Zirconium silicate plays a vital role in various applications within the oil and gas industry. However, many decision-makers face uncertainty about the performance criteria that govern its usage. This article addresses those concerns by outlining the key performance standards necessary when employing zirconium silicate. Readers will gain insights into its critical qualities and testing methods, providing a reliable resource for choosing the right materials for their operations. Moreover, understanding these standards helps ensure that companies maximize material efficiency and reliability, building confidence in their supply chains.

This image depicts zirconium silicate in its raw form, highlighting its mineral characteristics and versatility in applications.

What Are Key Performance Standards for Zirconium Silicate?

To start, it is essential to define this material and its importance in industrial applications. Known for its unique characteristics, zirconium silicate is widely used in the oil and gas sector due to its exceptional durability and resistance to harsh environments. This makes it a reliable choice for various demanding applications, ranging from drilling to refining processes.

The key performance standards for zirconium silicate in these industries can be categorized into three main areas: mechanical properties, thermal stability, and chemical resistance. Each of these categories plays a crucial role in ensuring the material can withstand the challenging conditions it will encounter during use.

Mechanical properties often include factors like tensile strength, hardness, and flexibility, which are critical for structural integrity when subjected to stress. Thermal stability refers to how well it can maintain its properties under extreme heat, which is especially important in drilling applications where high temperatures are prevalent. Finally, chemical resistance ensures that the material can endure exposure to various solvents and compounds commonly found in oil and gas operations without deteriorating.

Why are these standards critical? They help ensure reliability and efficiency in operations, significantly impacting overall operational success and safety. By adhering to these standards, companies can enhance their ability to select the right materials tailored to their specific needs, boosting productivity and minimizing potential risks.

| Performance Criteria | Description | Importance |

|---|---|---|

| Tensile Strength | Resistance to being pulled apart | Critical for structural integrity |

| Thermal Stability | Ability to maintain properties under heat | Protects against thermal degradation |

| Chemical Resistance | Withstanding harsh chemicals | Enhances longevity and performance |

These criteria help organizations minimize risks and optimize material choices, ensuring smoother operations.

Key Factors Influencing Performance Standards

When assessing the performance standards of zirconium silicate, consider the following factors:

- Material Purity: Impurities can significantly alter performance.

- Processing Techniques: Methods used during manufacturing can impact durability.

- Environmental Conditions: Actual use conditions, like pressure and temperature, shape overall performance.

Why Is Zirconium Silicate Used in Oil and Gas?

Zirconium silicate finds extensive use in the oil and gas industry due to its exceptional properties. Its unique composition makes it a preferred choice in various applications where durability and resistance are paramount.

Applications in drilling and exploration involve utilizing zirconium silicate in drilling fluids. These fluids help improve viscosity and stability, essential for effective drilling operations. By enhancing the overall performance of drilling equipment, zirconium silicate leads to smoother operations, reduces downtime, and enhances the capability to reach difficult reservoirs.

Another critical aspect is its role in enhancing operational efficiency throughout the production process. Zirconium silicate improves the performance of various machinery and equipment, leading to lower operational costs in the long run. Its inherent properties, such as high thermal and chemical resistance, can significantly reduce maintenance costs, allowing companies to allocate resources more effectively.

Moreover, compared to alternative materials, zirconium silicate offers numerous benefits. These include superior mechanical strength and thermal stability, making it ideal for challenging environments. Its ability to withstand extreme temperatures and corrosive substances ensures reliability in operations often plagued by harsh conditions.

In addition to its functional properties, zirconium silicate also contributes to sustainability initiatives. Its long lifespan reduces the frequency of replacements, thus minimizing material waste and promoting more eco-friendly practices within the industry.

| Advantage | Description | Application Area |

|---|---|---|

| Thermal Resistance | Maintains structure at high temperatures | Drill bits, machinery components |

| Chemical Durability | Resists corrosion from solvents | Oil refining and processing |

| Cost-Effectiveness | Reduces frequency of replacements | General operational budget |

In summary, the combination of its unique properties and its versatile applications makes this material an indispensable element in oil and gas operations, helping to improve overall productivity and efficiency.

This image illustrates the various applications of zirconium silicate in the oil and gas industry, showcasing its versatility and effectiveness.

How Do Performance Criteria Impact Zirconium Silicate Usage?

Understanding performance criteria is vital for the effective use of zirconium silicate in various applications. These criteria dictate how this material can be utilized, directly influencing the overall reliability and success of operations in the oil and gas industry.

