In the world of materials used for bonding and adhesion, zirconium silicate is a prominent choice due to its unique properties. However, many professionals encounter challenges related to its adhesion capabilities. This article addresses these concerns by exploring effective methods you can use to enhance zirconium silicate’s adhesion properties. You will discover practical solutions that can improve performance, leading to better outcomes in applications such as coatings and composites. Our insights are backed by industry expertise, ensuring you receive reliable and actionable information that can significantly enhance the effectiveness of your materials.

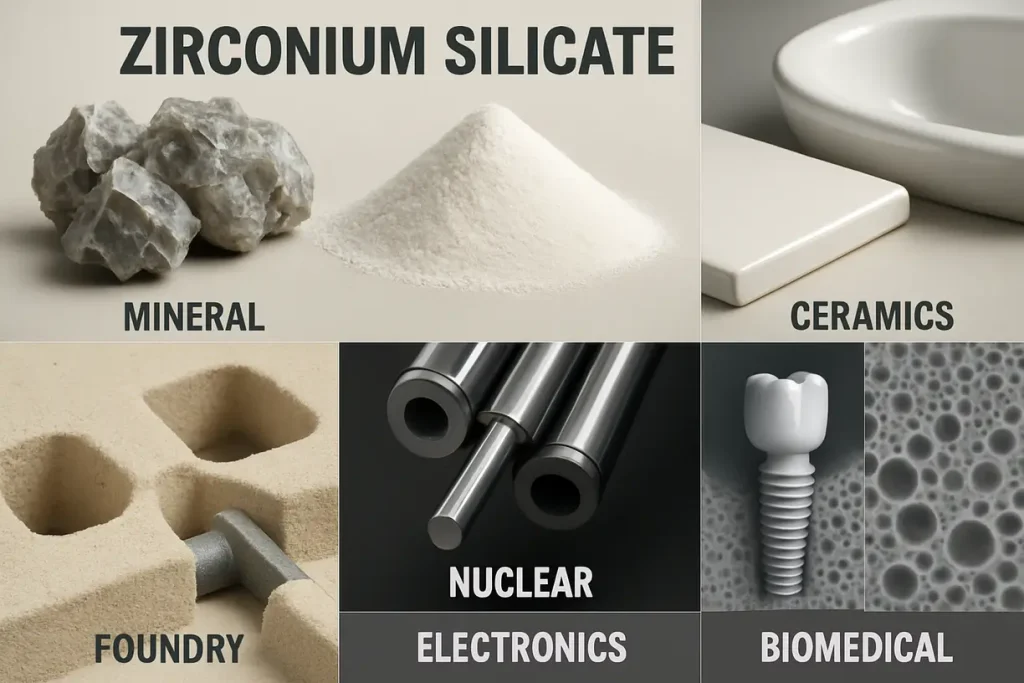

This image illustrates different forms of zirconium silicate used in various applications.

How Does Zirconium Silicate Function in Adhesion?

Zirconium silicate plays a critical role in various industries, particularly in manufacturing ceramics, glass, and paints. It acts as a bonding agent, providing strength and durability. In simple terms, when zirconium silicate is used in products, it helps create a strong connection between materials, enhancing the overall performance and longevity of the final product.

Understanding how zirconium silicate functions begins with its chemical composition. It primarily consists of zirconium oxide and silicon dioxide, which contribute to its stability and resistance to thermal shock. These qualities make it an excellent candidate for applications where adhesion strength is vital, particularly in environments exposed to high temperatures or mechanical stress.

Additionally, zirconium silicate exhibits notable chemical resistance. This makes it suitable for use in aggressive environments, such as chemical processing or marine applications, where exposure to corrosive substances is a concern.

Moreover, zirconium silicate is known for its compatibility with different substrates. This flexibility makes it highly versatile, allowing it to be used in various formulations. For example, in ceramic tiles, this material helps ensure that the glaze bonds effectively to the body of the tile, leading to a smoother finish and enhanced durability.

Zirconium silicate’s functionality can be summarized in the following key points:

- Bonding Agent: Creates strong connections between various materials.

- Thermal Resistance: Withstands high temperatures without losing adhesion strength.

- Chemical Resistance: Maintains performance in corrosive environments.

- Versatility: Compatible with a range of substrates for diverse applications.

This substance’s importance cannot be understated. It serves as an essential component in enhancing adhesion properties across multiple industries, paving the way for better performance in applications that rely on effective bonding.

What Factors Affect Zirconium Silicate’s Adhesion?

