When it comes to the international zirconia powder trade, supply chain challenges can significantly impact logistics and efficiency. Buyers, especially decision-makers like purchasing managers, often grapple with issues such as fluctuating market demands, logistical hurdles, and compliance with regulations. Understanding these challenges is crucial for effective decision-making. In this article, we will address the key supply chain issues affecting zirconia powder and offer practical solutions to overcome them, ensuring a smooth procurement process. With insights backed by industry experts, this article serves as a reliable resource for navigating these complexities effectively.

What Are the Key Supply Chain Challenges?

Understanding the core challenges in the supply chain can help businesses identify areas for improvement. Several factors influence the international zirconia powder trade.

One significant challenge is logistical inefficiencies. Shipping delays and transportation mishaps can disrupt the supply chain. For example, customs clearance issues and inadequate transportation infrastructure can lead to increased lead times. Imagine the impact this has when waiting for essential materials!

Another hurdle is the impact of global trade policies. Tariffs, sanctions, and trade agreements can influence supply availability and pricing. Businesses must stay updated on these changes to adapt their procurement strategies.

Additionally, supply chain disruptions caused by natural disasters or geopolitical tensions can have profound effects. Such events can lead to shortages or increased costs, compelling companies to find alternate suppliers quickly.

In summary, awareness of these challenges is vital. They not only affect costs but also influence overall business strategy. With proactive planning, businesses can mitigate these risks.

| Supply Chain Challenges | Examples |

|---|---|

| Logistical Inefficiencies | Delays in shipping, customs issues |

| Global Trade Policies | Tariffs affecting pricing |

| Supply Chain Disruptions | Natural disasters, geopolitical tensions |

Key Challenges List:

- Supplier Reliability: Dependence on consistent suppliers can lead to vulnerability in supply.

- Inventory Management: Fluctuating demand may cause either surplus stock or shortages.

- Transportation Costs: Rising fuel prices directly impact shipping expenses.

- Regulatory Compliance: Adhering to varying international regulations can be complex and costly.

- Communication Gaps: Misalignment between suppliers and businesses can create operational inefficiencies.

How Do Logistics Impact Zirconia Powder Supply?

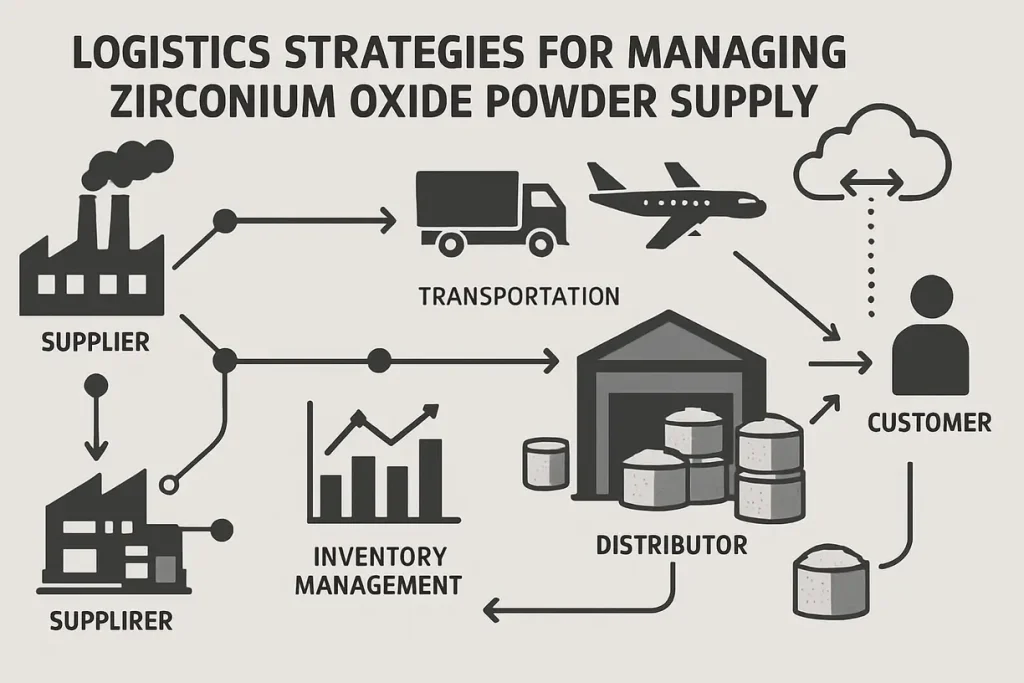

Logistics play a crucial role in maintaining a steady supply of zirconia powder. The logistics chain encompasses everything from transportation management to warehousing and distribution.

