In manufacturing and materials engineering, high-performance materials are essential for operations demanding durability and stability under intense thermal conditions. But here’s the challenge: many materials degrade when exposed to high temperatures, leading to costly downtimes and inferior product quality. This article discusses how zirconium silicate enhances high-temperature performance by providing superior thermal stability and resistance to thermal shock. Trust the information provided, as we’ve researched various applications and properties of zirconium silicate, offering data-driven insights relevant for decision-makers and purchasing managers.

This image shows zirconium silicate powder, highlighting its role in manufacturing.

What Are Zirconium Silicate and Its Properties?

Zirconium silicate, often recognized for its unique characteristics, is a mineral composed mainly of zirconium, silicon, and oxygen. It exists in both natural and synthetic forms. Let’s break this down: zirconium silicate boasts excellent resistance to corrosion, high durability, and remarkable thermal stability. These properties make it particularly valuable in various industrial applications, ranging from ceramics to refractory linings.

One significant feature is its high melting point, typically around 2,600 degrees Celsius or 4,700 degrees Fahrenheit. This means that it can withstand extreme temperatures without breaking down or changing its physical structure. Such resilience is essential in settings where materials are subjected to severe thermal stress. Customers considering its use will often find that the compound fulfills their high-temperature application needs efficiently.

Additionally, zirconium silicate has a low thermal conductivity, which aids in thermal shock resistance. This characteristic allows it to endure rapid temperature changes, minimizing the likelihood of cracking or structural deformation. As a result, industries favor zirconium silicate in applications where maintaining material integrity under intense heat is crucial.

Zirconium-based materials are commonly used in properties that include:

- Corrosion Resistance: Highly resistant to acids and bases, making it suitable in chemically aggressive environments.

- Durability: Exceptional wear resistance contributes to the longevity of products made from this material.

- Non-toxicity: Safe for use in various applications, including those in food and pharmaceutical industries.

These properties enable zirconium silicate to find applications across diverse fields such as ceramics, refractory materials, coatings, and even electronics.

| Properties | Values |

|---|---|

| Melting Point | ~2,600 °C (4,700 °F) |

| Thermal Conductivity | Low |

| Chemical Stability | High |

| Corrosion Resistance | Excellent |

| Durability | High wear resistance |

Why Is Zirconium Silicate Used in High-Temperature Environments?

Understanding why zirconium silicate is favored in high-temperature settings requires a closer look at its specific advantages. What makes it stand out? First, the material displays exceptional thermal shock resistance, which means it can survive sudden shifts in temperature—a crucial aspect for industrial processes involving high heat loads and varying operational conditions.

Comparatively, alternative materials may not hold up as well under similar conditions. For example, materials like alumina or silica often crack or degrade more quickly, compromising performance and escalating operational costs. As manufacturers seek reliable alternatives, the choice of this mineral becomes evident, particularly due to its reliability and performance assurances.

Specific industries relying on zirconium silicate include the aerospace sector, where components must endure extreme conditions without failure. For instance, insulation materials must protect sensitive electronic devices from the detrimental effects of heat. In these instances, the performance of this compound significantly enhances the longevity and safety of applications.

Furthermore, in the metal processing industry, this material acts to reduce slag formation in high-temperature furnaces, which improves operational efficiency and product quality. This minimizes operational hazards commonly associated with high-temperature production processes.