Key metrics for performance evaluation include specific tests for tensile strength, thermal stability, and chemical resistance. Companies must assess these characteristics to determine if the material they are considering will meet the necessary requirements for its intended purpose.

Furthermore, compliance with industry standards and guidelines is essential for manufacturers and suppliers. Adhering to both international and local regulations ensures consistent performance and safety in operational settings. Organizations must routinely review these standards to remain compliant and competitive, as changes can occur based on advancements in technology and materials discovery.

The impact on cost-effectiveness and reliability cannot be overstated. By prioritizing a thorough understanding of the performance criteria, businesses can minimize risks associated with material selection and usage. This proactive approach not only enhances overall operational efficiency but also contributes to significant cost savings in the long run. A well-informed selection process can reduce failures and downtimes, reinforcing the stability of supply chains.

| Impact Area | Description | Example |

|---|---|---|

| Reliability | Adherence to standards improves trust | Fewer operational disruptions |

| Cost Savings | Reducing material failures saves money | Longer material lifespan |

| Regulatory Compliance | Meeting standards facilitates operations | Avoids legal complications |

Considerations for Performance Standards

When evaluating performance criteria, keep these points in view:

- Testing Environment: It’s vital that simulation conditions closely resemble actual operational settings to ensure realistic assessments.

- Quality Control: Implementing strict quality checks during sourcing and production processes helps maintain standards.

- Continuous Improvement: Regular feedback from field applications can guide refinements in performance criteria, enabling better material choices over time.

In summary, understanding and adhering to performance standards significantly affects the successful application of zirconium silicate in oil and gas operations. By focusing on these criteria, organizations can enhance reliability and efficiency, ultimately leading to improved operational outcomes.

What Are the Physical Properties of Zirconium Silicate?

When assessing zirconium silicate, examining its physical properties is crucial. These properties dictate how well it performs in various applications within the oil and gas sector.

Mechanical strength is one of the primary characteristics. This material exhibits high tensile strength, making it ideal for use in environments that place significant stress on materials during drilling operations or machinery interactions. The ability to maintain structural integrity under stress ensures the reliability of equipment and systems that rely on this substance.

Thermal stability is another key property. The material can withstand high temperatures without degrading. This capability is particularly important in drilling applications where heat buildup is common, ensuring that performance remains consistent even under extreme conditions. High thermal stability allows for safer operations, reducing the likelihood of material failure that could jeopardize projects.

Additionally, resistance to chemical degradation is critical. Zirconium silicate remains stable in the presence of various harsh chemicals, including solvents often found in oil and gas applications. This stability is particularly valuable in processes where exposure to corrosive substances can occur, allowing for longer equipment lifespans and reducing the need for frequent replacement.

These essential properties contribute to the overall effectiveness of zirconium silicate in operational settings. Leveraging these characteristics helps companies ensure they make informed choices about material applications and enhance the longevity of their operations.

| Property | Feature | Significance |

|---|---|---|

| Mechanical Strength | High tensile strength | Resists stress during drilling |

| Thermal Stability | Maintains form under heat | Prevents material failure |

| Chemical Resistance | Resists corrosive environments | Enhances longevity |

Key Physical Properties of Zirconium Silicate

Here are some significant physical properties to consider:

- Density: Affects the material’s behavior in various applications, influencing its performance under diverse conditions.

- Molecular Structure: Determines stability and reactivity, impacting its suitability for specific use cases.

- Viscosity: Relevant for applications involving fluid dynamics and drilling, affecting how well it interacts in different mixtures.

Understanding these physical properties allows companies to make tailored decisions regarding their material selections and applications. Such knowledge is invaluable in optimizing performance across various operational scenarios.med decisions about their material selections and applications.

How Is Zirconium Silicate Tested for Performance Standards?

Testing zirconium silicate for performance standards involves various methods designed to validate its suitability for specific applications within the oil and gas industry.

Common testing methods and protocols include conducting tensile strength tests, thermal cycling tests, and chemical exposure assessments. Each of these methods gives insights into how well zirconium silicate performs under different conditions.

The distinction between laboratory vs. field tests is significant. Laboratory tests provide controlled environments for testing, while field tests offer data based on real-world applications. Integrating results from both testing types ensures a comprehensive understanding of performance.

