Zirconium silicate plays a vital role in enhancing glass quality, addressing common concerns in the manufacturing process. Manufacturers often struggle with achieving desired glass properties such as durability and clarity. This article will explore how zirconium silicate contributes to these key areas, offering practical insights that can help businesses optimize their glass formulations. With comprehensive research and real-world applications, readers will gain valuable knowledge on how to leverage zirconium silicate for improved glass quality and performance.

How Does Zirconium Silicate Improve Glass Quality?

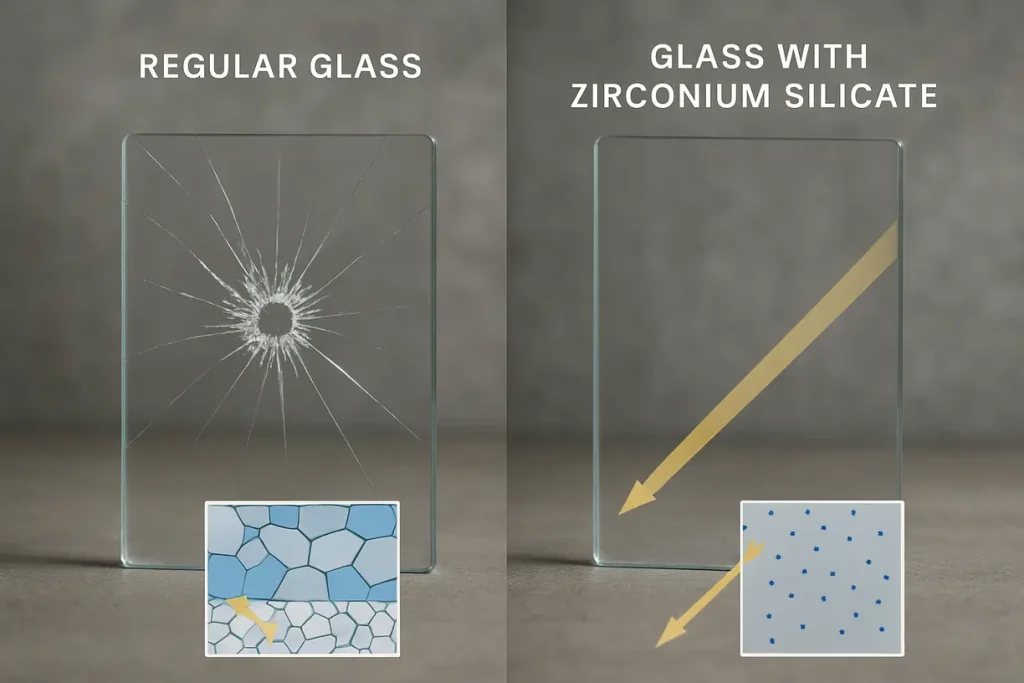

Zirconium silicate is a mineral additive that brings a multitude of benefits to glass manufacturing. First and foremost, it enhances the mechanical properties of glass, leading to heightened durability which is particularly crucial in applications that require resistance to wear, impact, and thermal shock. This durability is essential for various industries, including automotive, construction, and consumer goods, where product longevity is a primary concern.

Additionally, zirconium silicate improves clarity and overall aesthetic appeal, making it attractive for high-end applications such as premium architectural glass and luxury consumer products. The transparency achieved through the use of this material meets the growing consumer demand for visually appealing glass products.

Historically, zirconium silicate has been used for decades in the glass industry, recognized for its ability to provide both strength and stability. Its effectiveness makes it a critical component in a wide range of glass products, from architectural structures to intricate designs in fine glassware. Understanding its pivotal role not only assists manufacturers in enhancing their product quality but also helps meet the evolving expectations of consumers for outstanding glass performance.

Have you ever wondered how something so small can make such a big difference? The addition of zirconium silicate can elevate the final product, making a noticeable impact on both performance and consumer satisfaction.

The following table highlights the key benefits of incorporating zirconium silicate into glass production:

| Benefit | Description |

|---|---|

| Enhanced Strength | Improves overall durability |

| Increased Clarity | Enhances visual quality |

| Thermal Stability | Provides resistance to thermal shock |

In summary, zirconium silicate not only strengthens glass but also increases its visual appeal, making it an essential additive in achieving high-quality glass products. Manufacturers can confidently use this mineral to elevate their offerings and meet increasing consumer expectations.