In summary, organizations seeking reliable materials to withstand heat without loss of integrity find that zirconium silicate offers a multitude of advantages.

| Industry | Purpose of Zirconium Silicate |

|---|---|

| Aerospace | Component reliability under heat |

| Metal Processing | Reduce slag in furnaces |

| Ceramics | Production of durable products |

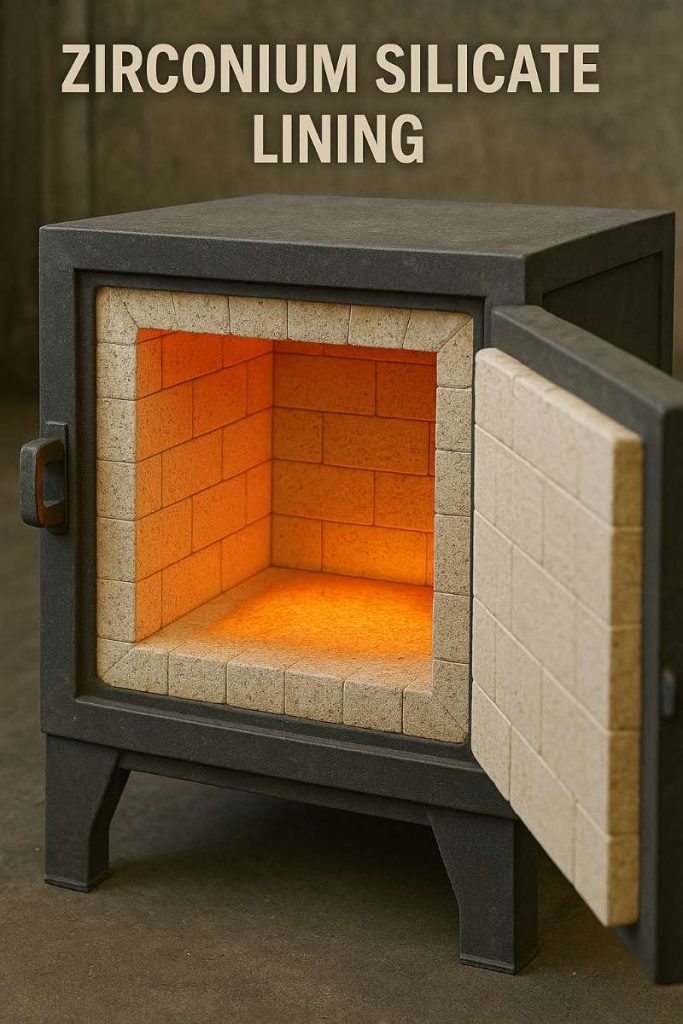

This image illustrates a high-temperature furnace showcasing zirconium silicate linings that ensure thermal stability and protection.

How Does Zirconium Silicate Perform Under Extreme Conditions?

When assessing the performance of zirconium silicate in intense conditions, several factors come into play. How does it actually hold up? An analysis reveals that this compound exhibits remarkable thermal conductivity properties along with high tensile strength, which are essential for maintaining material effectiveness and integrity.

Case studies provide valuable insights into real-world applications. For instance, in the production of ceramic tiles, zirconium silicate retains its structural integrity even when subjected to continuous heat exposure, resulting in fewer defects. This characteristic allows manufacturers to produce high-quality products that withstand wear and tear without significant degradation over time.

Moreover, its low thermal expansion minimizes the risk of cracking during manufacturing processes that involve sudden temperature fluctuations. Many users have reported lower failure rates and enhanced productivity when employing this material in their operations, which translates to higher profitability and operational outcomes.

But that’s not all: different applications demonstrate how zirconium silicate contributes to performance. For example, in the field of aerospace, its robustness has been critically evaluated in parts meant for jet engines, where extreme thermal conditions are known to affect integrity and strength.

The evidence is clear: organizations that utilize zirconium silicate enjoy improved performance in high-temperature applications. It’s a valuable addition that pays off in multiple ways.

| Performance Factors | Values |

|---|---|

| Thermal Conductivity | Low |

| Tensile Strength | High |

| Expansion Rate | Minimal |

What Are the Common High-Temperature Applications for Zirconium Silicate?

