When it comes to zirconium silicate, understanding why this material may fail safety standards is crucial for manufacturers and decision-makers alike. If you’re a purchasing manager or involved in production, you recognize the importance of this issue. Failures can lead to product recalls, increased costs, and damage to your brand’s reputation. This article provides a detailed examination of the factors that contribute to safety test failures. By addressing the root causes and offering practical solutions, we aim to help you navigate these challenges effectively. Trust us; the insights and actionable advice here can bolster your processes and decision-making.

What Are Safety Standards for Zirconium Silicate?

Safety standards for zirconium silicate are regulations established to ensure the material’s quality and performance in various applications. These standards are designed to protect public health and the environment. Major organizations such as ASTM International set testing protocols to evaluate the safety and integrity of zirconium silicate products.

The significance of adhering to these safety standards cannot be overstated. Non-compliance can result in legal retribution, loss of marketability, and diminished trust among clients. Organizations that fail to meet these standards often face heightened scrutiny from regulators.

For example, suppose a company neglects to follow safety standards during manufacturing. In that case, it risks producing zirconium silicate with unacceptable impurities or structural weaknesses. These flaws can lead to failed testing and ultimately a product that cannot be safely used in various applications. Therefore, understanding these standards is not just regulatory protocol but a business imperative.

| Safety Standard | Organization | Purpose |

|---|---|---|

| ASTM C1723 | ASTM | Evaluates zircon products for industrial applications |

| ISO 13006 | ISO | Addresses safety and quality for ceramic materials |

| IEC 62321 | IEC | Assesses environmental impacts of materials |

Key Considerations for Safety Standards

When evaluating safety standards for zirconium silicate, consider the following:

- Regulatory requirements relevant to your industry

- The types of tests mandated (e.g., mechanical, thermal, chemical)

- The potential risks of non-compliance, including legal implications

- The importance of third-party certifications for added credibility

What Factors Impact Zirconium Silicate Performance?

The performance of zirconium silicate hinges on several key factors that can influence its integrity. These include material composition, manufacturing processes, and environmental conditions.

Material composition plays a crucial role in determining the material’s quality. Variations in mineral content can lead to inconsistencies that affect safety testing outcomes. For example, impurities added during the mining process can compromise the final product’s structural integrity.

Manufacturing processes are equally important. Inconsistent practices, like temperature control and mixing methods, can introduce weaknesses into the zirconium silicate. Ensuring a stable manufacturing environment can mitigate risks substantially.

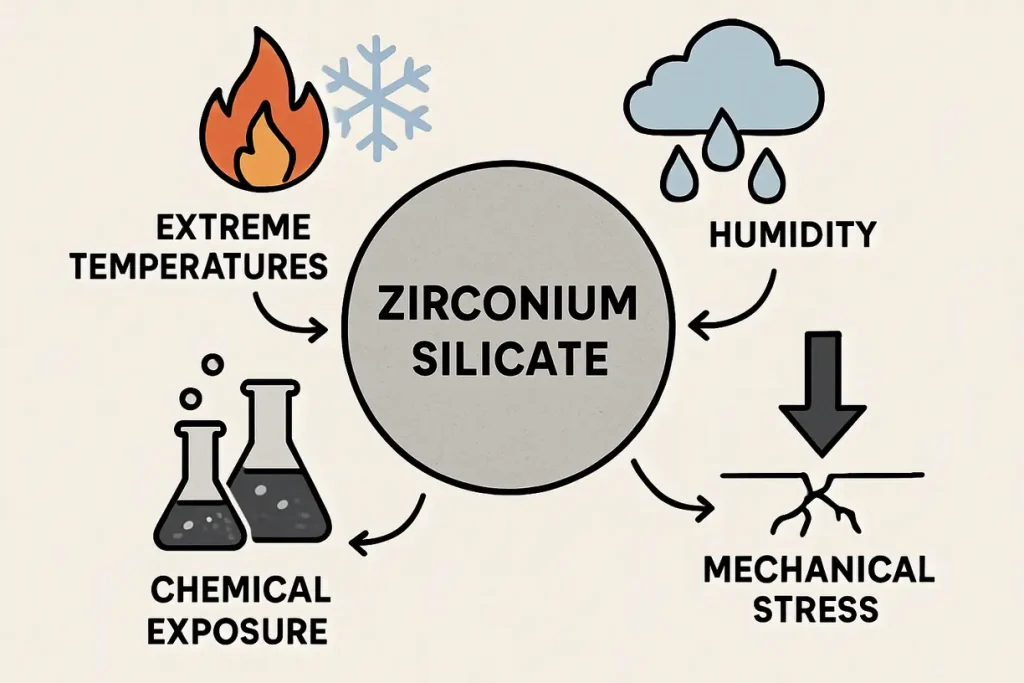

What about environmental conditions? Factors such as humidity and temperature can also impact the material throughout its lifecycle. Storing zirconium silicate in inappropriate conditions can lead to degradation, which may not become apparent until safety tests are conducted.

