Purchasing managers and ceramic professionals often struggle to fully grasp the complex optical physics behind opacification, specifically regarding the refractive index. Misunderstanding these properties leads to inconsistent glaze finishes, production defects, and wasted resources, leaving you at a disadvantage in a competitive market. This guide demystifies the 1.93 refractive index of Zirconium Silicate, offering clear, actionable insights to optimize your ceramic production and enhance product quality.

What Is Zirconium Silicate in Glaze Science?

Zirconium Silicate (ZrSiO₄) is a compound valued for its chemical stability and high melting point in ceramic glazes.

Why is chemical stability crucial?

Resistance to corrosion maintains glaze integrity. Here is why this matters: You need materials that withstand harsh firing conditions without degrading.

- High thermal endurance

- Resistance to chemical corrosion

- Structural integrity maintenance

How does it enhance durability?

It significantly contributes to mechanical strength. But that’s not all: Your end-users expect products that resist wear and tear.

- Scratch resistance

- Hardness improvement

- Longer service life

The role of aesthetic enhancement

It provides visual appeal in porcelain and tiles. Consider this: You can achieve smoother finishes that captivate your customers.

- Smoother surface texture

- Vibrant color support

- Premium gloss appearance

Key Takeaway: Zirconium Silicate is the foundational element for high-quality ceramics, offering you a dual benefit of superior structural durability and premium aesthetic appeal.

| Feature | Benefit | |

|---|---|---|

| Stability | Prevents degradation | |

| Hardness | Resists scratching | |

| Texture | Improves feel |

Analysis: ZrSiO₄ is indispensable for manufacturers prioritizing long-term product resilience alongside visual quality.

Refractive Index of Zirconium Silicate Explained

Zirconium Silicate possesses a high refractive index of approximately 1.93, determining how it interacts with light.

Understanding the 1.93 measurement

This figure represents the ratio of light speed and optical clarity. What does this mean for you? You can predict how light propagates through your glaze layers.

- Light propagation speed

- Vacuum vs. material ratio

- Optical clarity assessment

Common measurement techniques

Experts use Refractometry and Spectroscopy. How do we know? You should rely on precise data to ensure consistency.

- Angle of refraction analysis

- Wavelength assessment

- Spectroscopic quality checks

Impact on brilliance and depth

The index creates visual depth and striking finishes. The bottom line is this: Your high-end lines will benefit from the visual depth this index provides.

- Visual depth enhancement

- Glossiness manipulation

- Consumer perception of quality

Key Takeaway: Mastering the high refractive index of Zirconium Silicate allows you to engineer glazes with superior brilliance and optical depth.

| Metric | Impact | |

|---|---|---|

| 1.93 Index | High Brilliance | |

| Refraction | Light Bending | |

| Depth | Visual Quality |

Analysis: A high refractive index is the primary driver for creating visually competitive, high-gloss ceramic finishes.

