In the world of composite materials, understanding what surface features influence zirconia powder functionality is crucial for manufacturers and purchasing managers. Zirconia is frequently used due to its strength and versatility. However, many decision-makers struggle with how surface characteristics affect performance. This article will clarify this topic, offering insights that can help you make informed purchasing decisions. With a focus on practical applications and real-world examples, we’ll provide valuable information that can enhance your understanding of zirconia powder.

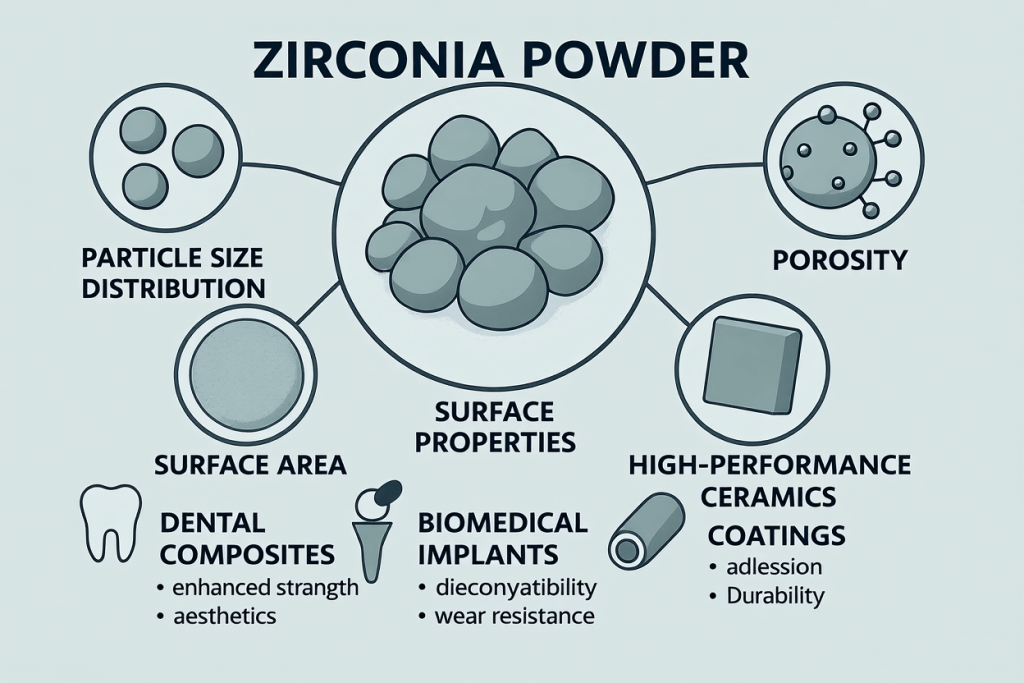

This image illustrates the various surface features of zirconia powder as they relate to its applications in composites.

What Are Surface Features of Zirconia Powder?

Surface features of zirconia powder refer to the physical and chemical attributes that can impact its functionality in composite materials. To begin, let’s define these features. They include particle size, shape, surface roughness, texture, and chemical composition. Each of these factors plays a significant role in determining how zirconia interacts with other materials.

Particle size is crucial; smaller particles present a larger surface area, enhancing adhesion and bonding capabilities within the composite. Shape influences how well the particles pack together, affecting the density and stability of the end product.

Surface roughness is another key aspect; a rougher surface can provide increased mechanical interlocking, improving the overall strength of the composite. Additionally, texture plays a role in how the zirconia particles disperse in the matrix material, impacting the homogeneity and performance of the composite.

Furthermore, chemical composition is vital, as variations or impurities in zirconia can influence its reactivity and compatibility with different matrix materials. The relationship between these surface features and their impact on functionality is complex, making it essential for manufacturers to consider these attributes when selecting zirconia powder for specific applications.

Here are some key surface features to consider:

- Particle Size: Affects bonding strength.

- Shape: Influences packing density.

- Surface Roughness: Affects mechanical interlocking.

