In industries where precision is critical, the choice of materials can significantly impact performance and outcomes. A common concern among purchasing managers is understanding how specific properties of materials, such as thermal expansion, affect their applications. Zirconia powder is gaining attention for its favorable thermal expansion characteristics, making it valuable in precision applications. This article will explain how these properties benefit various sectors, focusing on real-world applications and insights derived from industry standards. With extensive experience in material science, this discussion aims to guide decision-makers in evaluating zirconia powder for their needs.

1. What Are Thermal Expansion Properties of Zirconia Powder?

Thermal expansion describes how materials change in size or volume due to temperature changes. This property is especially important in industries that demand high accuracy and reliability. Zirconia powder showcases unique thermal expansion properties that set it apart from other materials used in similar applications. Unlike many substances that can expand and contract unpredictably when heated or cooled, zirconia expands and contracts in a very controlled manner.

This stability under thermal stress is essential for many applications. For instance, in the manufacturing of precision components, if a material distorts as temperatures fluctuate, it can lead to parts that do not fit together correctly, compromising the overall functionality of the assembly. Zirconia, or zirconium dioxide, is renowned for maintaining its dimensions even with temperature variations. This property helps eliminate concerns about warping, distortions, or misalignments that could degrade performance.

Zirconia’s capability to withstand thermal stress makes it suitable for critical applications across various sectors, including aerospace, electronics, and medical devices. In these industries, any slight dimensional change can have substantial consequences, potentially affecting safety and efficiency. The predictable thermal expansion of zirconia powder plays a vital role in ensuring the durability and reliability of products made from this material.

The consistent thermal stability of zirconia simplifies the design process for engineers and material scientists. It allows them to create components with precise specifications and confidence in their performance over time. As such, zirconia often enhances the lifespan of products, especially those subjected to extreme temperatures or operational stresses, ultimately leading to better reliability.

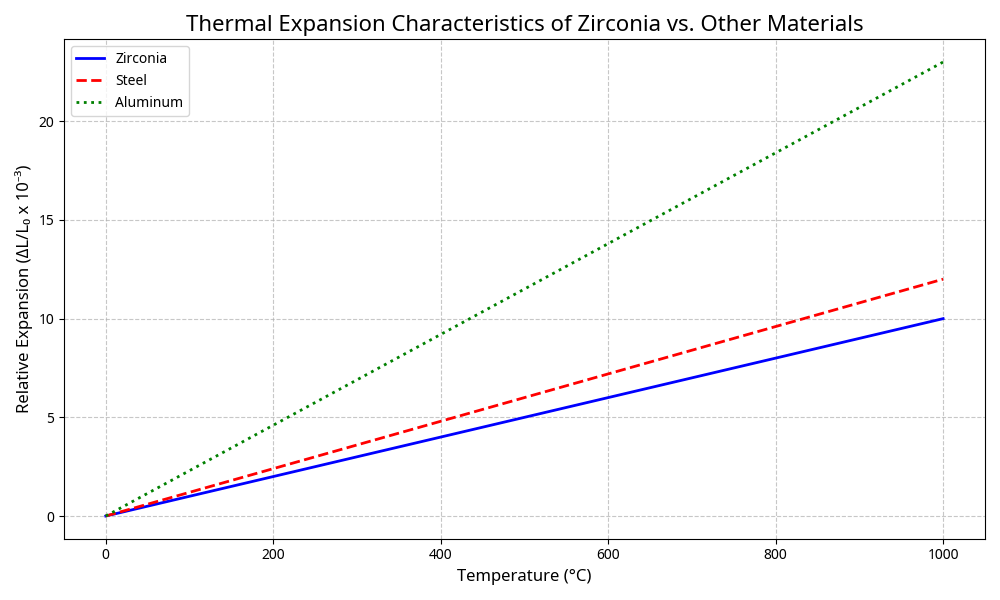

This image illustrates the thermal expansion properties of zirconia powder compared to other materials.

2. How Does Zirconia Powder’s Thermal Expansion Compare to Other Materials?

When considering materials for precision applications, comparing thermal expansion rates is key. Zirconia powder typically exhibits a lower thermal expansion coefficient than most metals and many ceramics. This characteristic provides a significant advantage in maintaining dimensional stability, especially in high-precision environments.

For example, common metals like aluminum and steel have higher thermal expansion rates, meaning they expand more when heated. This can lead to misalignments and potential mechanical failures in applications where precise fitting is crucial. In contrast, zirconia’s lower expansion ensures that components fit together correctly, even under varying temperature conditions, thereby increasing reliability.