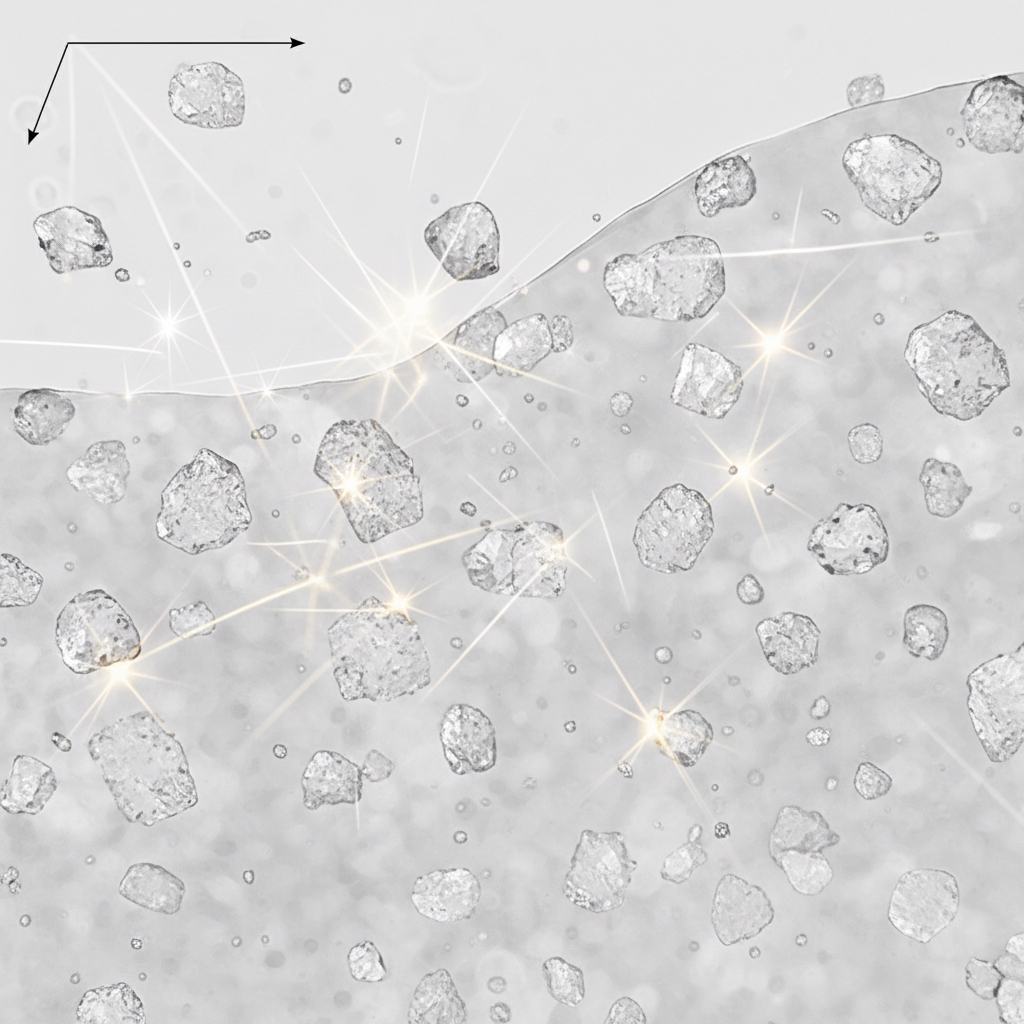

Zirconium Silicate Opacification in Glazes

Zirconium Silicate creates non-transparent glazes by effectively scattering light.

How does light scattering work?

It works by masking the underlying clay body. Let’s look closer: You can effectively mask the clay body color.

- Photon scattering

- Opacity generation

- Reflection mechanics

Hiding surface defects

Opacity functionally hides substrate imperfections. Why is this critical? You can reduce waste by disguising minor substrate imperfections.

- Masking uneven textures

- Covering substrate blemishes

- Creating uniform surfaces

Creating a premium appearance

Opacity enhances the perception of luxury. Think about it: You position your brand in the premium segment with opaque finishes.

- Clean, modern look

- Whiteness enhancement

- Luxury market appeal

Key Takeaway: Leveraging the opacification properties of Zirconium Silicate enables you to produce flawless, uniform surfaces that hide defects and project luxury.

| Function | Outcome | |

|---|---|---|

| Scattering | High Opacity | |

| Masking | Defect Hiding | |

| Finish | Premium Look |

Analysis: Effective opacification is not just aesthetic; it is a functional tool for increasing yield by masking substrate variations.

Factors Affecting Zirconium Silicate Refraction

Composition, temperature, and particle size are key influencers of Zirconium Silicate refraction.

The role of chemical composition

Purity and additives dictate performance. It turns out: You must monitor impurities to maintain consistent optical properties.

- Impurity impact

- Additive customization

- Chemical balance

Temperature influence during firing

Heat causes density and structural changes. Here is the catch: You need precise kiln control to prevent density shifts that alter appearance.

