In today’s manufacturing landscape, companies face a constant need to enhance product quality while keeping costs in check. For businesses involved in glass production, the choice of raw materials can significantly impact both performance and profitability. Glass serves as a crucial component in numerous industries, including construction, automotive, and consumer goods. This article addresses a pivotal question: how does this specialized mineral enhance the glass manufacturing process?

Zirconium silicate is increasingly being recognized for its ability to improve the durability, clarity, and efficiency of glass products. By understanding the unique properties and benefits of this material, manufacturers can optimize their processes, reduce waste, and enhance their product offerings. With extensive industry experience, we provide insights that empower decision-makers to make informed choices about their materials and production methods that ultimately lead to enhanced operational efficiency.

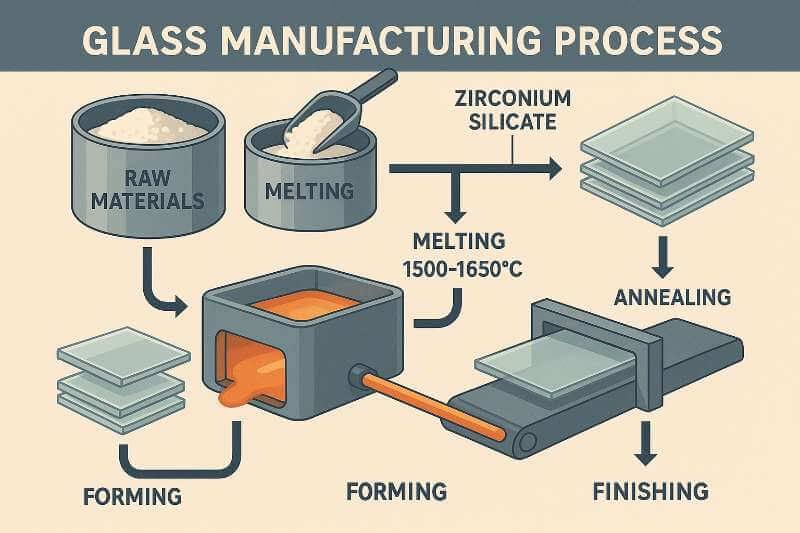

This image illustrates the role of zirconium silicate in enhancing the properties of glass.

How Is Zirconium Silicate Used in Glass Production?

Zirconium silicate plays a key role in modern glass production, primarily serving as a valuable additive. It is derived from zircon, a mineral that has been utilized in industry for centuries, dating back to early civilizations where it was used for decorative objects. The mineral is mined from various locations around the world, purified, and then processed for industrial applications. Here’s the deal: this compound contributes significantly to the formulation of various glass types, including flat glass for architectural uses, packaging glass for food and beverages, and specialty glass for electronics and medical applications. Its presence enhances the overall quality, performance, and aesthetic appeal of these materials.

This unique mineral impacts glass formulations in several ways. Firstly, it provides thermal stability, which is essential during manufacturing processes that involve high temperatures exceeding 1500 degrees Celsius. The stability ensures that the glass maintains its integrity throughout the melting and molding processes. Secondly, it helps improve the viscosity of glass melts, facilitating better flow during forming processes. A more manageable viscosity allows for smoother production operations and can enhance the precision of molded glass shapes. Furthermore, this compound significantly increases the strength of glass, contributing to reduced breakage rates during production and end-use.

When integrated properly, this mineral offers substantial benefits, including improved optical clarity. It helps minimize defects in the glass, which enhances aesthetic quality and marketability. Signs of clarity, color uniformity, and surface smoothness are critical in influencing consumer decisions. Ultimately, the effective use of this material can lead to a more efficient manufacturing process that not only fulfills market demands but also positions manufacturers competitively within the industry.

What Are the Advantages of Zirconium Silicate?

The advantages of incorporating zirconium silicate into glass production processes are numerous and diverse, influencing both the functional and aesthetic qualities of the finished products. You might be asking yourself: what specific benefits does it provide to manufacturers and their customers?

First, we should consider its chemical stability. This mineral is highly resistant to corrosion and extreme temperatures, which supports its durability in intense processing environments. Manufacturers can expect longer-lasting materials that are less susceptible to deterioration, leading to lower replacement costs over time. This longevity is essential for glass products used in high-stress applications, such as automotive glass and decorative tableware.

Second, temperature resistance is another critical advantage. Materials containing zirconium silicate can maintain their structural integrity even at elevated temperatures experienced during glass production. For example, during the forming process, the ability to sustain high heat can result in improved glass qualities like clarity and uniformity. As a result, manufacturers can optimize their production processes for efficiency without compromising the finish quality.

