The study of zirconium silicate has gained significant attention due to its varied applications across industries, ranging from ceramics to electronics. However, many professionals may struggle to keep up with the latest research that could impact their business decisions regarding this material. This article addresses concerns about how new findings reshape our understanding of zirconium silicate properties. By presenting the latest insights, this article aims to inform decision-makers about critical advancements that can enhance their product quality or operational efficiency. Trust in our content is founded on thorough research and expert opinions that equip you with the necessary knowledge.

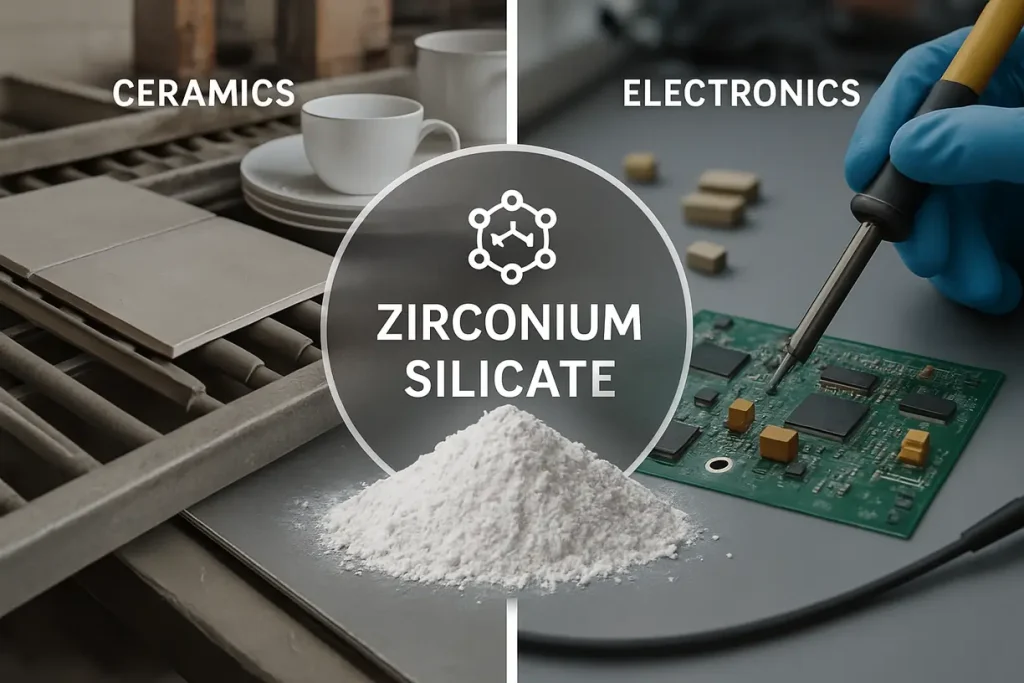

This image illustrates the diverse applications of zirconium silicate in various industries like ceramics and electronics.

How Does Zirconium Silicate Function at a Molecular Level?

Understanding how zirconium silicate functions at a molecular level is essential for its effective use in industrial applications. So, let’s break down its chemistry. Zirconium silicate consists mainly of zirconium dioxide and silica. This combination gives it unique properties, such as high thermal stability and excellent chemical resistance.

The way zirconium silicate behaves in different conditions lies at the heart of its applications. For one, its crystalline structure allows it to tolerate high temperatures, making it ideal for furnace linings and refractory materials. Additionally, its low thermal expansion helps maintain stability under temperature changes, which is crucial in processes where materials undergo rapid heating or cooling.

Applications that utilize these properties include the production of high-performance ceramics and glass. Due to its chemically inert nature, this material is also used in coatings and sealants. When it comes to ceramics, the high durability improves the lifespan of products made from this material.

Zirconium silicate’s molecular behavior can significantly impact each industry that relies on it. In manufacturing, for example, the right understanding of these properties can lead to better-quality outputs. Overall, grasping the molecular mechanics helps in leveraging its full potential in various applications.

Key properties of zirconium silicate include:

- High thermal stability

- Chemical inertness

- Low thermal expansion

- Excellent mechanical strength

| Property | Description |

|---|---|

| Composition | Zirconium dioxide and silica |

| Thermal Stability | High, suitable for high-temperature applications |

| Chemical Resistance | Excellent, minimizes reactions with other materials |

What Recent Studies Have Shaped Our Understanding?