| Factor | Description | Impact |

|---|---|---|

| Material Composition | Variability in mineral content | Affects structural integrity |

| Manufacturing Process | Temperature control, mixing methods | Introduces weaknesses |

| Environmental Conditions | Humidity, temperature | Causes degradation over time |

Key Performance Indicators

To assess the performance of zirconium silicate, you may want to monitor these indicators:

- Compressive strength

- Thermal stability

- Resistance to chemical exposure

- Particle size distribution

This image depicts varying environmental conditions that can affect the performance of zirconium silicate materials.

How Do Impurities Affect Zirconium Silicate?

Impurities in zirconium silicate can significantly affect its safety performance. These impurities often stem from contamination during mining, processing, or handling. Common contaminants include metals, organic compounds, or other minerals. Each type of impurity can present unique challenges in safety testing.

Impurities may not only lead to failed safety tests but can also jeopardize the material’s performance in actual applications. For instance, the presence of certain metals might alter thermal properties, resulting in unsafe operating conditions.

Identifying and analyzing these impurities is essential. Techniques such as spectrometry can help detect unwanted elements in zirconium silicate. Quality control measures, including regular testing and enhanced processing, are effective strategies to minimize contamination and ensure product safety.

In summary, managing impurities is critical for quality assurance and safety compliance. Companies that prioritize rigorous testing of materials before use will safeguard their products and reputation.

| Type of Impurity | Source | Potential Impact |

|---|---|---|

| Heavy Metals | Mining process | Compromises thermal properties |

| Organic Compounds | Processing | May affect stability and performance |

| Foreign Minerals | Handling | Causes structural weaknesses |

Common Sources of Impurities

The following are typical sources of impurities in zirconium silicate:

- Contaminated raw materials during mining

- Inadequate cleaning protocols in processing facilities

- Poor storage conditions exposing materials to contaminants

- Equipment wear and tear that introduces foreign particles

What Role Does Temperature Play in Safety Tests?

Temperature is a vital factor in the safety testing of zirconium silicate. The material’s performance can change dramatically under various temperature conditions. For instance, extreme heat can lead to phase changes that may weaken the material.

Safety assessments often involve controlled testing environments to simulate real-world use. However, if tests are conducted at inappropriate temperatures, results may not reflect actual performance.

So, what are the recommended practices? It’s advisable to adhere strictly to the specified temperature ranges outlined in safety standards when conducting tests. This practice ensures accurate evaluations and mitigates risks related to temperature fluctuations.

As a best practice, organizations should establish guidelines for temperature control during the production process. Consistently applying these practices can significantly improve outcomes in safety testing.

| Temperature Range | Testing Relevance |

|---|---|

| Below 100°C | Standard physical integrity |

| 100°C to 150°C | Testing for thermal stability |

| Above 150°C | Evaluating melting point and structural changes |

Recommended Temperature Monitoring Practices

To ensure the integrity of safety tests, consider implementing these monitoring practices:

- Regularly calibrate temperature sensors used in testing

- Document temperature conditions during all testing phases

- Utilize alarm systems to notify personnel of deviations

- Conduct periodic audits of temperature-controlled storage units

How Does Particle Size Influence Test Outcomes?

Particle size plays a crucial role in the performance of zirconium silicate. Smaller particles tend to have a larger surface area, which can enhance certain properties like reactivity. However, this can lead to increased risks of defects in safety tests.

You might be wondering, how does this affect testing outcomes? Different industries might require specific particle sizes for optimal performance. Failing to meet these specifications can result in inconsistent results during safety assessments.

Regular monitoring and controlling particle size during production can prevent potential failures in testing. Techniques such as sieving or laser diffraction can be used to determine and maintain appropriate particle sizes.