Why is efficient logistics so important? Delays in transportation can lead to production halts, which can be costly. Factors such as route optimization, cargo handling, and delivery scheduling are critical. Companies must ensure that they are working with reliable logistics partners to minimize risks.

Common logistical hurdles like inadequate transportation options or inefficient warehousing can severely impact supply. For instance, a lack of proper storage facilities can lead to damage or spoilage of materials, further complicating the supply process.

Best practices include investing in technology to monitor logistics operations continuously and build relationships with multiple carriers. This way, any sudden disruptions can be addressed swiftly, ensuring that supplies continue to flow smoothly.

| Logistics Factors | Impact on Supply |

|---|---|

| Transportation Management | Directly affects lead times |

| Cargo Handling | Can lead to damage or delays |

| Warehousing | Storage conditions impact quality |

This image illustrates the logistics strategies crucial for effective zirconia powder supply management.

Logistics Best Practices:

- Partner with Multiple Carriers: To ensure flexibility and less risk of delays.

- Implement Inventory Tracking Systems: To provide real-time updates on stock levels.

- Optimize Delivery Routes: Use technology to determine the most efficient paths for shipping.

- Train Staff in Logistics Operations: Ensuring team members are knowledgeable about best practices.

- Evaluate Logistics Providers Regularly: To maintain service quality and performance standards.

What Role Does Technology Play in the Supply Chain?

Technology is reshaping modern supply chains, including the trade of zirconia powder. What are the latest innovations driving this change? Advanced logistics software, automation, and data analytics are transforming how businesses manage supply chains.

One major benefit of technology is improved efficiency. Software solutions can track shipments in real time, allowing companies to predict delays before they occur. This proactive approach to logistics ensures minimal disruptions.

Data analytics plays a significant role in predicting trends and managing inventory. By analyzing historical data, businesses can forecast demand more accurately and adjust their inventory levels accordingly. This can help prevent overstocking or stockouts.

Real-world examples illustrate these benefits. Companies utilizing automated ordering systems report smoother operations and fewer errors. Meanwhile, businesses leveraging analytics have reported up to a 20% reduction in operational costs.

In conclusion, investing in technology is not just a trend; it’s a necessity for modern supply chains.

| Technology Solutions | Benefits |

|---|---|

| Advanced Logistics Software | Real-time tracking |

| Automation | Reduces errors |

| Data Analytics | Improves demand forecasting |

How Do Market Fluctuations Affect Zirconia Suppliers?

Market fluctuations can deeply affect zirconia suppliers in numerous ways. What factors are at play here? Economic shifts, consumer demand, and global events all influence market stability.

Economic instability, such as inflation or recession, can lead to price volatility in zirconia powder. When prices rise unexpectedly, businesses may struggle to manage costs effectively. On the other hand, in times of lower demand, suppliers may need to lower prices to attract buyers, impacting their profit margins.

Seasonal trends also affect demand. For instance, in certain industries like ceramics, the demand for zirconia may peak during specific times of the year. Suppliers must be prepared to scale production up or down based on these trends.

To mitigate the impacts of market fluctuations, companies can diversify their customer base or consider strategic partnerships. These steps allow businesses to spread risk and maintain stability even during market shifts.

| Market Factors | Impact on Zirconia Suppliers |

|---|---|

| Economic Shifts | Price volatility and profit margins |

| Seasonal Trends | Peaks and troughs in demand |

| Global Events | Disruptions in supply and pricing |

Market Fluctuation Considerations:

- Economic Indicators: Monitoring inflation rates and economic forecasts can help anticipate price changes.

- Consumer Trends: Understanding shifts in consumer preferences can guide production adjustments.

- Competitor Actions: Stay aware of competitors’ pricing strategies that could influence market conditions.

- Global Trade News: Engaging with international news can uncover potential disruptions ahead of time.

- Internal Demand Forecasting: Accurate demand forecasting helps in planning production schedules effectively.

What Impact Do Environmental Regulations Have?

Environmental regulations are increasingly influencing the zirconia trade. Why are these regulations significant? Compliance with environmental standards can create challenges but also opportunities for businesses.

On one hand, navigating regulatory requirements can be complex and time-consuming. Suppliers must ensure that their practices comply with regulations surrounding emissions, waste disposal, and resource usage. This often requires investment in clean technologies and sustainable practices.

On the other hand, adhering to these regulations can become a competitive advantage. Companies that prioritize sustainability attract clients who value environmental responsibility. This alignment with consumer values is becoming essential in today’s market.

Future trends indicate that regulations will continue to tighten, making it crucial for businesses to stay ahead. Establishing environmentally friendly practices now will position companies well for the future.

| Environmental Regulations | Impact on Business |

|---|---|

| Compliance Costs | Increased operational expenses |

| Sustainability Practices | Competitive advantage |

| Future Trends | Continued regulatory pressure |

Environmental Compliance Steps:

- Conduct Regular Audits: To ensure adherence to environmental standards.

