The manufacturing of dental products presents significant challenges for industry players. Many professionals face issues related to product durability, aesthetic appeal, and patient satisfaction. Zirconium silicate emerges as a viable solution to these concerns, as it enhances the quality and longevity of dental products. This article will delve into the properties and applications of zirconium silicate, demonstrating its essential role in dental manufacturing. With insights drawn from industry experts and real-world applications, readers can trust that the information provided here is both credible and valuable.

The dental industry is continuously evolving, experiencing advancements in materials and techniques that shape how dental practices deliver care. As dental health remains a priority, manufacturers are increasingly seeking high-performance materials that not only meet industry standards but also improve patient satisfaction. Understanding how certain materials, such as zirconium silicate, can offer tangible benefits is essential for any decision-maker in this space.

What Is Zirconium Silicate and Its Composition?

Zirconium silicate, a naturally occurring mineral, plays a critical role in dental manufacturing. It is composed mainly of zirconium, silicon, and oxygen. The mineral’s unique chemical structure contributes to its stability and strength, making it an ideal candidate for various dental applications.

This compound boasts several intrinsic qualities. For example, its high melting point allows it to endure the rigorous conditions encountered during dental product creation without compromising its structural integrity. This makes it particularly suitable for applications that demand resilience and durability.

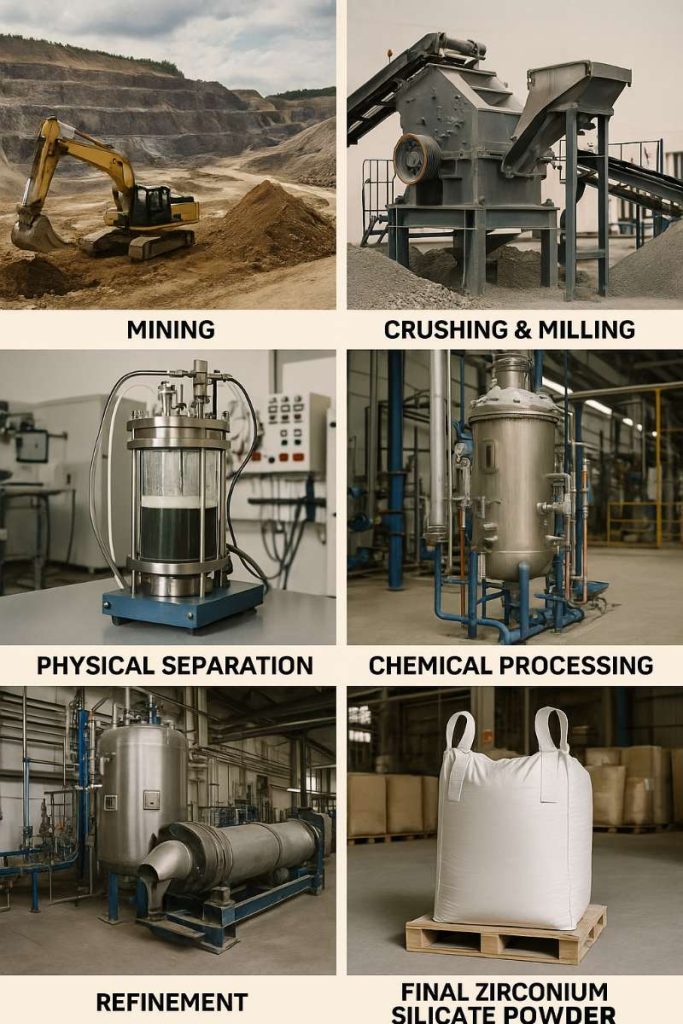

The processing methods used to refine zirconium silicate also play an essential role in determining its final properties. Through processes like crushing and grinding, manufacturers can produce fine particles that are essential for creating dental ceramics. These particles are then combined with other materials to form a composite that can be molded into the desired shape for dental products.

What’s noteworthy is the interaction of zirconium silicate with other materials used in dental applications. Its compatibility with dental ceramics enhances the overall properties of the final products, providing benefits such as improved translucency and a natural appearance when utilized in restorations. For instance, when integrated into a dental crown, zirconium silicate helps create a product that can withstand the challenges of daily use while offering aesthetic appeal.

But what happens when you fail to consider the importance of this compound? The consequences can be severe, leading to inferior dental products that may compromise patient care. Quality must always be a priority, thus understanding zirconium silicate’s role is vital in achieving high standards in dental manufacturing.

Why Is Zirconium Silicate Important for Dental Products?

