In the competitive landscape of industrial coatings, decision-makers frequently search for the most effective materials to enhance product durability and performance. Zirconium silicate stands out as a vital choice for advanced coatings due to its unique properties and advantages. Companies face challenges like environmental regulations, cost efficiency, and the need for superior product performance. This article addresses these concerns by exploring how this material can meet these needs and elevate coating solutions. With reliable data and industry insights, readers will understand just why this material is important for modern applications.

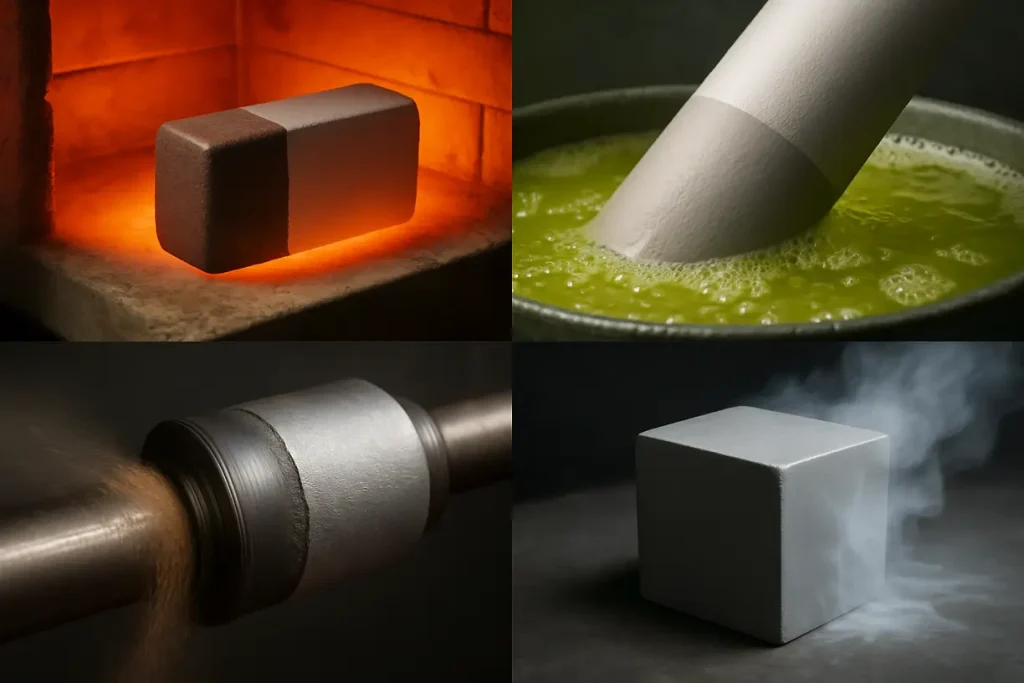

This image illustrates the application of zirconium silicate in advanced industrial coatings, showcasing its critical role in enhancing durability.

Why Is Zirconium Silicate a Preferred Choice for Coatings?

Zirconium silicate is an increasingly popular selection in the coatings industry for several compelling reasons. Its excellent physical and chemical properties make it a strong contender against other materials, ensuring that coatings can meet rigorous performance standards.

First, zirconium silicate offers superior hardness and durability. This ensures that coatings maintain their integrity and appearance over time, effectively resisting wear and damage from daily use and environmental exposure. This property is especially beneficial for applications in high-traffic areas where durability is crucial.

Second, the chemical stability of this compound means it resists degradation from various environmental factors, including moisture, UV radiation, and harsh chemicals. This resilience contributes to the longevity of the coatings, allowing them to perform well even in challenging conditions, thus reducing the need for frequent touch-ups or replacements.

Furthermore, many industries prefer zirconium silicate due to its non-toxic nature, aligning with modern sustainability efforts. As environmental concerns grow, companies are looking for materials that comply with regulations without sacrificing performance. The use of non-toxic materials not only protects workers and consumers but also helps businesses align with heightened sustainability standards.

