In today’s business environment, sustainability is a driving concern for purchasing managers and decision-makers. Companies face pressure to meet eco-friendly standards while maintaining productivity and profitability. Interestingly, zirconium silicate presents a viable solution. This material not only supports sustainability goals but also enhances resource efficiency and reduces emissions. In this article, we will discuss how this mineral contributes to environmental sustainability, helping your business thrive while making a positive impact. With insights derived from industry experts, you will understand the practical benefits of incorporating zirconium silicate into your operations.

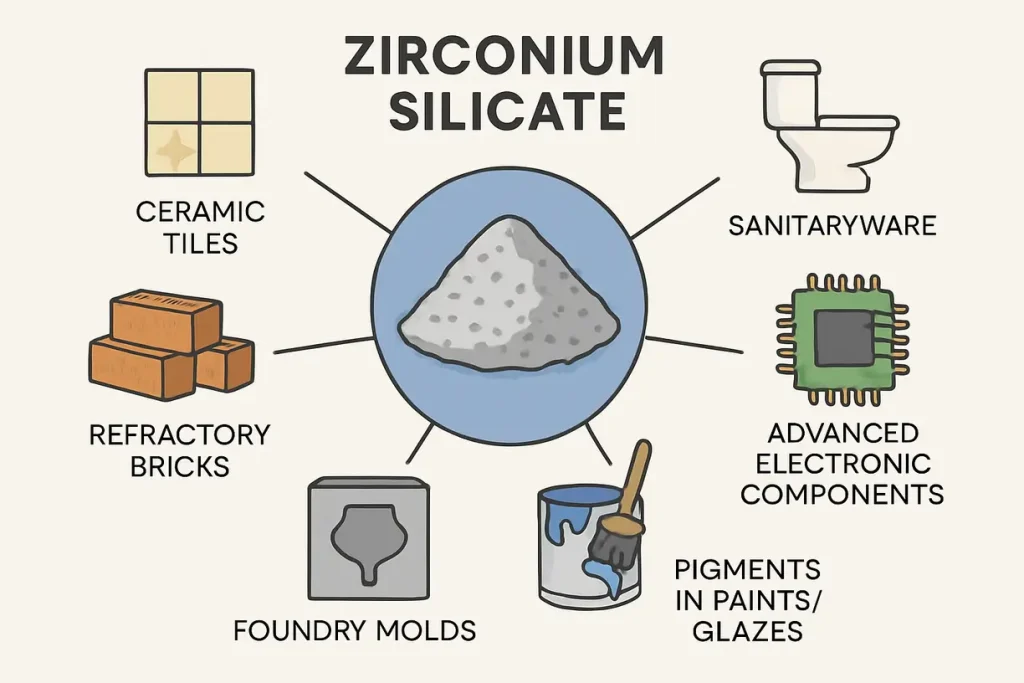

How Is Zirconium Silicate Used in Industry?

Zirconium silicate finds multiple applications across various industries. It is primarily used in ceramics as a white pigment, enhancing the durability and aesthetic appeal of ceramic products. From tiles to tableware, this mineral helps manufacturers create high-quality products that stand out in a competitive marketplace.

Another significant application lies in glass production. Many glass makers incorporate this material to improve the strength and thermal resistance of their glass products. This makes glass windows, bottles, and tableware more durable, ensuring that they withstand everyday wear and tear.

Beyond ceramics and glass, zirconium silicate serves a vital role in the coatings industry. It acts as a filler, helping improve the performance of coatings by making them more resistant to wear and tear. This increased durability is crucial for industries like automotive and construction, where longevity and appearance significantly influence customer satisfaction.

Additionally, the electronics sector has begun to embrace zirconium silicate for its insulating properties. As technology evolves, manufacturers require materials that can endure higher temperatures and provide effective insulation. This mineral fits these needs excellently, making it a valuable option for future developments in electronics.

Here’s the deal: Understanding the versatile applications of zirconium silicate can guide decisions in selecting essential materials. Knowing where this mineral fits into your products will enable better strategic planning, ultimately leading to improved outcomes in production.

To further illustrate its versatility, here are other industries that utilize zirconium silicate:

- Textiles: It functions as a dyeing agent.

- Aerospace: Used in coatings that require high thermal stability.

- Cosmetics: Acts as a thickening agent in various beauty products.

