Zirconium silicate holds significant potential for enhancing abrasive and polishing products in various industries. Many businesses face challenges in attaining optimal results when using conventional materials that may not provide durability or efficiency. This article offers insight into how zirconium silicate can address these issues, providing tangible benefits such as increased efficiency, improved surfaces, and reduced costs. As industry professionals specializing in material applications, we have seen firsthand the transformative impact this mineral can have on product performance and quality. Understanding these advantages can empower businesses to make informed decisions about their manufacturing processes and product development.

What Are the Key Properties of Zirconium Silicate?

Zirconium silicate is renowned for its exceptional hardness and durability. It has a high melting point that reaches over 2700 degrees Celsius, making it suitable for applications that involve extreme heat. Additionally, its chemical stability means it resists corrosion and reactions with other substances. This characteristic extends its usability in various conditions, particularly in abrasive environments where resilience is key.

Zirconium silicate can withstand extreme conditions. For example, when used in grinding applications, it maintains its integrity and effectiveness longer than many traditional abrasive materials like alumina and silica. This longevity translates to significant savings in replacement costs and maintenance for companies.

In terms of applications, zirconium silicate is utilized in various products: from high-performance sandpaper to grinding wheels and polishing compounds. The versatility of this mineral allows manufacturers to tailor its use to meet specific requirements across diverse industries, including automotive, aerospace, and manufacturing. Many businesses have reported improved results, leading to higher customer satisfaction and loyalty.

Here’s the reality: its unique properties position this mineral as a top contender in abrasives, with the capacity to enhance overall product function. By leveraging these characteristics, companies can elevate their production capabilities while satisfying stringent quality standards.

| Property | Description |

|---|---|

| Hardness | Extremely hard and durable |

| Melting Point | High melting point (>2700 °C) |

| Chemical Stability | Excellent resistance to chemicals |

| Toxicity | Non-toxic; safe for various applications |

How Does Zirconium Silicate Enhance Abrasive Performance?

Zirconium silicate enhances abrasives through its unique physical structure and exceptional hardness. This mineral’s particular grain shape allows for effective material removal, translating to improved efficiency during grinding and polishing. Its unique structure acts like a superior cutting tool, enabling more precise finishes on various materials.

When manufacturers incorporate this mineral into their abrasive products, they provide a sharper cutting edge. This aspect leads to faster material processing, directly impacting the bottom line by reducing the time and labor associated with finishing processes. For example, in a typical grinding operation, using zirconium silicate can result in up to a 30% improvement in cutting speed, contributing to substantial time savings over numerous operations.

The load-bearing capacity of zirconium silicate also contributes to its effectiveness. This material can resist wear longer than many conventional abrasives, maintaining its cutting efficiency throughout its lifespan. This means fewer tool changes and lower operational costs. Companies have reported that switching to abrasives containing this mineral has led to a reduction in tool-related downtime by as much as 25%.

Moreover, it produces less dust compared to other materials, leading to a cleaner workplace. Reduced dust levels can also translate into improved health and safety for workers, decreasing the risk of respiratory issues and enhancing comfort. Many manufacturers are now prioritizing dust control in their operations, leading them to opt for abrasive materials that minimize particulate generation.

Consider this: switching to zirconium silicate not only streamlines production processes but also enhances workplace conditions, thereby increasing employee satisfaction and productivity levels.

| Performance Metric | Traditional Abrasives | Zirconium Silicate Abrasives |

|---|---|---|

| Cutting Efficiency | Moderate | High |

| Tool Longevity | Short Term | Long Term |

| Dust Generation | High | Low |

| Surface Finish Quality | Average | Superior |

| Labor Costs | Higher | Reduced |

What Advantages Does Zirconium Silicate Offer in Polishing Products?