- Texture: Impacts overall dispersion in the matrix.

- Chemical Composition: Determines compatibility with other materials.

By understanding and optimizing these surface features, manufacturers can tailor zirconia powder to meet the specific needs of various composite applications, enhancing performance and durability.

How Do Surface Characteristics Influence Functionality?

The surface characteristics of zirconia powder do not just determine its appearance; they play a vital role in its performance. So, how do these features impact functionality?

One major influence is through the interaction of zirconia with the matrix material in composites. When zirconia powder exhibits a rough surface texture, it can create stronger mechanical interlocks with the matrix, enhancing the overall strength of the composite. This roughness can also contribute to improved stress distribution, preventing localized failures under load.

Additionally, the particle size and shape contribute to how evenly the zirconia disperses within the matrix. In practical terms, well-dispersed zirconia enhances properties like toughness and thermal stability. Smaller particles can fill voids more effectively, enhancing the density and integrity of the final composite. Conversely, poorly dispersed zirconia may lead to weak spots and reduced performance, as unmixed clusters can act as stress concentrators.

Another aspect to consider is the chemical composition of zirconia. Impurities or variations in the material can alter bonding processes, affecting thermal and electrical conductivity. Thus, a comprehensive understanding of these functionalities can lead to informed decisions that maximize the potential of zirconia in various applications.

| Surface Characteristics | Impact on Functionality |

|---|---|

| Roughness | Enhances mechanical interlocking with matrix |

| Particle Size | Affects dispersion; smaller sizes often improve properties |

| Chemical Composition | Impurities can weaken bonds, affecting conductivity |

Here, we summarize some specific ways surface characteristics influence functionality:

- Increased Bond Strength: Rougher surfaces provide more contact area for bonding.

- Enhanced Thermal Stability: Better dispersion contributes to consistent thermal properties across the composite.

- Improved Toughness: Smaller, well-dispersed particles enhance the material’s ability to absorb energy under stress.

- Electrical Conductivity: Purity and surface energy will affect the overall conductivity in electronic applications.

Recognizing these impacts allows manufacturers to refine their material selections, contributing to high-performance, reliable composite products.

What Factors Affect Surface Characteristics?

Several factors contribute to the surface characteristics of zirconia powder. Let’s examine these factors.

First, particle size and morphology are critical. The production method can influence how particles are shaped and sized, which in turn affects how they behave within a composite. For example, spray drying often results in spherical particles, which can enhance flowability during mixing.

Next, surface roughness and texture are impacted by the manufacturing process. Chemical treatments or milling can create a rough surface that improves bonding but may also increase wear in applications like grinding media. Understanding these trade-offs is essential for making the right choice based on application requirements.

Lastly, the chemical composition of zirconia leads to variation in its properties. Different formulations may introduce variations in surface energy, which affects how the material interacts with liquids and other materials. Recognizing these factors enables manufacturers to tailor properties to suit specific needs.

| Factors Affecting Surface Characteristics | Descriptions |

|---|---|

| Particle Size and Morphology | Influences how zirconia behaves and disperses |

| Surface Roughness and Texture | Determines bonding strengths and wear characteristics |

| Chemical Composition | Affects interaction with other materials |

In addition to these factors, consider the following influences on surface characteristics:

- Production Techniques: Different methods produce varying particle shapes and sizes.

- Environmental Conditions: Humidity and temperature during processing can impact surface features.

- Purity Levels: Higher purity usually leads to better performance and predictability.

- Post-Processing Treatments: Additional treatments can enhance surface qualities for specific applications.

How Does Zirconia Powder Perform in Composites?

Zirconia powder’s performance in composites is conditioned by its surface characteristics. So, how does this material hold up under different conditions?

Typically, zirconia is known for its excellent mechanical properties, including high strength and fracture toughness. When incorporated into composites, it can significantly enhance these properties. For instance, in dental applications, zirconia’s durability makes it easy to maintain and enhances the longevity of dental restorations.