Recent studies have provided groundbreaking insights into zirconium silicate properties. These findings are not only intriguing but also practical for industrial applications. For instance, recent research from institutions such as the University of Illinois has uncovered how impurities can influence the properties of zirconium silicate.

A key study highlighted the impact of varying levels of dopants on the thermal stability and mechanical strength of zirconium silicate. Researchers found that certain dopants increased the material’s durability, thereby enhancing its usability in high-stress environments.

Another critical area of focus has been the behavior of zirconium silicate under mechanical stress. New findings suggest that the material can exhibit unexpected flexibility without compromising its integrity. This opens up new avenues for its use in applications that require both strength and adaptability, like advanced electronics.

Furthermore, collaborative research efforts among international universities are addressing specific challenges encountered in zirconium silicate applications. These collaborations lead to a better understanding of how the material can perform under varied conditions.

The implications of these findings are profound. For businesses, staying informed about these developments can lead to smarter decisions about material selection and usage. Understanding the latest research could drastically improve product quality and performance.

Recent studies have uncovered:

- The effects of specific dopants on mechanical strength.

- Flexibility characteristics under mechanical stress.

- Collaborative research addressing application challenges.

| Research Area | Key Findings |

|---|---|

| Effects of Dopants | Certain dopants enhance durability |

| Mechanical Behavior | Exhibits flexibility under stress |

| Collaborative Studies | Focus on overcoming challenges in applications |

Why Are Zirconium Silicate Properties Important in Industry?

Zirconium silicate offers several properties that make it invaluable across various industries. To illustrate, let’s look at its significance in key sectors.

In the ceramics industry, zirconium silicate is known for its high strength and thermal stability. These attributes are essential for producing tiles and sanitary ware that can withstand everyday stresses. Additionally, its resistance to thermal shock means fewer production defects and longer-lasting products.

In the glass industry, zirconium silicate plays a crucial role in enhancing the durability and clarity of glass products. Its inert nature also prevents unwanted chemical reactions, ensuring the purity of glass formulations. This means producers can create higher-quality glass with improved durability.

Moreover, its use in refractories is important, particularly for industries like steelmaking and foundries where high-temperature processes are standard. The ability of zirconium silicate to maintain structural integrity at extreme temperatures is a game-changer.

Ultimately, the importance of these properties for industry professionals cannot be understated. Integrating zirconium silicate based on its strengths can lead to improved product performance and satisfaction among end-users.

Applications of zirconium silicate include:

- High-performance tiles and sanitary wares

- Quality enhancement in glass production

- Refractories for steelmaking

- Protective coatings for various surfaces

| Industry | Importance of Zirconium Silicate |

|---|---|

| Ceramics | High strength, thermal stability |

| Glass | Enhances durability and prevents chemical reactions |

| Refractories | Maintains integrity at high temperatures |

What Challenges Does the Industry Face with Zirconium Silicate?

Despite its advantages, zirconium silicate poses several challenges for manufacturers. Let’s examine some of them.

Sourcing high-quality zirconium silicate can sometimes be problematic. Not all suppliers provide materials with consistent properties, which can compromise end products. This inconsistency makes it important for manufacturers to establish reliable relationships with vetted suppliers.

Another challenge relates to processing and handling. Zirconium silicate can be abrasive, leading to wear and tear on machinery. Manufacturers must invest in specialized equipment that can handle such materials without incurring additional costs.

Furthermore, while recent research promises improvements, there are still gaps in understanding how variations in processing affect zirconium silicate properties. This knowledge gap can lead to unexpected results during production, creating potential risks for companies.

Addressing these challenges involves:

- Building strong relationships with reliable suppliers.

- Investing in equipment suited for abrasive materials.

- Implementing better quality control measures.

Addressing these challenges is vital. By focusing on establishing quality control measures and improving supplier relationships, businesses can navigate potential pitfalls associated with zirconium silicate.

| Challenge | Description |

|---|---|

| Sourcing Quality | Inconsistent properties from different suppliers |

| Processing Wear | Abrasive nature causes machinery wear |

| Knowledge Gaps | Lack of understanding of processing effects |

This image depicts the challenges faced in sourcing high-quality zirconium silicate in various industries.

How Can New Findings Optimize Zirconium Silicate Applications?

The latest research opens new paths for optimizing zirconium silicate applications. So, how can industries leverage these findings?

First, manufacturers can benefit from using dopants identified in recent studies to enhance the mechanical properties of their products. By carefully selecting these additives, companies can create offerings that perform better in their respective applications.

