In the rapidly changing field of ceramics, manufacturers face numerous challenges that can significantly hinder product quality and performance. This dynamic environment requires constant adaptation to market demands, technical advancements, and customer expectations. Many professionals seek materials that enhance durability while meeting stringent production demands. Zirconium silicate offers a viable and effective solution to address these needs. This versatile compound enhances the strength and longevity of ceramic products, allowing for innovation in both design and functionality. By incorporating this material into their processes, businesses can achieve superior results that satisfy not only technical specifications but also customer preferences.

This article provides a deep insight into its applications, advantages, and effectiveness in transforming advanced ceramics. With real-world examples and credible insights, readers will gain a clearer understanding of how to harness this material for optimal performance in ceramics.

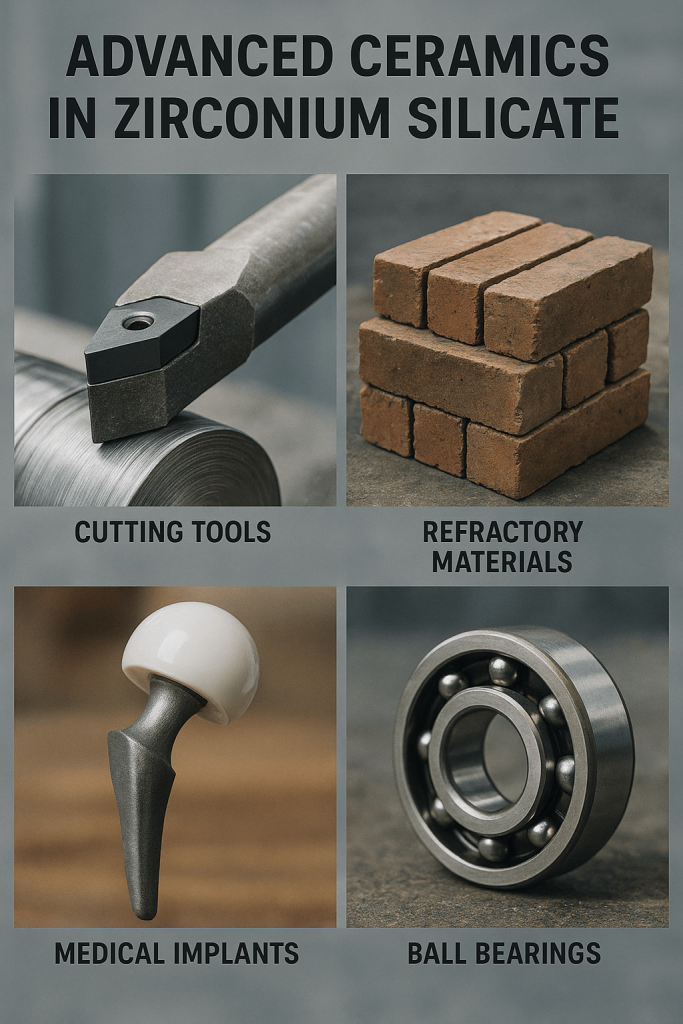

This image shows various advanced ceramic applications that utilize zirconium silicate for enhanced performance and durability.

How Does Zirconium Silicate Improve Ceramic Performance?

Zirconium silicate boasts properties that significantly enhance ceramic performance in a variety of applications. Its high strength, chemical stability, and resistance to thermal shock make it an excellent choice for various uses, especially in environments where traditional materials may fail.

The material’s unique structural properties, featuring a complex crystalline arrangement, contribute to its impressive mechanical characteristics. This structural integrity allows zirconium silicate to absorb and dissipate stress more effectively, which is crucial for maintaining the performance of ceramics in demanding situations. This structure not only increases the hardness of the ceramics but also improves their ability to withstand sudden temperature changes without cracking or deforming. This durability is essential for applications in industries such as aerospace and automotive, where components must operate under extreme conditions, including high heat and mechanical stress.

