In industrial applications, maintaining the durability of coatings presents a significant challenge for purchasing managers and decision-makers. Coatings often face a barrage of wear, exposure to corrosive chemicals, and thermal stress in demanding environments, leading to concerns about their longevity and effectiveness. This situation raises the critical question: How can manufacturers enhance coating durability? Zirconium silicate offers a viable solution through its remarkable properties.

This mineral plays a pivotal role in enhancing the performance of various coatings, leading to longer lifespans and significantly reduced maintenance costs. With proven effectiveness and a reliable reputation in the industry, zirconium compounds stand out as an excellent choice for many applications. In this article, we will explore how the addition of this mineral improves coating durability and discuss its practical implications for businesses across different sectors.

The image illustrates the application of zirconium silicate in coatings, showcasing its use in various industrial settings.

How Does Zirconium Silicate Improve Coating Durability?

The incorporation of this mineral significantly enhances the durability of coatings utilized in industrial environments. This improvement is achieved through a combination of its unique physical and chemical properties. The primary function of zirconium silicate is to amplify the wear and abrasion resistance of coatings, which is critical in high-traffic areas.

The durability of coatings impacts everything, from element longevity to operational efficiency and maintenance budgets. A coating that can withstand harsh conditions reduces the frequency of repairs and replacements needed, which directly cuts operational costs and enhances productivity. For purchasing managers, the bottom line is clear: investing in coatings that last longer leads to better resource management.

One of the standout qualities of zirconium compounds is their hardness. Coatings that contain this mineral exhibit markedly higher abrasion resistance compared to standard formulations. This means that surfaces remain intact and perform reliably even under mechanical stress. The integration of zirconium silicate creates a more resilient coat, enabling manufacturers to significantly extend the life of their products.

Moreover, the mineral contributes to improved thermal stability within coatings. High temperatures can often cause standard coatings to degrade and lose their protective qualities. However, when zirconium silicate is included in the formulation, the coatings become more stable and better equipped to handle extreme heat conditions. This characteristic drastically reduces the risk of thermal degradation, making coatings suitable for applications where heat resistance is essential.

In summary, zirconium silicate emerges as a transformative additive for industrial coatings, allowing manufacturers to raise the performance standards of their products significantly and ensure long-lasting durability even in the most arduous conditions.

| Property | Without Zirconium Silicate | With Zirconium Silicate |

|---|---|---|

| Abrasion Resistance | Moderate | High |

| Thermal Stability | Low | High |

| Lifespan of Coating | Average | Extended |

| Maintenance Frequency | Regular | Reduced |

What Are the Key Benefits of Zirconium Silicate?

Incorporating zirconium silicate into coatings yields multiple benefits essential for industrial applications.

Firstly, wear resistance ranks as a primary advantage. Coatings infused with this mineral can better handle mechanical stress than those without, which is crucial in environments with heavy machinery or significant foot traffic. Reduced wear translates into longer-lasting products, creating more value over time.

Next, we have improved chemical resistance. Industrial environments frequently expose coatings to harsh chemicals, from strong acids to aggressive solvents. Zirconium silicate enhances the coating’s ability to resist these substances effectively, ensuring that the underlying surfaces remain protected and functional. This characteristic is particularly significant for industries that handle corrosive materials, where downtimes due to coating failures can lead to substantial financial losses.

Furthermore, better thermal stability is another compelling benefit. In sectors like aerospace and automotive, coatings are often exposed to extreme temperatures. Products that maintain their integrity and performance under thermal stress are invaluable. Integrating zirconium silicate helps ensure that coatings resist damage from heat, effectively preventing degradation and extending the working life of critical machinery.

Ultimately, these benefits lead to significant cost savings. Fewer failures mean lower maintenance and downtime costs, allowing businesses to allocate resources more effectively. By investing in coatings enhanced with this mineral, companies not only increase their operational efficiency but also boost their overall profitability.