Zirconium silicate provides numerous advantages when included in polishing formulations. Its hardness contributes to a more effective polish, thereby significantly enhancing surface finishes on various materials such as metals, glass, and ceramics. Companies find that products containing this mineral yield smoother, glossier finishes, which are crucial for attracting customers who value quality aesthetics.

This image illustrates the application of zirconium silicate in polishing products, enhancing surface finishes.

One major advantage is the speed of polishing. Zirconium silicate allows users to achieve desired results much faster than conventional polishing agents. For instance, its integration in a polishing compound can reduce process times by up to 40%, thereby increasing overall efficiency. This enhanced speed translates into shorter processing times, allowing businesses to meet tight deadlines and fulfill larger orders.

Moreover, zirconium silicate is chemically stable, ensuring that it does not react adversely with other components in polishing products. This stability leads to consistent product quality and minimizes the risk of batch variations. For manufacturers, the predictability of product performance is invaluable, especially in high-stakes environments where quality cannot be compromised.

Another important benefit is its versatility. This mineral can be used in a variety of polishing applications, from automotive finishes to delicate electronic components. Whether used in metal polishing pads or as part of a liquid polishing slurry, zirconium silicate adapts well to different formulations and processes.

Here’s an essential point: businesses leveraging zirconium silicate can expect improved aesthetics in their final products. A better finish enhances the perceived value of their offerings, leading to greater customer satisfaction, repeat purchases, and ultimately a stronger bottom line.