Interpreting test results is vital for decision-makers. Understanding the data can influence procurement strategies and operational implementations. For example, if testing reveals high chemical resistance, it may prompt a company to use zirconium silicate in applications where other materials would fail.

| Testing Type | Method | Purpose |

|---|---|---|

| Laboratory Testing | Controlled environment tests | Evaluate mechanical properties |

| Field Testing | Real-world application assessments | Confirm performance reliability |

In conclusion, effective testing of zirconium silicate is pivotal for confirming its performance characteristics and suitability for various operational requirements.

Best Practices for Testing Zirconium Silicate

To ensure robust testing, companies should:

- Follow Established Protocols: Utilize standardized procedures for consistency.

- Employ Qualified Personnel: Ensure skilled professionals conduct the tests.

- Document Results Thoroughly: Maintain comprehensive records of testing outcomes.

What Challenges Exist When Using Zirconium Silicate?

Despite its advantages, challenges can arise when using zirconium silicate in oil and gas applications.

Common issues in application include potential compatibility challenges with other materials in drilling fluids and equipment. This can lead to unexpected failures or reduced efficiencies if not carefully managed.

Another significant challenge is the compatibility with other materials. If zirconium silicate is used alongside incompatible materials, it may result in premature wear and tear or operational disruptions.

Furthermore, maintenance poses its challenges. While zirconium silicate has durability, consistent operational demands can prompt wear over time, necessitating ongoing maintenance practices to ensure optimal performance.

Companies need to anticipate these challenges and develop strategies to mitigate them. Understanding how zirconium silicate interacts with other materials and implementing proper maintenance routines can greatly alleviate potential issues.

| Challenge | Description | Solution |

|---|---|---|

| Compatibility Issues | Conflicts with other materials | Conduct thorough assessments |

| Maintenance Needs | Wear over time | Regular inspections and upkeep |

Strategies for Overcoming Challenges

To effectively address potential challenges, consider the following strategies:

- Conduct Compatibility Tests: Assess interactions with other materials before full-scale application.

- Implement Maintenance Protocols: Regular maintenance can extend material longevity.

- Train Personnel: Ensure that staff understands risks associated with zirconium silicate usage.

In summary, recognizing potential challenges is essential for the successful implementation of zirconium silicate in operations.

How Can Companies Ensure Quality Supply of Zirconium Silicate?

Securing a quality supply of zirconium silicate is critical for companies in the oil and gas sector. The right suppliers can greatly influence the performance and reliability of materials.

Sourcing from reputable suppliers is the first step. Companies should do their research and choose suppliers known for high-quality materials. Verifying the supplier’s track record in terms of delivering performance-compliant zirconium silicate is crucial.

The importance of certificates and compliance cannot be overstated. Suppliers should provide certifications that demonstrate their materials meet relevant industry standards. This helps reassure buyers of the quality and reliability of the material.

Recommended best practices for procurement involve establishing relationships with suppliers who can provide consistent quality. Long-term agreements or contracts can often secure better quality and pricing, allowing for predictable supply chains.

| Best Practice | Description | Benefit |

|---|---|---|

| Choose Reputable Suppliers | Verify track records | Enhances material reliability |

| Require Certifications | Ensure compliance with standards | Reduces risks |

| Long-term Agreements | Establish reliable supply chains | Saves on procurement costs |

Key Elements for Ensuring Quality Supply

To ensure quality in your supply chain, focus on:

- Supplier Audits: Regularly assess supplier capabilities and compliance.

- Clear Communication: Establish open lines for discussing quality and expectations.

- Inventory Management: Maintain adequate stock levels to avoid supply shortages.

In conclusion, proactive sourcing and supplier management are necessary for ensuring a consistent supply of high-quality zirconium silicate.