To summarize, the advantages of zirconium silicate position it as a smart choice for companies aiming to develop high-performance coatings that deliver lasting value.

| Benefit | Description |

|---|---|

| Wear Resistance | Higher durability against mechanical stress |

| Chemical Resistance | Better protection from corrosive elements |

| Thermal Stability | Improved performance at extreme temperatures |

| Cost Savings | Reduced maintenance and downtime costs |

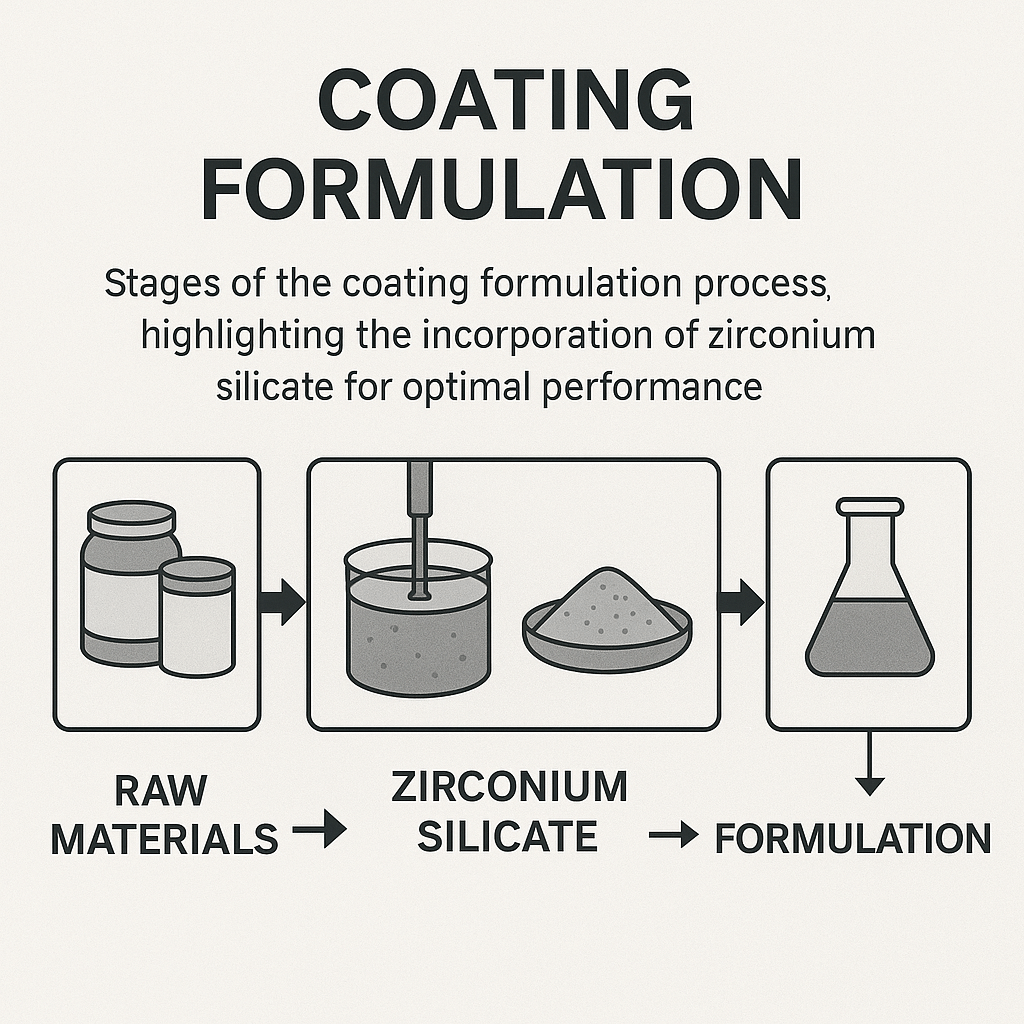

The image illustrates the different phases of coating formulation, highlighting where zirconium silicate is added for optimal performance.

How Is Zirconium Silicate Used in Coating Formulations?

Understanding how zirconium silicate is utilized in coating formulations sheds light on its practical applications and benefits.

Typically, it is integrated during the mixing phase. Manufacturers add zirconium silicate to the resin or binder during the formulation process, allowing for uniform distribution throughout the coating material. Achieving this uniformity is crucial, as inconsistencies can hinder performance and compromise the durability benefits that this mineral provides.