Finally, zirconium silicate enhances the texture of glass products. It serves as a refining agent, producing smoother surfaces that not only enhance appearance but also improve performance characteristics such as scratch resistance. A high-quality glass product that exhibits both beauty and functionality meets or exceeds consumer expectations and stands out in a competitive market. Thus, by incorporating this mineral, companies can position themselves as leaders in quality and innovation.

| Advantage | Benefit |

|---|---|

| Chemical Stability | Durability and longevity in harsh conditions |

| Temperature Resistance | Ability to handle higher production temperatures without compromising integrity |

| Surface Refinement | Enhanced smoothness and clarity, resulting in more attractive and functional products |

How Does Zirconium Silicate Improve Glass Quality?

Incorporating zirconium silicate into glass production can lead to substantial quality improvements that resonate through various aspects of the final product. Here’s why this matters: high-quality glass is essential for maintaining a competitive edge in the marketplace across various sectors, from consumer goods to industrial applications.

One of the prime enhancements provided by this substance is increased durability. Glass formulated with zirconium silicate is capable of withstanding greater physical stress without breaking. This increased resilience is critical for applications ranging from cookware to architectural elements, where strength is non-negotiable. For instance, automotive windshields and commercial glass facades benefit immensely from this compound as it ensures safety and reliability.

Moreover, we cannot overlook the optical properties of glass enhanced through this mineral. Zirconium silicate contributes to improved clarity and brightness, creating transparency that is both appealing and functional. Reduced impurities and defects translate into clearer glass, which meets the aesthetic preferences of consumers. Higher clarity can also improve the perceived value of finished products, leading to increased sales and customer satisfaction.

Studies comparing glass products containing and lacking zirconium silicate show that glass with this additive exhibits superior resistance to scratching and chemical attacks. In sectors where environmental factors play a role, such as window glass exposed to sunlight and pollutants, this added benefit extends product lifespan and enhances customer satisfaction. For manufacturers, these qualities not only promote customer contentment but also build a loyal customer base willing to invest in higher-quality products.

What Challenges Are Associated with Using Zirconium Silicate?

While incorporating zirconium silicate offers valuable benefits, there are also challenges that manufacturers must navigate to fully capitalize on its potential. Let’s explore this: what obstacles might arise when integrating this specialized material into glass production?

One primary concern is sourcing and availability. The high-quality form of zirconium silicate can sometimes be difficult to obtain due to fluctuating market conditions and mining capabilities. Manufacturers should be prepared for potential supply chain disruptions, which can affect production schedules and overall operational efficiency. Establishing solid relationships with reliable suppliers is crucial to ensuring consistent access to the necessary materials.

Another consideration is cost. Zirconium silicate can be more expensive than traditional glass additives like soda ash or limestone. Manufacturers must conduct careful analyses to balance improved performance against these higher costs. Companies may employ financial modeling to help assess the potential return on investment for integrating this additive versus maintaining existing practices. For some, this may involve shifting budgets or finding efficiencies in other areas to accommodate increased material costs.

Compatibility with existing glass formulations presents additional challenges. Not all glass products are designed to accommodate zirconium silicate, and improper integration can lead to quality issues during and after the production process. As such, extensive research and development are essential to determine the ideal blending ratios for different glass types. Conducting thorough tests prior to large-scale implementation is necessary to prevent issues that could impact production quality and timelines.

| Challenge | Description |

|---|---|

| Sourcing and Availability | Fluctuations in market supply affecting availability for consistent production |

| Cost | Higher material costs in relation to traditional glass additives |

| Compatibility | Potential quality issues due to improper integration with existing formulations |

This image shows a glass manufacturing process, highlighting where zirconium silicate can be integrated.

How Do You Incorporate Zirconium Silicate in Glass Recipes?

The successful incorporation of zirconium silicate into glass production involves careful planning and execution to maximize its properties. What steps should manufacturers follow? Let’s break it down into clear, actionable points.

First, manufacturers must establish recommended blending ratios. A standard approach is to begin with a small percentage, often around 1-5% of the total mixture. This initial step can provide a controlled experimentation phase for assessing performance enhancements. From there, adjustments may be made based on observed outcomes, allowing the manufacturer to optimize the formulation for specific types of glass or production applications. Each glass type may require its unique ratio, so constant testing is essential to strike a balance.

Following this, proper mixing processes are crucial to ensuring that zirconium silicate is evenly distributed throughout the glass batch. Advanced mixing equipment, such as high-shear mixers or planetary mixers, can facilitate a more homogeneous mixture. Inconsistent mixing can lead to variations in quality, affecting everything from the final appearance to product durability. Precise control of mixing times and speeds is essential to optimize the distribution of the additive.