Moreover, zirconium silicate can be easily integrated into current coating formulations. Its compatibility enhances performance without requiring extensive changes to production processes, making it both practical and efficient for manufacturers. The ease of incorporation allows for smoother transitions in formulation and production while maintaining high-quality output.

| Properties | Zirconium Silicate | Alternative Materials |

|---|---|---|

| Hardness | High | Moderate |

| Chemical Stability | Excellent | Variable |

| Environmental Impact | Low (non-toxic) | Higher (toxic options) |

| Integration Ease | Easy | Difficult |

What Are the Technical Advantages of Zirconium Silicate?

Zirconium silicate has a range of technical advantages that make it desirable for coatings. These strengths are particularly important in applications where long-term performance is critical.

One of the standout features is its hardness. This property allows coatings to resist scratches and abrasion, which is crucial for products exposed to wear and tear.

Another significant advantage is its thermal stability. This material remains stable at high temperatures, making it suitable for applications requiring heat resistance.

Additionally, it shows impressive resistance to chemical corrosion. It protects coated surfaces from harsh cleaning agents and environmental chemicals, which is essential for maintaining product integrity.

So, why does this matter? When manufacturers choose zirconium silicate, they enhance the durability and longevity of their coatings. This leads to reduced maintenance costs, higher customer satisfaction, and ultimately, a competitive edge in the marketplace.

Key Technical Benefits of Zirconium Silicate:

- Superior hardness: Ensures coatings resist physical wear, making them ideal for high-use applications.

- Thermal stability: Maintains properties at elevated temperatures, ensuring reliability in extreme conditions.

- Chemical resistance: Protects against degradation from aggressive substances, ensuring long-term integrity.

| Technical Advantages | Description |

|---|---|

| Hardness | High scratch and abrasion resistance |

| Thermal Stability | Maintains integrity at high temperatures |

| Chemical Resistance | Withstands exposure to harsh chemicals |

How Does Zirconium Silicate Improve Coating Performance?

Zirconium silicate significantly boosts coating performance in various aspects, making it a preferred choice for manufacturers aiming for high-quality results.

First, it enhances adhesion properties, ensuring that the coatings bond effectively to substrates. This improved adhesion is critical because it leads to longer-lasting applications with better performance over time, thereby reducing the risk of premature peeling or flaking.

What’s more? The material also contributes to the aesthetic appeal of coatings. Its fine particle size enhances uniformity, allowing coatings to achieve increased glossiness and richer color vibrancy. These aesthetic improvements are particularly important in consumer-facing products, where appearance can significantly influence buyer decisions.

Moreover, zirconium silicate improves wear resistance, meaning the coated surfaces can withstand mechanical stress without degrading. This is particularly beneficial in industries where surfaces are subjected to high levels of friction, such as manufacturing and automotive, reducing the need for frequent maintenance and reapplication.

Additionally, the thermal stability of zirconium silicate prevents degradation at high temperatures, ensuring that coatings remain effective in extreme conditions. This quality is essential for applications exposed to heat sources or fluctuating temperature environments, maintaining functionality and appearance over time.

By integrating zirconium silicate into coatings, manufacturers can achieve products that not only look good but also perform exceptionally well over time, contributing to customer satisfaction and loyalty.

Performance Enhancements from Zirconium Silicate:

- Enhanced adhesion: Promotes better bonding on various substrates.

- Aesthetic improvement: Increases gloss and color richness.

- Increased wear resistance: Ensures longevity under mechanical stress.

| Performance Benefits | Details |

|---|---|

| Enhanced Adhesion | Strong bond with substrates |

| Aesthetic Enhancement | Improved gloss and color vibrancy |

| Increased Wear Resistance | Better durability under stress |

In What Industries Is Zirconium Silicate Commonly Used?

Zirconium silicate sees widespread application across various industries due to its unique characteristics and versatile properties.

In the automotive sector, this material is often used in coatings for vehicles. It provides a durable finish that protects against environmental damage like UV rays, humidity, and chemicals. As a result, vehicles coated with zirconium silicate maintain their appearance and performance over time, leading to higher customer satisfaction.

