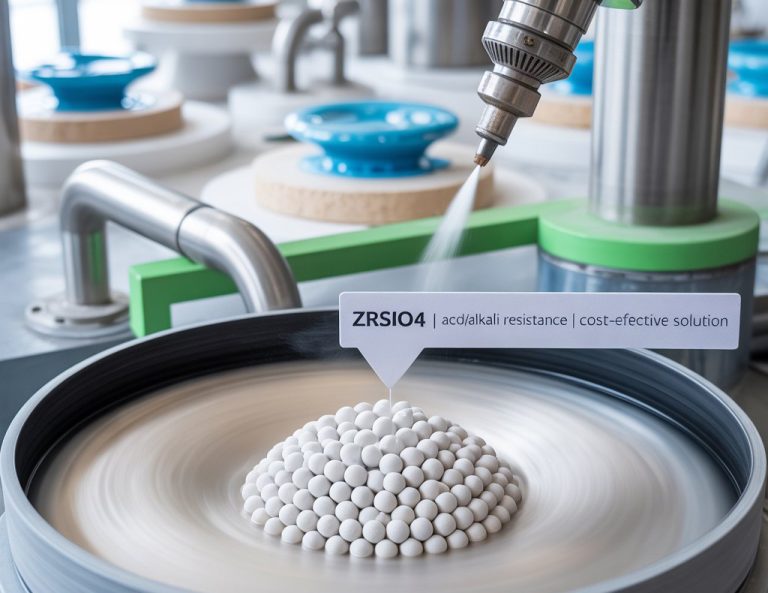

Zirconium silicate beads (chemical formula ZrSiO₄) are high-performance ceramic grinding media known for their cost-effectiveness, moderate hardness (Mohs hardness ~7.5), and excellent chemical stability. Produced from natural zircon sand via high-temperature sintering, they exhibit low metal ion leaching, making them ideal for cost-sensitive grinding applications with moderate contamination tolerance.

Key Features:

| Product Specification |

|---|

| Chemical Composition |

| ZrO₂ | SiO₂ | Others |

|---|---|---|

| ≥65% | 30-35% | ≤1.00% |

Note: Chemical composition depends on specfications

| Physical Charactenstics |

|---|

| Densily | Bulk Density | Vickers Hardness |

|---|---|---|

| >4.1g/cm³ | ≥2.5g/cm³ | >900Hv |

| Specifications(mm) |

|---|

| Ф0.6-0.8 | Ф0.8-1.0 | Ф1.0-1.2 | Ф1.2-1.4 | Ф1.4-1.6 |

| Ф1.6-1.8 | Ф1.8-2.0 | Ф2.5-3.0 | Ф3.0-3.5 | Ф4 |

| Ф5 | Ф6 | Ф7 | Ф8 | Ф10 |

Note: Specificafions can be customized to customer’s requirements.

Quality, delivery, technology, all in one place!.

Email us: sales01@qglobalindustry.com