The importance of this mineral in dental products cannot be overstated. Not only does it enhance the quality of restorations, but it also influences their long-term performance and reliability, built upon several key attributes that make this material outstanding in its category.

For instance, zirconium silicate improves the overall strength of dental restorations significantly. This increased durability helps reduce the risk of fractures and failures during use—a pressing concern in dental practices where patients expect long-lasting results. The high tensile strength of products made from zirconium silicate contributes to enhanced resistance against everyday forces, which is particularly beneficial for dental crowns and bridges that endure significant chewing pressure.

In addition to durability, zirconium silicate is highly regarded for its aesthetic qualities. Its ability to mimic the natural appearance of teeth is a game-changer for patients looking for restorations that blend seamlessly with their surrounding dentition. The translucency of zirconium silicate allows for light penetration, resulting in a more lifelike appearance. This is crucial when it comes to patient satisfaction, as many individuals rely on dental restorations to improve their smiles.

Furthermore, the biocompatibility of zirconium silicate establishes it as a safe option for dental applications. Materials that do not elicit adverse reactions in patients are essential for providing comfort and ensuring successful outcomes. This property is particularly important for individuals with allergies or sensitivities to certain metals or materials commonly used in dentistry.

If you are a manufacturer striving to elevate the quality of dental products, let this mineral guide your decisions. Its unique properties directly correlate with enhanced product performance, making it a crucial component in modern dentistry.

How Is Zirconium Silicate Processed for Dental Use?

Processing zirconium silicate for dental applications involves a series of meticulous steps. The journey begins with the extraction of raw zirconium silicate from mineral deposits. This raw material is typically found in sand or rock formations, requiring careful mining and collection processes to ensure purity.

Once extracted, the mineral undergoes several refining processes designed to remove impurities and enhance its qualities. Crushing and grinding are the primary techniques used, breaking down the raw material into smaller particles suitable for further processing. This step is critical, as the size and purity of the particles directly influence the performance of the final dental product.

Further treatments often include thermal processing, where the material is subjected to high temperatures in controlled environments. This step not only eliminates any remaining impurities but also improves the material’s strength and stability. While high temperatures are necessary, precise control is essential to avoid altering the chemical properties of zirconium silicate.

Quality control measures are paramount throughout these processes. Manufacturers conduct various tests to assess the purity and performance of the material. Such comprehensive testing ensures the consistency of the zirconium silicate used in dental applications, aligning with industry standards.

Consider the implications of not maintaining rigorous quality control. If suppliers fail to ensure that their products meet defined specifications, manufacturers may end up with materials that compromise the efficacy of their dental products, leading to dissatisfied patients and increased warranty claims.

In summary, the journey of zirconium silicate from extraction to final product is complex but critical for achieving consistent quality in dental solutions. Each step must be approached with diligence and expertise.

The image illustrates the various stages of processing zirconium silicate, emphasizing refinement methods.

Table 1: Common Processing Steps for Zirconium Silicate

| Step | Description |

|---|---|

| Extraction | Obtaining raw zirconium silicate from natural sources |

| Refining | Crushing, grinding, and separating to enhance purity |

| Treatment | Thermal processing to improve properties |

| Quality Control | Conducting tests at various stages for consistency |

What Types of Dental Products Use Zirconium Silicate?

This versatile mineral finds applications across a range of dental products, each benefiting from its unique properties. Some key items include:

- Crowns: Used for covering damaged teeth, restorations made from zirconium silicate offer unparalleled strength and aesthetics. They are ideal for patients seeking durable solutions that blend seamlessly with their natural teeth.

- Bridges: Essential for replacing missing teeth, zirconium silicate-based bridges provide the strength needed to support biting and chewing forces. These products also retain a natural appearance, ensuring patient confidence.

- Veneers: Thin shells that are applied to the front surface of teeth, veneers made from zirconium silicate enhance the aesthetic appeal of a smile. Their resemblance to natural teeth helps individuals achieve their desired look without extensive dental work.

- Inlays/Onlays: Used to restore damaged areas of teeth, these indirect restorations benefit from the structural advantages provided by zirconium silicate, leading to better functional outcomes.

The reliability that comes with products using zirconium silicate fosters confidence among dental professionals and their patients. With increasing consumer demand for high-quality aesthetic solutions, manufacturers that incorporate this mineral into their offerings position themselves favorably in the market.

In a competitive environment where brand reputation matters, understanding the applications of zirconium silicate ensures that manufacturers can meet patient needs effectively and maintain high standards.