The image showcases zirconium silicate used in automotive coatings, highlighting its role in enhancing vehicle durability.

The aerospace industry also utilizes this material in protective coatings. Its exceptional resistance to high temperatures and chemicals makes it an ideal choice for components that experience extreme conditions. This ensures that vital parts of aircraft remain protected, contributing to overall safety and performance.

Additionally, the manufacturing sector increasingly relies on zirconium silicate for industrial equipment coatings. Its durability enhances equipment longevity and minimizes maintenance needs, translating to reduced operational costs for manufacturers. Industries such as heavy machinery and construction benefit significantly from the use of this material coatings.

And let’s not forget: the architectural sector benefits from zirconium silicate in decorative coatings. Its visual appeal and performance ensure that buildings maintain their integrity and aesthetics over time, contributing to the longevity of structures while allowing for a variety of design options.

Industries Benefiting from Zirconium Silicate:

- Automotive: Coatings for vehicle exteriors ensuring durability and resistance to environmental factors.

- Aerospace: Protective finishes for parts under extreme conditions, guaranteeing safety and longevity.

- Manufacturing: Coatings for machinery and industrial equipment that enhance operational efficiency and reduce maintenance.

- Architecture: Decorative coatings for buildings, providing both aesthetic enhancements and protection against weathering.

| Industry | Applications |

|---|---|

| Automotive | Vehicle coatings |

| Aerospace | Protective coatings for parts |

| Manufacturing | Coatings for industrial equipment |

| Architecture | Decorative finishes for buildings |

What Are the Environmental Benefits of Using Zirconium Silicate?

Zirconium silicate offers several environmental benefits that align with current sustainability initiatives, making it a material of choice for eco-conscious manufacturers.

First, it is a non-toxic material, making it safe for both workers and end-users. This significantly reduces liability and safety concerns in manufacturing environments, ensuring a healthier workplace and minimizing risks associated with hazardous materials.

Another advantage is the low environmental impact during production. Companies can contribute to reducing their carbon footprint by choosing materials that require less energy and produce fewer harmful emissions. This aligns well with global efforts to mitigate climate change.

Furthermore, the longevity of coatings made from zirconium silicate means fewer replacements over time. This leads to less waste and lower overall resource consumption, promoting a more circular economy where materials are utilized to their fullest potential before disposal.

Additionally, as the demand for environmentally friendly products increases, using zirconium silicate can enhance a company’s brand image and appeal to a broader customer base that values sustainability.

To put this in perspective: Opting for this material can significantly enhance a company’s commitment to sustainability while also providing economic advantages through reduced waste and energy consumption.

Environmental Advantages of Zirconium Silicate:

- Non-toxic: Safe for human health and the environment.

- Low emissions in production: Contributes to a smaller carbon footprint.

- Reduction in waste: Longer-lasting coatings result in less material waste.

| Environmental Benefits | Description |

|---|---|

| Non-Toxic | Safe for workers and consumers |

| Lower Carbon Footprint | Requires less energy to produce |

| Reduced Waste | Longer-lasting coatings decrease replacements |

How Does Zirconium Silicate Compare to Other Materials?

Zirconium silicate is often compared to alternative materials to highlight its strengths and advantages in coatings.

When compared to titanium dioxide, zirconium silicate shows superior hardness and chemical resistance. While titanium dioxide is primarily a pigment, this compound provides both performance and aesthetic benefits, making it suitable for coatings that require not just functionality but also visual appeal. This makes it a better choice for applications in harsh environments where durability is critical.

But that’s not all! Against silica-based coatings, this compound typically offers better durability and thermal stability. Silica can degrade under extreme conditions, whereas zirconium silicate maintains its properties, thus ensuring that coatings remain effective over time. The enhanced thermal stability of this material means it can withstand higher temperatures without losing structural integrity, making it ideal for applications in industries like aerospace and automotive.