In addition, the consistency of zirconia powder’s thermal expansion behavior allows for predictable manufacturing processes. This predictability is vital when creating multi-material assemblies, such as those found in advanced aerospace components or intricate medical devices.

Moreover, when zirconia powder is used alongside metals in surgical tools or high-tech devices, this combination capitalizes on the strengths of both materials. Zirconia maintains consistent dimensions while metals provide necessary toughness and structural support. The result is enhanced performance reliability and a reduced risk of failure.

| Material | Thermal Expansion Coefficient (10^-6 /°C) |

|---|---|

| Zirconia Powder | 10.5 |

| Aluminum | 23.1 |

| Steel | 11-15 |

| Common Ceramics | 5-7 |

This table shows how zirconia powder stands out in thermal stability compared to commonly used materials, highlighting its strength as a choice for precision applications.

3. What Makes Zirconia Powder Valuable in Precision Applications?

The value of zirconia powder in precision applications stems from several key properties: consistency, strength, and resistance to wear. Each of these attributes plays a crucial role in enhancing the performance of components across various sectors, making zirconia an indispensable choice.

Consistency in Dimensions

One of the primary advantages of zirconia powder is its ability to maintain consistent dimensions during fluctuations in temperature and humidity. This property is critical in applications where tight tolerances are essential, such as in aerospace and automotive components. Consistency reduces the risk of mechanical failures and ensures that components fit together perfectly, ultimately enhancing the overall reliability of the final product.

Exceptional Strength

Zirconia powder is known for its remarkable strength and toughness. This makes it suitable for demanding applications where mechanical stresses are high. For example, in medical devices, zirconia serves not only as a fitting material for prosthetics but also as a durable medium for dental crowns, capable of withstanding forces exerted by chewing. The high strength of zirconia helps ensure that these components last longer and perform optimally under pressure.

Resistance to Wear

Another vital characteristic of zirconia is its outstanding wear resistance. In industrial settings where components are subject to continuous friction and abrasion, zirconia powder can help reduce wear and prolong the lifespan of machinery. Its durability translates to lower maintenance costs and minimal downtime, both of which are crucial for businesses focused on efficiency and productivity.

Applications Across Industries

These properties make zirconia powder a popular choice across various industries, including:

- Aerospace Components: Used in parts that must withstand fluctuating temperatures and mechanical stresses.

- Dental Applications: Employed in dental crowns for their excellent fit and wear resistance.

- High-Performance Equipment: Ideal for manufacturing instruments that require precise tolerances, leading to enhanced reliability.

In conclusion, the unique combination of consistency, strength, and wear resistance makes zirconia powder invaluable for precision applications, allowing companies to innovate and improve performance reliably.

4. How Do Environmental Factors Affect Zirconia Powder’s Thermal Expansion?

EEnvironmental conditions can influence the performance of materials, and zirconia powder is no exception. Understanding how these factors interact with zirconia’s thermal expansion properties can help companies make informed decisions during the manufacturing process.

Temperature Variations

Extreme temperature fluctuations can pose challenges for many materials. However, zirconia powder is uniquely positioned to manage these changes effectively. Its robust structure allows it to maintain dimensional stability even when subjected to severe thermal cycling. This means that components made from zirconia can withstand heating and cooling without significant risk of distortion.

Humidity Levels

While humidity may have a lesser impact than temperature, it is still essential to consider. In humid environments, zirconia powder’s properties can be influenced by moisture absorption, which could lead to slight variations in its performance. Proper handling methods must be employed to prevent moisture-related issues, ensuring that the material retains its quality and functionality.

Duration of Exposure

The length of time that zirconia powder is exposed to various environmental conditions also plays a role in its performance. Long-term exposure to extreme temperatures or high humidity can gradually affect the material properties. Therefore, manufacturers need to assess the operational environment and choose appropriate processing techniques to mitigate any potential degradation over time.

| Environmental Factor | Impact on Zirconia Powder |

|---|---|

| Temperature Variations | Maintains dimensional stability |

| Humidity Levels | Minimal impact but requires careful handling |

| Duration of Exposure | Long-term exposure can affect performance reliability |

This table outlines how environmental factors affect zirconia powder properties. Understanding these influences allows manufacturers to optimize their processes and enhance the longevity of their products. By being mindful of these considerations, companies can ensure that they leverage zirconia’s advantages while minimizing any potential challenges that may arise in specific environments.

5. What Role Does Zirconia Powder Play in High-Temperature Applications?

In high-temperature environments, such as aerospace and manufacturing, materials must withstand substantial heat without losing integrity. Zirconia powder meets this challenge confidently due to its remarkable thermal stability and high melting point, making it suitable for applications where temperatures can exceed 1000°C.