Understanding what affects zirconium silicate’s adhesion properties is crucial for improving performance. Several factors come into play.

First, the chemical composition of zirconium silicate itself can impact its adhesive abilities. The ratios of zirconium oxide and silicon dioxide and the presence of impurities can all influence how well it bonds to other materials. If the composition is not optimized, the material may fail to adhere properly.

Next, physical attributes play a significant role. The particle size, shape, and distribution of zirconium silicate affect how it interacts with the materials it bonds. Smaller particles generally increase surface area, enhancing adhesive strength. Conversely, larger particles may lead to poor adhesion due to inadequate contact with substrates.

Environmental factors, such as moisture and temperature, also affect adhesion. Higher humidity can lead to hydrolysis, reducing bond strength. Similarly, extreme temperatures can alter the properties of the adhesive or the substrates, leading to potential failure.

By paying attention to these critical factors, you can effectively enhance the adhesion qualities of zirconium silicate in your applications.

| Factor | Impact on Adhesion |

|---|---|

| Chemical Composition | Affects bonding potential |

| Particle Size and Shape | Influences surface contact area |

| Environmental Conditions | Can enhance or weaken adhesion |

How Can Surface Treatments Improve Adhesion?

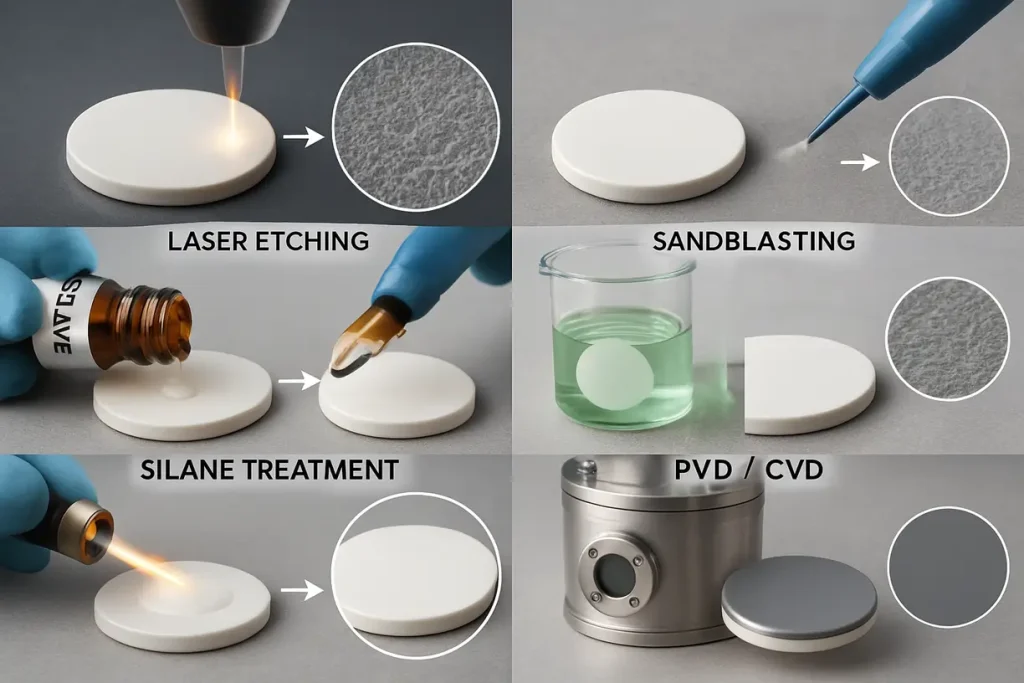

Surface treatments are vital for enhancing zirconium silicate’s adhesion properties. These processes prepare surfaces and improve bonding between materials.

One common approach is sandblasting. This method cleans and roughens the surface, increasing texture and improving adhesion. A rough surface allows for better mechanical interlock between the zirconium silicate and the substrate, resulting in stronger bonds.

Chemical etching is another effective treatment. This technique uses chemicals to alter the surface properties, creating a more reactive surface. By increasing surface energy, the adhesion potential rises. It’s particularly useful for materials that require precise adhesion.

Coatings can also be applied to improve bond strength. For example, applying a primer can create a more favorable environment for the zirconium silicate to adhere properly. Primers are specifically formulated to promote bonding with various substrates, making them an excellent choice for enhancing adhesion.