| Benefit | Details |

|---|---|

| Improved Finish | Smoother, glossier surfaces |

| Speed of Application | Quicker results |

| Chemical Stability | Consistent quality |

| Versatility | Suitable for various materials |

| Application Types | Metals, glass, ceramics |

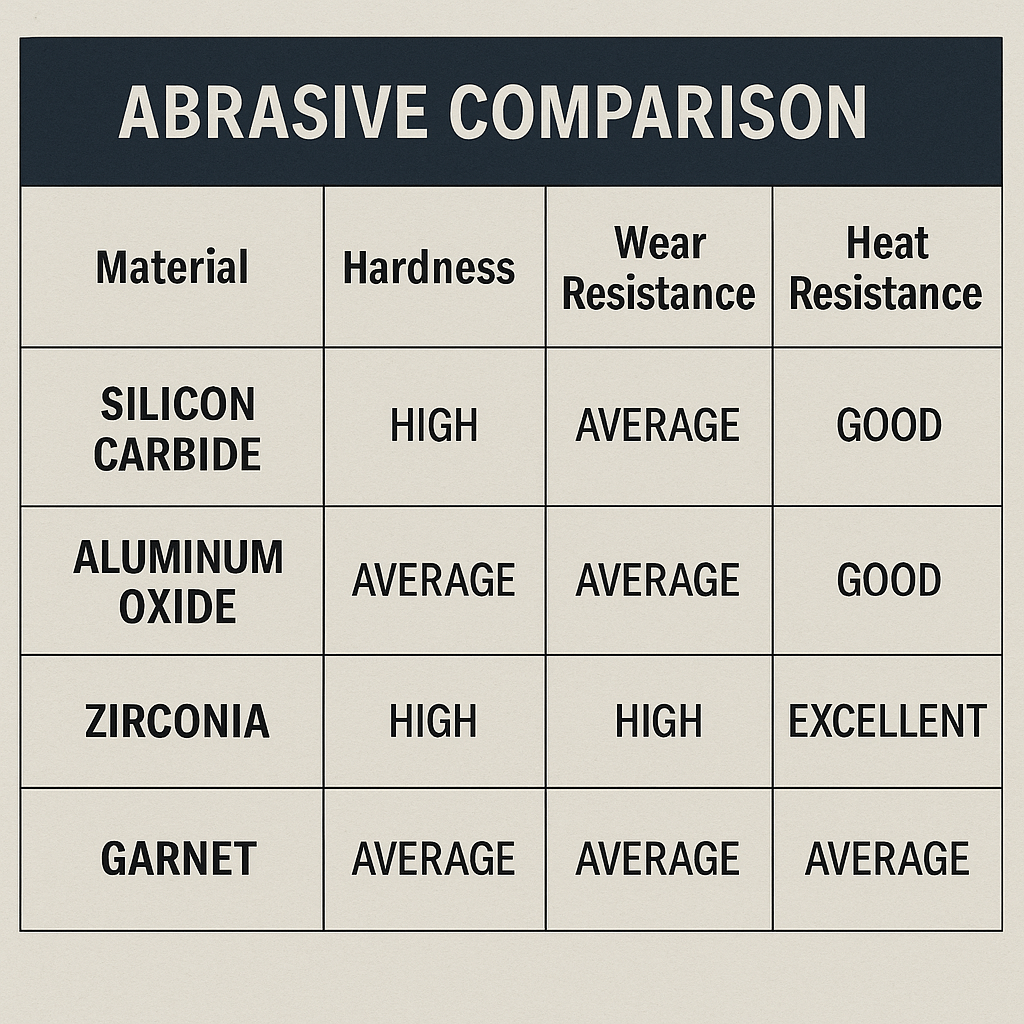

How Does Zirconium Silicate Compare to Other Materials in Abrasives?

When comparing zirconium silicate to alternative abrasive materials like alumina and silica, several advantages stand out. First, zirconium silicate boasts a higher hardness level, enabling it to cut and grind materials more effectively. This characteristic is crucial in industries where precision and quality are paramount.

Another comparison point is cost efficiency. Despite sometimes higher upfront costs for zirconium silicate products, their longevity and efficiency lead to lower overall expenses. Companies that utilize this mineral often observe reduced replacement and maintenance costs, creating significant long-term savings.

Furthermore, zirconium silicate produces fewer defects during the grinding process, resulting in a higher yield of usable products. This efficiency not only saves money but also ensures consistent quality—critical in industries where precision matters. The result is a more streamlined manufacturing process that enhances productivity across the board.

Let’s break it down: businesses assessing abrasive materials should prioritize performance metrics in their evaluations. The superior effectiveness of this mineral ensures that manufacturers receive value that offsets initial costs over time. Companies should consider factors such as:

- Long-term material costs: Reduced frequency of replacements.

- Improved quality yields: Less waste and higher satisfaction.

- Enhanced productivity: Faster processing times leading to increased output.

By focusing on these aspects, businesses can position themselves advantageously in the market while ensuring that they provide top-quality products.

A comparative table showcasing the performance of different abrasives, emphasizing zirconium silicate’s superiority in key metrics.

| Material | Hardness | Longevity | Cost Efficiency | Quality Consistency |

|---|---|---|---|---|

| Zirconium Silicate | High | Long | High | High |

| Alumina | Medium | Medium | Medium | Medium |

| Silica | Low | Short | Low | Low |

What Industries Benefit Most from Zirconium Silicate Use?

Several industries benefit significantly from using zirconium silicate in their abrasive and polishing products. The automotive industry, for example, relies heavily on high-quality finishes for parts. Automakers and suppliers often incorporate this mineral to achieve superior results while maintaining efficiency.

The manufacturing sector also sees considerable benefits. As machines produce components, they require reliable abrasives for shaping and finishing. The durability and effectiveness provided by this mineral make it a preferred choice for many manufacturers. Businesses in this sector are continually searching for materials that not only meet but exceed production standards.

Aerospace is another key industry that benefits from utilizing zirconium silicate. The precision required in aircraft parts demands high-quality abrasives. Here, zirconium silicate fits the bill, providing the necessary attributes for ensuring safety and reliability in aerospace engineering.

Moreover, the electronics industry integrates zirconium silicate in polishing processes related to semiconductor manufacturing. The demand for smooth, defect-free surfaces in electronics means manufacturers frequently utilize this mineral within their production lines, which helps them meet stringent quality standards.

