In the field of ceramic materials, understanding the properties of ZrSiO₄ is crucial for professionals seeking to enhance product quality. Despite its significance, many purchasing managers and decision-makers struggle with the complexities of the refractive index, specifically the aspect where ZrSiO₄ boasts a refractive index of approximately 1.93 and its role in opacification. This article offers clear insights into these concepts, aiding businesses in making informed decisions. With credible industry data and practical applications, we ensure that you feel empowered to apply this knowledge effectively within your own operations.

What Is ZrSiO₄ and Its Importance in Glaze Science?

Zirconium silicate, or ZrSiO₄, serves as a key material in glaze science. This compound is vital due to its various attributes such as chemical stability, high melting point, and outstanding durability. Manufacturers often leverage these properties to enhance the performance and aesthetics of ceramic products. ZrSiO₄ is particularly valued for its role in creating durable and visually appealing glazes for porcelain, tiles, and fine ceramics.

The unique characteristics of ZrSiO₄ make it indispensable in industries that prioritize quality. Its ability to resist chemical corrosion allows ceramics to maintain their integrity under challenging conditions. When used in glaze formulations, it contributes not only to a product’s mechanical strength but also to its visual appeal by creating smoother finishes and enhancing color vibrancy. Additionally, ZrSiO₄ plays a significant role in the thermal stability of ceramics, ensuring that they withstand high temperatures without warping or losing structural integrity.

In essence, ZrSiO₄ establishes a foundation for high-quality ceramic products, attracting manufacturers looking to increase service life and aesthetic quality.

To illustrate this point further, take the ceramics industry. Companies that utilize ZrSiO₄ in their products often see improved customer satisfaction due to superior product performance. Understanding its role enables businesses to innovate and stay competitive in a crowded market.

The versatility of ZrSiO₄ extends beyond aesthetics. For instance, in the production of sanitary ware, the use of ZrSiO₄ contributes to improved whiteness and brightness of the glazes. This not only enhances the appearance of the final product but also aligns with consumer preferences for clean and modern designs.

How Is the Refractive Index Defined and Measured?

Refractive index quantifies how light propagates through a material, defined as the ratio of the speed of light in a vacuum to the speed of light in the material. For ZrSiO₄, with a refractive index of approximately 1.93, this measurement is critical in determining how light interacts with ceramic glazes. The refractive index is an essential parameter in assessing the optical clarity and brilliance of glazes, making it a vital consideration in product development.

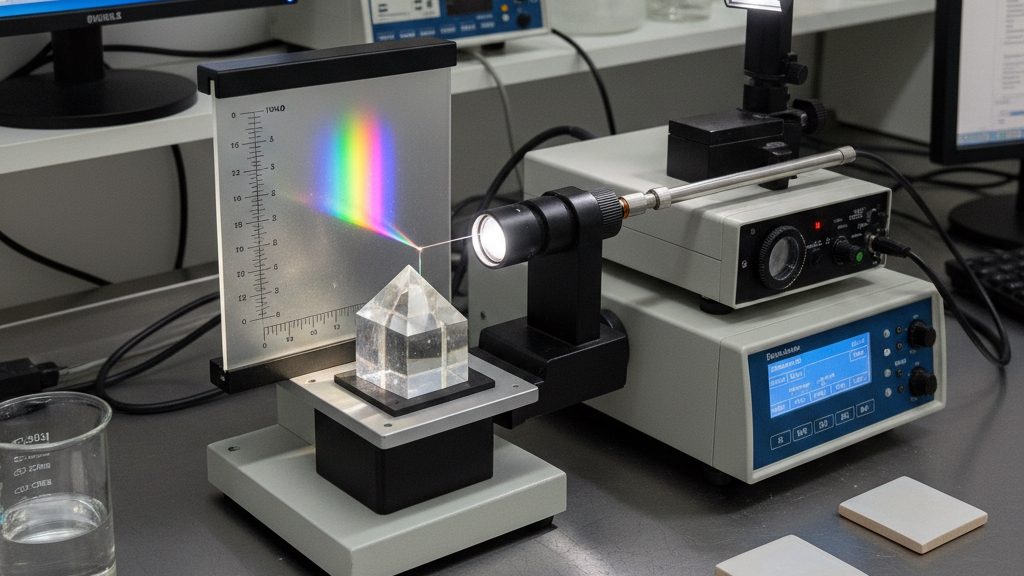

Measuring refractive index can be achieved through various methods. Refractometry is the most common technique; it involves directing light through a sample and analyzing the angle of refraction. This allows manufacturers to determine the specific refractive index, essential for achieving desired optical properties in finished products.