In aerospace engineering, zirconia is often used in critical components like heat shields and thermal barriers. These parts require materials that not only endure extreme temperatures but also maintain their structural integrity during flight conditions. Zirconia’s consistent thermal expansion ensures that these components remain properly aligned, reducing the risk of mechanical failures that could jeopardize safety.

Similarly, in automotive applications, zirconia powder is used in engine components exposed to high heat. It serves as an effective material for parts such as piston rings and exhaust valves. The thermal properties of zirconia contribute to improved performance, reduced wear, and extended lifespan of these components, ultimately leading to better fuel efficiency and reliability in vehicles.

Safety and Reliability

The safety factor is also crucial in high-temperature applications. Zirconia has consistently proven to be a reliable choice over time, which mitigates the risk of component failure. Enhanced reliability translates to reduced downtime, lower maintenance costs, and heightened overall efficiency in manufacturing processes.

Furthermore, the adoption of zirconia powder in high-temperature operations is continuously expanding. As industries look for advanced materials that can endure harsh conditions, the demand for zirconia is likely to rise, fostering innovation and development in its applications.

This image represents how zirconia powder is used in high-temperature applications like aerospace engineering.

6. How Can Companies Leverage Zirconia Powder in Their Products?

Companies aiming to incorporate zirconia powder into their products must consider its advantages for specific applications. The effective use of zirconia can enhance product offerings across numerous sectors.

Application in Electronics

Zirconia powder is becoming a popular choice in the electronics industry. Its dielectric properties make it suitable for insulating materials in capacitors, semiconductors, and other electronic components.

Medical Devices

In the medical field, zirconia powder is valuable for crafting devices that require precision and durability. From surgical tools to prosthetics, zirconia plays an essential role in the development of high-quality medical equipment.

Enhancements in Industrial Machinery

Manufacturers can use zirconia powder in industrial machinery that undergoes high-stress and high-temperature operations. The material’s resistance to wear and corrosion helps maintain equipment integrity and performance.

| Industry | Zirconia Powder Application |

|---|---|

| Electronics | Insulators and semiconductor components |

| Medical Devices | Surgical tools, dental crowns, and prosthetics |

| Industrial Machinery | Components that face high wear and demanding environments |

This table summarizes how various industries can leverage zirconia powder in their products.

7. What Are the Challenges Associated With Using Zirconia Powder?

Despite its many benefits, zirconia powder is not without challenges. Companies should be aware of several factors before incorporating this material into their production processes, as addressing these challenges can ensure optimal performance and cost-effectiveness.

Cost Implications

Zirconia powder can be more expensive than conventional materials, which may affect the overall budget of a project. Organizations must weigh the higher initial costs against the long-term advantages. While lower-cost materials might seem appealing at first, the superior durability and performance of zirconia can lead to lower maintenance and replacement costs over time.

Availability Issues

Sourcing high-quality zirconia powder can prove challenging. Not all suppliers offer the same quality standards, and inconsistency in material quality can compromise product performance. Companies must conduct thorough supplier evaluations to ensure they partner with those who can consistently deliver high-grade zirconia.

Handling and Processing Considerations

Zirconia powder requires careful handling to maintain its intrinsic properties. It tends to be more sensitive to processing conditions compared to other materials; thus, specialized equipment and trained personnel may be necessary to manage it properly. If handled incorrectly, the material can become degraded, leading to subpar product quality. Companies need to invest in training and safety protocols to mitigate these risks.

Maintenance of Properties

Over time, zirconia powder can undergo changes that affect its properties, especially if exposed to extreme environmental conditions. Regular assessments and quality control checks can help in identifying any potential degradation, ensuring that the materials used continue to meet required standards.

By understanding and addressing these challenges, companies can effectively leverage the qualities of zirconia powder while minimizing risks and enhancing overall productivity.

8. How to Select the Right Zirconia Powder for Your Needs?

Selecting the appropriate type of zirconia powder is essential for achieving desired outcomes. Several factors must guide this decision-making process.

Factors to Consider

- Application Requirements: Consider the specific needs for your application, such as strength, thermal stability, and wear resistance.

- Supplier Reliability: Partner with suppliers who can guarantee quality and consistency in their products. This step is crucial for maintaining performance.

- Customization: Some applications may benefit from custom formulations of zirconia powder. Discussing your needs with suppliers can lead to tailored solutions that enhance performance.