- Firing curve control

- Density alteration

- Structure modification

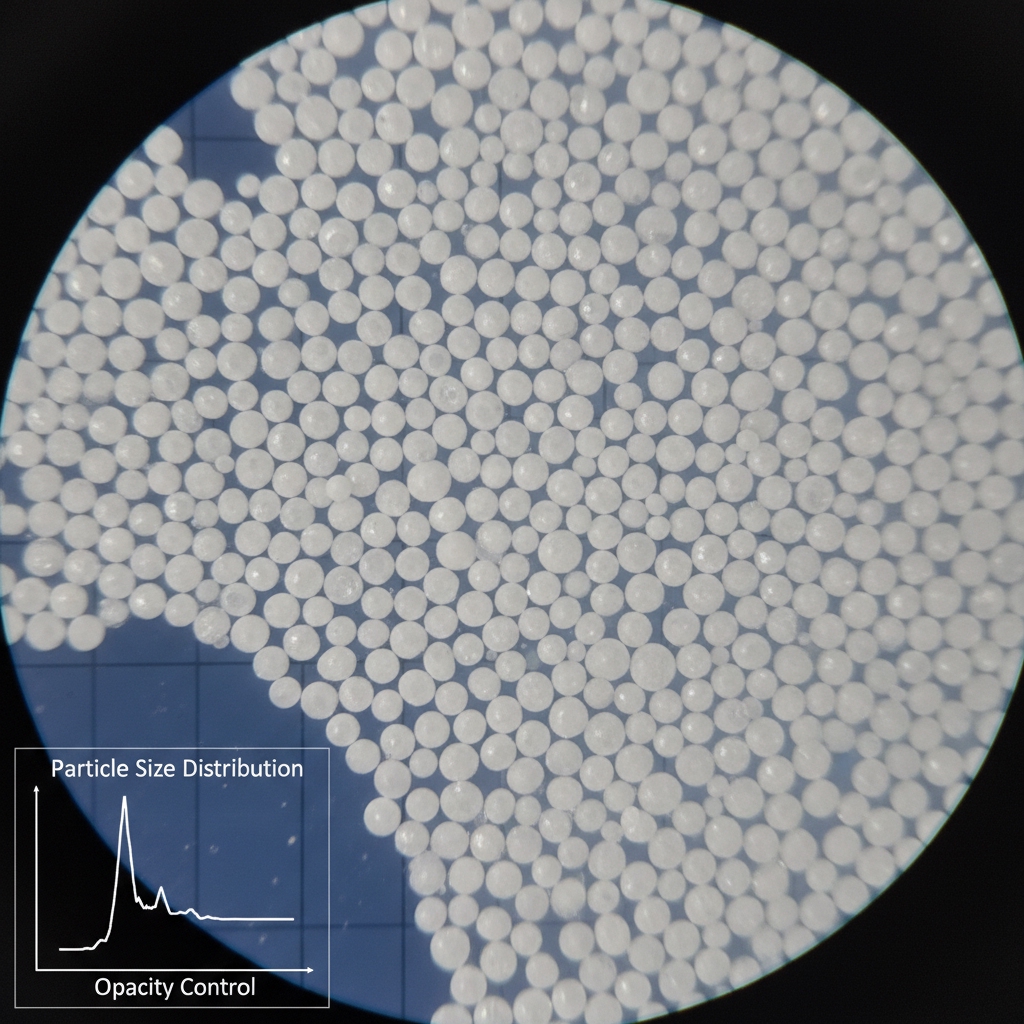

Why particle size matters?

Micronization dictates scattering effects. You might be wondering: You achieve better opacity with finer, more uniform particle distribution.

- Scattering efficiency

- Distribution uniformity

- Micron-level adjustments

Key Takeaway: Controlling the particle size and purity of Zirconium Silicate gives you precise command over the final refractive quality of your product.

| Factor | Effect | |

|---|---|---|

| Purity | Consistent Optics | |

| Heat | Structure Density | |

| Size | Scattering Power |

Analysis: Consistent raw material specifications are critical, as slight variations in particle size can drastically alter the glaze’s optical performance.

How Manufacturers Use Zirconium Silicate Today

Zirconium Silicate is versatile across ceramics, electronics, and sanitary ware industries.

