Zirconium silicate technology is making a significant impact across various industries. As businesses seek advanced materials that improve product performance and sustainability, they must navigate a landscape filled with possibilities and challenges. The potential benefits and applications of zirconium silicate can address these concerns directly, offering solutions that enhance durability and efficiency. This article provides insights into the latest advancements, practical applications, and future trends of zirconium silicate technology. With years of research and development backing its capabilities, this guide aims to empower decision-makers and purchasing managers with the information they need to make informed choices.

How Does Zirconium Silicate Technology Work?

Zirconium silicate is a naturally occurring mineral that combines zirconium, silicon, and oxygen. This unique combination results in a material with exceptional properties suitable for a variety of industrial applications. Understanding how this technology operates is fundamental for decision-makers looking to adopt innovative materials into their operations.

The mineral’s composition grants it a high melting point along with remarkable chemical stability, allowing it to perform effectively under extreme conditions. These characteristics are particularly beneficial in applications involving ceramics and glass manufacturing, where durability and performance are crucial. By acting as a key additive in numerous materials, zirconium silicate effectively increases their strength and resistance to wear.

When incorporated into manufacturing processes, this material enhances product quality by improving several structural characteristics. From tiles that are more abrasion-resistant to glass products that demonstrate greater clarity, the advantages are multifaceted.

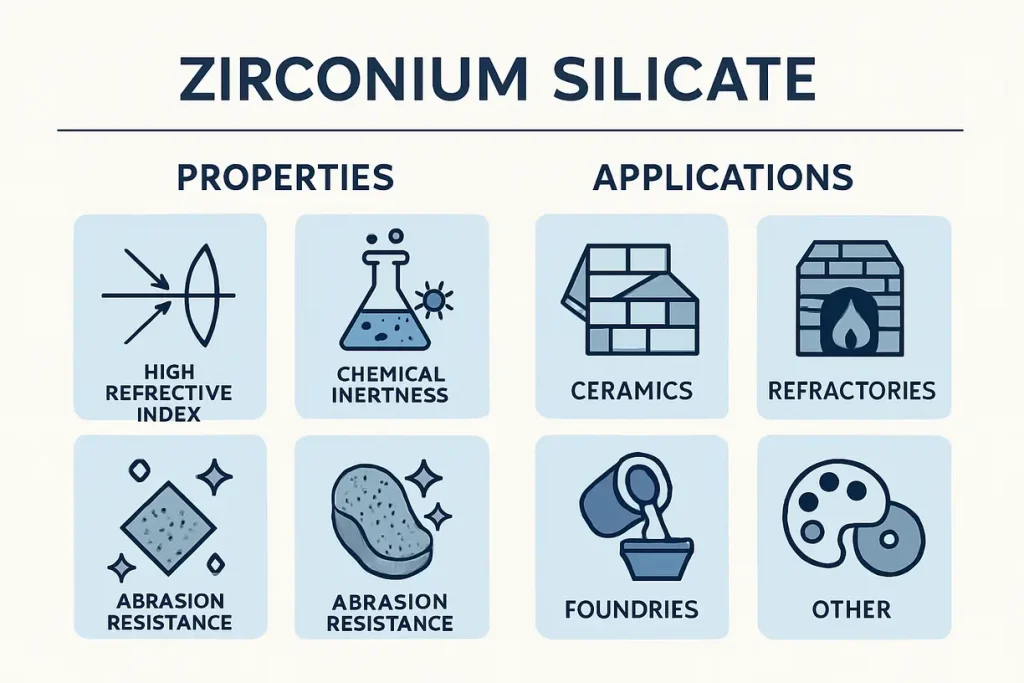

This image illustrates the unique properties of zirconium silicate and its various applications across industries.

Key applications of this advanced material include:

- Ceramics: Enhancing strength and durability in tiles and pottery, making them capable of withstanding wear and tear.

- Glass: Improving clarity and chemical durability by preventing deterioration over time.

- Refractories: Providing essential heat resistance in high-temperature environments, crucial for industries like aerospace and metal manufacturing.

- Coatings: Adding scratch resistance and prolonging the longevity of various surfaces, thus enhancing overall product appeal.

- Plastics: Increasing strength and thermal stability in composite materials used in diverse applications.

By leveraging these beneficial properties, companies can innovate their offerings and improve overall quality across a range of products, driving competitiveness in their respective markets.ove overall product quality, making it a valuable component in the ongoing evolution of material science.

What Recent Innovations in Zirconium Silicate Are Emerging?