Here’s an important takeaway: zirconium silicate supports various industries by enhancing productivity and output quality. Its adaptability and efficiency make it a valuable asset in many applications.

| Industry | Use Case Description | Benefits |

|---|---|---|

| Automotive | High-quality finish on parts | Enhanced aesthetics |

| Manufacturing | Reliable abrasives for shaping | Increased productivity |

| Aerospace | Precision abrasives for safety | Improved compliance |

| Electronics | Polishing for defect-free surfaces | Higher quality assurance |

How Can Manufacturers Incorporate Zirconium Silicate in Their Processes?

Incorporating zirconium silicate into manufacturing processes requires a thoughtful and strategic approach. Companies should begin by evaluating their existing formulations. Identifying where this mineral can replace or enhance traditional materials is key to maximizing effectiveness and ensuring a seamless transition.

When blending zirconium silicate with other components, precise ratios are crucial. Conducting tests on small batches helps manufacturers determine optimal mixing levels. This step is essential for ensuring that the resulting product meets specific performance criteria. Keeping thorough records of the formulation process can aid in replicating successful batches in the future.

Training staff on the properties and handling of this mineral also proves beneficial. Understanding how to utilize zirconium silicate effectively can lead to better operational outcomes while minimizing errors. Training sessions may include hands-on workshops illustrating best practices in material handling, mixing, and application.

Moreover, manufacturers should monitor their processes after the integration of zirconium silicate. Regular assessments help identify any adjustments needed to optimize results continuously. Utilizing metrics such as production speed, quality control data, and feedback from operators can provide valuable insights into how well the integration is working.

Remember this: the successful incorporation of zirconium silicate revolves around careful planning and thorough execution. The rewards, including improved performance and efficiency, are well worth the effort.

| Implementation Step | Details | Expected Outcome |

|---|---|---|

| Evaluate Existing Formulations | Identify where zirconium silicate fits | Improved performance |

| Conduct Small Batch Testing | Determine optimal blending ratios | Consistent quality |

| Staff Training | Educate teams on properties and handling | Fewer errors, higher safety |

| Monitor Performance | Assess and adjust for optimal results | Continuous process improvement |

What Are the Challenges and Considerations When Using Zirconium Silicate?

While zirconium silicate offers many advantages, businesses must also consider potential challenges. One challenge is sourcing high-quality zirconium silicate. Variability in product quality can affect overall performance, so ensuring a reliable supplier is crucial for maintaining consistent results.

Another consideration is cost fluctuation. Raw material prices can change based on market conditions, which may impact budgeting decisions. Companies should closely monitor market trends and establish relationships with multiple suppliers to mitigate financial risks and secure stable pricing.

Proper handling procedures must be established to optimize safety and performance. While this mineral is generally safe, utilizing personal protective equipment (PPE) during processing can prevent exposure to fine particles. Providing workers with adequate training on health and safety regulations helps create a safer working environment.

Additionally, companies should be aware of any specific regulations surrounding the use of zirconium silicate in their industry. Compliance is essential to avoid potential legal ramifications and maintain a good standing with regulatory bodies. Keeping current with environmental and safety standards is critical for long-term operational success.

Here’s a practical tip: proactively addressing these challenges can ensure that the benefits of zirconium silicate can be fully realized. Early identification and response to potential issues lead to smoother operations and better outcomes.