Applications in tiles and porcelain

It is standard for glazing durability. For example: You see this standard applied in almost every high-quality tile.

- Floor tile durability

- Wall tile aesthetics

- Porcelain dinnerware

Role in sanitary ware production

It ensures whiteness and hygiene. Whatever the case: Your sanitary products gain the clean, white look consumers demand.

- Brightness improvement

- Chemical resistance

- Modern design compliance

Emerging use in electronics

It provides insulation and thermal stability. Believe it or not: You can utilize its thermal properties for component insulation.

- Electrical insulation

- Component housing

- Wear resistance

Key Takeaway: Incorporating Zirconium Silicate into your production line opens doors to diverse markets, from durable construction materials to precision electronics.

| Sector | Use Case | |

|---|---|---|

| Tiles | Glaze Durability | |

| Sanitary | Whiteness | |

| Tech | Insulation |

Analysis: The material’s dual nature of optical beauty and physical toughness makes it a cross-industry staple.

Solving Zirconium Silicate Production Challenges

Common Zirconium Silicate hurdles include sourcing consistency, contamination, and processing errors.

Navigating supply chain issues

Availability and regional sourcing vary. The reality is: You need reliable suppliers to avoid costly production halts.

- Regional availability

- Lead time management

- Supplier vetting

Preventing material contamination

Handling protocols are vital. It gets worse: You risk entire batches if handling protocols are lax.

- Storage hygiene

- Handling equipment cleanliness

- Impurity testing

Reducing processing defects

Application techniques must be precise. What’s the solution? You must invest in training to minimize application errors.

- Staff training programs

- Process monitoring

- QC checkpoints

Key Takeaway: Proactive management of your Zirconium Silicate supply chain and handling procedures effectively eliminates the most common production risks.

| Challenge | Solution | |

|---|---|---|

| Supply | Vetted Sources | |

| Dirt | Hygiene Rules | |

| Defects | Staff Training |

Analysis: Operational discipline in handling raw materials is as important as the material quality itself for defect reduction.

Enhancing Products with Zirconium Silicate

Understanding Zirconium Silicate properties fuels innovation and product differentiation.

Strategies for visual differentiation

Create unique effects and colors. Imagine this: You can create signature looks that competitors cannot easily replicate.

- Unique color palettes

- Custom textures

- Visual depth experiments

Optimizing for maximum durability

Formulate for wear resistance. Best of all: You deliver value by selling products that last longer.

- Abrasion resistance testing

- Formula optimization

- Long-term wear analysis

Expanding your product range

Diversification opens new revenue streams. Here is the deal: You can enter new market segments with specialized formulations.

- Premium tier development

- Technical ceramic applications

- Custom client solutions

Key Takeaway: Deep knowledge of Zirconium Silicate empowers you to transition from standard manufacturing to innovative, market-leading product development.

| Strategy | Benefit | |

|---|---|---|

| Visuals | Unique Branding | |

| Formula | Long Life | |

| Range | New Markets |

Analysis: Innovation in ceramics is driven by the chemical mastery of opacifiers, allowing for new aesthetic and functional heights.

Zirconium Silicate vs. Other Opacifiers

Zirconium Silicate compares favorably against Tin Oxide and Titanium Dioxide regarding cost and performance.

Comparison with Titanium Dioxide

Titanium often causes color variance. You might ask: You avoid the yellowing effect of titanium by choosing zirconium.

- Color neutrality

- Cost variance

- Application suitability

Why choose Zirconium over Tin Oxide?

Economic and stability factors favor Zirconium. Let’s be honest: You save on raw material costs without sacrificing opacity.

- Price stability

- Supply abundance

- Opacifying efficiency

Cost-benefit analysis for production

ROI and efficiency are superior. The numbers don’t lie: You achieve a better balance of quality and cost with zirconium.