Innovation in zirconium silicate technology is ongoing, with researchers and companies continually experimenting to discover new applications and effects. Recent advancements encompass a variety of areas, ranging from processing techniques to formulation enhancements aimed at maximizing performance. These innovations not only expand the usability of this technology but also address specific industry needs.

One notable development is the refinement of production processes, which are becoming increasingly efficient and environmentally friendly. For example, new methods have been developed that reduce energy consumption and waste during manufacturing, reflecting a growing emphasis on sustainability in industrial practices. This shift is particularly important as businesses strive to meet both economic and environmental goals.

Additionally, researchers have been investigating the possibilities of creating hybrid materials. By combining zirconium silicate with other compounds, they are discovering new composites that exhibit enhanced properties, such as better strength-to-weight ratios and improved thermal performance. These advancements allow industries to utilize the benefits of zirconium silicate while enhancing its capabilities with complementary materials.

Emerging applications are also being explored, including its potential in the renewable energy sector. For instance, there is growing interest in using zirconium silicate-based materials in solar panel manufacturing, where durability and efficiency are critical. Such innovations demonstrate the adaptability of zirconium silicate technology and its potential role in driving future industry trends.

This table highlights recent innovations:

| Innovation Type | Description |

|---|---|

| Processing Techniques | More efficient production methods |

| New Formulations | Blended with other materials |

| Enhanced Properties | Improved strength and stability |

Some recent trends include:

- Sustainable production methods aimed at reducing carbon footprints.

- Advanced hybrid materials that blend zirconium silicate with other compounds.

- Focused research on applications in renewable energy technologies, such as solar panels.

These innovations offer tangible benefits, such as improved product longevity and better performance under adverse conditions, ensuring that industries remain competitive in a rapidly evolving marketplace.der adverse conditions, ultimately driving greater adoption of zirconium silicate across various industries.

How Can Zirconium Silicate Improve Product Performance?

Products that incorporate this advanced material tend to outperform their peers, driving increased interest from manufacturers seeking a competitive edge. One of the key benefits is the remarkable durability of materials infused with this mineral compound, making them ideal for challenging environments where traditional materials may fall short.

A few critical aspects of performance improvement include increased resistance to thermal shock, enhanced mechanical strength, and reduced wear. These properties make it particularly advantageous in sectors requiring high-performance materials, including aerospace and automotive industries.

Key benefits of improved performance include:

- Enhanced Durability: The material’s structure significantly increases resistance to mechanical stress and wear, allowing products to last longer in demanding applications.

- Thermal Resistance: Capable of withstanding extremely high temperatures, this technology ensures that components maintain their integrity and function in environments that experience rapid temperature fluctuations.

- Chemical Stability: The compound demonstrates exceptional performance in corrosive situations, making it suitable for various industrial applications where exposure to harsh chemicals is a concern.

For instance, in the ceramic industry, tiles made with this technology have demonstrated superior abrasion resistance, significantly extending their life cycle and minimizing the need for replacement. Similarly, its heat resistance allows for use in furnace linings, where exposure to extreme temperatures is a common challenge.

Consider this comparative table of performance metrics:

| Performance Metric | Zirconium Silicate | Standard Alternatives |

|---|---|---|

| Thermal Stability | Excellent | Moderate |

| Wear Resistance | Superior | Average |

| Service Life | Extended | Limited |

These enhancements not only contribute to superior product quality but also present significant cost savings over time, reinforcing the value of adopting this innovative material. Overall, the advantages associated with improved performance make it an attractive option for industries aiming to elevate their product offerings.

What Are the Cost Implications of Using Zirconium Silicate?

Understanding the cost implications of zirconium silicate technology is crucial for businesses. While the initial investment may appear higher compared to conventional materials, the long-term benefits often outweigh these costs.

For one, the durability and performance of materials that incorporate this advanced technology lead to reduced downtime and maintenance expenses. As these high-quality materials can endure more wear and tear, companies will save both time and money in the long run by opting for options that last longer.

Factors influencing cost include:

- Raw Material Sourcing: The availability of zirconium-based materials can fluctuate, affecting pricing.

- Processing Methods: The efficiency and technology used in production play a significant role in final costs.

- Market Demand: Shifts in demand within various sectors can influence price dynamics and supply availability.

It’s important to assess these factors when calculating potential expenses. Companies may find that budgeting for higher upfront costs makes sense when the resulting savings on maintenance and replacement are considered over time.