In summary, the various uses of zirconium silicate demonstrate its significance in multiple sectors. As businesses strive for innovation, this mineral emerges as a cornerstone for creating sustainable and resilient products that fulfill market demands.

| Industry | Application | Benefits |

|---|---|---|

| Ceramics | Pigment and durability enhancer | High-quality products |

| Glass | Strength and thermal resistance | Durable glass items |

| Coatings | Filler for performance improvement | Increased product longevity |

| Electronics | Insulating properties | Enhanced performance in technological applications |

Illustration of zirconium silicate applications in ceramics and glass products, showcasing its versatility.

What Are the Environmental Benefits of Zirconium Silicate?

Zirconium silicate is celebrated for its potential environmental benefits. One of the primary advantages is its ability to contribute to lower carbon emissions during production. Compared to other materials, the production process for this mineral can be less energy-intensive. This reduction in energy requirements is crucial in lowering the overall carbon footprint associated with manufacturing.

Moreover, utilizing zirconium silicate promotes recycling. This mineral can often be repurposed within production cycles. When businesses incorporate it into their operations, they can minimize waste and make better use of resources already in circulation.

You might find it interesting: These sustainability measures not only benefit the environment but also bring financial savings. Businesses that employ eco-friendly practices often benefit from cost reductions associated with waste disposal and energy consumption.

Here are some of the key environmental advantages associated with using zirconium silicate:

- Reduced Water Usage: The production of zirconium silicate typically requires less water than other materials.

- Lower Toxicity: It often has a lower environmental toxicity than traditional fillers and additives.

- Natural Resource Conservation: Using this mineral allows the transition from synthetic composites to more sustainable materials.

While specific data can fluctuate, studies suggest that companies using zirconium silicate have reported a decrease in waste production by up to 30%. This statistic underscores the potential for making significant strides towards sustainability.

Additionally, the durability associated with zirconium silicate ensures that products manufactured with it tend to have longer lifespans. This reduced need for frequently replacing items contributes to the conservation of resources and lessens the environmental burden of disposal.

In conclusion, the environmental benefits of this mineral underscore its importance in sustainable practices. For businesses wanting to make an impact, using zirconium silicate can lead to substantial eco-friendly outcomes.

| Benefit | Impact |

|---|---|

| Lower carbon emissions | Reduced energy consumption |

| Promotes recycling | Minimizes waste and resource usage |

| Decreased waste production | Up to 30% less waste during manufacturing |

| Increased product durability | Longer lifespan reduces need for replacements |

How Does Zirconium Silicate Contribute to Resource Conservation?

Resource conservation is a significant concern for businesses today. Zirconium silicate addresses this issue in several ways. First, it is derived from abundant mineral sources. This availability means that businesses do not face the same supply chain pressures present with rarer materials.

Furthermore, this mineral provides a lightweight alternative in various applications, lowering shipping costs and energy consumption during transport. By reducing the weight of products, companies can transport more with less, leading to resource conservation across logistics.

Let’s break it down: Using zirconium silicate can enhance operational efficiency while conserving essential resources. Companies committed to sustainable practices benefit from reduced material costs and environmental impact.

When using this mineral in production, manufacturers often notice fewer defects and stronger product performance. This improvement means less waste results from scrapped items due to flaws. Companies can enjoy savings from more efficient manufacturing processes.

Moreover, the ability of zirconium silicate to reduce raw material usage is notable. When it serves as a filler or pigment, it can lessen the demand for more expensive or environmentally damaging counterparts, significantly impacting manufacturers’ overall resources.

On a larger scale, companies that implement zirconium silicate in their operations can become leaders in resource conservation. By setting an example, they can inspire other organizations to follow suit, creating a collective movement towards sustainability in their sectors.

In summary, the role of this mineral in resource conservation makes it a strategic choice for companies aiming to enhance operational efficiency while preserving essential materials.

| Resource Conservation Aspect | Explanation |

|---|---|

| Abundant mineral sources | Reduces supply chain pressures |

| Lightweight alternative | Lowers shipping costs and energy consumption |

| Fewer defects in production | Saves costs from scrapped items |

| Leadership in sustainability | Encourages industry-wide adoption of eco-friendly practices |

What Role Does Zirconium Silicate Play in Reducing Emissions?

Reducing emissions has become a primary focus for numerous industries. This mineral can play a crucial role in achieving this goal. The production of zirconium silicate is typically associated with lower emissions compared to other silicate materials.

Here’s why that matters: A lower level of emissions during production translates to cleaner air quality and compliance with regulations. Companies leveraging this mineral can enjoy a more significant competitive edge due to regulatory compliance and improved public perception.