Furthermore, the versatility of zirconium silicate allows it to be used in a variety of formulations, providing manufacturers with more options to tailor their coatings. This adaptability is a significant advantage when competing against more specialized materials that may lack such broad application potential.

Understanding these comparisons allows manufacturers to make informed decisions when selecting materials for their coatings.

| Comparison Criteria | Zirconium Silicate | Titanium Dioxide | Silica-Based Coatings |

|---|---|---|---|

| Hardness | High | Moderate | Low |

| Thermal Stability | Excellent | Moderate | Low |

| Chemical Resistance | High | Low | Moderate |

What Innovations Are Currently Emerging in Zirconium Silicate Coatings?

The coatings industry is witnessing innovative advancements related to zirconium silicate, driven by the demand for improved performance and sustainability.

Recent developments include new formulations that enhance the material’s characteristics. These innovations are aimed at improving application techniques and performance metrics. For instance, researchers are working on modifying the particle size and distribution of zirconium silicate to optimize its dispersion in coatings, which can lead to enhanced performance and easier application.

But don’t stop there! Case studies illustrate successful applications of advanced coatings in specialized environments. Manufacturers have started to explore functional coatings that not only protect surfaces but also impart specific features such as anti-fogging or anti-microbial properties, thereby broadening the applicability of zirconium silicate.

Developments in nano-coatings are also emerging, where zirconium silicate is utilized at a microscopic level. These nano-coatings can provide extraordinary performance enhancements, such as improved hydrophobic properties that repel water or dirt, making surfaces easier to clean and maintain.

Innovators are also focusing on formulating zirconium silicate coatings that are easier to apply and cure under lower temperatures, which can significantly lower energy consumption during the manufacturing process.

This image depicts recent innovations in zirconium silicate coatings, showcasing advanced applications in challenging environments.

As manufacturers continue to push boundaries, the future looks promising for zirconium silicate in coatings, making it an essential component in the ongoing evolution of the coatings industry.

Emerging Innovations in Zirconium Silicate:

- New formulations: Enhancements that improve thermal and chemical resistance.

- Functional coatings: Incorporating additional properties for specific applications.

- Nano-coatings: Providing superior performance enhancements at a microscopic level.

- Energy-efficient application: Lower curing temperatures for reduced production costs.

| Innovations | Examples |

|---|---|

| Enhanced Formulations | New mixtures that boost performance |

| Specialized Applications | Coatings designed for marine environments |

| Nano-Coatings | Utilizing zirconium silicate at a microscopic level for advanced features |

| Energy-Efficient Solutions | Formulations that cure at lower temperatures to save energy |

What Should You Consider When Selecting Zirconium Silicate?

When considering this silicate for coatings, there are key factors to evaluate.

First, look for quality. Not all formulations are created equal, and selecting a reputable supplier is crucial.

Moreover, pricing is essential. It’s important to balance cost with performance and durability. Often, the initial investment in a high-quality zirconium silicate will yield better long-term results.

Additionally, consider how easily the material integrates into your existing production processes. A seamless transition can save time and reduce complications.

Evaluating these aspects will help ensure you make an informed decision when implementing zirconium silicate in your coatings.

Considerations for Selection:

- Supplier reputation: Research and evaluate potential suppliers’ quality standards.

- Cost-effectiveness: Assess long-term benefits against upfront costs.

- Integration capability: Ensure compatibility with existing processes to streamline operations.

| Selection Criteria | Consideration |

|---|---|

| Quality | Choose reputable suppliers |

| Pricing | Balance cost with durability |

| Integration | Ensure compatibility with production |

How Can Companies Optimize the Use of Zirconium Silicate?

To maximize the benefits of zirconium silicate, companies should adopt best practices throughout their production processes.

First, testing should be conducted to tailor formulations specific to application needs. This can lead to optimized performance and reduced waste.

Furthermore, training staff is vital. Employees should understand the properties and handling of this silicate to ensure effective application.

