In recent years, zirconia powder has gained remarkable traction in various industries worldwide. This rapid growth prompts many professionals to ask: what factors are driving its rise in international markets? Most purchasing managers face crucial challenges in selecting materials that ensure performance while aligning with market trends. This article addresses these concerns by examining the unique aspects of zirconia powder and the factors contributing to its increasing popularity. By the end of this read, you will understand why zirconia powder stands out as a material of choice, backed by reliable insights from industry experts.

What Are the Unique Properties of Zirconia Powder?

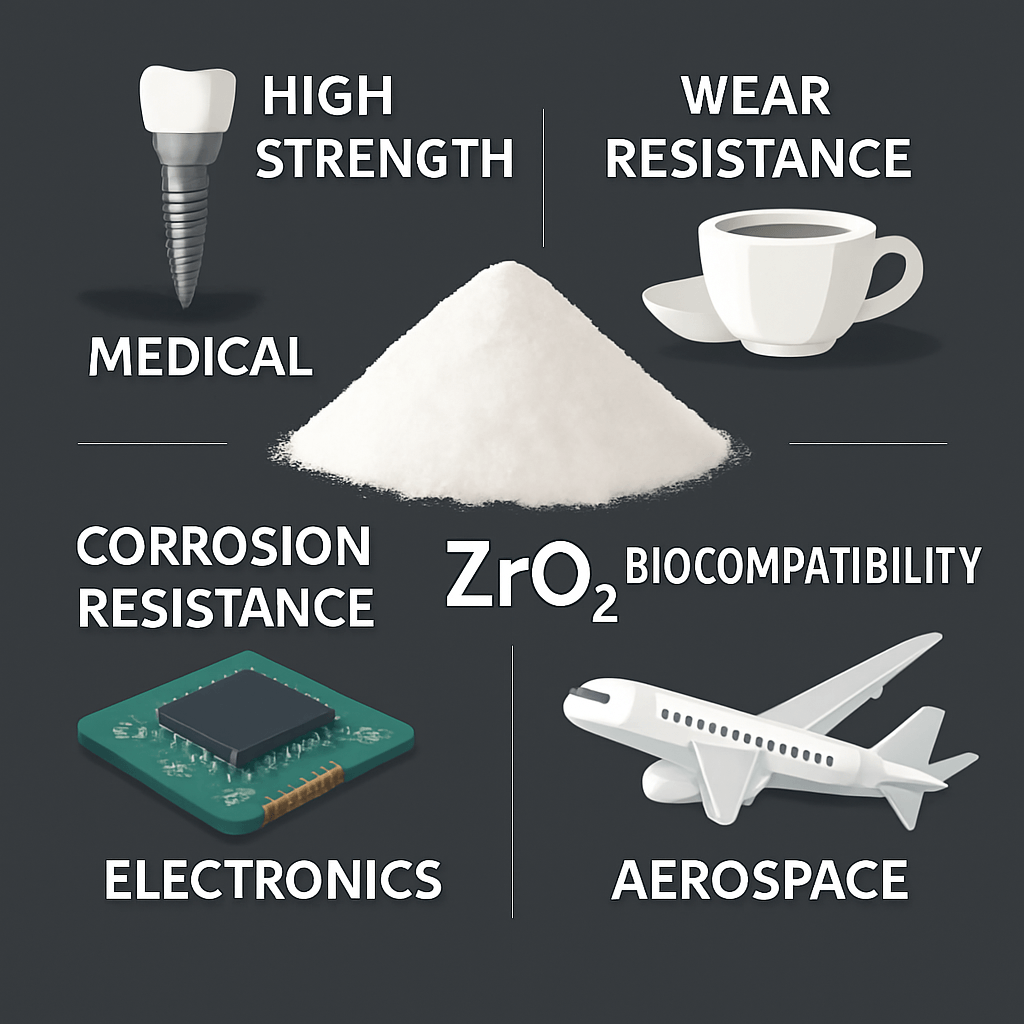

Zirconia powder is renowned for its unique properties, setting it apart from other materials. Its toughness, resistance to corrosion, and thermal stability make it suitable for various applications. For instance, zirconia is an excellent insulator, which is why it is often used in electronics and thermal barriers.

Moreover, zirconia has a high melting point. This property is particularly useful in manufacturing high-performance ceramics and metal alloys. Additionally, zirconia is biocompatible, making it an ideal choice for medical applications, such as dental implants and prosthetics.

But why do these properties matter? They provide industries with materials that enhance product durability and effectiveness. As such, organizations find that using zirconia powder can lead to improved operational efficiency and performance.

Here are some noteworthy benefits of zirconia’s unique properties:

- Chemical stability: Resistant to acids and bases, suitable for harsh environments.

- High strength: Provides excellent mechanical properties for structural applications.

- Low thermal conductivity: Effective in thermal barrier coatings.

| Property | Description | Industry Application |

|---|---|---|

| Toughness | Excellent wear resistance | Manufacturing, Automotive |

| Corrosion Resistance | Resists degradation in harsh environments | Electronics, Aerospace |

| Thermal Stability | Can withstand high temperatures | Construction, Energy |

| Biocompatibility | Safe for medical use | Healthcare, Dental |

This image illustrates the unique properties of zirconia powder, showcasing its diverse applications in various industries.

How Is Zirconia Powder Used Across Industries?