Table 2: Dental Products Utilizing Zirconium Silicate

| Product Type | Key Benefits |

|---|---|

| Crowns | Strength, longevity, and aesthetic appeal |

| Bridges | Excellent replacement for missing teeth |

| Veneers | Natural appearance and improved aesthetics |

| Inlays/Onlays | Durable solutions for repairing damaged teeth |

What Are the Advantages of Using Zirconium Silicate in Dentistry?

The advantages of utilizing zirconium silicate in dental applications extend far beyond its inherent qualities. Its integration into dental products results in a multitude of benefits that resonate with both practitioners and patients.

First, consider its strength. Products made with this mineral exhibit remarkable durability, translating to fewer instances of fractures during daily use. This strength is especially valuable in load-bearing restorations like crowns and bridges, where mechanical forces are constantly at play.

In terms of aesthetics, zirconium silicate surpasses many alternatives. The natural tooth-like appearance it provides plays a pivotal role in customer satisfaction, addressing the visual aspect of dental restorations. Patients are increasingly concerned about how dental treatments affect their smiles, and zirconium silicate delivers high-quality results.

One cannot overlook its biocompatibility. Materials that can be safely integrated into the human body without adverse reactions are especially valuable in dentistry. This safety factor ensures that patients can undergo restorations with confidence, knowing that the products used enhance their overall dental health.

From a financial standpoint, while products made with zirconium silicate may have a slightly higher upfront cost, the investment proves worthwhile over time. Their durability and reduced risk of replacement lead to lower long-term costs for dental practices, allowing for better budget management.

In a landscape where patient care and financial efficiency intersect, using zirconium silicate can significantly improve outcomes.

Table 3: Advantages of Zirconium Silicate in Dentistry

| Advantage | Description |

|---|---|

| Strength | Increased durability leads to fewer replacements |

| Aesthetic appeal | Mimics natural teeth for improved visual outcomes |

| Biocompatibility | Ensures patient safety and comfort |

| Cost-effectiveness | Reduces long-term replacement expenses |

How Does Zirconium Silicate Contribute to Patient Outcomes?

The impact of zirconium silicate on patient outcomes is profound. As mentioned earlier, its strength contributes to fewer complications associated with dental restorations. Patients receiving products made with this material often report enhanced comfort and functionality, allowing them to eat and speak normally without concern.

Aesthetics play a vital role in overall patient satisfaction. When patients feel pleased with the appearance of their dental restorations, they are more likely to have positive feelings about their dental experiences. This is crucial for practices that rely on word-of-mouth referrals and repeat patients.

Recent clinical studies highlight the advantages of zirconium silicate in enhancing both functionality and visual appeal. These studies indicate that restorations made with this material not only endure regular wear but also maintain their integrity over time, contributing to long-lasting patient satisfaction.

Moreover, the ease with which dental professionals can work with zirconium silicate simplifies the restorative process. Techniques for shaping and finishing this material are well established, reducing chair time for patients and improving workflow efficiency in dental practices.

The cumulative effects of these properties elevate patient experiences, solidifying loyalty to practices that prioritize high-quality materials. By committing to the use of zirconium silicate, dental manufacturers and providers can foster positive outcomes and cultivate lasting relationships with their patients.

The image shows a patient smiling confidently with a zirconium silicate dental crown, reflecting aesthetic success.

Table 4: Patient Outcomes with Zirconium Silicate

| Outcome | Observation |

|---|---|

| Satisfaction | Higher satisfaction with aesthetic results |

| Durability | Fewer complications reported |

| Functionality | Improved functional performance noted |

| Comfort | Enhanced patient comfort and natural feel |

What Challenges Are Associated with Using Zirconium Silicate?

Despite the abundant benefits, there are challenges associated with the use of zirconium silicate in dental applications. These challenges should not be overlooked, as navigating them effectively can determine the success of its implementation.

Processing the material requires specialized equipment and expertise. Not all manufacturers may have access to the technology necessary for ideal processing, leading to variations in quality. Investing in training and necessary machinery is essential to ensure consistent high-quality output.

Surface flaws can also be an issue during production. Proper handling and care in processing are vital to avoid damaging the material and compromising the aesthetics or functionality of the final product. Employing stringent quality-control measures at each stage of production can mitigate this risk, but they require diligence and commitment.

Another challenge lies in the experience of dental practitioners and suppliers with zirconium silicate. As the utilization of this material grows, some professionals may hesitate due to a lack of familiarity. Continuous education and resources to aid understanding can help overcome this barrier.

Ultimately, addressing these challenges is possible through collaboration and investment in training. By fostering a knowledgeable workforce and ensuring proper handling, those in the dental industry can successfully integrate zirconium silicate into their offerings.