One notable type of formulation involves paints used in industrial coatings. Here, zirconium silicate not only enhances the performance characteristics but also improves aesthetics—coatings appear smoother and maintain their finish for an extended period. This aspect is important, especially in customer-facing applications, where the product’s appearance reflects on brand quality.

Another common application is in ceramics. Zirconium silicate provides not just durability but also contributes to visual effects. In tile and ceramic coatings, it can create a glossy finish that appeals to consumers while ensuring strength and resistance to wear and tear.

Moreover, coatings for outdoor applications benefit significantly from this mineral. Environmental exposure, such as UV light and moisture, can degrade many standard coatings over time. By enhancing weather resistance, zirconium silicate prevents premature degradation, ensuring that products maintain their visual and functional integrity.

Zirconium compounds can, therefore, be a game-changer for formulation practices. By incorporating this mineral, manufacturer gains not only enhanced performance but also improved marketability of their products. Customers increasingly seek high-quality coatings that perform well under challenging conditions, and formulations with this additive can help meet those expectations seamlessly.

| Coating Type | Application | Benefits |

|---|---|---|

| Industrial Paint | Machinery, surfaces | Durability, aesthetics |

| Ceramics | Tiles, fixtures | Strength, visual appeal |

| Outdoor Coatings | Structural coatings | Weather resistance, UV stability |

What Role Does Zirconium Silicate Play in Coating Performance?

The contribution of zirconium silicate to coating performance is profound and multi-faceted. It enhances many aspects that collectively improve the overall functionality of coatings.

One crucial aspect lies in its ability to reinforce the matrix of the coating. When mixed into formulations, it becomes an integral part of the coating structure. This reinforcement helps create a robust barrier that reduces incidences of chipping and peeling over time, which is vital for maintaining a protective layer around structures and equipment.

Additionally, zirconium silicate plays a role in minimizing phase separation, which can occur during the curing process. This property prevents defects like bubbles or uneven thickness that can compromise the performance of the coating. A successful cure results in a smooth, uniform surface that prolongs aesthetic appeal and protective qualities.

Another beneficial attribute is improved flexibility. Coatings must often flex under stress for various applications without cracking. Zirconium silicate provides the necessary flexibility while retaining hardness, allowing for high resilience even in dynamic environments. This quality is particularly important in fields that require coatings to expand and contract due to temperature changes or mechanical movements, such as aerospace and automotive sectors.

Thus, understanding the pivotal role this mineral plays in formulations illuminates why it has become indispensable in modern coatings. It not only enhances durability but also overall performance, leading to superior coating functionalities across diverse applications.

| Performance Aspect | Without Zirconium Silicate | With Zirconium Silicate |

|---|---|---|

| Matrix Reinforcement | Weak | Strong |

| Defect Resistance | Prone to imperfections | Smooth finishes |

| Flexibility | Limited | Enhanced |

How Can Businesses Implement Zirconium Silicate Effectively?

Implementing zirconium silicate effectively requires careful consideration and strategic practices. Following a thoughtful approach can help businesses maximize the benefits this mineral offers.

First, assessing formulation needs is paramount. Different industrial applications will necessitate varying concentrations of the mineral. Understanding the specifics of the intended use scenario aids in determining the right amount needed to capitalize on its performance benefits. This consideration helps ensure that the formulations meet contractual obligations and performance expectations.

Next, ensuring precision in the mixing process is critical. Achieving a uniform distribution of zirconium silicate is essential for maximizing performance benefits. Inconsistencies could lead to uneven performance and could ultimately undermine the advantages that this mineral provides in terms of durability.

Furthermore, compatibility testing with other ingredients is a crucial step. There are instances where certain components may not react favorably with zirconium silicate. Conducting thorough trials to identify potential interactions allows manufacturers to refine their formulations effectively and avoid any adverse reactions that could compromise performance.

Finally, implementing regular testing for durability establishes a robust quality control process. Ongoing assessments can help identify any performance issues early in the production cycle. This proactive approach allows businesses to adapt and refine their formulations as necessary, ultimately ensuring that the coatings meet market demands and performance standards.