Take a look at the following table that summarizes cost comparisons:

| Cost Factor | Zirconium Silicate | Traditional Materials |

|---|---|---|

| Initial Investment | Higher | Lower |

| Long-term Savings | Significant | Marginal |

| Maintenance Cost | Low | High |

Ultimately, while the initial investment for this technology may require a larger budget, the potential for substantial cost savings—through increased performance and reduced frequency of material replacement—makes a compelling case for its adoption in industry.arger initial investment, the potential for cost savings through increased performance, lower maintenance needs, and enhanced product longevity is undeniable. Being strategic about the switch to zirconium silicate can help businesses not only recoup their initial costs but also gain a competitive edge in their respective markets.l for cost savings through increased performance is undeniable.

How Does Zirconium Silicate Contribute to Sustainability?

Sustainability is a central theme in modern manufacturing, with companies striving to reduce their environmental footprint. Zirconium silicate contributes to sustainable practices in several ways.

First, zirconium silicate is often more energy-efficient to produce than many conventional materials. The high durability of products made from zirconium silicate means they can last longer, reducing the frequency of replacement and minimizing waste.

Notable sustainability aspects include:

- Energy Efficiency: Reduced energy requirements during production.

- Recyclability: Many formulations can be recycled, promoting circular economies.

- Extended Lifespan: Longer-lasting products reduce overall material consumption.

Moreover, many formulations allow for recycling, which further supports environmentally sustainable practices. As industries become increasingly focused on sustainability, incorporating zirconium silicate can align with corporate responsibility objectives.

Here’s a clear breakdown of sustainability contributions:

| Sustainability Aspect | Contribution |

|---|---|

| Energy Efficiency | Lower production energy use |

| Longevity | Reduces material waste |

| Recyclability | Supports circular economy |

This image highlights the sustainable practices in zirconium silicate production, emphasizing energy efficiency and recyclability.

This commitment to sustainability can enhance brand reputation and appeal to eco-conscious consumers, providing businesses with a significant competitive edge.

In What Ways Can Industries Implement Zirconium Silicate Technology?

Integrating zirconium silicate into industrial processes requires a clear strategy. Businesses must evaluate how this technology can fit into existing workflows and enhance productivity while minimizing disruption. A methodical approach can ensure a smooth transition and maximize the benefits of this innovative material.

Consider starting with a pilot program to assess the practical applications of zirconium silicate in specific projects. This approach allows companies to identify areas for improvement before adopting it on a larger scale. By testing its effectiveness in controlled scenarios, businesses can gather valuable data that informs wider implementation strategies.

Recommended implementation strategies include:

- Collaboration with Suppliers: Engaging with knowledgeable suppliers can provide crucial insights into zirconium silicate’s properties and best practices in its application. Suppliers can offer technical support and resources that ensure optimal performance.

- Stakeholder Engagement: Involving key stakeholders from various departments, such as production, R&D, and finance, can help foster a comprehensive understanding of the technology’s benefits and challenges. Interdepartmental collaboration minimizes resistance and enhances collective buy-in.

- Staff Training: Providing thorough training programs is essential to equip employees with the necessary skills to work with zirconium silicate effectively. This includes understanding its handling, processing techniques, and safety measures. Well-informed staff are more likely to embrace the new material and utilize it effectively.

- Continuous Monitoring and Feedback: After implementing zirconium silicate, it is vital to continuously monitor its performance and gather feedback from users. This allows for real-time adjustments, optimizing processes and addressing challenges as they arise.

It is also vital to work with suppliers who understand zirconium silicate and can offer technical support throughout the transition process. Training staff on handling new materials and processes will support successful implementation.

Here’s a breakdown of implementation strategies:

| Strategy | Description |

|---|---|

| Pilot Programs | Test applications in controlled settings |

| Supplier Partnerships | Collaborate with knowledgeable vendors |

| Staff Training | Ensure team is well-informed and proficient |

| Stakeholder Engagement | Involve interdepartmental teams for comprehensive understanding |

| Continuous Monitoring | Gather feedback to optimize usage and processes |

By adopting a structured approach to the integration of zirconium silicate, industries can enhance their operational efficiency while capitalizing on the distinct advantages that this material brings.

What Are the Challenges in Adopting Zirconium Silicate?

While zirconium silicate offers a range of benefits, there are challenges associated with its adoption. Common misconceptions about cost and performance can hinder decision-making.

Additionally, the transition to using zirconium silicate may require significant changes in production processes. Resistance to change among employees could also pose a barrier, making clear communication essential.

Common challenges include:

- Misunderstanding of Costs: Incorrect assumptions can lead to hesitance in investment.

