Zirconium silicate plays a crucial role in the production of building materials, yet many industry professionals may not fully grasp its significance. This composite material can effectively resolve various issues related to durability, environmental sustainability, and overall efficiency in construction processes. In a market increasingly focused on creating sustainable and long-lasting products, businesses must consider the integration of zirconium-based solutions into their material offerings. Reliable research and extensive applications indicate that its unique properties make it a strong candidate for enhancing performance across numerous applications.

This article will thoroughly examine how zirconium silicate improves the quality and functionality of building materials, address common concerns within the industry, and provide actionable insights for decision-makers seeking to upgrade their production standards and ensure long-term success.

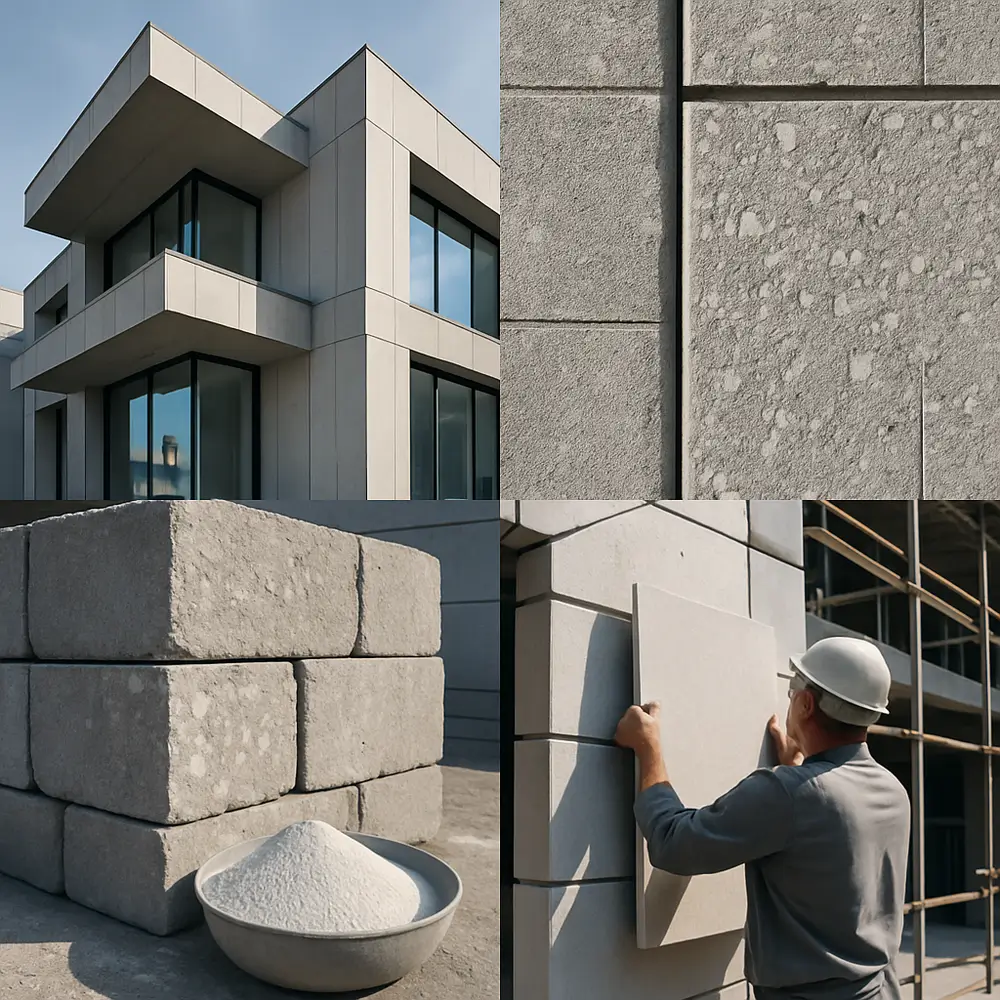

This image showcases various building materials enhanced by zirconium silicate, highlighting its applications in modern construction.

How is Zirconium Silicate Used in Building Materials?

Zirconium silicate serves multiple important functions in the production of various building materials. A comprehensive understanding of its applications is essential for industry professionals who are eager to innovate and improve the performance of their offerings.

Primarily, zirconium silicate is used as a key raw material in both ceramics and glass manufacturing, along with other composite materials. Its incorporation significantly enhances the physical properties of these materials, including high thermal stability and exceptional chemical resistance. These characteristics are critically important for maintaining quality in construction materials that will face harsh environmental conditions.

