Used in structural and electronic ceramic components, kiln furniture, and grinding media.

2. Refractory Materials

Essential in foundry coatings, furnace linings, and high-heat insulation applications.

3. Dental & Medical Ceramics

Supports high-purity needs for dental blocks and biocompatible zirconia-based medical components.

4. Pigments & Glazes

Provides opacity, whiteness, and stability in ceramic glaze and tile pigment applications.

Zirconium material widely used in new energy batteries, new materials, oral dentures and other biomedical, military bulletproof, stainless steel precision casting, ceramic color glaze, precision casting coating, grinding and other fields

Get A Free Quote

Non-toxic, odorless powder (color can be customized).

Stable chemical properties, high purity, narrow particle size distribution, controllable specific surface area.

Good roundness, smooth and bright surface, high density, strength and stability, strong acid and alkali resistance, excellent toughness, compressive strength, impact resistance, not easy to break, minimal wear on equipment, fine grinding media

The refractive index is high at 1.93-2.01, the chemical stability is good, and the melting point of zirconium silicate is high: 2500 degrees Celsius.

Good roundness, smooth and bright surface, uniform and dense internal structure, uniform and consistent particle size distribution. It has excellent toughness, compressive strength, impact resistance, and will not break.

Zircon powder has high refractive index and good chemical stability. It is a high-quality and low-cost emulsifier and is widely used in the production of various building ceramics, sanitary ceramics, daily ceramics, first-class handicraft ceramics, etc.

Pure zircon sand usually appears in a colorless and transparent state with a square column structure. It is often dyed yellow, orange, red, brown, etc. due to different origins, types and quantities of impurities.

Global Industry has a leading R & D, production, after-sales services team, constantly improve the production line, optimize the production process, and build a series of complete industry industry chains from R & D, production, quality inspection, channels, services, etc. The company currently has more than 100 employees.

We are a factory with our own production line and QC team in China.

Our MOQ starts from 100 kg. Trial orders and pilot runs are welcome.

Absolutely. Every shipment includes full documentation. Additional test reports can be provided upon request.

Typically 7–14 days for standard products. Custom specs may take slightly longer.

Yes. We support custom purity, particle size, and even composite blends tailored to your application.

Get a fast quote, request samples, or speak directly with our technical sales team.