| Challenge/Consideration | Solution/Strategy |

|---|---|

| Sourcing Quality Material | Partner with reliable suppliers |

| Cost Fluctuation | Monitor market trends; secure stable pricing |

| Proper Handling Procedures | Implement PPE usage policy |

| Regulatory Compliance | Stay informed on industry regulations |

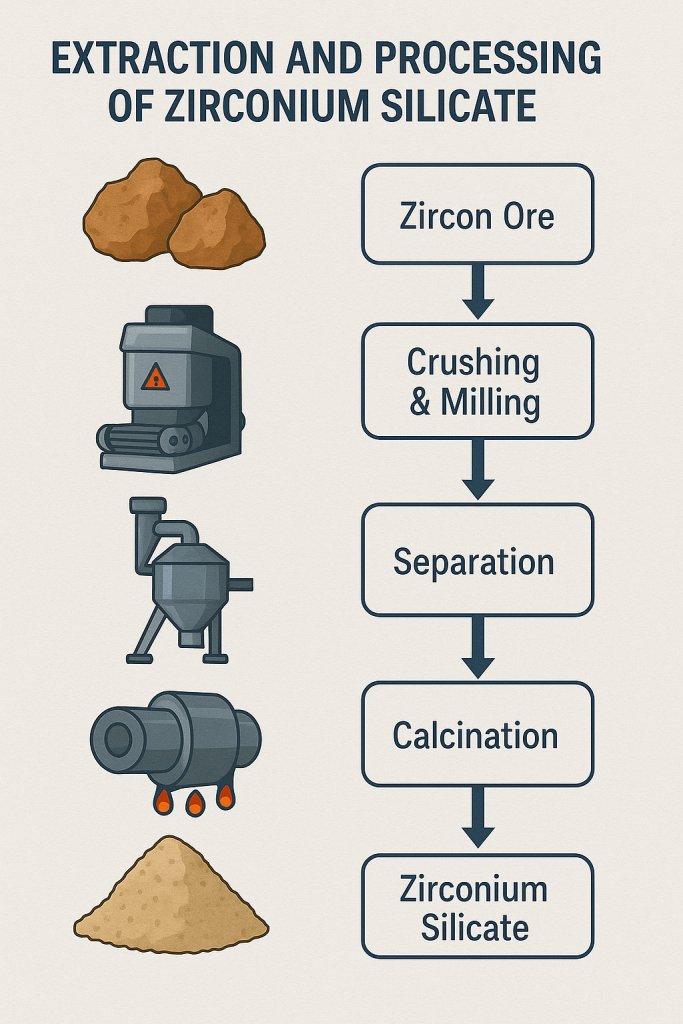

How Is Zirconium Silicate Sourced and Processed?

Sourcing zirconium silicate requires a focus on quality and sustainability. Most of this material is derived from zircon, a mineral found in sandy deposits. Reliable sourcing involves choosing suppliers who prioritize ethical mining practices and environmental stewardship in extraction and processing.

This image showcases the extraction and processing stages of zirconium silicate from raw zircon minerals.

Processing zircon into zirconium silicate involves multiple careful steps. Initially, zircon undergoes a heating process to remove impurities and enhance purity. This refining process is critical for ensuring that the final product meets specific quality and performance standards expected in industrial applications.

Quality control is paramount throughout the sourcing and processing phases. Regular testing and inspections help maintain product integrity, ensuring that materials retain their desired properties. For example, implementing strict quality protocols can decrease the likelihood of defective batches, resulting in fewer complaints from clients and better overall satisfaction.

Furthermore, companies should explore innovative processing methods that enhance sustainability. Techniques such as waste recycling and energy-efficient production can reduce the environmental impact associated with the production of zirconium silicate.

Here’s a takeaway for businesses: selecting the right suppliers and establishing strong quality protocols can greatly influence material performance. Focusing on sustainable practices not only enhances brand reputation but can also attract eco-conscious clients, which can be a significant differentiator in a competitive market.

| Sourcing Step | Description |

|---|---|

| Raw Material Extraction | Sourced from zircon minerals |

| Initial Processing | Heating to remove impurities |

| Quality Control | Regular testing for performance standards |

| Sustainable Practices | Selecting eco-friendly suppliers |

What Future Trends Are Emerging for Zirconium Silicate in Industry?