Manufacturers should also look to existing case studies and industry examples for insights. Evaluating successful implementations of zirconium silicate can provide valuable information and inspire process innovations. Reviews of peer experiences can reveal best practices and common pitfalls that others may have encountered, allowing companies to avoid these mistakes. Learning from others’ accomplishments can streamline product development efforts by reducing the risk of experimentation failure.

| Step | Action Item |

|---|---|

| Establish Blending Ratios | Begin with initial ratios of 1-5% and adjust as necessary based on testing results |

| Ensure Proper Mixing | Utilize advanced equipment for thorough and consistent distribution of materials |

| Analyze Success Stories | Learn from case studies to streamline processes and reduce trial and error |

What Innovations Are Emerging in Glass Manufacturing?

As the glass industry continues to adapt to changing demands and advancements in technology, new innovations are constantly shaping the way products are developed. Consider this: what innovations are on the horizon, and how might they impact the integration of zirconium silicate?

Recent advances in technology have introduced more efficient production methods, often involving automation and real-time monitoring systems. Advanced manufacturing techniques that employ sensors and data analytics can ensure that material characteristics are optimized at every stage of production. For example, automated systems can adjust the temperature and mixing ratios in real time, enhancing overall product quality. Notably, such technology increases the precision of material integration, especially when zirconium silicate is involved, allowing manufacturers to achieve consistent results.

Furthermore, sustainability remains a pivotal theme within the glass manufacturing sector. There is a growing trend toward recycling glass, known as cullet, as companies strive for eco-friendly practices. By incorporating recycled materials and balancing their integration with zirconium silicate, manufacturers can create stronger products while focusing on sustainability. Innovations that blend recycled glass with new materials lead to a reduction in waste and can enhance brand image among environmentally conscious consumers.

Additionally, a new wave of research and development in coatings and surface treatments for glass products is emerging. These advancements are leading to applications that offer enhanced functionalities, such as self-cleaning surfaces or increased thermal insulation. The incorporation of zirconium silicate may serve to improve the efficiency and durability of these coatings. Companies that remain updated on these trends can gain a significant competitive advantage by offering superior products aligned with contemporary consumer demands.

| Innovation | Description |

|---|---|

| Automation | Enhanced real-time monitoring for improved consistency and product quality |

| Sustainability | Greater emphasis on recycling materials leading to eco-friendly glass production |

| Advanced Coatings | Development of functional enhancements that improve surface characteristics and durability |

How Can Companies Assess Their Needs for Zirconium Silicate?

To assess the need for integrating zirconium silicate into glass production, companies must engage in careful evaluation processes that take into account current and future production requirements. So how should organizations approach this?

First, manufacturers should evaluate their existing production capacities. Understanding these operational limits can help determine whether the addition of zirconium silicate would bring value. For example, if a company experiences frequent breakage of its glass products, it may indicate that additional strength from this additive could be beneficial.

Next, conducting thorough materials assessments is essential. Evaluating current glass formulations may reveal opportunities for performance improvements. If specific attributes such as increased durability or reduced weight are targeted goals, integrating this mineral might provide the necessary enhancements. A thorough analysis of current product performance also allows manufacturers to identify limitations and areas needing improvement.

Engaging in consultations with experts and raw material suppliers is a practical approach. Having discussions with industry professionals familiar with the applications and advantages of zirconium silicate can yield valuable insights for manufacturers. Building these relationships may lead to better access to knowledge and networking opportunities within the materials supply chain. Collaborating with knowledgeable consultants helps organizations better address their specific needs while ensuring they are not overlooking beneficial advancements.

| Assessment Area | Focus Points |

|---|---|

| Production Capacities | Analyze existing limits to determine the potential value of integrating new materials |

| Material Analysis | Identify specific performance improvement opportunities in current formulations |

| Expert Consultation | Engage with suppliers and professionals for insights tailored to your specific production needs |

What Are Industry Standards for Zirconium Silicate?

Understanding the industry standards for zirconium silicate is critical for maintaining compliance and ensuring quality assurance throughout the glass production process. What guidelines should companies follow to stay up to date?

First, manufacturers must be aware of regulatory frameworks that govern the use of zirconium silicate and other materials. Many governments and environmental regulatory bodies have established guidelines to ensure the safe handling and application of industrial materials. Being apprised of any regulatory changes is essential for maintaining compliance and avoiding potential penalties.

Quality assurance measures need to be robust and in place to ensure consistency in product quality. Implementing rigorous testing protocols can help ensure that every batch of zirconium silicate meets predetermined industry standards. This may include both internal assessments, such as material performance under various conditions, as well as third-party verification to establish credibility and trustworthiness.