- Invest in Green Technologies: Such as renewable energy and efficient manufacturing processes.

- Educate Employees on Sustainability: Training staff in eco-friendly practices enhances compliance.

- Engage in Sustainable Sourcing: Prioritize suppliers who also follow environmental regulations.

- Create a Resource Management Plan: To reduce waste and improve resource utilization.

How Can Businesses Achieve Supply Chain Resilience?

Building supply chain resilience is essential for any company involved in the zirconia trade. What strategies support resilience? A proactive approach involves implementing several key practices.

First, risk management is critical. Identifying potential supply chain risks allows companies to develop strategies to mitigate these risks. This might include diversifying suppliers or having backup logistics plans.

Second, strengthening relationships with stakeholders is vital. Close collaboration with suppliers, shipping companies, and even customers can enhance communication and coordination. This ultimately leads to a more adaptable supply chain.

Lastly, companies should focus on building a flexible supply chain structure. Why is flexibility important? It allows businesses to respond quickly to unexpected changes, whether they are due to market shifts or external disruptions.

In essence, resilience is about preparing for uncertainty and being able to react effectively when challenges arise.

| Resilience Strategies | Benefits |

|---|---|

| Risk Management | Reduces vulnerabilities |

| Strong Stakeholder Relations | Enhances collaboration and support |

| Flexible Supply Chain | Quick response to changes |

What Are the Best Practices for Supplier Relationships?

Effective supplier relationships foster a smoother supply chain process. So, what best practices should companies implement? Clear communication, collaboration, and performance management are key.

First, open lines of communication help prevent misunderstandings. Regular check-ins and updates build trust between businesses and suppliers. This transparency ensures that everyone is aligned on expectations.

Next, selecting reliable suppliers based on performance data is crucial. Businesses should assess potential suppliers not only on price but also on their reliability, quality, and service levels.

Finally, performance management helps in maintaining high standards. Establishing regular performance reviews allows companies to address any issues proactively and work together for improvements.

In conclusion, strong supplier relationships are vital for a successful zirconia trade.

| Best Practices | Key Benefits |

|---|---|

| Clear Communication | Prevents misunderstandings |

| Supplier Selection | Ensures reliability |

| Performance Management | Maintains high standards |

This image illustrates effective practices for managing supplier relationships in the zirconia industry.

Practices for Strong Supplier Relationships:

- Set Clear Expectations: Establish performance metrics and standards upfront.

- Foster Open Communication: Encourage a culture of transparency to share concerns and successes.

- Recognize and Reward Performance: Offer incentives for suppliers who exceed expectations on quality or delivery.

- Engage in Joint Planning: Collaborate on forecasting and inventory management to align goals.

- Maintain Flexibility: Be willing to adapt terms as business needs change.

How Can Companies Mitigate Supply Chain Risks?

Mitigating supply chain risks is essential for smooth operations in the zirconia powder trade. What steps should be taken to address these risks? A thoughtful approach includes risk identification, assessment, and contingency planning.

First, identifying common risks helps businesses know what to prepare for. This includes threats like supplier insolvency, transportation delays, and compliance breaches.

Next, assessing these risks allows companies to prioritize their strategies. For instance, the likelihood and impact of each risk can guide resource allocation and planning.

Lastly, developing contingency plans is key. This might involve having alternative suppliers at the ready or emergency logistics options. Being prepared can significantly lessen the impact of unexpected problems.

Ultimately, a proactive approach to risk management leads to a more resilient supply chain.

| Risk Mitigation Steps | Expected Outcomes |

|---|---|

| Risk Identification | Awareness of potential threats |

| Risk Assessment | Focused resource allocation |

| Contingency Planning | Reduced impact from disruptions |

Risk Mitigation Strategies:

- Conduct Scenario Planning: Prepare for worst-case scenarios to understand potential impacts.

- Diversify Supply Sources: Reduce reliance on a single supplier to enhance flexibility.

- Monitor Supply Chain Performance: Regularly review metrics to identify emerging risks.

- Communicate with Supply Partners: Foster an environment where issues can be discussed openly.

- Train Staff for Crisis Management: Equip employees with skills to handle supply chain disruptions effectively.

What Future Trends Could Affect the Zirconia Trade?

Looking ahead, several trends may influence the zirconia powder trade. What should businesses watch for? Innovations, regulatory changes, and shifts in consumer behavior are key areas to consider.

Technologically, smart factories and automation are becoming more prevalent. These advances can lead to greater efficiency and lower costs. Companies that adopt these technologies early may gain a significant market advantage.