Beyond its manufacturing process, zirconium silicate enhances the performance of products, which may further decrease emissions during their use phase. For instance, products that incorporate this material often require less energy to operate, leading to lower emissions over time.

Furthermore, companies that switch to zirconium silicate often report a notable reduction in greenhouse gases. This fact is crucial for businesses seeking to meet sustainability targets while making a difference in the fight against climate change.

The benefits extend to operations as well:

- Decreased Toxic Emissions: During processing and manufacturing, using this mineral can minimize the release of harmful substances.

- Life Cycle Emissions Reductions: Examining the entire life cycle of products that contain zirconium silicate can reveal substantial overall emissions reductions.

It is clear that integrating this mineral into manufacturing processes can lead to reduced emissions. This not only contributes to a healthier planet but also promotes corporate responsibility.

| Emission Reduction Strategy | Impact |

|---|---|

| Lower emissions during production | Cleaner manufacturing processes |

| Improved product energy efficiency | Reduced emissions during use |

| Compliance with environmental regulations | Better regulatory standing |

| Positive corporate image | Enhanced public perception |

How Can Zirconium Silicate Improve Product Durability?

When it comes to manufacturing, durability is a vital factor that impacts customer satisfaction. Zirconium silicate significantly improves the durability of products across various sectors.

In ceramics, for instance, this mineral enhances the strength and fracture resistance of items. This durability leads to fewer breakages during production and shipping, saving businesses money in the long run.

Now you might be asking: What does this mean for my company? When products are more resistant to wear and tear, customers are more likely to be satisfied with their purchases, ultimately leading to repeat business and increased loyalty.

Similarly, in the glass industry, zirconium silicate reinforces the glass, making it resilient to scratches and chips. This improved durability ensures that products maintain their aesthetic appeal while meeting practical usage demands, which is critical for customer retention.

Furthermore, manufacturers that incorporate resilient materials into their offerings can position themselves strategically within their markets. Durable goods often result in fewer warranty claims, which can lead to significant savings on service and replacement costs.

Beyond the immediate benefits, companies that prioritize durability can enhance their brand reputation. Offering high-quality products positions businesses as trusted leaders, paving the way for increased sales and market expansion.

In conclusion, zirconium silicate plays a critical role in improving product durability. By opting for this mineral, companies can deliver higher-quality products that resonate well with consumers.companies can deliver higher-quality products that resonate well with consumers.

| Durability Improvement Aspect | Explanation |

|---|---|

| Enhanced strength in ceramics | Reduces production and shipping losses |

| Increased resistance in glass | Maintains aesthetic appeal and usability |

| Higher customer satisfaction | Promotes repeat purchases and brand loyalty |

| Enhanced brand reputation | Positions companies as trusted leaders |

What Are the Economic Advantages of Using Zirconium Silicate?

The economic advantages of incorporating zirconium silicate into production processes are significant. Businesses that use this mineral often enjoy cost savings in several areas.

Let’s analyze: First and foremost, zirconium silicate is cost-effective in terms of raw material sourcing. With its abundant supply, purchasing it typically incurs lower costs compared to rarer alternatives.

Additionally, the performance benefits provided by zirconium silicate lead to enhanced operational efficiency. As mentioned before, the durability of products means fewer returns and less waste. This contributes to savings on both production and logistical fronts.

Moreover, companies utilizing this mineral often experience a decrease in energy costs. Its lighter weight results in lower transportation expenses, which can add up significantly over time.

Finally, businesses committed to sustainability and environmental responsibility tend to attract more customers today. This increasing demand for eco-friendly products can lead to new market opportunities, creating more extensive revenue streams for organizations that leverage zirconium silicate.

To provide a clearer picture, let’s consider these economic factors:

- Reduced Production Costs: Savings derived from using lower quantities of expensive raw materials.

- Less Waste: Better design techniques utilizing this mineral can contribute to reduced scrapping rates.

- Enhanced Profit Margins: Companies can improve their overall profitability through efficient production and positive market positioning.

In summary, the economic benefits of using zirconium silicate extend beyond immediate savings. They open the door to enhanced competitiveness, innovation, and customer appeal.

| Economic Advantage | Benefit |

|---|---|

| Cost-effective sourcing | Lower raw material costs |

| Increased operational efficiency | Savings from reduced wastage |

| Decreased energy costs | Lower transportation expenses |

| New market opportunities | Attracts environmentally conscious consumers |

How Does Zirconium Silicate Improve Energy Efficiency?