This image illustrates the role of zirconium silicate in enhancing glass strength and clarity.(文件夹128)

What Are the Chemical Properties of Zirconium Silicate?

Zirconium silicate, with a chemical formula of ZrSiO4, exhibits specific properties that are crucial in glass production. Its structure includes zirconium and silicon, which are essential elements that contribute to its unique characteristics. This mineral possesses not only a high melting point of around 2,600°C but also excellent thermal stability, allowing it to perform effectively under varying temperature conditions typically encountered in glass manufacturing processes.

Moreover, zirconium silicate is known for its exceptional chemical inertness, making it resistant to many acids and bases. This property is particularly beneficial in glass formulations, as it prevents unwanted reactions that could compromise the final product’s integrity. Its low solubility in water also minimizes the risk of leaching during the glass manufacturing process, ensuring that the quality of the glass remains unaffected throughout the production and its subsequent use.

To summarize these key chemical properties, refer to the table below:

| Property | Description |

|---|---|

| Chemical Formula | ZrSiO4 |

| Melting Point | 2,600°C |

| Thermal Stability | Excellent |

| Solubility | Low in water |

So, why are these properties important? Knowing these attributes helps manufacturers choose the right materials for their specific needs while ensuring the quality and performance of the glass is maintained throughout its lifecycle. Understanding zirconium silicate’s chemical profile can aid in formulating more robust glass products that meet demanding application requirements.

What Role Does Zirconium Silicate Play in Glass Formulation?

When zirconium silicate is incorporated into glass formulations, it acts as a stabilizer that maintains the integrity of the glass matrix throughout the production process. This stabilizing role is vital, as it helps to ensure that the glass retains its shape and strength, especially when subjected to heat and forming techniques.

In addition to stabilizing, zirconium silicate enhances various properties crucial for quality glass production. These properties include improved strength, thermal resistance, and chemical durability. By mixing zirconium silicate with silicates and other raw materials, manufacturers can create an improved glass structure that resists mechanical impacts and environmental stressors. This is particularly important for applications where safety and longevity are paramount, such as automotive and architectural glass products.

Notably, zirconium silicate also allows for more flexibility in glass formulations. Companies can tailor the mix to better match specific requirements, whether aiming for tougher glass for construction or clearer glass for decorative purposes.

In this context, consider the following advantages offered by zirconium silicate in glass formulations:

- Increased mechanical strength, making glass less prone to breaking

- Improved resistance to heat and thermal shock, allowing for versatile use in various environments

- Enhanced chemical durability, which translates to greater longevity in products exposed to harsh conditions

Curious about how this all comes together in practice? The effective use of zirconium silicate can invariably lead to significant improvements in product quality, ensuring that manufacturers can meet the varying demands of the market while delivering dependable glass solutions.roduct quality and lifespan, reinforcing the value of its inclusion in glass formulations.

How Does Zirconium Silicate Affect Glass Aesthetics?

The impact of zirconium silicate extends beyond durability and strength. It also plays a vital role in the aesthetics of glass. This mineral contributes significantly to clarity and color properties, making glass products visually appealing to consumers and fitting for decorative applications.

For high-end glass applications, such as luxury windows or ornate glassware, clarity is paramount. Zirconium silicate helps achieve a degree of transparency that meets industry standards, thus enhancing marketability. Additionally, it minimizes imperfections like bubbles or cloudiness that can adversely affect the visual quality, leading to greater consumer satisfaction and brand loyalty. The ability to produce a flawless glass surface is not just a cosmetic concern; it influences how the product is perceived in the marketplace.

Zirconium silicate also influences the light transmission properties of glass, ensuring that it can effectively filter or reflect light without compromising its appearance. This is particularly important in architectural glass, where the interplay of light can enhance interior spaces.

An analysis of how it improves aesthetics can be summarized in this table:

| Aesthetic Feature | Benefit |

|---|---|

| Clarity | Increases overall transparency |

| Color Properties | Minimizes coloration defects |

| Light Transmission | Improves control over light quality |

How can manufacturers leverage this information? By incorporating zirconium silicate, companies can significantly boost the visual appeal of their glass products. This improvement can lead to increased customer satisfaction and ultimately drive higher sales and brand recognition. Investing in such additives allows manufacturers to cater to the higher end of the market, where aesthetics and quality are key selling points.esthetics not only attracts buyers but also sets a product apart in a competitive market.

What Are the Benefits of Using Zirconium Silicate?