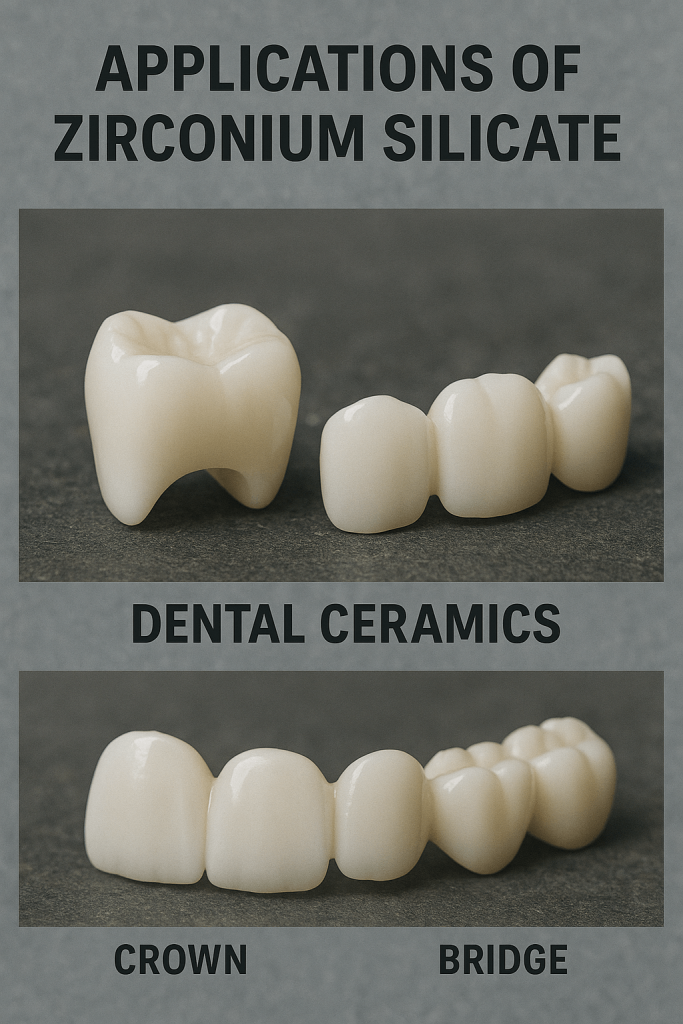

In detail, the inclusion of zirconium silicate strengthens ceramics by providing better resistance against wear and tear, which is especially beneficial in applications requiring the long-term durability of products. Items such as dental prosthetics, which endure significant daily wear, and industrial machinery parts are just a few examples that benefit immensely from this added durability. Manufacturers in these fields can see a substantial reduction in repair and replacement costs due to the longevity of products made with zirconium silicate, enhancing their overall profitability.

Here’s a comparison: Standard ceramic materials tend to fracture or degrade more frequently in high-stress environments. In contrast, ceramics enhanced with zirconium silicate stand up to these challenges, showcasing better performance over time. This capability not only enhances customer satisfaction but also strengthens the reputation of manufacturing companies that prioritize high-quality materials.

Given its growing recognition as a key additive, it’s clear that its established success across various industries proves it to be an invaluable asset for improving overall product quality and ensuring reliability in challenging situations. By leveraging these advantages, manufacturers can confidently meet the increasing demands of their respective markets.

What Are the Key Applications of Zirconium Silicate in Ceramics?

The versatility of zirconium silicate allows it to find numerous applications across different sectors. Its unique properties make it particularly valuable in various ceramic products that require durability and aesthetic appeal.

One of the most notable applications lies within dental ceramics. Zirconium silicate is widely used to create crowns, bridges, and veneers due to its aesthetic appeal and mechanical strength. Dentists and dental technicians appreciate how this material closely mimics the appearance of natural tooth enamel, while also standing up to the biting forces encountered in everyday use. Its biocompatibility further enhances its role in dental applications, making it a preferred choice.

In industrial ceramics, zirconium silicate is utilized in the production of floor tiles, sanitary ware, and components for electrical insulation. These applications benefit from the material’s thermal stability and chemical durability, allowing for robust products that can withstand both mechanical stress and environmental exposure.

Electronic manufacturers often rely on zirconium silicate in dielectric materials, which serve critical roles in capacitors and insulators. The stability and insulating properties contribute to better-performing electronic devices, especially in high-frequency applications where reliability is paramount.

Here’s an overview of key applications:

| Application Area | Specific Use |

|---|---|

| Dental Ceramics | Crowns, bridges, veneers |

| Industrial Ceramics | Floor tiles, electrical insulation parts |

| Electronics | Capacitors, insulating materials |

With applications spanning these crucial industries, the versatility of zirconium silicate underscores its essential role in advancing ceramic technology.