Second, understanding the flexibility of zirconium silicate under stress can lead businesses to rethink designs. For example, using zirconium silicate in structural components can provide greater durability while enabling lighter constructions.

The insights gained from collaborative research initiatives also encourage businesses to adopt a more integrated approach. Engaging with research institutions can help companies stay ahead of the curve and adapt to changing demands.

Strategies for leveraging new findings include:

- Integrating identified dopants for enhanced performance.

- Rethinking product designs for durability.

- Collaborating with research institutions for innovative ideas.

Ultimately, utilizing new findings effectively can yield significant advantages. By applying contemporary research, manufacturers can enhance product quality, reduce costs, and increase customer satisfaction.

| Optimization Strategy | Benefit |

|---|---|

| Use of Identified Dopants | Improved mechanical properties |

| Rethink Product Designs | Greater flexibility and durability |

| Collaborate with Researchers | Access to innovative solutions |

What Are the Safety Considerations When Using Zirconium Silicate?

Safety is paramount when handling any industrial material, including zirconium silicate. What do you need to know about its handling?

Professionals should always prioritize using personal protective equipment (PPE) when working with zirconium silicate to avoid inhalation or skin contact. This helps reduce the risk of respiratory issues or allergic reactions.

Furthermore, proper ventilation is critical in workplaces where zirconium silicate is processed. Adequate airflow minimizes exposure to dust, which can help prevent health-related issues among workers.

Regulatory compliance is another vital aspect. Companies must adhere to local guidelines governing the handling and use of zirconium silicate. This not only ensures worker safety but also helps avoid potential legal complications.

Key safety measures include:

- Using appropriate PPE such as masks and gloves.

- Ensuring proper workplace ventilation.

- Adhering to relevant regulatory guidelines.

Best practices should be implemented to create a safe working environment. Implementing thorough training programs for workers can improve safety and compliance.

| Safety Consideration | Recommendations |

|---|---|

| Use of PPE | Masks, gloves, and protective eyewear |

| Proper Ventilation | Ensure adequate airflow in workspaces |

| Regulatory Compliance | Follow local guidelines for handling materials |

How Is Zirconium Silicate Being Used in Emerging Technologies?

Emerging technologies are increasingly benefiting from zirconium silicate’s unique properties. So, what applications are on the rise?

In advanced manufacturing, zirconium silicate is gaining attention for its use in additive manufacturing processes, particularly 3D printing. Its high thermal stability makes it an ideal candidate for producing intricate designs that require durability.

Moreover, the electronics industry is discovering new applications for zirconium silicate in components like capacitors and insulators. The material’s ability to withstand high temperatures and its insulating properties enhance the performance of electronic devices.

In the energy sector, zirconium silicate is being investigated for its potential in energy-efficient applications. Its thermal stability can contribute to better efficiencies in various energy systems.

Emerging applications include:

- Use in 3D printing for complex structures.

- Enhancements in capacitors and insulators in electronics.

- Potential usage in energy-efficient systems.

Companies focused on innovation will find that integrating zirconium silicate into new technologies can result in significant performance benefits. By leveraging these emerging applications, manufacturers can enhance their offerings and stay competitive.

| Emerging Technology | Application |

|---|---|

| Additive Manufacturing | 3D printing of durable components |

| Electronics | Capacitors and insulators |

| Energy Efficiency | Applications in energy systems |

This image showcases the use of zirconium silicate in advanced manufacturing and electronic applications.

What Future Research Directions Are Suggested for Zirconium Silicate?

Future research can significantly enhance our understanding of zirconium silicate. What areas should scientists focus on?

One promising direction involves investigating how zirconium silicate interacts with different materials. Understanding these interactions could improve its compatibility in mixed-material applications, benefiting a range of industries.

Another vital area for exploration is its behavioral change under various environmental conditions. Researching these dynamics can lead to breakthroughs in developing superior materials that adapt to extreme conditions.

Collaboration will be key in these efforts. Universities and research institutions must work hand in hand with industry players to address specific challenges and share results that could propel the material’s advancements.

Future research directions may include:

- Studying interactions with other materials.

- Examining performance under varied environmental conditions.

- Enhancing collaboration between academia and industry.