Energy efficiency has emerged as a critical aspect of modern manufacturing processes. Utilizing zirconium silicate can contribute greatly to this efficiency.

The production of this mineral is less energy-intensive compared to many alternatives. By employing it, businesses can reduce their overall energy consumption. This reduction translates into cost savings for manufacturers operating on tighter margins.

Think about this: Beyond production, zirconium silicate enhances the efficiency of the end products. For instance, ceramics and glass products made with this mineral often retain better thermal properties. This means they require less energy for heating or cooling, leading to long-term savings.

Furthermore, because these products tend to have longer lifespans, companies experience fewer replacements. This contributes to further energy efficiency by minimizing the need for constant production of new items.

Here are additional ways using zirconium silicate can improve energy efficiency:

- Waste Reduction: Efficient production processes lead to less scrap and reduced energy waste.

- Lower Lifecycle Costs: Products last longer and require less energy over their lifespan.

- Operational Cost Reductions: Less energy usage during production directly impacts profit margins.

Ultimately, the relationship between zirconium silicate and energy efficiency benefits both manufacturer and consumer. As energy costs continue to rise, businesses that prioritize this mineral position themselves to thrive.

| Energy Efficiency Aspect | Explanation |

|---|---|

| Lower production energy requirements | Reduces overall energy consumption |

| Improved thermal properties | Less energy needed for heating/cooling |

| Longer-lasting products | Reduces need for constant replacements |

| Enhanced market positioning | Attracts energy-conscious consumers |

What Challenges Are Associated with Zirconium Silicate Use?

Despite the various benefits of zirconium silicate, challenges do exist. Understanding these hurdles is essential for businesses considering this mineral.

One common challenge involves market perception. Some industries may view zirconium silicate as inferior to other silicates, despite its advantages. Overcoming this perception requires educating stakeholders about its benefits and applications, emphasizing how it can contribute to overall sustainability goals.

Here’s a reality check: Transitioning to suppliers of this mineral may present logistical and procurement challenges, as not all suppliers may stock it. Companies need to invest time into identifying reliable sources to ensure a smooth supply chain.

Additionally, the initial investment costs can also be a barrier. Organizations must evaluate potential savings against the initial costs of switching materials, which can sometimes deter businesses from making the change.

Lastly, integrating zirconium silicate into existing production processes may require adjustments. Training staff and recalibrating machinery could present additional challenges that necessitate management attention.

To mitigate such challenges, businesses could consider:

- Investing in Training: Offering education about the mineral’s advantages can help ease adoption.

- Supplier Partnerships: Establishing strong partnerships with reliable suppliers can create stability in the supply chain.

- Cost-Benefit Analysis: Engaging in thorough analysis may reveal long-term savings that offset initial costs.

In conclusion, while challenges do exist, the strategic benefits of incorporating zirconium silicate often outweigh the drawbacks. By working through these issues, businesses can position themselves for long-term gains.