Evaluating Suppliers

It’s also helpful to evaluate suppliers based on their track record, customer service, and technical support capabilities. The right partnership can significantly influence your success in leveraging zirconia powder.

| Selection Criteria | Importance |

|---|---|

| Application match | Determines the effectiveness of the material used |

| Supplier reliability | Ensures consistent quality and availability |

| Customization options | Provides tailored solutions for specific needs |

This table reflects critical criteria to guide the selection of zirconia powder.

9. What Innovations Are Emerging in Zirconia Powder Technology?

The field of zirconia powder is witnessing several innovations, expanding its applications and benefits. Companies should stay informed about these advancements to maximize the use of this material.

Recent Technological Advancements

Research and development are leading to enhanced formulations of zirconia. These developments focus on improving properties like thermal conductivity and wear resistance, making the material even more valuable.

Future Trends

As industries evolve, the demand for more sustainable and efficient materials grows. Zirconia powder is following this trend. Companies exploring eco-friendly manufacturing processes are investigating the potential of zirconia in reducing environmental impacts while maintaining performance standards.

Impact on Industry Standards

These innovations can lead to new industry standards, further establishing zirconia as an essential material in high-performance applications.

| Innovation Area | Potential Impact |

|---|---|

| Enhanced Formulations | Improved properties for broader applications |

| Sustainability Trends | Contribution to eco-friendly manufacturing practices |

This table highlights emerging areas of innovation influencing zirconia powder technology.

10. How Do Cost and Quality Impact Zirconia Powder Sourcing?

The economics of sourcing zirconia powder is critical for businesses, and understanding the relationship between cost and quality is paramount.

Navigating Supplier Options

Choosing a supplier involves balancing cost against quality. While lower prices may seem appealing, they can result in poorer quality materials that lead to failures in application.

Balancing Cost with Quality

Investing in high-quality zirconia may incur higher upfront costs. However, these investments often lead to lower maintenance expenses and improved product longevity. The long-term financial benefits should factor into purchasing decisions.

Long-Term Supplier Relationships

Building strong relationships with reliable suppliers can lead to better pricing and priority access to high-quality materials. Establishing trust and clear communication can benefit both parties.

| Cost vs. Quality | Considerations |

|---|---|

| Lower-cost options | Potential trade-offs in material reliability and performance |

| Quality investments | Long-term gains in product performance and reduced failure rates |

This table summarizes the relationship between cost and quality in sourcing zirconia powder.

Conclusion

In summary, the thermal expansion properties of zirconia powder offer substantial benefits for precision applications across multiple industries. Its predictable behavior under temperature changes, combined with its strength and durability, enhances performance and reliability in products. Companies that choose zirconia powder can expect improved product quality and reduced maintenance costs. To learn how Global Industry can support your sourcing decisions and optimize your usage of zirconia, please reach out for tailored solutions that meet your specific needs. Together, we can ensure successful outcomes and sustainable practices.

FAQ Section

Q1: What are the thermal expansion properties of zirconia powder?

Zirconia powder has a low thermal expansion coefficient, typically around 10.5 x 10^-6/°C. This means it experiences minimal dimensional changes with temperature fluctuations, making it highly stable for precision applications where maintaining exact dimensions is critical, such as in aerospace and medical devices.

Q2: How does zirconia powder compare to other materials regarding thermal expansion?

A2: Unlike metals like aluminum and steel, which generally have higher thermal expansion rates, zirconia powder remains more dimensionally stable under temperature changes. This lower rate helps to avoid issues like thermal stresses and distortions, ensuring that components retain their exact fit and function even when subjected to extreme temperatures.

Q3: What industries benefit from zirconia powder’s properties?

Zirconia powder is beneficial in several industries, including aerospace, automotive, electronics, and healthcare. In aerospace, it’s used for high-performance components that must endure variable temperatures, while in healthcare, zirconia serves in dental applications for its durability and aesthetic qualities. Its versatility makes it an asset in any high-precision environment.

Q4: What challenges should companies anticipate when using zirconia powder?

Companies may encounter challenges such as the higher cost of zirconia powder compared to traditional materials, which could impact budget considerations. Additionally, sourcing high-quality zirconia can be complex, requiring careful supplier selection. Handling these materials safely during production also necessitates specialized training and equipment to preserve their properties.

Q5: How can organizations stay updated on zirconia powder innovations?

Organizations can stay informed by subscribing to industry newsletters, participating in conferences, and engaging with academic and research institutions focused on material science. Networking with industry peers can also provide insights into emerging technologies and trends surrounding zirconia powder, keeping companies at the forefront of material innovation.