In the ceramics industry, zirconium silicate is often found in products such as tiles, sanitary ware, and tableware. When mixed with other compounds, it contributes to improved strength and durability, thereby minimizing the potential for cracks and breaks—issues that can compromise not only the aesthetic appeal but also the safety and usability of the finished product.

When it comes to glass production, zirconium silicate is valued for its role in enhancing clarity and resilience. Its inclusion helps prevent defects like bubbles or cloudiness in high-end glass products. Moreover, when these glass materials experience temperature fluctuations, the stabilizing properties of zirconium silicate help ensure that the structural integrity remains intact, making it especially useful in insulating glass applications and architectural glass used in buildings.

Considering these various applications, it becomes clear that the integration of zirconium silicate can lead to improved product quality across the board, which is a critical factor for any construction project aiming for longevity and reliability.

| Application | Benefits | Typical Industries |

|---|---|---|

| Ceramics | Increased strength and durability | Construction, flooring |

| Glass | Greater clarity and thermal stability | Home appliances, architecture |

| Composite materials | Enhanced chemical resistance | Aerospace, automotive |

What Are the Key Benefits of Zirconium Silicate?

The integration of zirconium silicate into building materials provides numerous advantages that can be pivotal for companies focusing on quality and performance. Recognizing these benefits can guide procurement departments and decision-makers in their material choices.

One of the standout benefits is improved durability. Compared to traditional materials like clay or some synthetic composites, products that incorporate zirconium silicate often demonstrate greater resistance to wear and tear. This enhancement is particularly important in high-traffic areas where flooring materials or structural components are subject to significant stress. Furthermore, materials infused with this compound can withstand severe environmental conditions, such as extremes in temperature and humidity.

Another key advantage relates to cost-effectiveness. While the initial investment in zirconium silicate may be higher than for some conventional alternatives, its longer lifespan can lead to substantial savings over time. Businesses that invest in high-quality materials tend to see reductions in maintenance costs, fewer replacements, and decreased downtime due to repairs. Over time, the overall costs associated with construction and maintenance can be significantly reduced.

Moreover, the environmental impact is increasingly important in today’s market. With a growing emphasis on sustainable practices, the use of zirconium silicate can facilitate reduced ecological footprints in construction activities. This material can often replace less environmentally friendly alternatives, promoting greener building practices and aligning with the increasing demand for corporate sustainability.

| Benefit | Impact on Production |

|---|---|

| Enhanced durability | Reduced need for frequent replacements |

| Cost-effectiveness | Lower long-term operational costs |

| Environmental sustainability | Alignment with green building initiatives |

Which Industries Rely on Zirconium Silicate?

The versatility of zirconium silicate allows several industries to utilize it extensively within their production processes. Understanding which sectors benefit from this material can help businesses identify potential partnerships and market opportunities.

The construction industry is perhaps the most significant user of zirconium silicate, where its unique properties are frequently leveraged in various products such as tiles, bricks, and diverse structural components. Its ability to enhance durability and aesthetic qualities makes it an ideal choice for applications where both performance and appearance are critical.

In the ceramics manufacturing sector, zirconium silicate is widely employed to improve the mechanical properties of tableware, sanitary products, and decorative items. This compound plays a vital role in increasing resistance to chipping and scratching, thus contributing to the longevity of ceramic products that experience regular use.

Moreover, the glass industry takes advantage of zirconium silicate in the production of high-end glassware and architectural glass. Its incorporation leads to better product stability, clarity, and resistance to chemical attacks, making it a critical component for products that need to meet stringent quality standards.

Lastly, sectors engaged in aerospace and automotive manufacturing especially look toward zirconium silicate for its performance under extreme conditions. Its ability to maintain structural integrity and performance excellence when faced with high temperatures makes it essential for components that require both safety and reliability.

| Industry | Uses |

|---|---|

| Construction | Structural elements, tiles |

| Ceramics | Tableware, sanitary products |

| Glass | High-end consumer products |

| Aerospace and Automotive | Engine components, structural parts |

How Does Zirconium Silicate Compare to Alternatives?

When evaluating the use of zirconium silicate, it becomes essential to understand how it stands against alternative materials available in the market. A clear comparison can provide insights into making informed decisions concerning material selection.

Zirconium silicate frequently outperforms traditional materials such as feldspar or kaolin when assessing thermal resistance and mechanical strength. For instance, in applications where products face temperature changes, the enhanced stabilizing properties help maintain structural integrity and reduce instances of cracking.

When comparing it to synthetic alternatives, zirconium silicate boasts a significant safety advantage. Many synthetic materials can leach harmful substances during production or use, while zirconium does not present the same level of health risk. This quality makes it a safer option throughout the entire lifecycle, from manufacturing to end-use.