Adopting these best practices leads to a more effective implementation of zirconium silicate into industrial coatings. It ensures that your products provide enhanced durability and reliability, contributing to overall client satisfaction and improved operational outcomes.

| Implementation Step | Importance |

|---|---|

| Formulation Assessment | Tailor zirconium silicate concentration |

| Mixing Process | Ensure performance consistency |

| Compatibility Testing | Prevent adverse reactions with other ingredients |

| Durability Testing | Adapt formulations based on real-world performance |

What Industries Benefit Most from Zirconium Silicate Coatings?

The applicability of zirconium silicate coatings spans multiple industries. Different sectors leverage this mineral’s unique properties to enhance their product offerings.

The aerospace industry stands out prominently. Aircraft are subject to extreme conditions, including high altitudes and corrosive environments. Coatings that incorporate zirconium silicate can withstand these challenges, ensuring safety and integrity while also reducing maintenance needs.

Similarly, the automotive industry relies heavily on these coatings. Vehicle finishes that incorporate this mineral offer enhanced protection while maintaining an appealing aesthetic. These formulations can better resist wear and tear, leading manufacturers to provide more robust warranties and boosting customer confidence in the products.

Moreover, construction and infrastructure present significant opportunities. Protective coatings are essential to combating environmental elements like rain, humidity, and UV exposure. Utilizing zirconium silicate improves weather resistance, greatly extending the usable life of structures and minimizing repairs and renovation costs.

Lastly, the marine sector benefits considerably from these coatings. Coatings for ships and boats face particularly harsh saltwater environments. The addition of zirconium silicate enhances resistance to corrosion, ensuring that vessels withstand the rigors of ocean voyages without sustaining significant damage.

Overall, industries that encounter significant operational challenges and require high-performance coatings benefit the most from this specific mineral. In summary, zirconium silicate addresses specific needs across various high-demand sectors, making it a versatile and valuable component in many formulations.

| Industry | Key Application | Benefits |

|---|---|---|

| Aerospace | Aircraft coatings | Durability, safety |

| Automotive | Vehicle finishes | Aesthetic longevity, wear resistance |

| Construction | Structural coatings | Environmental durability |

| Marine | Boat and ship coatings | Enhanced corrosion resistance |

How Does Zirconium Silicate Compare to Other Coating Materials?

In exploring coating materials, comparing zirconium silicate to alternatives provides valuable context for its benefits and applications.

First, let’s examine traditional silica-based materials. While commonly used, silica alone does not provide the same durability and thermal resistance as zirconium silicate. Therefore, users seeking enhanced surface performance may find this mineral a superior choice, particularly in demanding applications.

Next, synthetics represent another option. Synthetic polymers can offer excellent flexibility and weather resistance but often lack the hardness associated with zirconium compounds. In applications requiring high abrasion resistance, coatings with zirconium are more likely to perform effectively over time.

Additionally, when compared to metal-based coatings, zirconium silicate tends to be more environmentally friendly. Many metal coatings pose challenges related to disposal and environmental impact. Zicronium silicate offers an effective alternative that aligns with the increasing demand for sustainable practices within various industries.

Ultimately, while various options exist for coatings, zirconium silicate distinctly combines durability, thermal stability, and environmental considerations. In short, it stands out as a leading choice for businesses focused on developing high-performance coatings that meet customer expectations and regulatory standards.

| Material Type | Key Characteristics | Comparison with Zirconium Silicate |

|---|---|---|

| Silica-Based | Common use, moderate durability | Less effective in high-stress environments |

| Synthetic Polymers | Flexible, good weather resistance | Lacks hardness; not ideal for abrasion |

| Metal-Based | Durable but environmental concerns | More eco-friendly alternative |

What Challenges Might Companies Face When Using Zirconium Silicate?

Despite the numerous benefits, companies may encounter challenges when integrating this mineral into their coatings.

One primary concern is cost. While zirconium silicate effectively boosts performance, the initial investment can be higher than for other materials. Companies must weigh this upfront cost against long-term savings achieved through reduced maintenance and replacement needs.

Mixing precision poses another challenge. Achieving a uniform distribution of zirconium silicate requires careful handling and methodology. If formulations are not mixed correctly, it can lead to performance discrepancies that render the advantages of enhanced durability ineffective.

