Zirconium silicate plays a vital role in multiple industries, yet ensuring its quality can pose several challenges. Laboratories often grapple with identifying the most effective techniques for accurately analyzing this material. Selecting the right laboratory method is crucial for quality assurance, influencing everything from product performance to customer satisfaction. This article sheds light on the best laboratory techniques for analyzing zirconium silicate quality. We present practical insights from industry experts, establishing credibility in the methodologies discussed. You’ll gain a solid understanding of how various techniques can enhance your analysis processes, providing a pathway to more reliable outcomes.

An image showing zirconium silicate samples being analyzed in a laboratory, demonstrating the analytical processes described.

What Are the Key Laboratory Techniques for Zirconium Silicate Analysis?

The analysis of zirconium silicate revolves around several key techniques that ensure accuracy and reliability in results. These methods reflect the demands of both quality control and research environments.

First, X-ray Fluorescence (XRF) stands out as one of the leading methods for elemental analysis. It offers quick and non-destructive analysis, allowing laboratories to assess the elemental composition of zirconium silicate effectively. XRF excels in determining trace elements, which can be critical for evaluating quality standards. When manufacturers are faced with tight deadlines or require immediate insights, this method can provide fast feedback, crucial for production processes.

Scanning Electron Microscopy (SEM) is another integral technique. It provides high-resolution images that help in understanding the morphology of zirconium silicate particles. SEM can support the investigation of surface structures, highlighting features that influence material properties. This technique complements XRF by adding a visual dimension to the analysis. For example, manufacturers can observe particle sizes, shapes, and surface textures, enhancing their understanding of how these factors affect end-product performance.

Next, Inductively Coupled Plasma Mass Spectrometry (ICP-MS) offers sensitivity that few other methods can match. It measures trace elements at parts per trillion levels, essential for industries requiring stringent purity metrics. With its high precision, ICP-MS can detect even the smallest impurities that could compromise product quality. This level of accuracy is especially beneficial for electronics and aerospace applications, where material integrity is paramount.

Lastly, chemical analysis techniques further certify quality by assessing chemical composition. Laboratories often employ techniques like titration or gravimetric analysis to quantify specific components. These methods can identify unwanted impurities and ensure that the zirconium silicate meets necessary specifications. Combining these techniques can create a robust framework for quality testing in zirconium silicate.

| Laboratory Technique | Key Benefit | Application |

|---|---|---|

| X-ray Fluorescence | Quick and non-destructive analysis | Elemental composition |

| Scanning Electron Microscopy | High-resolution imagery | Morphological analysis |

| Inductively Coupled Plasma Mass Spectrometry | Extreme sensitivity | Trace impurity detection |

| Chemical Analysis Techniques | Accurate chemical composition measurement | Quality verification |

How Does X-ray Fluorescence (XRF) Work for Zirconium Silicate?

X-ray Fluorescence (XRF) is a powerful analytical technique frequently used to determine the elemental composition of materials, including zirconium silicate. Understanding its operational mechanism can clarify why it is favored in analytical laboratories.

XRF operates by directing X-rays onto a sample, causing atoms in the zirconium silicate to emit secondary X-rays. Each element produces characteristic X-rays corresponding to its unique atomic structure, which are subsequently collected to yield precise elemental identification and quantification.

By maximizing the resolution of results, XRF provides several notable benefits.

- Speed of Analysis: Laboratories can receive results in minutes, expediting decision-making processes.

- Minimal Sample Preparation: Often requiring only surface cleaning, this method saves time and reduces the risk of contamination.

- Non-destructive Nature: Analyzing samples without altering their physical state preserves them for future testing, essential for iterative processes.

However, while XRF has many advantages, it’s not without limitations. It may struggle with detecting certain light elements like lithium, beryllium, or boron. But here’s the catch—these limitations can often be mitigated by incorporating complementary techniques, thereby enhancing overall analysis quality.