While it is critical to highlight these advantages, it would also be wise to consider some limitations. The initial acquisition costs for zirconium silicate might be higher than those associated with certain traditional materials, which could deter some companies from making the switch. However, many find that the long-term benefits, including improved performance and durability, justify this upfront investment.

| Material | Strength | Thermal Resistance | Cost |

|---|---|---|---|

| Zirconium Silicate | High | Excellent | Moderate |

| Feldspar | Moderate | Moderate | Low |

| Kaolin | Moderate | Low | Low |

| Synthetic Alternatives | Varies | Often low | Varies |

Are There Any Health and Safety Concerns?

Health and safety concerns are paramount in any industrial context, and understanding the implications of working with zirconium silicate is crucial for mitigating risks effectively.

Zirconium silicate, when handled properly, poses relatively low health risks compared to various other mineral compounds. Nevertheless, precautions must be taken, as inhaling fine dust during processing can lead to respiratory irritations. It is essential for personnel involved in the handling and processing of this material to wear appropriate breathing protection and ensure that work areas are well-ventilated.

While the material itself is generally safe, some associated compounds or processing agents used in conjunction with zirconium silicate may carry additional safety risks. Therefore, companies must strive to understand and mitigate these risks through comprehensive safety training and effective workplace practices.

Additionally, ensuring compliance with local and international health regulations is vital. Consistent monitoring for compliance and ongoing education for workers regarding proper handling techniques can enhance the safety environment.

| Concern | Safety Measure |

|---|---|

| Respiratory irritants | Use of masks and proper ventilation |

| Handling & processing | Training programs for employees |

| Associated substances | Regular safety audits and checks |

What Production Techniques Incorporate Zirconium Silicate?

Optimizing production using zirconium silicate involves adopting effective methodologies and techniques that can enhance material properties to their fullest potential. Understanding these production techniques can lead to superior product outcomes.

In the ceramics industry, one particularly common method involves the mixing of zirconium silicate with other key raw materials, which typically occurs in a ball mill. This process ensures effective blending and distribution, which is crucial for enhancing the final product’s characteristics. During the firing phase, controlled temperature management is essential for developing the desired strength and structural integrity.

For glass production, incorporating zirconium silicate requires precise calculations concerning the ratios of materials used in the melting phase. This phase operates at extremely high temperatures, allowing zirconium to intermingle with other constituents to achieve optimal clarity and stability in the final glass product.

Additional techniques also exist within the realm of composite material fabrication, where bonding zirconium with polymers can yield highly resistant materials tailored for specific applications. Each of these methods necessitates specific machinery and a cohesive understanding of the material interactions involved. Investment in modern technology can yield substantial improvements in efficiency and product quality, aligning production processes with industry advancements.

| Production Method | Process | Key Considerations |

|---|---|---|

| Ceramics | Ball milling and firing | Temperature control during firing |

| Glass | High-temperature melting | Ratios of mixtures |

| Composite materials | Blending with polymers | Compatibility assessment |

The image illustrates the ceramics production process, showcasing mixing, shaping, and firing stages.

How Can Businesses Source Zirconium Silicate?

Finding reliable and consistent sources for zirconium silicate is paramount for businesses aiming to successfully integrate this material into their production lines. Establishing solid supplier relationships can provide essential continuity and quality assurance.

The initial step involves conducting thorough research to identify established suppliers active in the market. Investigating their reputations, certifications, and histories in providing zirconium-based materials will help determine their reliability. Additionally, requesting samples can be beneficial; this allows businesses to assess quality before committing to larger orders.

Networking at industry associations and trade shows can also expose businesses to potential suppliers while facilitating valuable connections with others in the zirconium silicate sector. Engaging with seasoned experts in material procurement can further streamline the sourcing process and provide insights into best practices.

It is crucial to prioritize quality over cost when sourcing zirconium silicate. Opting for high-grade materials may incur higher upfront costs, but doing so can lead to longer-lasting, higher-performance products that ultimately provide a strong return on investment.

| Sourcing Method | Advantages | Considerations |

|---|---|---|

| Direct supplier research | Quality assurance and reliability | Requires thorough vetting |

| Networking | Access to new suppliers and industry trends | Time-intensive |

| Sample requests | Evaluation of quality before purchasing | Can slow the procurement process |

What Trends Are Emerging in Zirconium Silicate Usage?

Staying attuned to emerging trends surrounding zirconium silicate usage can greatly benefit businesses seeking to gain a competitive edge. Being aware of these trends allows companies to identify new opportunities in a shifting market landscape.