Additionally, businesses might face hurdles with regulatory compliance. Some regions impose strict guidelines regarding coatings and materials utilized in various applications. Ensuring that zirconium compounds adhere to these regulations may necessitate thorough documentation and testing, adding complexity to the transition to using this mineral.

Approaching these challenges with proactive planning and implementation ensures successful integration of zirconium compounds into coating formulations. In summary, awareness of potential challenges and careful preparation can streamline the implementation process, maximizing the benefits this mineral provides across industries.

| Challenge | Description | Solutions |

|---|---|---|

| Cost | Higher initial investment | Evaluate long-term savings |

| Mixing Precision | Requires careful attention to distribution | Staff training on mixing best practices |

| Regulatory Compliance | Must adhere to specific guidelines | Maintain thorough documentation |

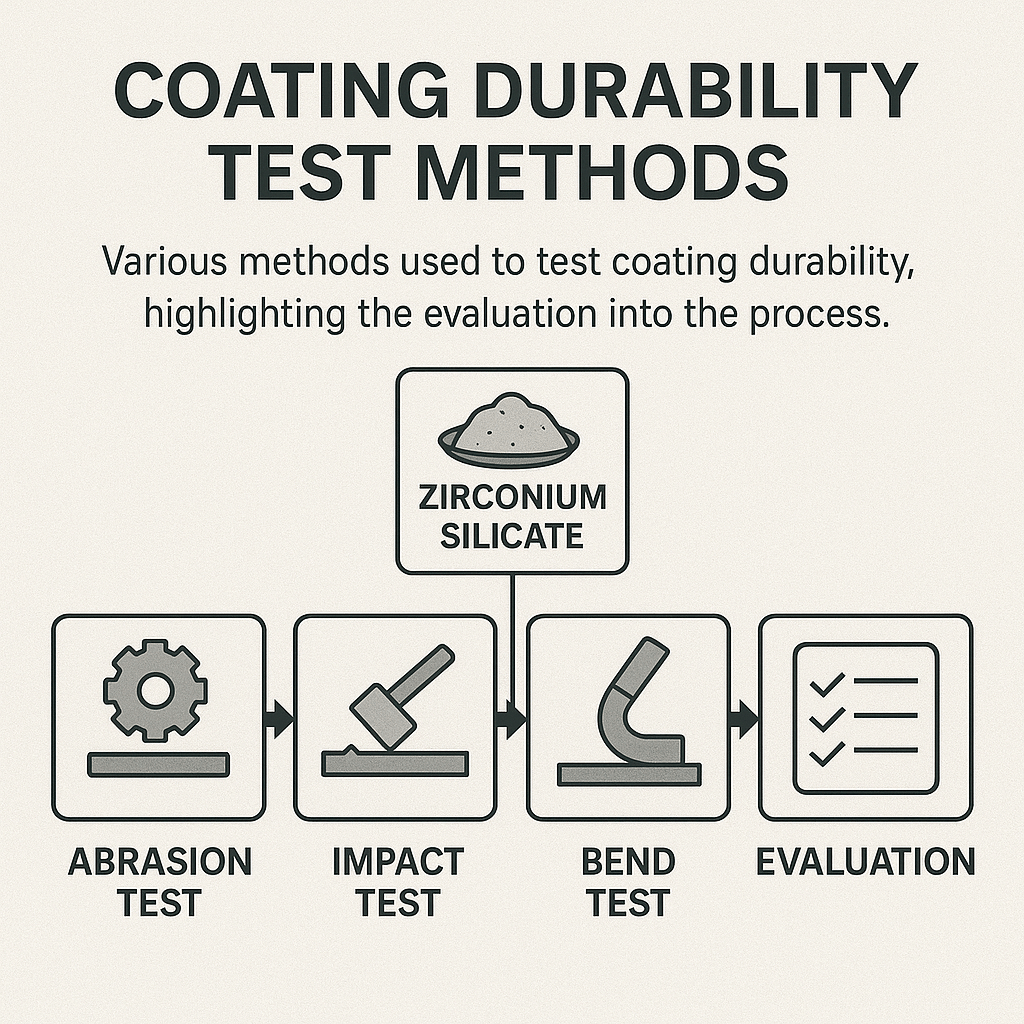

How Can Companies Measure Coating Durability?