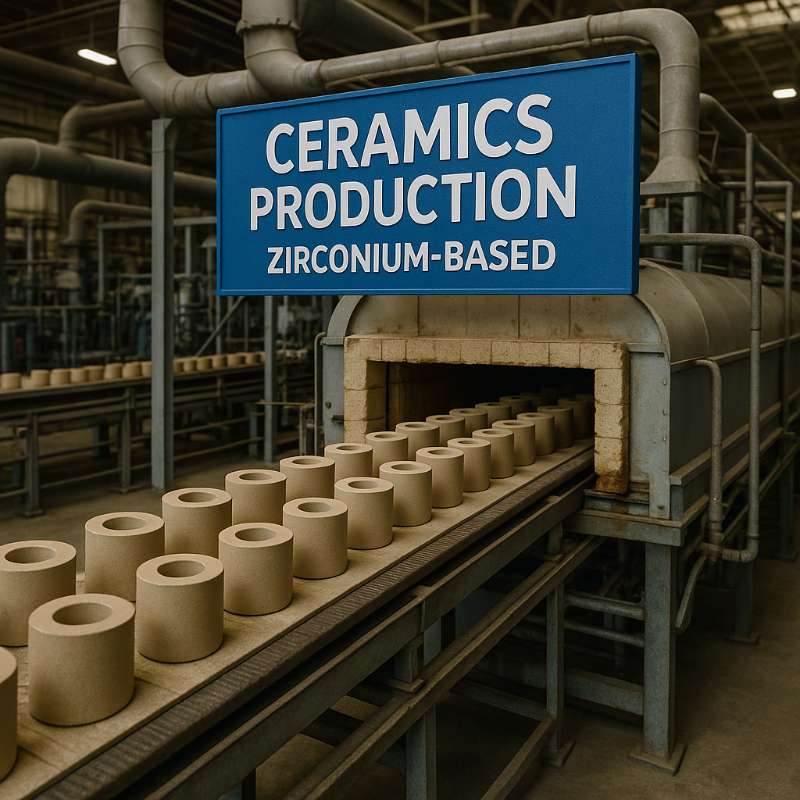

Zirconium silicate finds applications across various high-temperature scenarios. Where exactly is it utilized? The most notable use is in ceramics and refractories, where components must withstand extreme heat. It enhances both the lifespan and durability of these products, making them less likely to crack or wear out under duress.

In the aerospace industry, this material serves as an insulating agent due to its thermal stability, offering protection to sensitive components crucial for aircraft operations. Additionally, it plays a vital role in metallurgy, particularly in foundries and smelting operations where molten metal is processed. It helps maintain a steady temperature while minimizing any unwanted chemical reactions.

Moreover, industries focusing on glass production utilize zirconium silicate for its ability to survive the molten glass’s high temperatures. As a result, this characteristic also reduces wear on machinery, significantly improving overall production efficiency.

For a broader perspective, here are several industries that heavily rely on zirconium silicate and their specific applications:

- Aerospace: Where thermal insulation is vital, preventing failure of essential components.

- Ceramics: In tile and pottery production, enhancing durability and lifespan.

- Metallurgy: Applications in furnace linings to maintain stability and efficiency.

- Glass Manufacturing: Helps in maintaining the quality of finished products by providing heat stability.

In essence, organizations looking to enhance product quality in demanding environments often turn to this versatile material for its proven reliability.

| Application Area | Use of Zirconium Silicate |

|---|---|

| Ceramics and Refractories | Improved lifespan and durability |

| Aerospace | Insulation protection for sensitive components |

| Metallurgy | Steady temperature maintenance in furnaces |

| Glass Production | Reduces machine wear during processing |

This image depicts a ceramic production line using zirconium silicate materials, emphasizing durability in high-temperature applications.

How Can Zirconium Silicate Be Processed for Optimal Use?

Processing zirconium silicate involves several well-defined steps to maximize its performance capabilities. What’s the best way to work with it? The initial phase typically includes sourcing the raw material, which can be obtained in both natural and synthetic forms. Natural zirconium silicate, found in deposits in areas like Australia and South Africa, can be processed to meet specific material standards.