The use of zirconium silicate in glass production comes with a rich array of benefits. Firstly, it significantly improves mechanical properties, leading to stronger and more durable glass. This enhancement is critical in both commercial and residential applications, where the longevity of glass products is a priority. Stronger glass can withstand impacts and stresses that would typically lead to cracking or shattering.

In addition to increased strength, zirconium silicate enhances the glass’s resistance against environmental factors, such as humidity and temperature fluctuations. Glass products that incorporate this mineral tend to perform better against scratches, wear, and other forms of damage. This extended durability not only increases product life but also reduces the need for frequent replacements, offering significant cost savings over time.

Furthermore, zirconium silicate contributes to energy savings during processing. It reflects heat rather than absorbing it, allowing manufacturers to operate at lower temperatures during glass production. This reduction in production temperature not only conserves energy but also lowers overall manufacturing costs.

Consider the following benefits of using zirconium silicate in glass:

- Enhanced mechanical strength

- Improved durability and longevity

- Greater resistance to wear and thermal shock

- Energy conservation during the manufacturing process

Want to know the impact on the bottom line? Implementing zirconium silicate can lead to reduced replacement costs and increased customer retention, positioning businesses for greater success in the competitive glass market.ddition to glass formulations. This ultimately contributes to a more sustainable and profitable business model.

How Does Zirconium Silicate Influence Glass Processing?

Understanding how zirconium silicate affects the glass-making process is vital for manufacturers aiming to optimize efficiency and quality. By including this mineral additive in their formulations, they can significantly improve melting and forming processes.

When zirconium silicate is used, it aids in lowering the melting point of the glass batch. This reduction allows manufacturers to operate at lower temperatures, which not only saves energy but also reduces production costs. The lower energy requirements mean that facilities can operate more sustainably, contributing to eco-friendly manufacturing practices.

Moreover, zirconium silicate enhances the flow characteristics of the glass during shaping. It promotes better viscosity control, ensuring that the glass retains its desired shape without warping. This leads to greater consistency in product quality and reduces defect rates significantly. Less waste from defective products means improved productivity and cost-effectiveness.

The following table summarizes the processing advantages of zirconium silicate:

| Processing Advantage | Description |

|---|---|

| Lower Melting Point | Saves energy and reduces costs |

| Improved Flow | Enhances shaping consistency |

| Reduced Defects | Leads to higher product quality |

So, how does this benefit manufacturers? By optimizing processing, companies can improve productivity, lower operational costs, and ultimately offer a more reliable product to their customers, enhancing both reputation and market standing.s production processes thus represents a smart investment for manufacturers looking to stay competitive.y optimizing processing, companies can improve productivity and reduce waste, directly impacting profitability.

This image highlights the glass production process using zirconium silicate as an additive for enhanced quality.

What Are the Common Applications of Zirconium Silicate Glass?

Zirconium silicate is widely utilized in various sectors of the glass industry due to its unique properties. One prominent area is in construction, where it’s used in high-quality architectural glass. This type of glass not only offers impressive aesthetics but also delivers durability and energy efficiency, important for modern building designs. These properties make architectural glass more appealing to architects and builders, who prioritize sustainable and visually striking materials.

Another key application is in the automotive industry. The glass windows used in vehicles benefit significantly from zirconium silicate due to its strength and resistance to UV rays. This addition not only enhances overall safety but also maintains visual clarity over time, making it an essential component in windshields and side windows. Furthermore, the enhanced durability helps reduce the likelihood of chips and cracks, providing long-term benefits for both manufacturers and consumers.

Zirconium silicate also finds its way into specialty glass products used in laboratory and medical settings. Here, clarity and stability are paramount, as these products must often withstand harsh chemicals and extreme temperatures. The inclusion of zirconium silicate ensures that these glass items have the necessary resilience for demanding applications.

The following table presents common applications for zirconium silicate glass:

| Application | Description |

|---|---|

| Architectural Glass | Used in buildings for aesthetics and energy efficiency |

| Automotive Glass | Provides strength and UV resistance |

| Specialty Glass | Essential for laboratory and medical use |

What does this mean for businesses? Understanding these diverse applications allows manufacturers to target specific markets effectively, tailoring their products to meet industry needs. By recognizing where zirconium silicate can be beneficial, companies can enhance their offerings and ultimately maximize their product appeal and market presence.cate, companies can enhance their glass products and maintain a competitive edge in the market.

How Do Industry Standards Relate to Zirconium Silicate?