One notable trend is the increasing demand for green building materials. Many construction projects are actively seeking sustainable options, and zirconium silicate is gaining recognition for its ability to meet environmental standards while delivering exceptional performance. As consumers and businesses alike become more mindful of their ecological footprints, integrating this material into offerings can position companies as leaders in sustainability.

Additionally, innovative advancements in technology and production methods are paving the way for greater efficiency in the utilization of zirconium silicate. Novel approaches in material science frequently enhance the performance characteristics, prompting many manufacturers to reconsider their materials and practices.

Monitoring visible trends as they emerge will help businesses adapt quickly to the evolving market demands and maintain relevance in a competitive sphere.

| Trend | Impact | Future Outlook |

|---|---|---|

| Green building materials | Rising demand within the construction sector | Increased market segmentation |

| Advanced production methods | More efficient material use | Greater adoption of zirconium options |

How Can Businesses Optimize Production with Zirconium Silicate?

For companies, optimizing production processes with zirconium silicate stands to yield significant benefits. Implementing best practices in material handling can lead to enhanced efficiency and improved product quality.

One of the most effective strategies is investing in regular employee training. Equipping workers with knowledge about safe handling practices and the properties of zirconium silicate can minimize errors, optimize resources, and enhance workplace safety.

Also, utilizing modern technology in manufacturing processes is another optimization avenue. Upgrading machinery, adopting new mixing techniques, or investing in state-of-the-art quality control systems can significantly improve the quality of final products while streamlining operations.

Lastly, conducting effective quality control measures is crucial. Establishing robust testing procedures is essential to ensure that every batch of zirconium silicate meets predefined specifications. A proactive approach can save costs associated with poor quality and maintain product integrity, as well as enhance customer satisfaction.

| Optimization Method | Expected Outcome |

|---|---|

| Employee training | Enhanced knowledge and safety |

| Machinery upgrades | Improved material quality and efficiency |

| Quality control measures | Greater consistency in products |

The image highlights the various applications of zirconium silicate in construction materials, showcasing its versatility.

What Are the Cost Implications of Using Zirconium Silicate?

Gaining a clear understanding of the cost implications associated with using zirconium silicate is crucial for effective financial planning. Knowing both the initial investment and long-term costs provides a comprehensive framework for budgeting.

Typically, zirconium silicate commands a premium price compared to some traditional materials on the market. However, many businesses find that the benefits—such as higher durability, longevity, and reduced maintenance costs—generally outweigh the initial expenses. In practice, this can lead to substantial savings over the lifespan of materials, addressing underlying budget concerns that companies may face.

Furthermore, businesses need to factor in the potential costs linked to specialized equipment, training, and operational adjustments when integrating zirconium silicate. These investments can enhance overall efficiency, bolster product quality, and validate the decision to use this valuable material.

Consistently reviewing material costs alongside performance metrics can ensure informed decision-making and allow businesses to optimize their investments.

| Cost Factor | Description |

|---|---|

| Initial Materials Cost | Generally higher than some traditional substitutes |

| Equipment Investment | Costs associated with upgrading machinery |

| Long-term Savings | Reduced need for repairs and replacements |

Conclusion

Integrating zirconium silicate into building materials offers multiple advantages, including enhanced strength, resilience, and cost-effectiveness. Companies that utilize this material often experience fewer replacements and lower maintenance costs, demonstrating a clear return on investment. For businesses interested in exploring high-grade zirconium solutions, Global Industry is here to assist you in identifying suitable materials tailored to your needs. Our dedicated team provides comprehensive support, ensuring your production capabilities meet industry standards and align with modern trends. Contact us today for personalized assistance that can elevate your operational efficiency and product quality.

FAQ Section

Q1: What makes zirconium silicate valuable in building materials?

Zirconium silicate enhances strength, durability, and resistance to weathering, making it a preferred choice in construction.

Q2: Can zirconium silicate improve product lifespan?

Yes, materials incorporating this compound typically exhibit increased lifespan and reduced maintenance needs due to enhanced properties.

Q3: What industries benefit most from zirconium silicate applications?

Various sectors including construction, ceramics, and glass heavily rely on this material for a range of practical applications.

Q4: Are there any specific safety regulations for zirconium silicate use?

Yes, safety regulations vary by region, but consistent guidelines regarding workplace handling and exposure limits are generally enforced.

Q5: How do I find suppliers of zirconium silicate?

Researching industry directories, checking certifications, and requesting samples can help in finding reliable suppliers for this material.