Another reliable method is spectroscopy, which helps assess the material’s optical quality across a range of wavelengths. Understanding the refractive index of ZrSiO₄ not only helps ensure consistent glaze appearance but also assists manufacturers in predicting performance under different light conditions.

So why does this matter? The refractive index directly affects the opacity and visual depth of glazes. A higher refractive index can lead to visually striking finishes, ensuring that the end product stands out in a competitive market. Manufacturers aiming for high-end ceramic products prioritize materials with favorable refractive indices to attract discerning customers.

The relationship between refractive index and design elements is complex but significant. Designers can manipulate the refractive index to achieve specific visual effects such as glossiness and transparency in finishes. With ZrSiO₄’s high refractive index, producers can create glazes that not only look appealing but also enhance functionality by making surfaces easier to clean and maintain, qualities valued in commercial settings.

| Measurement Technique | Description |

|---|---|

| Refractometry | Analyses the angle at which light refracts |

| Spectroscopy | Assesses optical quality at various wavelengths |

Why Does Opacification Matter in Glaze Applications?

Opacification refers to the process of producing a non-transparent glaze. This characteristic enhances the visual appeal of ceramics while also serving functional purposes, such as hiding surface defects and uneven textures. ZrSiO₄ plays a pivotal role in achieving the desired level of opacification in glazes.

When manufacturers opt for ZrSiO₄, they benefit from its natural ability to scatter light. This scattering effect contributes to the opacity of the final product. The ability to produce opaque glazes not only attracts customers but also provides a competitive edge in the market. Opacified glazes are preferred in household ceramics because they can disguise imperfections and produce a uniform appearance.

Opacification can also influence the perception of product quality. Customers often associate a more opaque product with durability and luxury. This perception can be particularly advantageous for brands aiming to position themselves in the premium segment of the market.

Opacified glazes offer several advantages. First, they improve the overall visual quality of ceramic products. Second, achieving a high level of opacity can extend the range of aesthetic effects that can be achieved. Beyond appearance, the right opacified glaze can help mask underlying imperfections, ensuring a more uniform and polished finish.

Consider the case of bathroom tiles. A manufacturer using ZrSiO₄ can create bathroom tiles that are not only beautiful but also functional, hiding any imperfections from manufacturing while delivering a premium appearance. This enhances customer satisfaction and solidifies brand loyalty.

Additionally, the use of opacified glazes allows for creative freedom in design. Designers can experiment with various colors and textures, knowing that the opacification will prevent undesired effects from showing through. This flexibility encourages innovative designs and can lead to unique product offerings.

| Opacification Benefits | Impact |

|---|---|

| Hides defects | Uniform appearance |

| Enhanced aesthetics | Visually striking products |

| Greater customization | Expanded design possibilities |

What Factors Influence the Refractive Index of ZrSiO₄?

Several factors influence the refractive index of ZrSiO₄. These include its composition, temperature, and physical attributes such as particle size.

The composition of ZrSiO₄ can vary significantly, leading to differences in optical properties. The inclusion of additives or impurities may alter the refractive index, allowing manufacturers to tailor end products according to specific requirements. This customization is particularly beneficial in addressing specific customer needs or market trends.

Temperature also plays a crucial role. Higher temperatures can affect the refractive index by altering the material’s density and structure, which in turn influences how light interacts with the material. This becomes especially important in manufacturing environments where heating is necessary for glaze application. Monitoring the temperature during production can help mitigate any adverse effects on the refractive index.

Furthermore, the size and distribution of ZrSiO₄ particles can impact the way light is scattered. Smaller particles tend to produce a more pronounced scattering effect, enhancing opacity and overall appearance. Particle size distribution is a critical factor; a uniform distribution can lead to consistent optical results, while discrepancies can lead to variations in product quality.

So, how do manufacturers manage these factors? Regular testing during production can ensure that the right composition and particle size are maintained, providing valuable control over the refractive index and overall product quality. For best results, companies should establish internal quality assurance that includes routine checks on these factors to minimize variations.

| Influence Factor | Description |

|---|---|

| Composition | Variability impacts optical properties |

| Temperature | Alters density and structure |

| Particle Size | Affects light scattering dynamics |

How Do Manufacturers Utilize ZrSiO₄?

Manufacturers use ZrSiO₄ in numerous ways across various industries. Its unique attributes provide a range of applications in ceramic glazes, making it a go-to material for those looking to enhance the quality and aesthetics of their products.

In the ceramics industry, ZrSiO₄ serves as a vital ingredient in glazes for porcelain, stoneware, and tiles. This application not only improves visual appeal but also contributes to the durability and long-lasting qualities of these materials. The ability to create both functional and attractive products has allowed many companies to position themselves as leaders in the ceramics market.