Common surface treatment methods include:

| Surface Treatment Method | Description | Benefits |

|---|---|---|

| Sandblasting | Cleans and roughens surface | Increases mechanical interlock |

| Chemical Etching | Alters surface properties with chemicals | Promotes higher surface energy |

| Primers | Applied coatings that prepare surfaces | Enhances bonding with diverse substrates |

In summary, by implementing surface treatments, you can significantly enhance the adhesion properties of zirconium silicate. These methods are not only effective but also relatively straightforward to apply in various industrial processes.

This image depicts various surface treatment methods used to enhance adhesion properties of zirconium silicate.

What Additives Can Enhance Zirconium Silicate Adhesion?

Incorporating additives into zirconium silicate formulations can lead to noteworthy improvements in adhesion properties. These substances enhance bonding in various ways.

One of the most common additives is silanes. These compounds react chemically with surfaces, creating a stronger bond with zirconium silicate. They promote better interaction between the adhesive and substrates, improving overall performance.

Another effective additive is coupling agents. These agents help to bridge the gap between zirconium silicate and other materials, enhancing compatibility. This compatibility allows for a stronger and more durable bond, crucial for applications in coatings and composites.

Organic additives, such as plasticizers, can also be beneficial. They increase flexibility and improve adhesion to substrates by mitigating stress during thermal expansion or contraction. This flexibility is particularly important in environments where temperature fluctuations can occur.

Common additives to consider include:

| Additive Type | Function | Benefits |

|---|---|---|

| Silanes | Chemical bonding agent | Enhances adhesion strength |

| Coupling Agents | Bridges materials and improves compatibility | Increases bond durability |

| Plasticizers | Increases flexibility and reduces brittleness | Adaptable to temperature changes |

By carefully selecting and incorporating these additives, you can considerably improve the adhesion properties of zirconium silicate. The right additives can create substantial benefits for your products, ensuring long-lasting performance in various applications.

How Do Temperature and Humidity Impact Adhesion?

Temperature and humidity are critical factors that can significantly influence the adhesion of zirconium silicate. Therefore, understanding these environmental aspects is vital for successful applications.

High temperatures can lead to thermal expansion of materials. If zirconium silicate and the substrates have different thermal expansion coefficients, it can result in stress at the bond interface. This stress may lead to cracking or delamination of the adhesive over time.

Conversely, low temperatures can increase the viscosity of adhesives. When the adhesive is too thick, it may not flow well between surfaces, leading to insufficient adhesion. Therefore, maintaining optimal application temperatures is essential for achieving strong bonds.

Humidity also plays a crucial role. High humidity can cause hydrolysis of some adhesive systems, leading to weakened bonds. Additionally, moisture may interfere with chemical interactions between the adhesive and the substrates, limiting adhesion strength.

To mitigate these effects, consider these practices:

- Maintain Optimal Conditions: Monitor temperature and humidity closely.

- Use Humidity-Resistant Adhesives: Choose systems designed to withstand moisture.

- Perform Regular Quality Checks: To ensure adhesion remains effective under varying conditions.

To mitigate these effects, it is essential to monitor environmental conditions closely during the application process. Implementing controlled environments or using humidity-resistant adhesive systems can ensure better performance in varying conditions.

| Environmental Factor | Impact on Adhesion |

|---|---|

| Temperature | Affects stress at bond interface |

| Humidity | Can cause hydrolysis and weaken adhesive bonds |

What Best Practices Should You Follow for Testing Adhesion?