Once sourced, further processing may involve milling and grinding, which helps achieve the desired particle size for various applications. This stage is critical, as it directly affects the material’s overall performance, particularly when used in high-temperature environments.

Proper handling and storage practices are also essential for maintaining zirconium silicate’s effectiveness. Keeping it dry and at stable temperatures prevents any degradation before use, which is crucial to achieving optimal operations.

Innovative processing methods continue to emerge in the industry. As research progresses, there is an increasing focus on refining techniques that not only enhance the material properties but also reduce environmental impacts during processing.

Organizations might consider investing in these new techniques which offer:

- Enhanced Quality: Fine-tuning processing can improve overall material characteristics.

- Cost-Effectiveness: More efficient methods can reduce production costs over time.

- Environmental Responsibility: Innovative approaches often consider sustainability, improving their market appeal.

| Processing Stages | Description |

|---|---|

| Sourcing | Obtain natural or synthetic zirconium silicate |

| Milling | Achieve specific particle size for applications |

| Handling and Storage | Maintain dryness and stable temperatures |

What Are the Challenges in Using Zirconium Silicate?

Even with its advantages, zirconium silicate has its challenges. What obstacles might you face? First, while it excels in many environments, there are limitations that businesses must acknowledge. For instance, at temperatures exceeding 2,600 degrees Celsius, its performance may begin to decline. Users should carefully consider operational limits to avoid costly failures and ensure safety.

Cost factors also deserve attention. Sourcing high-quality zirconium silicate can come with a significant price tag. Organizations must weigh the material’s benefits against initial investment costs, as these can significantly impact budget planning and project feasibility.

Moreover, environmental regulations surrounding the mining and processing of this material also come into play. Companies need to ensure compliance with local and international regulations to avoid potential legal issues and financial penalties.

Here’s a quick summary of the challenges:

- Temperature Limitations: Performance may deteriorate beyond certain temperature points.

- High Sourcing Costs: Quality material often requires significant capital investment.

- Regulatory Compliance: Ensuring adherence to environmental standards is critical.

In summary, while zirconium silicate serves as a superior high-temperature material, awareness of its challenges is vital for informed decision-making.

| Challenges | Considerations |

|---|---|

| Temperature Limits | Performance drops beyond 2,600 °C |

| Cost Factors | High-quality material can be expensive |

| Environmental Regulations | Compliance with local laws is essential |

How Can Businesses Benefit from Using Zirconium Silicate?

Organizations leveraging zirconium silicate in their operations realize multiple benefits. What advantages can be realized? One crucial economic advantage includes the reduction in maintenance costs due to lower failure rates. When machinery performs reliably for longer periods, businesses can minimize costly downtime and save on replacement costs. This leads to increased productivity and reduced operational interruptions.

Another critical enhancement relates to product durability and performance. Companies that incorporate zirconium silicate often report better product quality and higher customer satisfaction. When consumers feel confident in the reliability of their products, it improves brand reputation and may encourage repeat business.

Case studies highlight organizations that have successfully integrated zirconium silicate into their systems. For instance, a steel manufacturing plant that switched to this material in their furnaces reported an astonishing 20% increase in production efficiency. This improvement not only boosted output but also reduced overall operational costs, demonstrating the compound’s practical impact.

In essence, here are some specific benefits and reasons to consider using this mineral:

- Economic Gains: Lower operating costs lead to enhanced profitability.

- Quality Improvements: Better durability increases customer satisfaction and loyalty.

- Productivity Boosts: Organizations can achieve more with less downtime.

In conclusion, businesses aiming for long-term growth can realize significant returns by strategically deploying zirconium compounds in their processes.

| Benefits | Description |

|---|---|

| Economic Advantages | Lower maintenance costs and reduced downtimes |

| Product Quality Improvement | Enhances customer satisfaction and brand reputation |

| Increased Production Efficiency | Case study example of a 20% boost in output |

What Future Trends Are Emerging in Zirconium Silicate Applications?