- Operational Disruptions: Implementation may disrupt existing workflows, requiring careful planning.

- Employee Adaptation: Training is crucial to help staff adjust to new materials and procedures.

Awareness of these challenges is the first step towards overcoming them. Companies can prepare by providing thorough training and creating an environment conducive to innovation.

Here is a summary of common challenges:

| Challenge | Potential Solution |

|---|---|

| Cost Misconceptions | Educate decision-makers on ROI |

| Process Transition | Provide needed resources for change |

| Employee Resistance | Foster an inclusive communication plan |

Understanding and addressing these challenges will be key to successful adoption of zirconium silicate technology.

What Future Trends Are Expected for Zirconium Silicate?

Looking ahead, the future of zirconium silicate technology appears promising. Innovations continue to flourish, driven by growing demand for advanced materials that meet the evolving needs of industries.

One trend is the development of hybrid materials that combine zirconium silicate with other compounds to enhance performance and versatility. This approach could open new markets and applications.

Emerging trends might include:

- Increased focus on environmentally friendly materials.

- Development of composites that leverage the strengths of zirconium silicate.

- Enhanced research in applications for advanced manufacturing processes.

Moreover, as manufacturers increasingly focus on sustainability, the demand for eco-friendly materials like zirconium silicate will likely rise. Companies that adopt these technologies early may find themselves well-positioned to dominate future markets.

Here’s a glimpse of expected trends:

| Trend | Description |

|---|---|

| Hybrid Materials | New combinations for enhanced properties |

| Eco-friendly Production | Emphasis on reducing environmental impact |

Staying ahead of these trends will ensure companies remain competitive and capable of meeting customer demands.

Conclusion

In summary, zirconium silicate technology is transforming industry standards by enhancing durability, performance, and sustainability. The investment in this material, despite higher initial costs, delivers clear long-term benefits through increased savings and improved product quality. As industries continue to face evolving challenges, zirconium silicate stands out for its ability to meet diverse demands across multiple sectors, including ceramics, aerospace, and automotive applications.

Moreover, the ongoing innovations in processing and formulation open new avenues for its use, reinforcing its role as a critical player in modern manufacturing. By adopting zirconium silicate technology, companies can not only improve their product offerings but also position themselves competitively in an increasingly sustainability-focused marketplace.

At Global Industry, we are at the forefront of this advancement. For your next project, consider how zirconium silicate can add value to your offerings. Connect with us today for insights that can drive your business forward and lead you into a more sustainable and efficient future. Your success starts with informed choices, and zirconium silicate may just be the key to unlocking your potential.

FAQ Section

Q1: What are the primary uses of zirconium silicate in industry?

Zirconium silicate is primarily used in ceramics, where it enhances the strength and durability of tiles and pottery. It is also a key ingredient in glass manufacturing, improving clarity and chemical resistance. In refractory applications, zirconium silicate provides critical heat resistance, making it ideal for furnace linings and related materials. Additionally, it finds application in coatings and plastics, where it contributes to surface durability and thermal stability.

Q2: How does zirconium silicate compare to other materials?

Compared to traditional materials, zirconium silicate generally offers superior thermal stability, which allows for better performance in high-temperature applications. It also has outstanding resistance to abrasion, significantly outlasting standard alternatives in wear-prone environments. This combination of properties makes zirconium silicate not only a reliable choice but also a more cost-effective solution in the long run, despite the higher initial investment.

Q3: What businesses benefit from zirconium silicate technology?

Various industries can benefit from zirconium silicate technology, including ceramics, aerospace, automotive, and electronics. Manufacturers in the ceramic sector can create more durable tiles and tableware, while aerospace and automotive industries leverage its high-performance attributes for parts that withstand extreme conditions. Electronics manufacturers benefit from its insulating properties in circuit boards and other components.

Q4: Are there any safety concerns associated with zirconium silicate?

Zirconium silicate is generally regarded as safe when handled appropriately. However, like any fine particulate material, it can pose inhalation risks if proper safety precautions are not taken during processing. It’s essential to follow standard industrial health and safety practices, including the use of personal protective equipment (PPE) and adequate ventilation when working with zirconium silicate.

Q5: What is the outlook for zirconium silicate technology in the next decade?

The outlook for zirconium silicate technology is promising, with expectations of continued advancements in both materials science and production techniques. As industries increasingly focus on sustainability and performance, the demand for high-quality, eco-friendly materials like zirconium silicate is likely to grow. Research into innovative applications, including potential uses in renewable energy technologies, will further enhance its relevance and market position over the next decade.