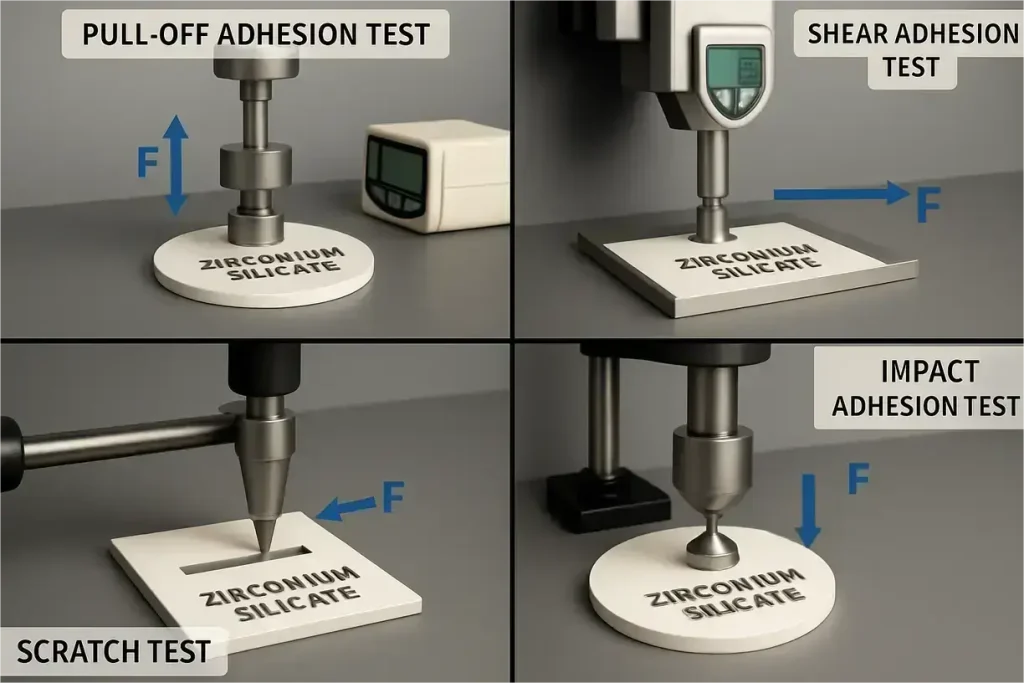

Testing the adhesion strength of zirconium silicate is critical to ensure its effectiveness. Following best practices for testing can lead to accurate measurements and enhance decision-making.

One reliable testing method is the peel test. This test involves applying force to peel apart bonded surfaces. It provides valuable insights into the adhesion strength and helps identify any weak points in the bond.

Another method is the shear test, where a force is applied parallel to the adhesive joint. This approach evaluates the adhesive’s resistance to sliding forces, offering practical information about its performance under stress.

Tensile tests evaluate the ultimate strength of the bond by pulling the materials apart. This method provides clear data on the material’s ability to withstand pulling forces over time.

Best practices for adhesion testing include:

- Consistency in Conditions: Maintain the same temperature and humidity levels.

- Regular Testing: Schedule tests routinely to monitor adhesion quality.

- Use Multiple Methods: Consider a combination of peel, shear, and tensile tests for comprehensive evaluation.

Consistency is key when conducting these tests. Ensuring that the conditions, such as temperature and humidity, remain constant is crucial for obtaining reliable results. Regularly testing adhesion strength can help track performance over time and lead to necessary adjustments for improved outcomes.

| Testing Method | Description | Purpose |

|---|---|---|

| Peel Test | Measures force required to peel bonded surfaces | Evaluates adhesion strength |

| Shear Test | Applies force parallel to the bond | Assesses resistance to sliding forces |

| Tensile Test | Pulls materials apart to measure strength | Determines ultimate bond strength |

The image shows various adhesion testing methods used to assess the performance of zirconium silicate.

How Can You Combine Zirconium Silicate with Other Materials?

Combining zirconium silicate with other materials can lead to enhanced performance and improved adhesion. Different combinations can yield unique properties.

For example, blending zirconium silicate with polymers can create flexible composite materials. These materials leverage the strength of zirconium silicate while utilizing the elasticity of polymers, making them ideal for applications like coatings and sealants.

Additionally, combining zirconium silicate with other fillers can enhance overall product performance. Fillers like calcium carbonate or titanium dioxide can improve the physical properties of the final product while promoting better adhesion.

Common combinations to consider include:

- Zirconium Silicate + Polymers: Results in flexible composites ideal for various applications.

- Zirconium Silicate + Calcium Carbonate: Enhances the overall physical properties.

- Zirconium Silicate + Titanium Dioxide: Improves adhesion and durability in coatings.

Case studies show the benefits of combining zirconium silicate with varying materials. For instance, in the automotive industry, mixtures of zirconium silicate with automotive paints have exhibited superior durability and adhesion properties, leading to longer-lasting finishes.

Successfully combining materials requires careful consideration of compatibility and intended applications. By understanding the interaction between different components, you can develop superior products that leverage the strengths of each material.

What Innovations Are Emerging in Zirconium Silicate Applications?

The exploration of zirconium silicate applications continues to evolve with emerging innovations. Researchers are investigating new methods that can significantly enhance adhesion properties.

Recent studies focus on the development of advanced zirconium silicate composites. These materials are designed to withstand higher temperatures and corrosive environments, expanding their utility in industrial settings.

Nano-coating technologies are also gaining attention. These coatings apply a layer of nanoscale materials over zirconium silicate, improving surface properties and adhesion strength. Such innovations promise improved performance in fields like electronics and aerospace, where durability and reliability are critical.