Measuring the durability of coatings effectively is crucial for ensuring products meet quality standards. Several methodologies exist to assess the performance of coatings that incorporate zirconium silicate.

First, abrasion tests are useful for evaluating surface wear. Various standardized methods, such as Taber abrasion tests, offer insights into how well coatings can withstand physical stress over time. These evaluations help identify potential weaknesses early in the product life cycle.

Second, chemical resistance testing is essential for evaluating how coatings perform against a range of substances. Subjecting samples to strong acids or solvents helps gauge resistance levels, allowing companies to predict real-world performance scenarios accurately.

Third, thermal cycling tests assess how coatings respond to extreme temperature changes. This simulation of weather conditions ensures that coatings remain functional and intact during real-world applications.

Lastly, visual inspections serve as a practical qualitative measure. Regular checks for peeling, chipping, or discoloration can indicate durability issues needing prompt addressing.

Implementing these testing methods will ensure that coatings deliver the expected results in performance and longevity. In summary, ongoing evaluation of durability is essential for maintaining high standards in industrial applications and ensuring customer satisfaction.

| Test Type | Purpose | Example Method |

|---|---|---|

| Abrasion Tests | Assess surface wear | Taber abrasion test |

| Chemical Resistance | Evaluate performance against substances | Immersion in acids/solvents |

| Thermal Cycling | Simulate temperature exposure | Subject samples to cycling tests |

| Visual Inspections | Identify physical defects | Regular surface checks |

This image outlines various methods used to test the durability of coatings, emphasizing the evaluation process.

What Future Developments Are Expected for Zirconium Silicate in Coatings?

Looking ahead, the future of zirconium silicate in coatings promises significant advancements as technological innovations continue to evolve.

Research into nanoparticles presents an exciting frontier. These developments aim to enhance the performance properties of zirconium compounds, potentially leading to coatings with even greater durability and specialized characteristics like self-cleaning or anti-fungal properties.

Another major focus is on sustainability. As industries increasingly prioritize environmental responsibility, manufacturers are exploring eco-friendly synthesis methods and alternative sources for zirconium. This emphasis on sustainability aligns with the growing consumer demand for green products in various markets.

Additionally, advancements in application techniques are anticipated to simplify usage. Innovations in spray technology and other application methods can improve consistency and efficiency when applying coatings, ensuring that every layer maintains optimal performance characteristics.

Understanding these developments will help businesses stay competitive within their respective markets. To summarize, the future of zirconium silicate appears bright, with opportunities for enhancements that promise better performance, sustainability, and ease of application across multiple sectors.

| Future Development | Description | Potential Impact |

|---|---|---|

| Nanoparticle Research | Explore enhanced performance properties | Improved durability and performance |

| Sustainable Practices | Eco-friendly production methods | Align with environmental standards |

| Application Techniques | Advancements in application technology | Simplified processes and enhanced application uniformity |

Conclusion

The insights presented above illustrate how zirconium silicate enhances coating durability across numerous applications. This mineral improves resistance to wear, chemical exposure, and thermal stress across various industries. By integrating zirconium compounds into formulations, organizations can substantially lower maintenance costs while significantly extending product lifespans. Global Industry can assist you with effective solutions tailored to your specific needs. Visit our website or contact us today to learn about how we can work together to implement zirconium silicate in your coating formulations and enhance overall performance while maximizing your resources.

FAQ Section

Q1: What is zirconium silicate? Zirconium silicate is a mineral used in coatings to improve their properties, providing increased durability and chemical resistance against harsh environments.

Q2: Why is coating durability important in industrial applications? Durability ensures that coatings last longer, ultimately reducing maintenance costs and protecting surfaces from wear and damage in operational settings.

Q3: How does zirconium silicate improve thermal stability in coatings? This mineral resists high temperatures, helping to maintain the coating’s integrity and functionality under extreme conditions.

Q4: What industries commonly use zirconium silicate in their coatings? Industries including aerospace, automotive, construction, and marine sectors often utilize zirconium-based coatings to enhance performance and durability.

Q5: Are there any drawbacks to using zirconium silicate in coatings? Some challenges that may arise include higher initial investment costs and the necessity for precise formulation to achieve optimal performance outcomes.