Moreover, as regulations evolve, businesses must adapt. Stricter environmental standards mean companies need to prioritize sustainability in their practices.

Lastly, consumer preferences continue to shift. More clients are focusing on sustainability and ethical sourcing. Companies that align with these values will attract more business in the long run.

To stay competitive, businesses must be aware of and adapt to these emerging trends.

| Future Trends | Impacts on Businesses |

|---|---|

| Technological Innovations | Increased efficiency |

| Stricter Regulations | Need for sustainable practices |

| Shifting Consumer Preferences | Demand for ethical sourcing |

This image highlights the emerging trends that may influence the zirconia powder market in the coming years.

Upcoming Trends List:

- Increased Use of AI in Supply Chain Management: Possible enhancements in decision-making and predictive analytics.

- Sustainability Initiatives: More companies adopting eco-friendly practices to meet consumer demand.

- Blockchain for Transparency: The use of blockchain technology to ensure transparency in sourcing and supply chains.

- Focus on Local Sourcing: Companies may shift towards local sourcing for reduction in shipping times and costs.

- Collaboration Platforms: Emerging technologies for seamless communication and coordination between stakeholders.

Why Is Data Transparency Important in Supply Chains?

Data transparency is a critical component of effective supply chain management. What makes it so vital? It builds trust among stakeholders and improves decision-making.

When companies share data with suppliers and partners, it fosters collaboration. Each stakeholder can make informed decisions based on accurate information, reducing the likelihood of misunderstandings.

Moreover, data transparency can help identify problems early. With clear visibility into operations, companies can quickly address faults before they escalate into larger issues.

Also, increasing public emphasis on ethical sourcing means consumers are more likely to support businesses that are transparent about their practices.

In summary, embracing data transparency can lead to enhanced collaboration and better overall supply chain performance.

| Data Transparency Benefits | Effects on Supply Chain |

|---|---|

| Improved Collaboration | Fewer misunderstandings |

| Early Problem Identification | Quick resolutions |

| Enhanced Trust | Greater consumer loyalty |

Conclusion

In this article, we explored the supply chain challenges impacting the international zirconia powder trade. Key issues include logistical inefficiencies, market fluctuations, and the growing importance of technology and sustainability. Ultimately, businesses that proactively address these challenges can enhance their operations and performance. Global Industry is poised to assist you further in optimizing your supply chain strategies. Reach out today for tailored solutions that drive success in the zirconia powder market.

FAQ Section

Q1: What factors contribute to supply chain challenges?

Factors contributing to supply chain challenges include logistical inefficiencies, such as transportation delays and inadequate infrastructure. Market fluctuations, driven by economic shifts or changes in consumer demand, also impact supply stability. Regulatory pressures can complicate compliance across different regions, adding further complexity to the supply chain. Furthermore, geopolitical tensions and natural disasters can lead to unexpected disruptions, impacting the availability and pricing of zirconia powder.

Q2: How can technology improve supply chain efficiency?

Advanced technologies can enhance supply chain efficiency in several ways. For instance, logistics software provides real-time tracking of shipments, enabling businesses to anticipate delays and optimize shipping routes. Automation reduces manual errors and increases speed in processes such as order fulfillment and inventory management. Data analytics offers insights into consumption trends, allowing better forecasting and inventory control, which ultimately minimizes costs and improves overall operational efficiency.

Q3: What are common risks in the zirconia trade?

Common risks in the zirconia trade include geopolitical instability, which can lead to supply shortages or pricing volatility. Economic factors, such as inflation or recession, may affect demand and disrupt supply chains. Compliance with ever-evolving environmental and trade regulations poses additional risks, requiring businesses to stay informed and adaptable. Additionally, reliance on single suppliers makes companies vulnerable to disruptions in quality or delivery, further complicating procurement efforts.

Q4: Why is supplier relationship management vital?

Effective supplier relationship management is essential because it fosters collaboration, trust, and open communication between businesses and their suppliers. Strong relationships lead to improved reliability and responsiveness from suppliers, ensuring that materials like zirconia are delivered on time and at the expected quality. These relationships also allow businesses to negotiate better terms and conditions, adapt to changing circumstances more quickly, and work collaboratively on innovation and problem solving.

Q5: What future developments should businesses watch?

Businesses should keep an eye on several future developments that could impact the zirconia trade. Technological advancements, particularly in automation and artificial intelligence, can streamline operations and enhance forecasting accuracy. Stricter environmental regulations mean companies must prioritize sustainability and green practices to remain competitive. Additionally, consumers are increasingly demanding ethical sourcing, leading businesses to adopt more transparent supply chain practices. Staying informed about these trends can help companies proactively adjust their strategies to maintain a competitive edge in the market.