In the glass industry, adhering to standards is crucial for ensuring quality, safety, and reliability. Zirconium silicate plays a significant role in meeting these essential quality benchmarks. Various organizations establish guidelines that ensure glass products are manufactured consistently and perform well under expected conditions.

Manufacturers must comply with specific regulations governing materials used in glass production. Zirconium silicate is well-regarded for its stability and non-toxic characteristics, making it a preferred choice for formulations that meet health and safety guidelines. This stability is vital, as it assures both manufacturers and consumers that the glass products are safe for use in homes, vehicles, and public buildings.

One important standard is ASTM C1036, which provides specifications for flat glass, including performance in various environmental conditions. Compliance with this standard ensures that glass made with zirconium silicate can withstand challenges like thermal expansion and mechanical stress.

Additionally, the ISO 9001 standard focuses on quality management systems. Manufacturers adhering to this standard demonstrate their commitment to producing high-quality glass consistently. This level of assurance builds trust with customers and stakeholders.

Consider the following standards relevant to zirconium silicate in glass:

| Standard | Focus |

|---|---|

| ASTM C1036 | Specifies the quality of flat glass |

| ISO 9001 | Quality management systems |

| EN 12150 | Safety glass standards |

Why is compliance important? Meeting industry standards not only enhances product credibility but also opens up new markets for manufacturers. By demonstrating compliance through the use of zirconium silicate, companies can differentiate their products, attract new customers, and maintain a competitive edge in the market.dustry standards not only enhances product credibility but also opens up new markets for manufacturers.

What Innovations Are Emerging with Zirconium Silicate?

The glass industry is constantly evolving, and zirconium silicate is at the forefront of several exciting innovations. Researchers and manufacturers are now focusing on developing new formulations that enhance its properties further, making it an even more versatile additive in glass products. This progress is crucial as it enables glass producers to meet growing demands for higher performance and sustainability.

One significant area of innovation involves the application of nanotechnology. This technology allows for the creation of smaller particles of zirconium silicate, which can improve dispersion within the glass matrix. Enhanced dispersion leads to improved consistency in glass products, reducing defects and enhancing overall quality.

Moreover, new methodologies are being introduced to optimize the processing of zirconium silicate. These innovations aim to refine the amount of zirconium silicate used in formulations, ensuring maximum effectiveness while minimizing costs. By fine-tuning its application, manufacturers can achieve better thermal stability and mechanical properties, which are increasingly necessary for modern glass applications.

Here are some recent innovations related to zirconium silicate:

- Enhanced formulations for better dispersion.

- Nanotechnology applications in glass.

- New methodologies for improved processing.

Are you ready to embrace the future? Keeping up with these trends can give businesses a competitive edge, enhancing their product offerings and ensuring that they remain relevant in a rapidly changing market. This proactive approach to integrating innovations in zirconium silicate can lead to significant advancements in product quality and functionality.