Moreover, bio-based adhesives containing zirconium silicate are being explored. These adhesives aim to reduce environmental impact while maintaining high adhesion standards. The shift towards more sustainable materials aligns with industry trends and consumer preferences for environmentally friendly products.

| Innovation | Description | Potential Impact |

|---|---|---|

| Advanced Composites | New materials for high-temperature applications | Expands utility in extreme environments |

| Nano-Coating Technologies | Enhances surface properties at the nanoscale | Improves durability and reliability |

| Bio-Based Adhesives | Environmentally friendly adhesive solutions | Aligns with sustainable industry trends |

As these innovations emerge, they open new doors for zirconium silicate applications across various industries. Keeping abreast of these trends can offer your business a competitive edge.

This image illustrates innovative applications of zirconium silicate in various materials and technologies.

What Challenges Might You Face with Zirconium Silicate Adhesion?

While zirconium silicate offers numerous benefits, there are challenges in achieving optimal adhesion. Recognizing these challenges can help in devising effective solutions.

One common issue is the inconsistent quality of zirconium silicate. Variations in manufacturing processes can lead to differences in chemical composition, affecting adhesion performance. Source materials should be closely monitored to ensure consistency.

Another challenge is dealing with surface contaminants. Dust, oils, and other substances can hinder adhesion, making surface preparation critical. Implementing rigorous cleaning protocols before applying zirconium silicate will help address this issue.

Temperature fluctuations can also create problems. As mentioned earlier, differential expansion and contraction can lead to bond failure. Using appropriate materials and adhesives that can accommodate temperature changes is essential for long-term adhesion.

| Challenge | Solution |

|---|---|

| Inconsistent Quality | Source materials should be monitored closely |

| Surface Contaminants | Implement rigorous cleaning protocols |

| Temperature Fluctuations | Use materials that accommodate changes |

By being aware of these challenges, you can proactively implement solutions that enhance adhesion performance and ensure the reliability of your products.

How Can You Ensure Consistent Quality in Adhesion?

Maintaining consistent quality in adhesion is imperative for businesses that rely on zirconium silicate. Implementing quality control measures is key to achieving this goal.

First, establishing standard operating procedures for material sourcing and preparation will help ensure the quality of zirconium silicate. Consistency in these processes directly affects adhesion strength.

Regular testing of adhesive performance is also crucial. By incorporating routine adhesion tests into your quality assurance protocols, you can track the performance of zirconium silicate over time. This data will help you identify any issues and address them promptly.

Additionally, choosing reliable suppliers is essential. Suppliers should provide consistent quality materials and be able to meet your specific technical requirements.

Finally, investing in training for staff responsible for applying zirconium silicate will improve overall performance. Well-informed employees can follow best practices, which greatly enhances the quality of adhesion in your applications.

| Quality Control Measure | Description |

|---|---|

| Standard Operating Procedures | Ensure consistent sourcing and preparation |

| Regular Performance Testing | Track adhesion performance over time |

| Supplier Selection | Prioritize reliable suppliers for quality materials |

| Staff Training | Educate employees on best application practices |

In summary, understanding how to enhance zirconium silicate’s adhesion properties involves a comprehensive approach. By recognizing the factors affecting adhesion, employing surface treatments and additives, and staying updated on innovations, you will significantly improve the performance of your products.

Conclusion

Throughout this article, we explored how to enhance zirconium silicate’s adhesion properties, emphasizing critical factors such as composition, testing methods, and emerging innovations. One significant benefit of applying these insights is improved product reliability, leading to higher customer satisfaction. At Global Industry, we are committed to helping you achieve the best results. Our team is here to guide you through optimizing your use of zirconium silicate for maximum impact. For further resources or assistance, please reach out to us today to strengthen your materials.

FAQ Section

Q1: How does zirconium silicate contribute to adhesion?

Zirconium silicate serves as a critical binding agent, enhancing the strength and durability of various adhesive formulations across multiple applications.

Q2: What types of surface treatments are effective for zirconium silicate?

Common surface treatments include sandblasting, chemical etching, and coating, each designed to improve interfacial bonding.

Q3: Are there specific additives that can significantly improve adhesion properties?

Yes, additives like silanes and coupling agents can boost adhesion by promoting better chemical interaction between zirconium silicate and substrates.

Q4: What environmental conditions may hinder adhesion effectiveness?

Temperature extremes and high humidity levels can adversely affect adhesion performance, necessitating controlled application environments.

Q5: What testing methods should I use to evaluate adhesion strength?

Recommended methods include peel tests, shear tests, and tensile tests, providing robust data on adhesion quality and reliability.