Another critical area is the electronics industry, where ZrSiO₄ finds its footing in insulating materials and components. These electrical applications benefit from ZrSiO₄’s thermal stability and resistance to wear, making it a potent material in product development. The growing demand for high-performance electronics has led to an increase in ZrSiO₄ usage, further demonstrating its versatility.

Let’s take a look at a successful case: A manufacturer specializing in high-end dinnerware successfully integrated ZrSiO₄ into its glaze formulas. The results were remarkable. They achieved a striking appearance paired with enhanced durability, leading to increased sales and customer satisfaction. This company’s commitment to quality, supported by the superior properties of ZrSiO₄, allowed them to create a niche market for themselves, catering to consumers willing to pay more for premium products.

As the demand for sustainable products grows, ZrSiO₄ also presents itself as an attractive option. It can replace harmful materials traditionally used in ceramics, appealing to environmentally conscious consumers and companies.

| Industry | Application |

|---|---|

| Ceramics | Glazes for porcelain and tiles |

| Electronics | Insulating materials |

| Automotive | Components requiring high durability |

What Are Common Challenges with ZrSiO₄ in Production?

While ZrSiO₄ offers numerous benefits, there are challenges that manufacturers might face. Sourcing the material can sometimes be difficult, as ZrSiO₄ is not always readily available in certain regions. This can lead to delays in production and increased costs. Securing a reliable supplier is paramount for maintaining consistent production schedules.

Handling ZrSiO₄ presents another challenge; it is essential to manage this material effectively to avoid issues such as contamination. Any impurities can significantly affect the material’s performance and ultimately impact the final product quality. Implementing stringent handling protocols can mitigate these risks.

Moreover, defects in the final product can arise from improper processing or application techniques. Ensuring that quality control measures are in place is imperative for manufacturers to minimize waste and maintain high standards. Training staff on best practices in handling and applying ZrSiO₄-containing glazes will help minimize defects and maintain product integrity.

In summary, addressing these challenges proactively can lead to more efficient operations. Regular training and robust procedures can help mitigate risks associated with ZrSiO₄ production. By developing strong relationships with suppliers and maintaining high standards throughout production, manufacturers can leverage the full potential of ZrSiO₄.

| Common Challenges | Impact |

|---|---|

| Sourcing | Potential production delays and costs |

| Contamination | Quality issues |

| Processing errors | Defects in end products |

How Can Understanding ZrSiO₄ Improve Product Development?

A clear understanding of ZrSiO₄ significantly enhances product development. From its optical properties to its mechanical strength, gaining insights into this material equips manufacturers with the knowledge needed for innovation. Businesses can embark on efforts to continuously improve their offerings through diversification and experimentation with ZrSiO₄-based formulations.

Having a thorough grasp of ZrSiO₄’s properties allows manufacturers to experiment with different compositions to create unique visual effects. This creativity can lead to innovative designs that attract customers. For example, combining ZrSiO₄ with complementary materials can yield innovative color palettes or textures, appealing to diverse consumer preferences.

Furthermore, knowledge of how to manipulate ZrSiO₄ in glaze formulations can lead to improved product durability. By optimizing formulations, manufacturers can create ceramics that withstand wear over time, thus delivering better value to customers.

So, what does this mean for your company? By leveraging a thorough understanding of ZrSiO₄, businesses can not only develop superior products but also enhance their market position. The potential to innovate and improve can set a company apart from its competitors.

| Improvement Area | Potential Benefit |

|---|---|

| Visual differentiation | Stand out in a competitive market |

| Durability | Increased customer satisfaction |

| Product range | Attract a diverse customer base |

Conclusion

Understanding the refractive index of ZrSiO₄ and its role in opacification is vital for businesses focused on ceramic product development. This article has highlighted the importance of this material, the methods of measurement, and its various applications. One clear benefit is how understanding these attributes can dramatically improve product quality and marketability. Global Industry encourages you to deepen your knowledge of ZrSiO₄ and its applications to stay at the forefront of ceramic innovation. For additional support or resources, connect with us today.

FAQ Section

Q1: What industries use ZrSiO₄?

ZrSiO₄ is primarily used in ceramics, glass manufacturing, and electronics due to its properties.

Q2: How is the refractive index of a material measured?

The refractive index can be measured using various techniques including refractometry and spectroscopy.

Q3: Why is opacification desired in glazes?

Opacification enhances the aesthetic quality of glazes and provides opacity for underlying materials.

Q4: What role does particle size play in refractive index?

Particle size can affect light scattering and, consequently, the effective refractive index of a glaze.

Q5: Are there alternatives to ZrSiO₄?

Yes, materials like titanium dioxide and zirconium dioxide can also provide opacification but with different properties.