This image depicts the application of zirconium silicate in dental ceramics, showcasing crowns and bridges made with this material.

How Does Zirconium Silicate Affect Manufacturing Processes?

The influence of this compound on manufacturing processes is profound and cannot be understated. Integrating zirconium silicate can lead to enhanced production metrics and improved cost efficiencies.

First and foremost, zirconium silicate improves processing speeds. Its excellent mixing properties allow for easier integration with other materials, ensuring a more uniform product in less time. This efficiency is vital in high-volume production scenarios, where time is money, and delays can significantly impact profitability.

Moreover, this additive minimizes waste during production. Ceramic materials that include zirconium silicate are less likely to crack or fail during processing, which can result in fewer rejected batches. This reliability translates into lower costs for manufacturers, as they can allocate resources more effectively and reduce the amount of raw materials wasted.

Here’s what you might be overlooking: Utilizing zirconium can lead to improved resource allocation, where fewer raw materials wasted means a more sustainable production model. The ability to create more resilient and uniform products positively impacts inventory management and customer satisfaction.

When manufacturers implement the use of zirconium silicate, they enhance not only output but also product quality. This improvement aids companies in maintaining a competitive edge, allowing them to meet customer expectations and industry standards without compromising on performance.

| Factor | Traditional Method | Method with Zirconium Silicate |

|---|---|---|

| Processing Time | Longer | Shorter |

| Waste Rates | Higher | Lower |

| Resource Efficiency | Moderate | Enhanced |

This table summarizes the transformative effects this compound brings to the production landscape, highlighting its importance in modern manufacturing.

What Benefits Does Zirconium Silicate Offer Over Alternatives?

When evaluating materials for ceramic applications, the numerous benefits of zirconium silicate become apparent. Manufacturers often weigh their options carefully, and this material frequently stands out among alternatives.

First, its superior mechanical strength serves as a significant advantage. While common alternatives may crack or deteriorate more quickly under stress, zirconium maintains its integrity longer. This property translates to enhanced product lifespan and a reduced need for customer replacements, promoting brand loyalty and trust among consumers.

Another critical advantage lies in the material’s inherent thermal stability. Competing materials can struggle to maintain performance under high temperatures, leading to premature failure and costly downtimes. Zirconium-based products, on the other hand, are designed to withstand extreme environmental conditions, providing reliable solutions for a range of industries.

Consider this: case studies have shown that products made with zirconium silicate consistently outperform those crafted from traditional materials over time. This reliability builds credibility with end users and can lead to increased sales, reinforcing the value of investing in high-quality components.

Here are some comparative attributes that showcase the benefits of zirconium silicate:

| Attribute | Zirconium Silicate | Alternatives |

|---|---|---|

| Mechanical Strength | High | Moderate to Low |

| Thermal Stability | Excellent | Often Limited |

| Lifespan | Extended | Shorter |

By choosing zirconium silicate, businesses are not just selecting a material; they are investing in products that promise superior performance and customer satisfaction.

How Can Companies Integrate Zirconium Silicate into Their Products?