As industries evolve, the applications for zirconium silicate also expand. What trends should you be aware of? Recent developments suggest a growing focus on research and development related to high-temperature materials. New innovations seek not only to improve processing methods but also to enhance material properties and exploration of additional applications.

Additionally, sustainability continues to play a crucial role in future trends. As organizations prioritize eco-friendly practices, sourcing zirconium silicate responsibly becomes increasingly important. The industry is already seeing shifts towards more sustainable mining and processing techniques to meet these new standards.

Market predictions indicate a steady demand for this material in key sectors such as aerospace, automotive, and energy industries. This trend signals continued investment in research, aiming to maximize its utility and application in high-performance environments.

To summarize the emerging trends for organizations looking to stay ahead:

- Research and Development: Focus on improving processing methods and applications.

- Sustainability Initiatives: Shift toward eco-friendly practices in sourcing and processing.

- Market Growth: Steady demand in key industries, leading to new opportunities.

In essence, businesses that remain informed and adaptable will benefit greatly from these emerging trends in zirconium applications.

| Future Trends | Description |

|---|---|

| Research and Development | Focus on improving processing methods and applications |

| Sustainability | Shift toward eco-friendly practices in sourcing |

| Market Predictions | Steady demand in key industries |

Conclusion

Zirconium silicate proves invaluable for businesses seeking high-temperature performance in various industries. Its unique properties, such as superior thermal stability and exceptional resistance to thermal shock, set it apart from other materials. These advantages lead to significant economic benefits, including reduced maintenance costs and enhanced product quality, which ultimately translates into stronger customer satisfaction and loyalty. Furthermore, by integrating zirconium silicate into their processes, organizations can achieve improved operational efficiency and competitiveness.

Engage Global Industry today to explore specialty solutions tailored for your specific high-temperature requirements, ensuring your operations remain efficient and reliable in even the most demanding environments. By collaborating with our experts, you will gain personalized insights and strategies that not only address your immediate operational challenges but also position your business for future growth. Let us help you optimize your processes with innovative materials that deliver long-lasting results and contribute positively to your bottom line.

FAQ Section

Q1: What are the key benefits of zirconium silicate?

Zirconium silicate provides remarkable thermal stability, allowing it to maintain integrity under extreme temperatures. It also exhibits high resistance to thermal shock, meaning it can withstand rapid temperature changes without cracking. Additionally, its durability in harsh chemical environments makes it a reliable choice for various industrial applications, enhancing overall product lifespan.

Q2: How does it compare to other materials?

Compared to traditional alternatives like alumina or silica, zirconium silicate delivers superior thermal shock resistance and longevity. While other materials may succumb to stress or environmental factors more quickly, zirconium silicate maintains its structural integrity, making it a preferred material for high-temperature and high-performance applications in industries such as aerospace and metallurgy.

Q3: What industries benefit the most from this material?

Sectors such as aerospace, ceramics, and metallurgy significantly benefit from zirconium silicate’s properties. In aerospace, it protects critical components from heat damage. The ceramics industry uses it for durable tiles and pottery, while metallurgy relies on it for efficient furnace operation, reducing slag and improving overall productivity.

Q4: Are there environmental concerns associated with this material?

While zirconium silicate itself is generally safe, its sourcing and processing can raise environmental issues. Mining operations must comply with local and international regulations to minimize ecological impact. Companies must prioritize sustainable practices to ensure responsible sourcing and processing of this valuable mineral.

Q5: What innovations are being developed for zirconium silicate?

Recent advancements in the field focus on improving processing techniques to enhance material properties and reduce environmental impact. Research is looking into new applications that leverage zirconium silicate’s unique characteristics, aiming to expand its usability in cutting-edge technologies such as electronics and advanced ceramics.