This image represents a dental lab setting where zirconium silicate products are processed, highlighting challenges in quality control.

Table 5: Challenges and Solutions with Zirconium Silicate

| Challenge | Potential Solution |

|---|---|

| High processing costs | Invest in training and equipment |

| Surface flaws | Implement stringent quality control measures |

| Lack of familiarity | Offer training and resources for staff |

How Is the Market for Zirconium Silicate Evolving?

The market for zirconium silicate is dynamic, reflecting the broader changes within the dental manufacturing industry. Innovators are gradually recognizing the benefits linked to this mineral, prompting a shift in materials used for dental products.

Growing knowledge about the advantages associated with zirconium silicate is leading more practitioners to choose it as a primary material. As manufacturers develop effective marketing strategies highlighting these benefits, we can expect to see an even wider adoption of this mineral in various dental solutions.

Technological advancements also influence the market landscape. New processing technologies are emerging that enhance the quality and efficiency of zirconium silicate production. This shift allows manufacturers to produce higher volumes of product while maintaining quality, ensuring that they can meet increasing demand.

As regulations shift, manufacturers must also keep pace with evolving requirements to ensure compliance. Understanding and adapting to regulatory frameworks is critical in maintaining market credibility and access.

For businesses in the dental sector, staying attuned to these changes is paramount. The ability to adapt resourcefully can spell the difference between success and stagnation in a competitive market.

What Should Decision-Makers Consider When Choosing Zirconium Silicate?

When it comes to selecting zirconium silicate for dental uses, decision-makers must think carefully about several factors. The first step is to investigate potential suppliers. A reliable supplier should possess a sound reputation within the industry and demonstrate a commitment to quality.

Understanding the specific properties of zirconium silicate offerings is also crucial. Different grades may exhibit varying characteristics; thus, alignment between product specifications and application requirements is essential.

Quality assurance practices form another critical piece of the puzzle. Inquire about the testing and certification processes employed by suppliers. This due diligence will help ensure that sourced materials meet industry standards and can be trusted for quality output.

Finally, while considering cost-effectiveness is a necessity, it’s also crucial to evaluate the long-term benefits associated with using high-quality materials. Investing in superior options can pay off significantly as they often lead to fewer replacements and reduced long-term costs.

In short, careful consideration is necessary to choose the right zirconium silicate that will yield the best results for dental applications. The payoff will be evident in both product quality and patient satisfaction.

Where Can Businesses Source Quality Zirconium Silicate?

Finding a reliable source for high-quality zirconium silicate is a fundamental step for any business in the dental field. Initiate your search by exploring suppliers who specialize in dental materials. Consider focusing on those who have a proven track record and are transparent about their quality assurance measures.

Networking within industry circles can also provide valuable insights. Engaging in industry-specific events, such as trade shows or conferences, creates opportunities to connect with suppliers. These platforms often allow for direct discussions about product specifications and mutual needs.

Don’t hesitate to ask potential suppliers about their certifications and quality control measures. A supplier committed to excellence will have robust systems in place to ensure that their products meet high standards.

In conclusion, sourcing quality zirconium silicate is integral to producing superior dental products. The quality of the materials will ultimately impact the reliability of the end products, influencing both patient satisfaction and the overall success of your practice or manufacturing unit.

Conclusion

This article has explored the significant role of zirconium silicate in dental manufacturing. Key insights highlighted the material’s strength, aesthetic properties, and biocompatibility, which underscore its value in producing high-quality dental products. By incorporating this mineral, manufacturers can elevate their offerings, achieving better patient satisfaction through durable and aesthetically pleasing results. Global Industry stands ready to support your sourcing of high-quality materials to enhance your dental practices. Connect with us today for reliable solutions to meet your dental needs.

FAQ Section

Q1: What are the main uses of zirconium silicate in dentistry? Zirconium silicate is primarily used for dental restorations like crowns, bridges, and veneers due to its durability and aesthetic qualities.

Q2: How does zirconium silicate compare to other dental materials? It offers superior strength and aesthetic results compared to many traditional materials, making it a preferred choice in modern dentistry.

Q3: What are the processing steps for zirconium silicate in dental applications? The processing includes extraction, refining, and specific manufacturing techniques tailored for dental applications to ensure quality and performance.

Q4: Are there any drawbacks to using zirconium silicate? Potential drawbacks include challenges in processing and some limitations in specific dental scenarios like extreme wear or misalignment.

Q5: How can businesses ensure they are sourcing quality zirconium silicate? Businesses should vet suppliers thoroughly, evaluate quality assurance practices, and consider certifications when sourcing this material.