- Lower production costs

- Higher yield rates

- Consistent results

Key Takeaway: Zirconium Silicate offers you the optimal balance of cost-efficiency and color stability compared to other market alternatives.

| Material | Pros | Cons | |

|---|---|---|---|

| Zirconium | Neutral & Stable | Moderate Cost | |

| Titanium | Strong Opacity | Yellowing | |

| Tin Oxide | High Opacity | High Cost |

Analysis: While alternatives exist, ZrSiO₄ remains the industry standard for its neutral color impact and economic viability.

Eco-Friendly Benefits of Zirconium Silicate

Zirconium Silicate has a strong sustainability profile as a replacement for hazardous materials.

Replacing harmful additives

It removes lead and toxic elements. Here is the good news: You can market your products as safer and cleaner.

- Non-toxic formulation

- Regulatory compliance

- Worker safety

Durability reduces waste

Lifecycle sustainability is improved. Think about the long run: You contribute to the circular economy by making products that don’t need frequent replacement.

- Extended product lifecycle

- Reduced landfill waste

- Lower replacement frequency

Meeting consumer demand for green products

Market trends favor eco-inputs. Don’t forget: You attract eco-conscious buyers by highlighting sustainable inputs.

- Green certification support

- Eco-labeling potential

- Brand reputation boost

Key Takeaway: Utilizing Zirconium Silicate positions your brand as a responsible leader in sustainable ceramic manufacturing.

| Benefit | Impact | |

|---|---|---|

| Safety | Non-Toxic | |

| Waste | Reduced | |

| Market | Eco-Friendly |

Analysis: Sustainability is no longer optional; ZrSiO₄ provides a pathway to greener production without compromising quality.

Future Trends in Zirconium Silicate Technology

Zirconium Silicate usage is evolving into nano-technologies and advanced glazing.

The rise of nano-zirconium

Ultra-fine particles are the new standard. What’s next? You can achieve unprecedented opacity levels with nano-scale materials.

- Superior scattering

- Lower usage rates

- High-tech applications

Smart coatings and functional surfaces

It enables antibacterial and self-cleaning glazes. Imagine the possibilities: You can offer tiles that actively keep environments cleaner.

- Antibacterial properties

- Easy-clean surfaces

- Advanced functionality

Global market shifts

Demand and supply trends are changing. Keep an eye on this: You need to stay agile as global demand for high-performance ceramics grows.

- Emerging market demand

- Technological integration

- Supply chain evolution

Key Takeaway: Staying ahead of Zirconium Silicate innovations ensures your production lines remain future-proof and competitive.

| Trend | Innovation | |

|---|---|---|

| Size | Nano-scale | |

| Function | Smart Surface | |

| Market | High Demand |

Analysis: The future of ceramics lies in functional performance, and advanced ZrSiO₄ processing is the key to unlocking these capabilities.

Conclusion

We have explored how the 1.93 refractive index and opacification power of ZrSiO₄ drive quality and durability. By mastering these elements, you ensure your products stand out for their brilliance and resilience. Global Industry is committed to fueling your innovation with the highest quality zirconium materials, ensuring your future is as bright and durable as the glazes you create.

FAQ Section

Can I use Zirconium Silicate in electronics?Yes, you can use it effectively due to its high thermal stability and insulation properties. It is an excellent choice for manufacturing durable electronic components that require resistance to heat and wear.

What’s the best way to ensure consistent opacity?The best approach is to strictly control particle size distribution. Fine, uniform particles maximize light scattering, ensuring a whiter and more opaque finish compared to coarser or irregular grades.

How do I know if Zirconium Silicate is better than Titanium Dioxide?You will know it is the better choice if you require a neutral white color without yellowing. While Titanium offers strong opacity, Zirconium Silicate provides superior color stability and neutrality for precise color matching.

Can I market Zirconium Silicate products as eco-friendly?Yes, you can generally position them as sustainable because the material is chemically stable and non-toxic. It frequently replaces hazardous substances like lead, improving the environmental safety profile of your final product.

What’s the best refractive index for high-gloss glazes?A refractive index around 1.93, found in Zirconium Silicate, is optimal for high-gloss finishes. This high level dictates significant light bending and scattering, directly resulting in the brilliance and depth desired in premium ceramics.