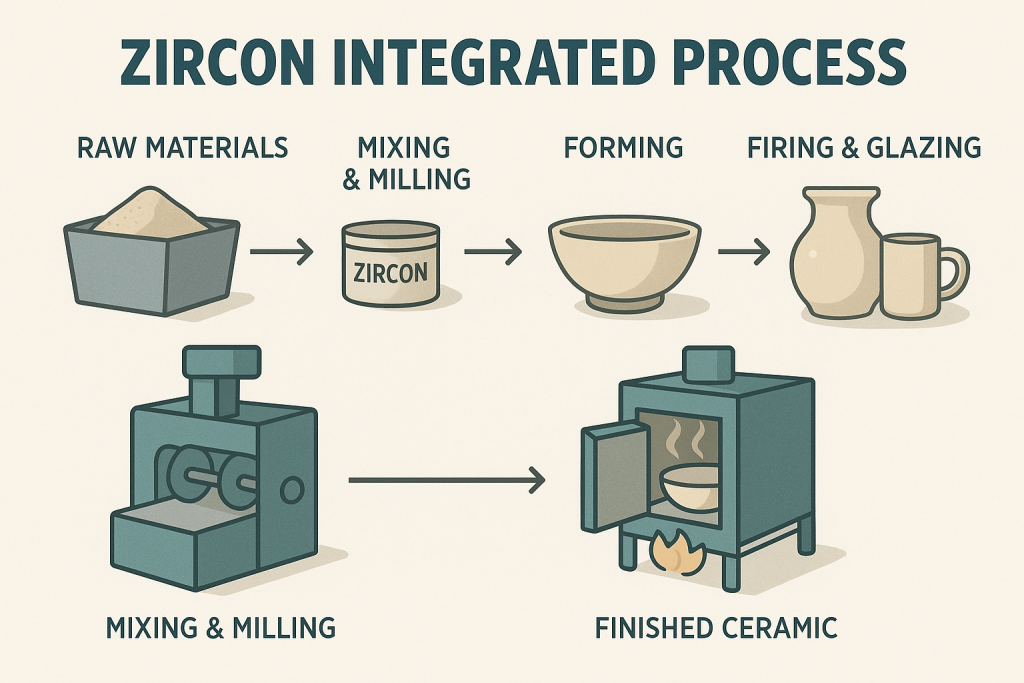

Integrating zirconium silicate into existing product lines requires strategic planning and careful consideration. Companies must understand their specific requirements and how this compound can enhance their offerings.

Initially, it is essential to assess the current production processes. Evaluate how incorporating this additive will impact existing materials and the overall production workflow. Understanding these dynamics will help manufacturers adapt their recipes while maximizing the benefits of the new material.

Next, manufacturers should collaborate with suppliers who possess experience in zirconium applications. These partnerships provide access to valuable insights and guidance regarding best practices for integration. Such cooperation can help address potential challenges and enable a smoother transition to incorporating zirconium into the production lineup.

This image illustrates the process of integrating zirconium silicate into ceramic manufacturing workflows.

Furthermore, companies should conduct thorough testing on mixed products to monitor performance during trials. Collecting data on how products behave under different conditions will be crucial in determining optimal proportions of zirconium silicate to use for the best outcomes.

In summary, successful integration requires:

- Comprehensive evaluation of current processes to identify potential improvements.

- Strong partnerships with knowledgeable suppliers who can provide necessary guidance.

- Rigorous testing for best outcomes, ensuring that performance meets or exceeds expectations.

When approached strategically, the integration of zirconium silicate can yield substantial returns on investment, as its benefits become evident in product quality and customer satisfaction.

What Are the Environmental Impacts of Using Zirconium Silicate?

Addressing environmental concerns has become a vital consideration for many businesses in recent years. The use of zirconium silicate brings both opportunities and challenges in this area.

One notable aspect is the sourcing of zirconium. Responsible extraction practices are crucial. When sourced sustainably, zirconium can contribute to a smaller ecological footprint compared to other materials. Companies that prioritize ethical sourcing can bolster their reputation among environmentally-conscious consumers while positively impacting the environment.

In production, manufacturers can achieve eco-friendliness through reduced waste. As established earlier, zirconium enhances material performance, which leads to fewer rejections and overall lower resource consumption.

Another important consideration involves adherence to regulatory standards. Companies must ensure they follow local and international guidelines related to zirconium usage. Compliance builds trust with stakeholders and demonstrates a commitment to environmental stewardship.

It’s worth noting: the trend toward sustainability in manufacturing continues to grow. Companies adopting eco-friendly practices are generally more appealing to customers who prefer to work with environmentally responsible businesses.

In summary, zirconium silicate can contribute positively to these goals when managed responsibly. Its properties enable manufacturers to produce high-quality products while minimizing environmental impact.

| Impact Area | Aspect | Concern/Opportunities |

|---|---|---|

| Sourcing | Sustainable practices | Positive environmental impact |

| Production Waste | Reduced | Eco-friendly manufacturing |

| Regulatory Standards | Compliance | Enhances company credibility |

This table emphasizes the environmental considerations surrounding the use of this material, showcasing its potential positive impact when integrated thoughtfully.

How Do Industry Trends Influence Zirconium Silicate Utilization?

Staying abreast of industry trends is vital for the successful implementation of zirconium silicate. Emerging technologies and changing customer preferences shape the future of this material’s utilization.

One key trend is the increasing demand for high-performance ceramics across various sectors. Industries such as aerospace and automotive are driving this change, requiring materials that can withstand extreme conditions and offer enhanced performance characteristics. The growth of these industries directly influences the demand for materials like zirconium silicate that offer reliable solutions.