| Challenge | Implication |

|---|---|

| Market perception issues | Requires education to change views |

| Supplier logistics | Finding reliable sources may take time |

| Initial investment costs | Needs careful cost-benefit analysis |

| Integration into existing processes | Training needed for smooth transition |

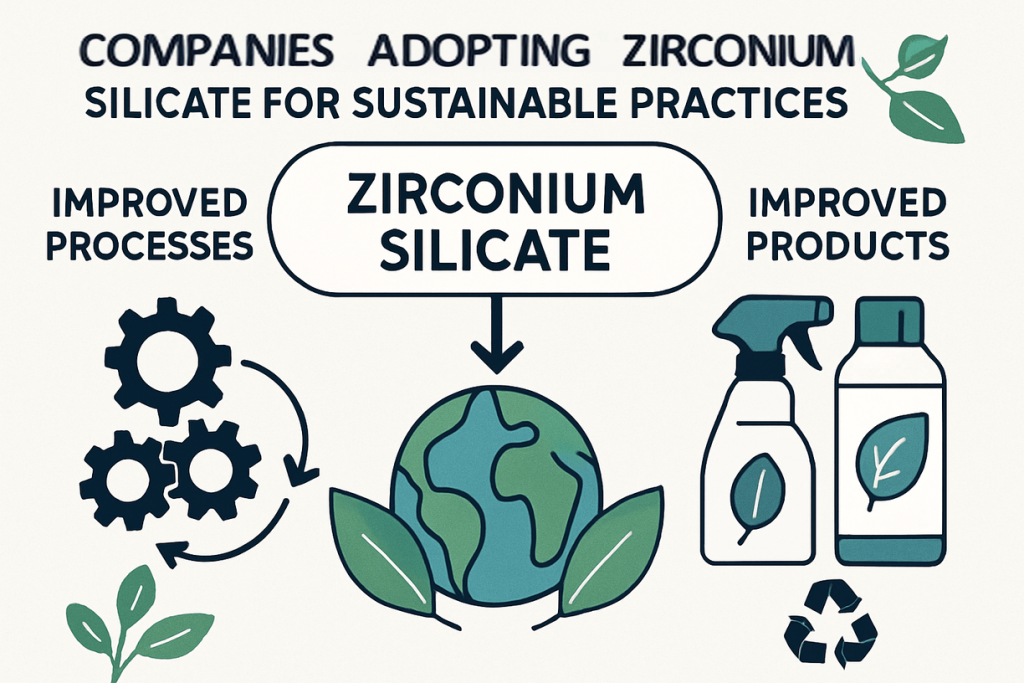

How Are Businesses Adopting Zirconium Silicate for Sustainability?

Many businesses today are prioritizing sustainability through the strategic adoption of zirconium silicate. They are recognizing its role in enhancing resource efficiency and minimizing environmental impact.

Several case studies illustrate successful applications of this mineral. In the ceramics sector, companies report increased product durability and reduced waste due to incorporating zirconium silicate. These improvements have led to enhanced market competitiveness and stronger brand loyalty.

The image displays various businesses applying zirconium silicate in their processes, showcasing innovation and sustainability.

You might find this inspiring: A recent automotive manufacturer shifted to this mineral for coatings and achieved significant improvements in product lifespan. This transition minimized waste while enhancing performance, which in turn led to a more robust product.

Furthermore, businesses utilizing zirconium silicate in their glass production have seen better thermal performance in their products, leading to enhanced energy efficiency. This energy conservation has made them more appealing to eco-conscious consumers, increasing sales.

Moreover, the construction industry is rapidly adopting such minerals as they seek sustainable solutions. Companies utilizing zirconium silicate products solidify their commitment to eco-friendly practices, creating a competitive advantage in this growing market.

To effectively implement zirconium silicate into their operations, businesses could consider:

- Creating Sustainability Initiatives: Developing clear goals involving this mineral can drive engagement.

- Collaborating with Innovators: Partnering with companies specializing in eco-friendly materials can yield new insights.

- Monitoring Performance Metrics: Tracking changes in efficiency and waste can provide tangible evidence of improvement.

In essence, businesses that adopt zirconium silicate gain a competitive edge. They can foster innovation while simultaneously making a positive impact on the environment.

| Business Case Study | Application | Impact |

|---|---|---|

| Ceramics manufacturer | Increased durability and reduced waste | Enhanced product competitiveness |

| Automotive coatings provider | Improved product lifespan | Minimized waste and increased reliability |

| Glass production company | Enhanced thermal performance | Higher energy efficiency and sales growth |

| Construction materials supplier | Adoption of zirconium silicate products | Strengthened commitment to sustainability |

Diagram showcasing various businesses adopting zirconium silicate for sustainable practices through improved processes and products.

Conclusion

In summary, zirconium silicate offers businesses a range of significant benefits related to sustainability. From reducing emissions and enhancing durability to promoting resource efficiency, this mineral provides practical and economic advantages. By using zirconium silicate, your organization can achieve a quantifiable reduction in environmental impact while also improving operational efficiency. Global Industry can guide you through the steps of integrating this mineral into your processes. Connect with us today to explore how we can help you join the movement towards responsible manufacturing and sustainability.

FAQ Section

Q1: What sustainability benefits come from using zirconium silicate? Using zirconium silicate can lead to reduced environmental impact, lower emissions, and enhanced resource conservation in various industrial processes.

Q2: In which industries is zirconium silicate commonly used? Zirconium silicate finds applications in ceramics, glass, and coatings, among other industries due to its valuable properties.

Q3: How does zirconium silicate compare to other materials regarding sustainability? This mineral generally offers lower environmental impact and better resource efficiency compared to many conventional materials, making it a favorable choice for sustainable practices.

Q4: What are the economic implications of using zirconium silicate? Adopting zirconium silicate can result in cost savings for manufacturers, increased efficiency, and potential growth opportunities within sustainability-focused markets.

Q5: Are there any challenges associated with the use of zirconium silicate? While this mineral has many advantages, challenges include market perception, initial investment costs, and the need for education in industries.