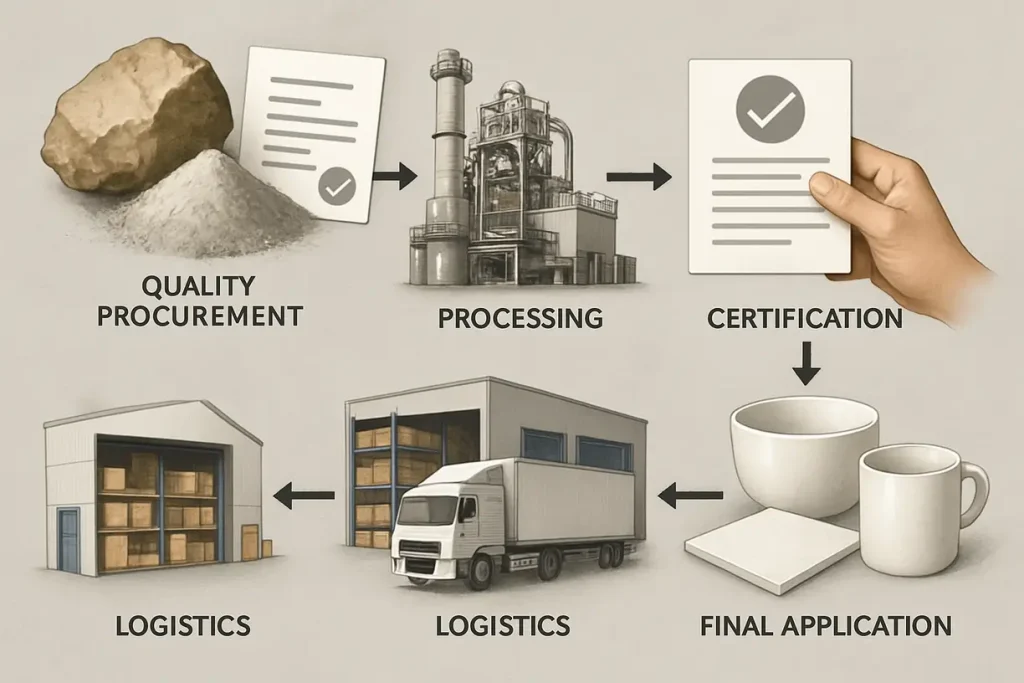

This image illustrates the supply chain management process for zirconium silicate, emphasizing the importance of quality sourcing and certification.

What Innovations Are Emerging in Zirconium Silicate Applications?

As industries evolve, so do the applications of zirconium silicate. Current research and development trends reveal innovative uses that enhance its value in oil and gas operations.

One such innovation is the integration of advanced composites that incorporate zirconium silicate. These new materials offer improved performance characteristics, providing companies with even better options for specific applications.

Future potential uses in oil and gas may include developments in drilling technologies and materials that improve the efficiency and effectiveness of extraction methods. Research into nanostructures may also contribute to enhancing the material’s properties, leading to potentially revolutionary advancements.

The impact of technology on performance is another exciting area of development. New processing technologies can optimize the properties of zirconium silicate, ensuring it meets the latest demands of the oil and gas industry.

| Innovation Area | Example | Potential Benefit |

|---|---|---|

| Advanced Composites | New materials combining zirconium silicate | Enhanced performance |

| Nanostructures | Research into smaller particle forms | Improved resistance and efficiency |

| Processing Technologies | Enhanced material optimization | Higher performance consistency |

Emerging Trends in Zirconium Silicate Research

Keep an eye on these promising trends:

- Enhanced Synthesis Methods: New approaches to production yielding higher purity.

- Application-Specific Formulations: Tailoring characteristics for niche uses.

- Sustainability Initiatives: Focus on eco-friendly processes in production and application.

In summary, the ongoing research and innovations surrounding zirconium silicate reveal promising avenues for its future application.

Conclusion

In summary, understanding the key performance standards for zirconium silicate is crucial for its effective use in the oil and gas industry. This article covered essential insights ranging from its mechanical and thermal properties to compliance considerations and innovations on the horizon. By focusing on these standards, companies can ensure they choose the best materials, leading to significant cost savings and operational improvements. Global Industry is here to support your needs—contact us today to learn more about our high-quality zirconium silicate solutions and how they can benefit your operations. Let’s build a successful partnership together!

FAQ Section

Q1: What makes zirconium silicate a preferred option in oil and gas?

Zirconium silicate offers high thermal stability and resistance to chemical reactions, making it suitable for harsh environments.

Q2: How is the performance of zirconium silicate tested?

Various methods, including mechanical strength tests and exposure to extreme conditions, assess its reliability and efficiency.

Q3: What industries outside oil and gas utilize zirconium silicate?

Industries such as ceramics, electronics, and pharmaceuticals also leverage zirconium silicate for its unique properties.

Q4: What are the most common challenges faced with zirconium silicate?

Challenges include compatibility issues with other materials and the necessity for regular maintenance.

Q5: What role does supplier certification play in using zirconium silicate?

Supplier certifications ensure quality and compliance with industry standards, providing confidence in material performance.