Let’s consider a comparison with other ceramic powders. Zirconia generally outperforms alumina and silicon carbide in tensile strength, making it a preferred choice in demanding applications. Its low thermal conductivity also allows for stability in high-temperature environments, which is a critical factor in aerospace and automotive industries.

Case studies illustrate this efficacy. For example, zirconia is often used in cutting tools due to its ability to withstand extreme conditions. The surface features contribute to how effectively it retains sharpness and durability in manufacturing processes.

| Performance Metrics | Zirconia | Alumina | Silicon Carbide |

|---|---|---|---|

| Tensile Strength | High | Medium | Medium |

| Thermal Conductivity | Low | Medium | Low |

| Fracture Toughness | High | Low | Medium |

Key performance metrics relevant to zirconia include:

- Durability: Resists wear and tear effectively.

- Fracture Toughness: Withstands cracking under load.

- Thermal Stability: Maintains properties at high temperatures.

- Corrosion Resistance: Endures harsh chemical environments.

Why Is Surface Treatment Important for Zirconia?

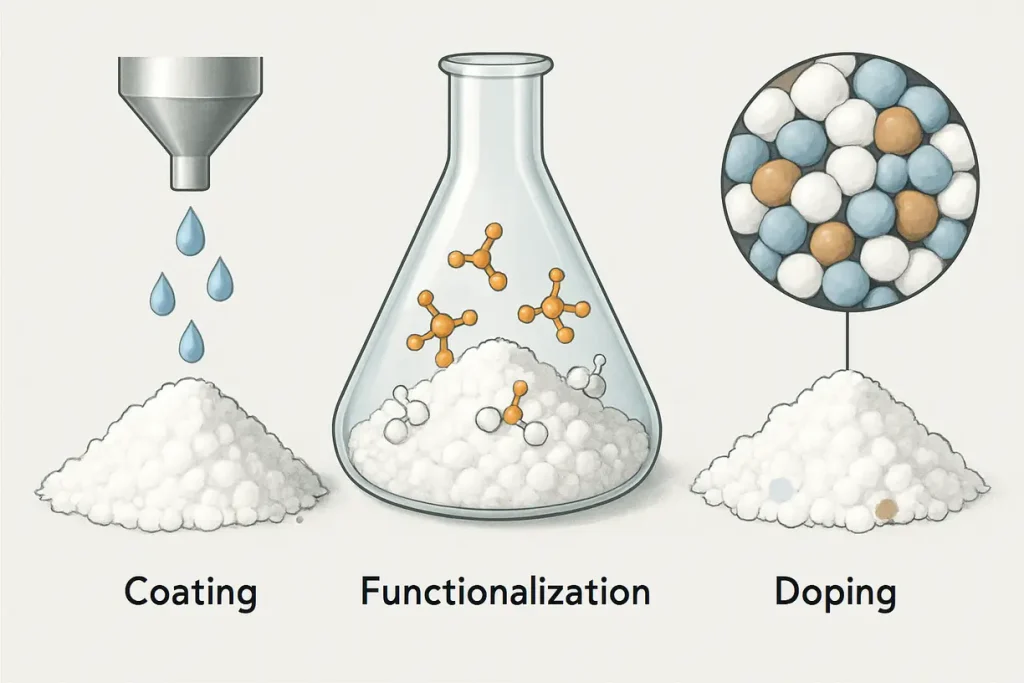

Surface treatment is vital for optimizing the performance of zirconia powder. What kind of surface treatments are commonly used? Treatments may include mechanical milling, chemical etching, or coating. Each treatment aims to modify the surface characteristics to enhance performance in various applications.

For instance, mechanical milling can improve surface roughness, promoting better bonding with other materials in the composite. By creating micro-level features on the zirconia surface, the overall surface area available for interaction is increased, leading to stronger adhesive bonds. This is particularly beneficial in applications where mechanical strength is paramount.