| Aspect | Description |

|---|---|

| Analysis Time | Minutes |

| Sample Preparation | Minimal |

| Element Detection Limitations | Light elements (Li, Be) |

| Non-destructive | Yes |

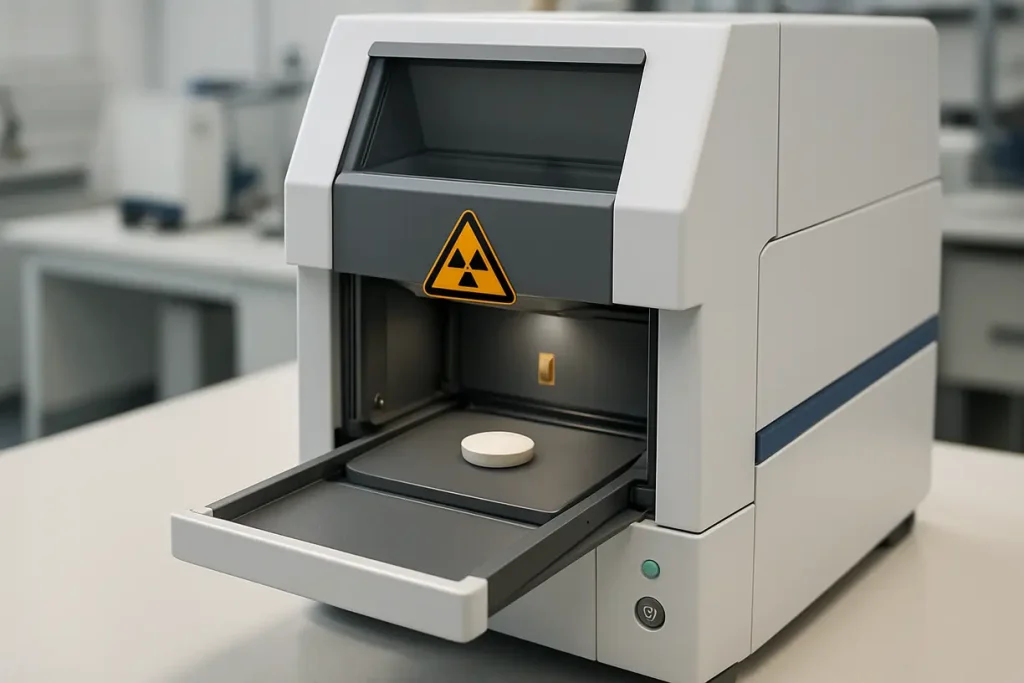

A laboratory XRF machine in action, showcasing the analysis of zirconium silicate samples.

What is the Role of Scanning Electron Microscopy (SEM)?

Scanning Electron Microscopy plays a critical role in the analysis of zirconium silicate. This technique provides invaluable insights into the material’s physical characteristics, including morphology and particle size, vital for applications in ceramics and refractories.

SEM utilizes a focused beam of electrons to scan the surface of a sample. When electrons interact with the sample, various signals are produced, which are then detected to create highly detailed images of the sample’s surface. This imaging capability allows researchers to visualize fine details at the micron and even nanometer scales. As an added bonus, modern SEMs can also include energy-dispersive X-ray spectroscopy (EDS) attachments, facilitating simultaneous elemental analysis.

One of the primary benefits of using SEM is its ability to uncover the topographical features of zirconium silicate particles. Understanding particle shapes and sizes can significantly influence the behavior of zirconium silicate in different applications, including thermal stability and flow properties. For instance, a uniform particle size can lead to improved performance in ceramics, while irregular shapes might affect product consistency in manufacturing.

Moreover, SEM can help identify potential defects in the zirconium silicate, such as cracks or inclusions. Recognizing these defects early in the production cycle can save costs and avoid product recalls later. So, what are the limits? SEM requires careful sample preparation, and the equipment can be expensive to operate and maintain, which can be a consideration for some laboratories.

| Feature | SEM Benefit | EDS Complement |

|---|---|---|

| Resolution | High-resolution imaging | Elemental analysis |

| Surface Characteristics | Detailed visual insights | Chemical composition determination |

| Particle Size Analysis | Critical for product performance | Quality checks |

How Does Inductively Coupled Plasma Mass Spectrometry (ICP-MS) Help?

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is regarded as one of the most sensitive analytical techniques available. Its ability to detect trace elements with extreme precision makes it an indispensable tool for analyzing zirconium silicate quality.

ICP-MS operates by ionizing the sample using an inductively coupled plasma, creating charged particles. These ions are then sorted and measured based on their mass-to-charge ratio. This process allows scientists to detect elements at incredibly low concentrations, which is vital for industries that demand high purity. For instance, regarding high-tech applications like electronics, even trace contamination can lead to product failure.

The workflow of ICP-MS begins with sample introduction, usually through a nebulizer that converts the liquid into an aerosol. This aerosol is then transported into the plasma, which ionizes the sample. After ionization, the ions travel through a series of lenses into a mass analyzer. Here’s a tip—the entire process is incredibly quick, often providing results in less than an hour.