In conclusion, managing particle size is essential for ensuring compliance with safety standards. Businesses that prioritize precision in this area are better equipped to meet safety requirements.

| Particle Size (µm) | Impact on Performance | Industry Implications |

|---|---|---|

| < 10 | Increased reactivity | Suitable for coatings |

| 10 – 50 | Standard use | Common in ceramics |

| > 50 | Reduced reactivity | May be unsuitable |

Best Practices for Particle Size Control

Employ these best practices to effectively manage particle size in zirconium silicate:

- Use precise sieving methods for consistent results

- Implement regular checks during production to monitor size distribution

- Apply proper milling techniques to achieve desired particle sizes

- Train staff on the significance of particle size in material performance

Why Are Chemical Reactions Relevant to Safety Failures?

Chemical reactions can lead to significant safety failures in zirconium silicate products. These reactions may occur during production, transport, or even in storage. Understanding these reactions is vital for production integrity.

Certain chemicals can react unfavorably with zirconium silicate, leading to breakdowns. For instance, if exposed to acidic environments, the material may degrade faster than anticipated. Organizations should emphasize testing in varied chemical environments to identify vulnerabilities.

To mitigate these risks, companies must implement rigorous chemical compatibility assessments. Regular evaluations, combined with proper materials handling protocols, can significantly reduce the likelihood of chemical-related failures.

Overall, chemical awareness enhances product reliability and safety.

| Chemical Interaction | Potential Outcome | Mitigation Strategies |

|---|---|---|

| Acid Exposure | Material degradation | Use protective coatings |

| Base Contact | Altered properties | Regular compatibility testing |

| Reactivity with Moisture | Structural failure | Control storage conditions |

What Testing Methods Are Used for Zirconium Silicate?

Several standardized testing methods evaluate the safety and performance of zirconium silicate. These protocols provide insight into the material’s behavior under various conditions. Testing methods range from mechanical assessments to thermal analyses.

So, what are some key testing techniques? Common methods include:

- Compression Testing: Evaluates the material’s load-bearing capacity.

- Thermal Analysis: Assesses reactions as temperature changes.

- Chemical Resistance Testing: Determines the material’s compatibility with various substances.

Using established protocols ensures consistency and reliability in safety testing. Organizations must remain vigilant in adhering to these testing methods to provide safe products.

In conclusion, understanding and employing the correct testing methods fosters confidence in the material’s safety and performance.

| Testing Method | Purpose | Key Focus Areas |

|---|---|---|

| Compression Testing | Evaluates load capacity | Structural integrity |

| Thermal Analysis | Assesses thermal properties | Reaction thresholds |

| Chemical Resistance Testing | Tests compatibility with substances | Long-term stability |

Factors Influencing the Choice of Testing Methods

Consider the following factors when selecting testing methods for zirconium silicate:

- Specific industry regulations that dictate testing approaches

- The intended application of zirconium silicate in products

- Available resources for conducting various testing methods

- The experience and expertise of the testing personnel

How Do External Factors Influence Safety Results?