Chemical etching may remove impurities, leading to improved chemical compatibility with matrix materials. This process not only cleans the surface but can also modify its chemical properties, enhancing interactions with the resin or polymer matrix. As a result, the compatibility between the zirconia and the composite material is greatly enhanced, improving overall performance.

Moreover, these treatments impact how zirconia performs under stress. Proper surface treatment can increase the hardness and wear resistance of zirconia, making it suitable for industrial applications. This is essential in contexts like cutting tools and grinding media, where durability is crucial.

A practical application can be seen in dental implants where a rough surface promotes better biological integration with bone. This enhanced bonding capability not only improves strength but also significantly enhances healing times, leading to more successful outcomes in dental procedures.

Furthermore, newer coating techniques, such as thin film coatings, can provide additional functionalities, such as enhanced corrosion resistance or improved thermal protection. These innovations are vital as they open new avenues for zirconia applications in harsh environments, such as aerospace and high-temperature industrial settings.

| Surface Treatments | Effects |

|---|---|

| Mechanical Milling | Enhances surface roughness for better bonding |

| Chemical Etching | Removes impurities and improves surface energy |

| Coating | Protects against wear and corrosion; enhances performance |

In summary, effective surface treatment not only enhances initial performance but also contributes to the longevity and reliability of zirconia-based composites in various applications.

This image shows various techniques for surface treatment of zirconia powder to enhance its properties.

What Testing Methods Assess Zirconia Surface Characteristics?

Assessing surface characteristics is essential for ensuring quality in zirconia powder. Which methods are most effective? Several analytical techniques are commonly employed.

For instance, Scanning Electron Microscopy (SEM) provides detailed images of the surface structure. This method allows for the examination of particle morphology and roughness at a microscopic level. By using SEM, one can identify defects or anomalies on the surface that could impact performance.

Another effective approach is Atomic Force Microscopy (AFM), which measures surface topography with high precision. AFM can reveal fine details about surface roughness and texture that are critical for understanding adhesion properties. It is particularly useful in analyzing small samples where accuracy is paramount.

Additionally, surface area analysis techniques are useful for determining how much surface is available for interaction in a given quantity of zirconia. Higher surface areas typically mean better performance, as more area allows for enhanced bonding in composites.

Best practices in testing involve a combination of these methods. This multi-faceted approach provides a comprehensive view of zirconia powder characteristics, ensuring that materials meet the necessary specifications for their intended applications.

- SEM Analysis: Offers high-resolution imaging for morphology studies.

- AFM Measurements: Provides precise information on surface roughness.

- Surface Area Testing: Evaluates the overall surface area available for interaction.

- X-ray Diffraction (XRD): Assesses phase composition and crystallinity.

| Testing Method | Purpose |

|---|---|

| Scanning Electron Microscopy | Analyzes surface structure and roughness |

| Atomic Force Microscopy | Provides precise measurements of topography |

| Surface Area Analysis | Determines available bonding area |

How Can Manufacturers Optimize Zirconia Performance?

To achieve the best results with zirconia powder, manufacturers can adopt several strategies. What are the best approaches?

First, selecting the right zirconia powder is essential. Decisions should be based on specific surface characteristics suitable for the intended application. Understanding the relationship between surface features and performance can guide this selection.

Next, optimizing processing conditions can dramatically influence the properties of the final composite. Adjustments in temperature, pressure, or mixing techniques may enhance the bonding qualities of zirconia.

Collaboration between suppliers and manufacturers is also vital. Suppliers can provide detailed specifications about their zirconia powders, allowing manufacturers to choose the ideal material. Sharing insights on expected performance can foster better outcomes.

Some actionable strategies include:

- Tailoring Particle Size: Adjust to meet specific process requirements.

- Refining Surface Treatments: Implement new methods to improve bonding.

- Regular Quality Checks: Ensure consistent performance across batches.

- Conducting R&D: Stay ahead of market trends and advancements in technology.