Technological advancements are also impacting how zirconium is processed and utilized. New manufacturing techniques enhance efficiency and allow for better integration into composite materials, leading to improved production methods and product designs.

As part of this trend: original equipment manufacturers (OEMs) are investing heavily in research and development related to zirconium use, exploring ways to improve its properties for specific applications. This commitment to innovation leads to new products and expands its application across various domains, contributing to advancements in ceramics.

Here’s a look at current industry trends shaping zirconium utilization:

| Trend | Description | Implications |

|---|---|---|

| High-Performance Demand | Growth in aerospace/automotive | Expands the applicability of zirconium |

| Technological Advancements | Enhanced processing techniques | Increases production efficiency |

These trends indicate a promising future for zirconium components, particularly in advanced ceramics, as various sectors evolve and demand innovation.

What Should Decision-Makers Know About Zirconium Silicate?

Decision-makers need to be well-informed about zirconium applications when considering its use in their products. Understanding key factors can empower purchasing managers to make educated choices that benefit their organizations.

Start by carefully evaluating current supplier relationships. A supplier’s expertise in this area can greatly affect the performance and quality of the final products. Look for partners who have a proven track record of producing high-quality products with zirconium in mind.

Consider the long-term implications of investing in this material. Integrating zirconium can improve immediate performance but also contributes lasting value through durability, reduced maintenance costs, and increased customer satisfaction.

It’s often recommended that decision-makers ask these questions during sourcing:

- What testing procedures do you employ for zirconium use?

- Can you provide references or case studies showcasing previous success in zirconium applications?

- What levels of support do you offer for companies new to using this material?

These inquiries guide informed decisions, ensuring alignment between suppliers and business objectives, ultimately leading to successful outcomes.

| Question | Purpose |

|---|---|

| Testing procedures | Assures product quality |

| References/case studies | Validates supplier capability |

| Support for new users | Helps ease the transition to utilizing zirconium |

Taking these steps can lead to valuable partnerships and outcomes, enhancing a company’s competitive position in the market.

Conclusion

Throughout this article, we have explored how zirconium silicate can transform advanced ceramic applications. We identified its remarkable properties, key applications, and benefits that stand out against traditional materials. By integrating this compound, businesses can enhance durability and efficiency while effectively reducing costs, which leads to better overall product offerings. For those ready to elevate their ceramic products, Global Industry stands prepared to support you in sourcing high-quality materials. Partner with us to discover concrete pathways to enhanced ceramic solutions, and ensure your products meet the highest standards of performance and durability. We are committed to helping you achieve your goals.

FAQ Section

Q1: What properties make zirconium silicate special?

Zirconium silicate is renowned for its high strength and exceptional durability. It also exhibits remarkable resistance to thermal shock, which enables it to maintain structural integrity under rapid temperature changes. This combination of properties makes it an ideal choice for applications in various industrial sectors, including aerospace and ceramics.

Q2: Why is zirconium silicate preferred in dental ceramics?

Zirconium silicate is preferred in dental applications due to its outstanding aesthetic qualities, closely mimicking natural tooth enamel. Additionally, its mechanical properties allow for durable and long-lasting dental restorations that can withstand biting forces without significant wear. Its biocompatibility is another crucial factor, ensuring safety and comfort for patients.

Q3: How does zirconium silicate impact manufacturing efficiency?

Integrating zirconium silicate can significantly enhance manufacturing efficiency by improving processing speeds and simplifying the mixing of materials. This results in faster production times and fewer defects during processing, leading to a reduction in waste. Consequently, manufacturers can achieve cost savings while maintaining high-quality standards in their final products.

Q4: Are there any risks associated with using zirconium silicate?

Potential risks include challenges related to sourcing practices, as the extraction of zirconium must adhere to ethical and sustainable standards. Additionally, companies must ensure compliance with local and international regulations concerning zirconium usage, as failure to do so can affect their market access and reputation. Addressing these risks is crucial for maintaining credibility.

Q5: What future developments can we expect in zirconium silicate applications?

Future developments in zirconium silicate applications may include advancements in processing technologies that enhance its properties, such as increased durability and improved integration into composite materials. Ongoing research is also likely to focus on expanding its use in emerging sectors, such as biomedical devices and high-performance electronics, thus broadening its market potential.