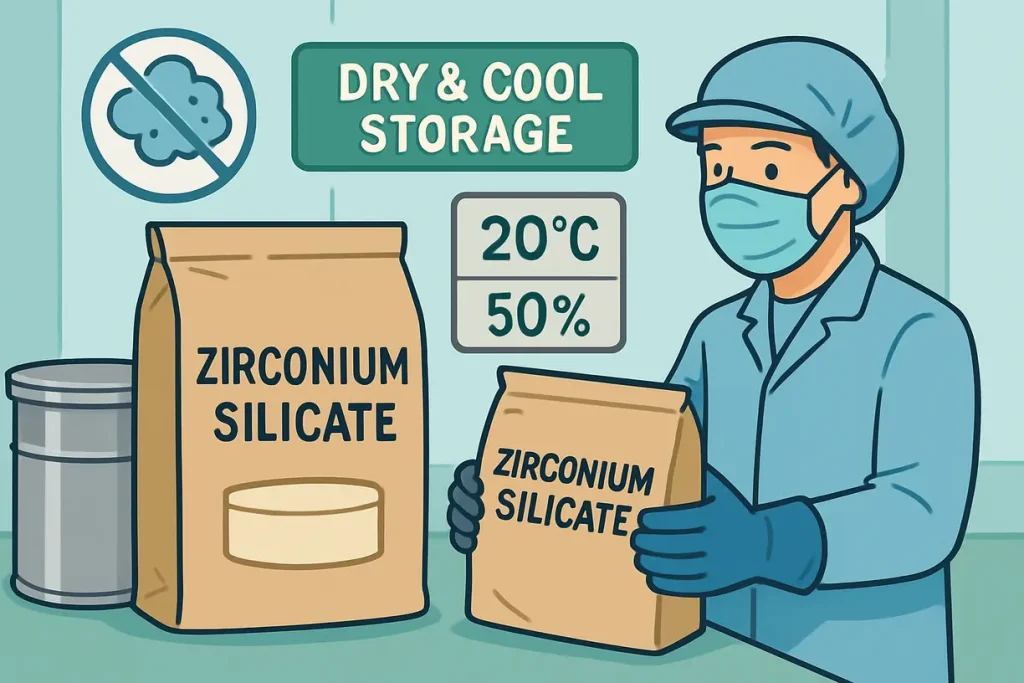

External factors can profoundly influence the safety results of zirconium silicate. Storage conditions, transportation methods, and application environments are critical components that organizations must consider.

Why is this important? Improper storage may expose the material to moisture or extreme temperatures, leading to degradation before materials even reach the testing phase. Similarly, transportation could result in mechanical stresses that compromise product integrity.

It is essential to establish clear guidelines for handling and storage. Training staff on proper protocols can significantly reduce the risk of external factors negatively affecting product quality.

In summary, maintaining control over these external conditions is crucial for ensuring safety and compliance.

| External Factor | Influence on Safety Results | Recommended Best Practices |

|---|---|---|

| Storage Conditions | May lead to moisture damage | Implement climate control |

| Transportation | Risk of physical damage | Use proper packaging |

| Application Environment | Alters material behavior | Assess compatibility during use |

This image showcases proper storage and handling procedures for zirconium silicate to maintain product integrity.

Recommendations for External Factors Management

To effectively manage external factors, consider the following recommendations:

- Conduct regular audits of storage facilities to assess conditions

- Educate employees on the importance of proper handling practices

- Utilize appropriate packaging to prevent transportation damage

- Monitor application environments to ensure compatibility

What Are Common Myths About Zirconium Silicate Safety?

Myths can mislead organizations about the safety of zirconium silicate. One prevalent misconception is that all zirconium silicate is inherently safe. While it is a robust material, its safety depends on compliance with proper standards and testing.

Another myth involves overestimating the material’s resistance to chemical reactions. While durable, zirconium silicate can still break down under certain conditions, particularly when exposed to strong acids or bases.

So, how can organizations address these myths? Education and ongoing training are crucial. Keeping staff informed about the real characteristics of zirconium silicate enhances safety awareness and compliance.

In conclusion, breaking down these myths fosters a culture of safety. By addressing misconceptions, organizations can make more informed decisions regarding their material use.

| Myth | Reality | Implications |

|---|---|---|

| All zirconium silicate is safe | Performance varies by composition | Must adhere to testing protocols |

| Zirconium silicate is unreactive | Reacts under certain conditions | Risks liabilities in use and testing |

Strategies for Addressing Myths

To effectively combat myths surrounding zirconium silicate, consider the following strategies:

- Develop educational materials that clarify facts and misconceptions

- Host training sessions to inform employees about material properties

- Share case studies that demonstrate real-world safety concerns

- Engage with industry experts to provide authoritative insights

How Can Businesses Ensure Zirconium Silicate Safety?

Businesses must adopt a proactive approach to ensure the safety of zirconium silicate. This involves rigorous supplier selection, internal quality control measures, and consistent monitoring.

What should this look like in practice? Companies can start by assessing their suppliers for compliance history and testing practices. A partnership with reliable suppliers significantly increases the chances of receiving high-quality materials.

Internal protocols should also include regular testing and quality audits. Ensuring that every batch meets safety standards before usage can prevent failures down the line.

To sum up, a commitment to rigorous safety practices is essential. Organizations that prioritize safety will not only meet regulatory demands but will also enhance their reputation in the marketplace.

| Business Strategy | Description | Benefits |

|---|---|---|

| Supplier Evaluation | Choosing compliant suppliers | Assured material quality |

| Quality Audits | Conducting routine assessments | Early detection of issues |

| Regular Testing | Ensuring ongoing safety compliance | Minimized risk of failures |

Key Actions for Strengthening Safety Measures

To strengthen your safety measures for zirconium silicate, focus on the following actions:

- Map out all supply chain partners for transparency and accountability

- Document safety protocols and ensure widespread access for employees

- Regularly update safety measures according to evolving regulations

- Foster an organizational culture committed to safety at every level

What Are the Consequences of Failing Safety Tests?