However, ICP-MS is not without its challenges. Sample preparation must be performed meticulously to avoid contamination, and the equipment demands a high level of maintenance. Additionally, while it excels at determining many elements, operational costs can be significant due to the specialized training and maintenance required. Still, the benefits far outweigh the drawbacks when it comes to ensuring zirconium silicate’s quality.

| ICP-MS Feature | Description |

|---|---|

| Detection Limit | Parts per trillion |

| Sample Type | Solutions or solids |

| Common Applications | Environmental analysis, materials testing |

What Techniques Are Used for Physical Property Testing?

Physical property testing is a fundamental aspect of ensuring zirconium silicate quality. This testing focuses on parameters like density, melting point, and thermal stability, all of which can significantly affect performance.

Density testing involves measuring the mass of a unit volume of zirconium silicate. Accurate density measurements can help predict how the material will behave during manufacturing processes. For example, a material with a higher density may be more durable but could also alter processing conditions.

Similarly, understanding the melting point of zirconium silicate informs manufacturers about the conditions under which the material will perform optimally. This data can be critical in applications like glass production, where failure to reach the appropriate melting temperature can compromise the final product.

Another important aspect is thermal stability, which is assessed through techniques such as Thermal Gravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC). TGA measures weight loss as a function of temperature, providing insight into thermal stability. This allows manufacturers to ascertain how zirconium silicate will behave under varying thermal conditions.

Moreover, physical property testing can significantly benefit from compiling comparative data across different samples. By evaluating and comparing properties, laboratories can establish thresholds for acceptable quality in zirconium silicate.

| Physical Property | Testing Method | Importance |

|---|---|---|

| Density | Hydrostatic weighing | Affects manufacturing behavior |

| Melting Point | Differential Thermal Analysis (DTA) | Performance profiling |

| Thermal Stability | TGA and DSC | Identifies phase changes |

How Can Thermal Analysis Be Utilized?

Thermal analysis techniques like TGA and DSC play pivotal roles in analyzing the thermal behavior of zirconium silicate. Understanding these thermal properties is essential for ensuring quality and performance.

Thermogravimetric Analysis (TGA) measures the change in weight of a sample as it is heated. This technique provides crucial information about weight loss due to moisture loss or decomposition. In the context of zirconium silicate, TGA can reveal temperatures at which the material begins to lose stability or undergo phase changes, enabling manufacturers to optimize production processes and conditions.

Differential Scanning Calorimetry (DSC) complements TGA by measuring heat flow. This technique identifies heat capacity and thermal transitions such as melting and crystallization points. For zirconium silicate, understanding these transitions can guide the production of end products with desired properties. In some instances, manufacturers use DSC to fine-tune formulations to better match application needs.

One major benefit of combining TGA and DSC results is that they provide a comprehensive understanding of thermal behavior. This data can help in predictive modeling for how zirconium silicate behaves under various processing conditions, ensuring that manufacturing parameters are aligned with performance requirements.

| Method | Key Focus | Application |

|---|---|---|

| Thermogravimetric Analysis (TGA) | Weight changes over temperature | Moisture content analysis |

| Differential Scanning Calorimetry (DSC) | Heat flow variations | Identifying thermal transitions |

What Are the Best Practices for Sample Preparation?

Sample preparation is crucial for reliable analytical results in zirconium silicate analysis. Properly preparing samples can significantly influence the quality and accuracy of test outcomes.

The first step involves drying the sample to remove any moisture. This is particularly vital because moisture can interfere with various analytical methods, especially those measuring weight or concentration. Once dried, the sample should be ground to a fine consistency. Achieving a uniform particle size enhances the accuracy of analytical results, as inconsistencies may lead to variations in responses during tests.

Best Practices in Sample Preparation:

- Samples should be handled in a clean environment: Contaminated samples can yield unreliable results and erode trust in the data.

- Use consistent tools and procedures: Standardizing preparation methods helps ensure that analysis remains consistent across batches.

- Reference materials should be included: Utilizing standard reference materials not only helps calibrate equipment but serves as a benchmark for evaluating test results against set quality standards.

Finally, employing best practices during sample preparation can lead to a more accurate representation of the material, ultimately enhancing the reliability of the analysis.

| Sample Preparation Steps | Consideration |

|---|---|

| Drying | Remove moisture, prevent bias |

| Grinding | Achieve consistency |

| Avoiding Contamination | Use clean tools and containers |

| Calibration | Utilize standard reference materials |

This image depicts a clean laboratory environment set up for sample preparation of zirconium silicate.

How Do Chemical Analysis Techniques Complement Testing?

Chemical analysis techniques are essential for complementing physical property evaluations in zirconium silicate. These methods assess the material’s chemical composition, which directly influences its quality.

Techniques such as titration and gravimetric analysis are frequently used in laboratories. Titration determines specific chemical components by reacting them with a reagent to obtain a measurable response. For zirconium silicate, this method can establish the concentration of certain oxides, which are critical for product specifications.