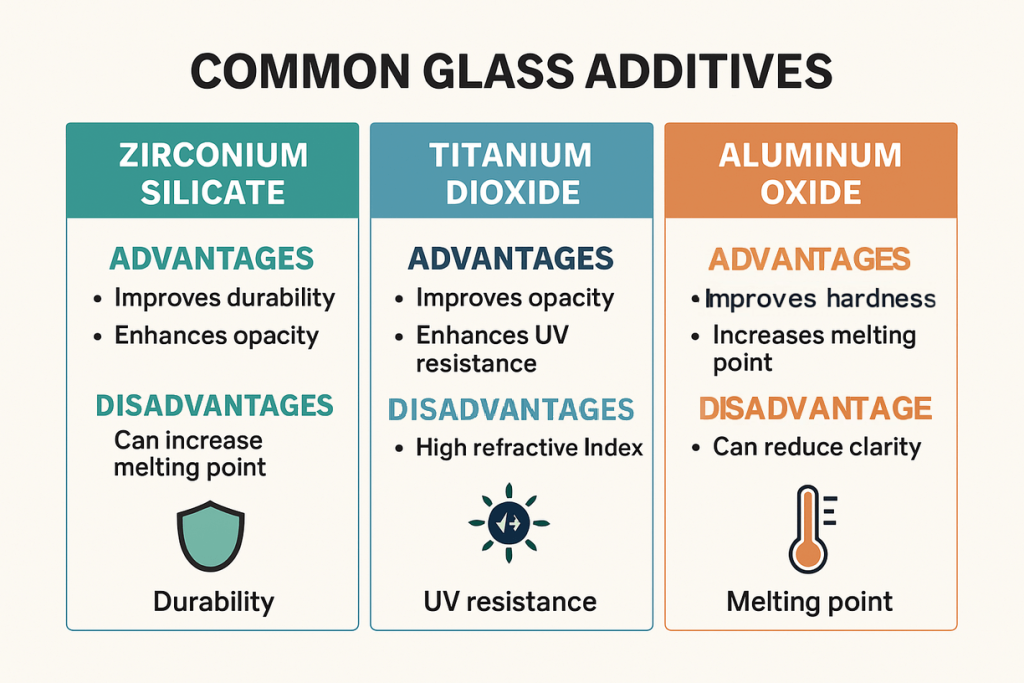

How Does Zirconium Silicate Compare with Other Additives?

When evaluating the use of zirconium silicate, it is important to consider how it stacks up against alternative glass additives. Some common competitors include titania and alumina. Each of these options has its own strengths and weaknesses in the context of glass production.

Zirconium silicate stands out not only for its impressive impact resistance and thermal stability but also for its contribution to the aesthetic qualities of glass. Unlike titania, which can sometimes decrease transparency, it typically preserves the glass’s clarity. Alumina, while effective in improving mechanical strength, can require higher melting points, which may raise processing costs.

In comparing these additives, manufacturers might consider several factors such as cost, effectiveness, and specific application requirements. Here is a table summarizing the comparison of glass additives:

| Additive | Strengths | Weaknesses |

|---|---|---|

| Zirconium Silicate | High durability, aesthetic quality | More expensive than some alternatives |

| Titania | Good UV resistance | Can affect transparency |

| Alumina | Increases mechanical strength | Higher melting point |

So, how should manufacturers proceed? A thorough evaluation of these options can help identify the most suitable materials for specific glass applications, ensuring the final product meets both operational and consumer standards effectively.

This image visually compares zirconium silicate with other glass additives, highlighting strengths and weaknesses for informed decision-making.

Conclusion

In summary, zirconium silicate plays a critical role in improving glass quality through its unique properties. It enhances mechanical strength, thermal resistance, and aesthetic appeal, leading to superior glass products. By utilizing zirconium silicate, businesses can achieve increased durability and customer satisfaction, reducing costs associated with replacements and returns.

At Global Industry, we are committed to providing insight on the best materials for your needs. Connect with us to learn how to optimize your production processes and product quality today. Explore our resources for more in-depth information tailored to your business.

FAQ Section

Q1: What applications benefit most from zirconium silicate?

Zirconium silicate is commonly used in architectural glass, automotive glass, and specialty glass products. In architectural applications, it enhances the durability and energy efficiency of windows and facades. In the automotive sector, it improves the strength and UV resistance of windshields, ensuring safety and longevity. Specialty glass products, such as laboratory glassware, also benefit from its thermal stability and clarity, making it essential for precise applications.

Q2: How does zirconium silicate impact glass durability?

Zirconium silicate plays a crucial role in increasing the durability of glass. Its unique chemical properties enhance the mechanical strength of glass products, making them more resistant to breakage. Additionally, it provides better resistance to thermal shock, allowing glass to withstand rapid temperature changes without cracking. This makes it an ideal additive for products that need to endure harsh environments or heavy usage.

Q3: Are there any environmental benefits of using zirconium silicate?

Yes, incorporating zirconium silicate can lead to environmental benefits in glass production. Its usage can enhance the energy efficiency of the manufacturing process, allowing for lower operating temperatures. This contributes to reduced energy consumption and lower carbon emissions. Moreover, because zirconium silicate is stable and non-toxic, it minimizes the need for harmful additives, making it a safer choice for both the environment and human health.

Q4: What are the processing challenges associated with zirconium silicate?

While zirconium silicate offers many advantages, there are some processing challenges. Manufacturers must ensure that it is compatible with other materials in the glass formulation. Additionally, precise management of processing temperatures is essential to maximize its benefits while preventing issues such as clumping or uneven distribution in the glass mixture. Careful formulation and batch testing can help mitigate these challenges during production.

Q5: How can companies stay updated on zirconium silicate innovations?

To stay current with innovations related to zirconium silicate, companies can follow industry publications and academic research. Attending relevant conferences and trade shows provides insights into the latest technological advancements and best practices. Moreover, participating in industry associations or joining specialized forums can help professionals network and share knowledge about new developments and applications in the glass sector.