The future of zirconium silicate across various industries looks promising. Ongoing research focuses on enhancing the properties of this mineral for specialized applications. Innovative modifications can improve performance characteristics even further, making it a critical material in the development of highly specialized abrasive and polishing products.

Another trend involves integrating zirconium silicate into advanced materials. As industries seek new materials for cutting-edge applications, this mineral can play a crucial role in developing superior high-performance products. The synergy between zirconium silicate and other advanced materials can drive significant advancements in technology and efficiency.

Sustainability is also becoming a focal point in the industry. Companies are increasingly seeking to minimize environmental impacts by refining their methods for sourcing and processing. As industries push for greener alternatives, the emphasis will shift more toward environmentally friendly practices, such as reducing carbon footprints and utilizing renewable energy in production processes.

Let’s highlight an essential observation: the evolution of technology is leading to exciting possibilities for zirconium silicate applications. Staying informed about these trends can position businesses as leaders, enabling them to capitalize on emerging market opportunities and meet evolving customer demands.

| Emerging Trend | Description |

|---|---|

| Property Enhancements | Ongoing research for performance features |

| Advanced Material Integration | New applications in high-performance products |

| Sustainability Focus | Eco-friendly sourcing and processing |

How Can Businesses Calculate the ROI of Switching to Zirconium Silicate?

Calculating the return on investment (ROI) for switching to zirconium silicate involves assessing several factors to make a comprehensive evaluation. Businesses should start by analyzing the costs associated with currently used materials. This detailed assessment provides a baseline for comparison, allowing for a clearer understanding of potential savings.

Next, companies must evaluate performance improvements. Key metrics to consider include productivity gains, reductions in dust generation, and enhancements in surface quality. By quantifying these improvements, businesses can determine the tangible benefits of incorporating zirconium silicate into their operations.

Operational savings should also play a significant role in the ROI calculation. Fewer tool changes and lower defect rates can translate into substantial savings over time. These numbers provide valuable insights into whether the switch to this mineral is financially viable.

Finally, businesses need to monitor long-term impacts after implementing the changes. Regularly reviewing performance allows for more accurate assessments of ROI and necessary adjustments to operational strategies. This practice not only supports financial health but also fosters continuous improvement.

Key insight here: conducting a thorough analysis equips companies with the information needed to make informed decisions regarding the investment in zirconium silicate and its overall benefits to their operations.

| ROI Calculation Factor | Description |

|---|---|

| Current Material Costs | Baseline for comparison |

| Performance Improvements | Quantified metrics for analysis |

| Operational Savings | Long-term cost reduction measures |

| Periodic Monitoring | Regular assessment of results |

Conclusion

In summary, zirconium silicate presents numerous benefits for abrasives and polishing products, significantly enhancing performance while reducing costs. Companies that incorporate this mineral can expect improved product quality, efficiency, and greater customer satisfaction. For evidence-based support and tailored material solutions, consider partnering with Global Industry. Take the next step in transforming your processes by contacting us for personalized advice on integrating zirconium silicate into your operations. Together, we can help you achieve exceptional results.

FAQ Section

Q1: What is zirconium silicate? Zirconium silicate is a naturally occurring mineral revered for its strength and durability, often utilized in abrasives and polishing products due to its high-performance attributes.

Q2: Why should I choose zirconium silicate over other abrasives? This mineral offers superior performance, efficiency, and cost-effectiveness compared to traditional options like alumina and silica, making it a smart choice for enhanced productivity.

Q3: In which industries is zirconium silicate most commonly used? Numerous sectors, including manufacturing, automotive, and aerospace, extensively use this mineral for its various performance advantages.

Q4: What are the environmental impacts of zirconium silicate production? The production process involves specific environmental considerations, yet many manufacturers embrace sustainable practices to minimize impact, making it a responsible choice.

Q5: How can I find reliable suppliers of zirconium silicate? Businesses should research reputable suppliers, evaluate quality certifications, and seek industry recommendations to identify trustworthy sources.