Finally, pursuing certification processes for materials can play an essential role in enhancing credibility and customer confidence. Obtaining certifications from recognized organizations validates the quality of zirconium silicate and provides manufacturers with a competitive edge. Companies that achieve certification enhance their market standing, which can translate from credibility to increased market share.

| Standard | Focus Area |

|---|---|

| Regulatory Compliance | Keep updated on all relevant regulatory guidelines for safe material usage |

| Quality Assurance Measures | Implement testing protocols to ensure compliance with industry standards |

| Certification Processes | Pursue recognition from governing bodies to validate the quality of materials used |

This image outlines various standards and regulations pertinent to the use of zirconium silicate in manufacturing.

How Do Other Industries Benefit from Zirconium Silicate?

Zirconium silicate serves critical applications beyond traditional glass manufacturing, reaching multiple industries that leverage its unique properties in diverse ways. What other industries find value in this material?

The ceramics industry widely utilizes zirconium silicate for its exceptional durability and temperature resistance, leading to applications in tiles, tableware, and sanitary ware. Products created in this sector benefit from a tougher structure, enhancing their lifespan and performance. In addition, the promotion of its use in ceramics translates to increased consumer confidence, particularly in markets focused on high-quality products.

In coatings, zirconium silicate acts as a valuable component in paints and protective finishes. Its contributions to improved adhesion prevent peeling and deterioration over time, essential in sectors such as construction and automotive. Manufacturers in the coatings sector are increasingly recognizing its potential to improve product performance, positioning themselves to compete effectively in a crowded marketplace.

Furthermore, both the aerospace and automotive industries are exploring the advantages of incorporating this specialized compound in applications requiring lighter materials with enhanced strength. For example, using zirconium silicate in lightweight components ensures high levels of reliability and strength, which is pivotal for both safety and efficiency. This evolution supports advancements towards higher performance and lower emissions, reinforcing a commitment to sustainability in these fields.

| Industry | Application |

|---|---|

| Ceramics | Enhancements in tiles, pottery, and sanitary ware for improved durability |

| Coatings | Increased adhesion and durability for paints and other protective finishes |

| Aerospace and Automotive | Lightweight, durable components designed to enhance performance and reduce weight |

What Is the Future of Zirconium Silicate in Glass?

Looking ahead, the role of zirconium silicate in glass manufacturing promises to evolve and expand in significance. What can we expect in the coming years regarding this compound and its applications?

Market trends indicate an increasing focus on high-performance materials as industries strive for better products. As sectors prioritize durability and quality, integrating this specialized mineral will likely see broader adoption, with manufacturers increasingly seeking to gain a competitive edge in their markets. The growing emphasis on high-quality and durable glass, especially in consumer products and building materials, reinforces the necessity of incorporating this compound.

Technological advancements will pave the way for innovative practices in glass production. As ongoing research continues exploring the capabilities and applications of zirconium silicate, new methods of integration may surface, leading to fresh opportunities for manufacturers. Businesses that remain proactive in adopting new technologies and techniques will position themselves favorably for long-term growth and market leadership.

Finally, sustainability will stay at the forefront of industry priorities. Increasing pressure to adopt environmentally friendly practices will see companies searching for materials that minimize environmental impact. By leveraging the qualities offered by zirconium silicate, manufacturers can address these challenges while simultaneously enhancing their commitment to sustainability. Companies that align their practices with societal expectations will foster enhanced brand loyalty and consumer engagement, driving future success.

| Future Trend | Description |

|---|---|

| Increased Performance Focus | Anticipated higher adoption rates as manufacturers amplify product quality demands |

| Technological Advancements | Continuous innovations leading to novel applications and methods |

| Sustainability Initiatives | Aligning practices with eco-friendly values while enhancing product capabilities |

Conclusion

In closing, zirconium silicate plays a transformative role in the landscape of glass manufacturing. Its ability to enhance durability, clarity, and production efficiency makes it an invaluable asset for manufacturers seeking to improve their product offerings. By incorporating this unique mineral, companies not only optimize their processes but also elevate their brands in a complex and competitive market environment. At Global Industry, we encourage you to critically evaluate your material choices today. For further insights into optimizing your glass production, connect with us to cultivate excellence in your manufacturing practices and achieve your business goals.

FAQ Section

Q1: What is zirconium silicate? Zirconium silicate is a mineral used primarily in glass and ceramics, enhancing various properties such as strength, durability, and clarity.

Q2: Why is this compound important in glass production? It improves the overall properties of glass products, including durability, resistance to damage, and aesthetic qualities that are vital in various applications.

Q3: Are there any drawbacks to using zirconium silicate? Challenges can arise regarding material sourcing, higher costs compared to traditional glass additives, and potential compatibility issues with existing formulations.

Q4: How do manufacturers incorporate this material into their glass formulations? Manufacturers typically blend specific ratios of zirconium silicate into their glass recipes during production to achieve desired qualities and performance benefits.

Q5: What trends are impacting the use of zirconium silicate in glass? Innovations in production technology and an increasing demand for high-quality, durable glass are driving its use across diverse industry applications.