Scaling up production can also involve refining processes. Emphasizing efficiency while maintaining quality will yield optimal results.

By following these guidelines, manufacturers can harness the full potential of this material in their coatings.

Best Practices for Using Zirconium Silicate:

- Conduct thorough testing: Tailor the formulations to meet specific needs.

- Provide adequate training: Educate employees on handling and properties.

- Refine production processes: Focus on efficiency while maintaining quality standards.

| Optimization Strategies | Actions |

|---|---|

| Tailored Formulations | Conduct thorough testing |

| Staff Training | Educate on properties and applications |

| Process Refinement | Focus on efficiency and quality |

What Challenges Are Associated with Using Zirconium Silicate?

Using zirconium silicate does present some challenges that companies should be aware of.

Sourcing high-quality materials can sometimes be difficult. Finding reliable suppliers is key to ensuring that the material meets performance standards.

Additionally, manufacturers may face issues during production. Adapting existing processes to incorporate zirconium silicate might require adjustments and training.

Moreover, companies must be mindful of regulatory compliance. Understanding industry standards is crucial to avoiding penalties and ensuring safe usage.

Recognizing these challenges allows businesses to prepare effectively and implement strategies for success.

Challenges in Implementing:

- Sourcing difficulties: Need for reliable suppliers to ensure quality.

- Production adaptation: May require training and adjustments to processes.

- Regulatory compliance: Must be aware of industry standards and regulations.

| Challenges | Considerations |

|---|---|

| Sourcing Quality | Identify reliable suppliers |

| Production Adaptation | Modify processes if necessary |

| Regulatory Compliance | Stay informed about industry standards |

Conclusion

In summary, zirconium silicate is a key player in the coatings industry due to its unique properties and numerous advantages. Its durability, chemical resistance, and environmental benefits make it a strategic choice for businesses seeking reliable coatings. One clear benefit is the long-lasting performance that contributes to overall cost savings. At Global Industry, we encourage you to explore how incorporating zirconium silicate can transform your coating solutions. By partnering with us, you can stay at the forefront of innovation and quality in the coatings market.

FAQ Section

Q1: What properties make zirconium silicate suitable for coatings?

Zirconium silicate is valued for its outstanding hardness, which enhances the scratch and abrasion resistance of coatings. Its excellent thermal stability allows it to maintain performance under high temperatures, while its chemical resistance helps protect surfaces from degradation caused by harsh substances, making it an ideal choice for a variety of applications.

Q2: How does zirconium silicate enhance coating durability?

Zirconium silicate improves several key performance factors of coatings, including adhesion, wear resistance, and gloss retention. By providing a strong bond to substrates, it reduces the risk of delamination, while its ability to withstand mechanical stress ensures that coatings remain intact over time, thus significantly contributing to the longevity and reliability of the final product.

Q3: In which industries is zirconium silicate most widely utilized?

Zirconium silicate is commonly employed across various industries such as automotive, aerospace, manufacturing, and architecture. In automotive applications, it protects vehicle exteriors; in aerospace, it provides thermal resistance for critical components; and in manufacturing, it enhances the durability of industrial equipment coatings. Its versatility makes it a popular choice in both functional and decorative applications.

Q4: What are the environmentally friendly aspects of zirconium silicate?

One of the key advantages of zirconium silicate is its non-toxic nature, which ensures safety for workers and end-users alike. The material’s production processes typically result in lower emissions and a reduced carbon footprint compared to alternative materials. Additionally, the enhanced durability of coatings made with zirconium silicate leads to less frequent replacements, thereby minimizing waste and contributing to more sustainable manufacturing practices.

Q5: What considerations should companies keep in mind when choosing zirconium silicate?

When selecting zirconium silicate, companies should assess factors such as supplier reliability to ensure consistent quality and performance. Pricing is another important aspect, as it should match the expected durability and long-term benefits of the material. Additionally, businesses should consider how well zirconium silicate will integrate into their existing production processes to avoid disruptions and optimize efficiency in their manufacturing operations.