Focusing on these efforts can lead to valuable insights. As new discoveries emerge, industries can adapt and evolve their practices, ultimately benefiting from cutting-edge advancements.

| Research Direction | Potential Benefits |

|---|---|

| Material Interaction Studies | Improved compatibility in applications |

| Environmental Behavior Studies | Development of materials for extreme conditions |

| Industry-Academic Collaboration | Accelerated research outcomes |

How Do Cross-disciplinary Approaches Enhance Zirconium Silicate Research?

Cross-disciplinary approaches have proven effective in advancing zirconium silicate research. So, why is collaboration important?

Engaging experts from different fields can lead to innovative solutions. For instance, combining chemical engineering with materials science can lead to new formulations that enhance zirconium silicate properties.

Real-world examples illustrate these benefits. Teams comprised of chemists, engineers, and environmental scientists can address multifaceted challenges, such as reducing waste in production processes while optimizing material properties.

This collaborative approach fosters creativity and opens up avenues for groundbreaking discoveries. Creating an environment that encourages knowledge sharing can lead to positive impacts on product development and overall industry practices.

Benefits of a cross-disciplinary approach include:

- Innovative solutions through shared expertise.

- Addressing complex challenges in product development.

- Enhanced creativity leading to new discoveries.

Ultimately, boosting cross-disciplinary research can create a stronger foundation for future advancements. Companies that support such initiatives will likely benefit from innovative solutions and a competitive edge.

| Benefit of Collaboration | Description |

|---|---|

| Innovative Solutions | Combining expertise from various fields |

| Real-World Applications | Addressing production challenges |

| Open Avenues for Discoveries | Encouraging knowledge sharing |

What Are the Key Takeaways for Industry Professionals?

For industry professionals, understanding zirconium silicate and its properties is crucial. What should you remember?

First, staying informed about recent studies can guide better decision-making regarding material selection. Understanding how new findings improve product quality can set your company apart.

Second, addressing challenges such as supplier quality and processing can help mitigate risks. Building relationships with reliable suppliers ensures consistency in your inputs.

Lastly, embracing safety measures will protect your workforce and maintain compliance with regulations. Prioritizing staff training can create a culture of safety that benefits both employees and the organization.

Core takeaways for success include:

- Keep updated with recent research.

- Focus on reliable supplier partnerships.

- Prioritize safety in the workplace.

In summary, effective management of zirconium silicate can significantly impact product performance. Global Industry offers resources and support to help you navigate these complexities and make informed choices.

| Key Takeaways | Action Items |

|---|---|

| Stay Informed | Monitor recent research |

| Address Challenges | Build reliable supplier relationships |

| Embrace Safety | Implement training and safety protocols |

Conclusion

In closing, understanding how new research is transforming our understanding of zirconium silicate can lead to substantial benefits for your business. Stay attuned to the latest developments, address challenges proactively, and prioritize safety. Consider contacting Global Industry today to learn more about how we can support your operational needs and enhance your business strategy.

FAQ Section

Q1: What is zirconium silicate primarily used for?

Zirconium silicate serves multiple industrial purposes, including the production of ceramics, glass, and refractory materials. Its unique properties, such as high thermal stability and chemical resistance, make it ideal for applications in environments that require durability and performance, such as in tiles, sanitary ware, and electronics.

Q2: How does zirconium silicate compare to other silicates?

Compared to other silicates, zirconium silicate often exhibits superior durability and resistance to thermal shock. This allows it to withstand extreme temperatures without deforming or breaking, making it a preferred choice for high-performance applications, especially in manufacturing and construction.

Q3: What are the safety precautions for handling zirconium silicate?

Proper safety measures include using personal protective equipment (PPE) such as masks, gloves, and safety goggles when handling zirconium silicate to prevent inhalation of dust and skin contact. Additionally, ensuring adequate ventilation in workspaces is essential to minimize exposure to airborne particles and maintain a safe working environment.

Q4: How does new research impact existing zirconium silicate applications?

Recent research can lead to improvements in processing techniques and characteristics of end products. For example, innovations in manufacturing methods or the discovery of new dopants can enhance the mechanical properties of zirconium silicate, potentially increasing efficiency and performance in applications like ceramics and electronics.

Q5: Are there any regulatory issues related to zirconium silicate usage?

Yes, industry professionals must adhere to relevant regulations, including environmental standards and health safety guidelines, which can vary by region and application. Compliance with these regulations is crucial to ensure safe handling and usage, as well as to avoid potential legal repercussions. Companies should stay informed about local regulations to improve worker safety and maintain operational standards.