Manufacturers increasingly rely on feedback to refine processes. Gathering data on actual application performance can lead to iterative improvements in product design.

| Optimization Strategies | Details |

|---|---|

| Material Selection | Choose zirconia based on specific requirements |

| Processing Optimization | Modify conditions for improved bonding |

| Supplier Collaboration | Work together to align specifications and needs |

What Trends Are Emerging in Zirconia Powder Utilization?

As industries evolve, so do the applications for zirconia powder. What are the latest trends? Innovations are emerging in the use of zirconia across various sectors.

In the medical field, zirconia is gaining attention for its biocompatibility. It is being used in a range of dental and orthopedic applications, enhancing both function and aesthetics.

In the automotive sector, zirconia powders are being investigated for use in fuel cells. Their properties can contribute to more efficient energy production, aligning with industry goals for cleaner technology.

Additionally, research is focusing on hybrid materials that combine zirconia with other substances to create customized properties. This trend allows for more versatility and tailored solutions to meet specific market demands.

Finally, increased interest in sustainability has prompted studies into recycling zirconia powders. Innovations can reduce waste and promote a more eco-friendly approach to material usage.

Emerging applications and uses for zirconia include:

- Dental Implants: Enhanced biocompatibility for better integration.

- Ceramic Coatings: Offers improved wear and thermal resistance.

- Fuel Cells: Explores efficient energy solutions for automotive applications.

- Advanced Composites: Merges zirconia with polymers for superior performance.

| Emerging Trends | Description |

|---|---|

| Medical Applications | Increased use in dental and orthopedic fields |

| Automotive Innovation | Potential in fuel cell technologies |

| Hybrid Materials | Combining zirconia with other materials |

| Sustainability Efforts | Focus on recycling and eco-friendly practices |

Conclusion

In summary, the performance of zirconia powder in composite applications is profoundly influenced by its surface characteristics. Understanding these features enables better decision-making for manufacturers and purchasing managers. By selecting the right surface properties, businesses can improve product durability and functionality. If you want to optimize your material choices, reach out to Global Industry for tailored solutions that meet your specific needs. Our expertise can help guide you in making the most informed decisions in your operations.

FAQ Section

Q1: What are the main surface features of zirconia powder?

Zirconia powder typically exhibits several key surface features, including particle size, which affects the overall reactivity and bonding capabilities; surface roughness, which influences adhesion and mechanical interlocking; and chemical composition, which determines compatibility with matrix materials. These features are crucial for tailoring zirconia to specific applications in composites.

Q2: How do surface characteristics impact zirconia functionality?

Surface characteristics significantly affect zirconia’s bonding with surrounding materials, which in turn influences various properties like mechanical strength, thermal conductivity, and wear resistance. For instance, a rougher surface may enhance mechanical interlocking, leading to a stronger composite, while a smoother surface may improve flowability during processing.

Q3: What methods can be used to assess zirconia powder surface characteristics?

Several analytical techniques are employed to assess the surface characteristics of zirconia powder. Scanning Electron Microscopy (SEM) provides high-resolution images to analyze particle morphology, while Atomic Force Microscopy (AFM) offers precise measurements of surface topography. Surface area analysis helps determine the amount of active bonding area available, which is crucial for the powder’s effectiveness in composites.

Q4: Why are surface treatments applied to zirconia powder?

Surface treatments are applied to zirconia powder to enhance its performance in composite applications. These treatments may include mechanical milling to improve surface roughness or chemical processes to remove impurities, resulting in better bonding with matrix materials. By optimizing surface properties, manufacturers can ensure that the zirconia powder performs consistently under various operational conditions.

Q5: What future trends are expected in zirconia powder usage?

Emerging trends in zirconia powder usage include increased integration in medical applications, such as dental implants, due to its biocompatibility. In the automotive sector, its potential use in fuel cells and advanced materials is being explored. Additionally, there’s growing interest in developing hybrid materials that combine zirconia with polymers for unique properties, along with innovations focused on sustainability and recycling to reduce environmental impact.