Gravimetric analysis complements titration by measuring mass changes as a result of specific chemical reactions. This method is often employed to quantify the amount of zirconium present in a sample. Using both methods provides a more comprehensive understanding of chemical composition, confirming that zirconium silicate meets required standards.

Laboratories may also employ spectroscopic methods, such as atomic absorption spectroscopy (AAS), for further verification of chemical composition. This multi-faceted approach to chemical testing not only enhances the accuracy of the data but also builds confidence in compliance with industry regulations.

| Chemical Technique | Key Benefit |

|---|---|

| Titration | Determines specific component concentrations |

| Gravimetric Analysis | Quantifies mass changes |

| Spectroscopic Methods | Provides additional verification of data |

What Challenges Do Laboratories Face in Zirconium Silicate Testing?

Laboratories face several challenges when analyzing zirconium silicate. These challenges can impact the credibility of results and the efficiency of testing.

First, maintaining sample integrity throughout the testing process is crucial. Contamination during handling or preparation can skew results, leading to significant discrepancies between actual and reported data. Additionally, varying sample characteristics, such as moisture content or particle distribution, can complicate analyses, making consistent results difficult to achieve.

Another challenge relates to the complexity of methods employed. Some techniques require sophisticated equipment and considerable training. This can lead to increased operational costs and the potential for human error. Establishing clear protocols that minimize errors is vital for achieving reliable results.

Frequent equipment maintenance and calibration are necessary. Sensitive devices like ICP-MS and SEM must be regularly serviced to ensure accurate measurements. Color changes in solutions or shifts in measurement readings can indicate a malfunction, requiring immediate attention.

To address these challenges, laboratories should foster a culture of continuous training and compliance with standard operating procedures. Regular workshops and knowledge-sharing sessions can keep all staff updated on best practices, reducing errors and enhancing overall laboratory performance.

| Challenge | Description |

|---|---|

| Sample Integrity | Risk of contamination |

| Complexity of Methods | Need for trained personnel |

| Equipment Maintenance | Requirement for frequent calibration |

How to Choose the Right Laboratory for Zirconium Silicate Testing?

Selecting the appropriate laboratory for zirconium silicate testing is paramount for ensuring high-quality results. But what should decision-makers consider during this process?

First, evaluating a laboratory’s experience and reputation in the field is essential. Laboratories that specialize in mineral analysis and have a history of reliable results will likely provide superior services. Checking industry affiliations can also indicate a laboratory’s level of commitment to quality standards.

Next, certifications and accreditations matter significantly. Look for labs that comply with industry standards. Accreditation from recognized organizations, such as ISO standards, indicates a commitment to quality and reliability. These certifications can often open doors to collaboration and provide greater market credibility.

Furthermore, consider the technological capabilities of the laboratory. Advanced techniques and state-of-the-art equipment are essential for high-precision analysis. Inquire about the laboratory’s capability to perform multiple testing methods to ensure comprehensive analytical support.

Lastly, compare turnaround times and customer service reputations between potential laboratories. Engaging with labs often leads to better partnerships and smoother communications, which can prove invaluable in high-stakes analysis scenarios.

| Consideration | Details |

|---|---|

| Experience | Specialization in mineral analysis |

| Certifications | ISO or similar standards |

| Technological Capabilities | Access to advanced equipment and methods |

Conclusion

This article has highlighted the essential laboratory techniques for analyzing zirconium silicate quality, focusing on methods like XRF, SEM, and ICP-MS. By leveraging these techniques, laboratories can ensure high-quality outputs that meet industry standards. The precise control over quality provided through these methods enables manufacturers to reduce errors and improve their products. At Global Industry, we encourage you to implement these practices in your analytical procedures. For additional resources, consider visiting our website for in-depth articles and expert insights that can further enhance your analytical capabilities.

FAQ Section

Q1: What is zirconium silicate used for? Zirconium silicate is primarily used in ceramics, refractories, and as a pigment in various applications.

Q2: Why is quality analysis of zirconium silicate important? Quality analysis ensures that zirconium silicate meets industry specifications, which affects product performance and reliability.

Q3: What is the most effective technique for zirconium silicate analysis? There isn’t a one-size-fits-all technique; the best method often combines several approaches like XRF and SEM.

Q4: How do I prepare a zirconium silicate sample for testing? Sample preparation involves drying, grinding, and sizing to ensure consistency and accuracy in analysis.

Q5: What should I consider when selecting a lab for zirconium silicate testing? Look for experience, certifications, technological capabilities, and reviews from previous clients to ensure reliability.