Failing safety tests can lead to serious consequences for businesses. The most immediate effect is often financial loss due to recalls and rework. Furthermore, repeated failures can result in increased scrutiny from regulatory bodies and damage to the brand’s reputation.

There are also legal ramifications. Companies found to be non-compliant may face lawsuits, resulting in steep penalties and loss of customers. This is especially impactful for businesses that rely heavily on trust and credibility.

So, what can businesses do to mitigate these risks? By focusing on proactive quality control and ongoing safety assessments, organizations can reduce the likelihood of failures.

In summary, understanding these consequences is vital for decision-makers. Proactive measures can lead to improved safety and substantial long-term savings.

| Consequence | Description |

|---|---|

| Financial Loss | Costs associated with recalls |

| Legal Ramifications | Risk of lawsuits and penalties |

| Reputation Damage | Loss of customer trust and business |

Potential Outcomes of Neglecting Safety Standards

Ignoring safety standards can lead to various negative outcomes, including:

- Increased regulatory inspections and audits

- Higher insurance premiums due to perceived risk

- Loss of business opportunities due to reputational harm

- A decrease in employee morale caused by unsafe working conditions

How Is Zirconium Silicate Being Improved for Safety Compliance?

The ongoing development of zirconium silicate focuses on enhancing safety compliance. Researchers are exploring innovative techniques and better additives to improve performance.

For instance, advances in manufacturing technologies allow for finer control of material properties. This improvement can lead to more consistent safety outcomes in testing.

What about industry collaboration? Partnerships between research institutions and manufacturers are vital. Such collaborations yield new insights, keeping businesses ahead of evolving safety standards.

In the future, our understanding of zirconium silicate safety will likely expand. Continued investments in research and development will open new pathways to better materials.

| Improvement | Description |

|---|---|

| Advanced Manufacturing Tech | Enhances material consistency |

| Industry Collaborations | Shares insights on safety |

| Research Investments | Innovates safer materials |

Conclusion

In a rapidly changing market, understanding the causes behind zirconium silicate’s safety test failures and implementing effective measures is paramount. Businesses must focus on maintaining high standards. By doing so, they will mitigate risks and enhance their overall product reliability.

The benefits of addressing these challenges can be profound. By ensuring compliance with safety standards, your organization can reduce costly incidents and build trust with your clients.

At Global Industry, we specialize in helping businesses achieve regulatory compliance while enhancing product safety. Reach out to us today to learn how we can support your organization’s efforts in improving safety standards.

FAQ Section

Q1: What are the key safety standards for zirconium silicate?

Various organizations, such as ASTM and ISO, establish stringent safety regulations to ensure that zirconium silicate meets required performance metrics. These standards focus on aspects like physical integrity, thermal stability, and chemical reactivity, which are vital for protecting public health and the environment. Compliance with these regulations is crucial for manufacturers seeking to maintain quality and safety in their products.

Q2: How does temperature affect zirconium silicate safety tests?

Extreme temperatures can significantly alter the properties of zirconium silicate. High temperatures may induce phase changes or structural weaknesses, leading to unexpected behavior during safety assessments. Conversely, testing at low temperatures might not accurately represent material performance under operational conditions. Therefore, it’s essential to follow specified temperature ranges outlined in testing protocols to ensure reliable outcomes.

Q3: What impurities are most concerning for zirconium silicate?

Common impurities such as heavy metals, organic compounds, and foreign minerals can severely compromise the safety and performance of zirconium silicate. These contaminants may interfere with the material’s properties, leading to failures in safety testing and reduced effectiveness in applications. Regular testing and strict quality control measures are necessary to identify and eliminate these impurities, thus ensuring the integrity of the final product.

Q4: What are the consequences of safety test failures?

Failing safety tests can lead to serious implications, including financial losses due to product recalls and rework. Legal repercussions may also arise, involving lawsuits and penalties if a product is found to be non-compliant. Additionally, repeated failures can damage a company’s reputation, resulting in loss of customer trust and decreasing market opportunities. Therefore, proactive quality control is imperative to mitigate these risks.

Q5: How can businesses improve zirconium silicate for better safety?

To enhance the safety profile of zirconium silicate, businesses should continually invest in research and development to explore new manufacturing techniques and additives. Collaborating with research institutions can provide valuable insights and keep companies updated on evolving safety regulations. Moreover, implementing rigorous quality control measures and conducting thorough safety assessments will help in producing more reliable and compliant zirconium silicate products.