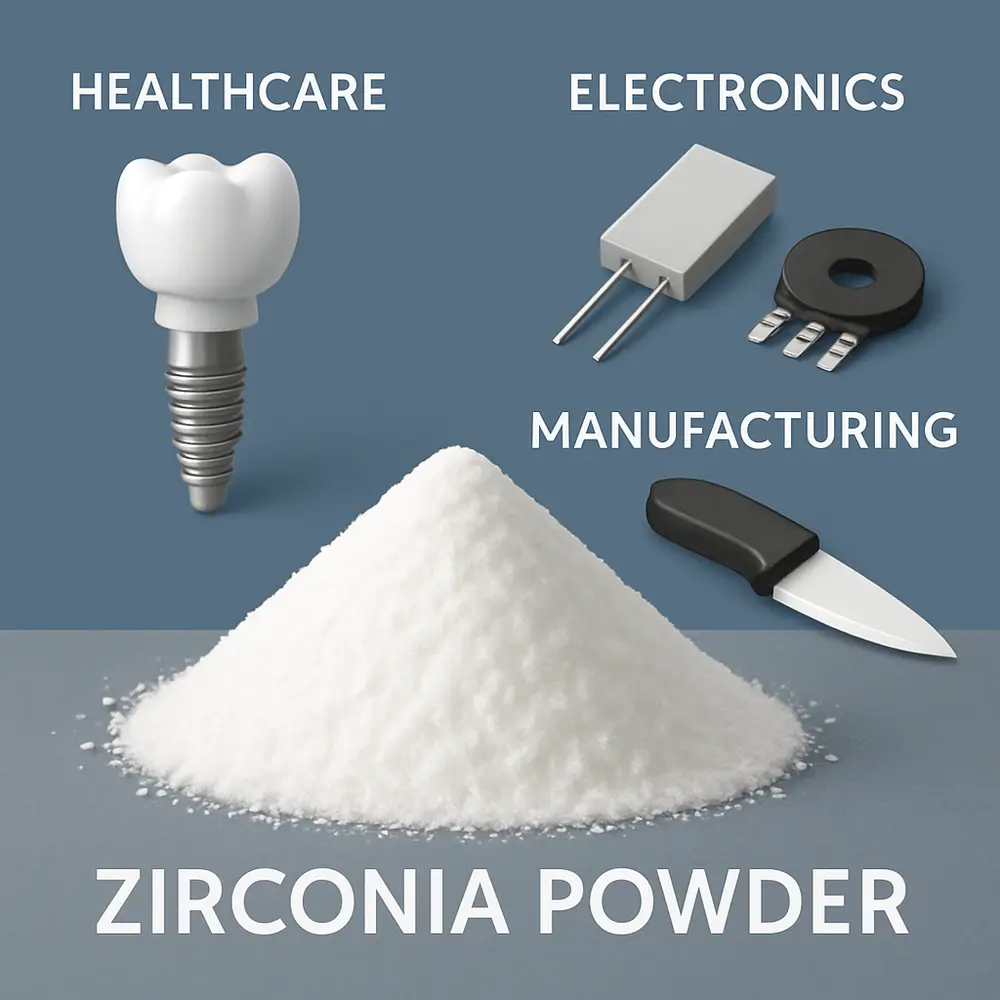

Zirconia powder finds applications in numerous industries, highlighting its versatility.

In healthcare, its biocompatibility allows for safe use in dental crowns and prostheses. Many dental practices prefer this material due to its aesthetic appeal and strength, providing patients with durable solutions.

In the manufacturing sector, zirconia is utilized for cutting tools and wear-resistant components. Industries rely on zirconia because it enhances the operational lifespan of tools, reducing replacement costs and downtime.

The electronics industry also benefits from zirconia’s insulating properties. It plays a crucial role in manufacturing components like sensors and capacitors, where temperature resistance is critical.

Interestingly, as industries evolve, the demand for zirconia powder continues to rise, reflecting its increasing importance in modern applications.

| Industry | Application | Benefits |

|---|---|---|

| Healthcare | Dental implants | Durable, aesthetic, and biocompatible |

| Manufacturing | Cutting tools | Enhanced tool life, cost-efficiency |

| Electronics | Capacitors and sensors | Effective insulation and temperature stability |

This image shows various applications of zirconia powder across healthcare, manufacturing, and electronics industries.

Benefits of Using Zirconia Powder:

- Enhanced Durability: Increases product longevity and reduces the need for replacements.

- Versatile Applications: Suitable for a wide range of uses across multiple industries.

- Cost-Effective: Reduces overall manufacturing expenses due to lower maintenance needs.

- High Performance: Provides reliable performance even under harsh conditions.

- Aesthetic Qualities: Especially important in medical and dental applications, combining function with appearance.

What Markets Are Experiencing High Demand for Zirconia Powder?

The demand for zirconia powder is surging in several key markets, primarily driven by technological advancements and increased consumer needs.

Regions like North America and Asia Pacific are leading in zirconia production. The construction and automotive sectors particularly influence this demand, as they seek materials that offer strength and cost-effectiveness.

Emerging markets in Latin America and Africa are also seeing growth. As these regions develop infrastructure and industrial capabilities, the need for high-quality materials like zirconia powder increases.

So, which regions should businesses watch closely? These market dynamics signal evolving opportunities for suppliers and manufacturers eager to expand their footprint globally.

| Region | Key Drivers | Market Opportunity |

|---|---|---|

| North America | Advanced manufacturing techniques | High demand in automotive sector |

| Asia Pacific | Rapid industrial growth | Expanding construction projects |

| Latin America | Infrastructure development | Increased demand in healthcare |

| Africa | Emerging industries | Adoption of advanced technologies |

Potential Growth Areas:

- Wind Energy: Usage in components for wind turbines.

- Healthcare Tech: Expanding applications in biocompatible implants.

- Automotive Innovations: Increasing demand for lightweight materials in electric vehicles.

- Cutting-edge Ceramics: New markets for advanced ceramic applications in construction.

- Consumer Electronics: Growing use in high-tech electronic devices.

What Are the Benefits of Using Zirconia Powder?

Choosing zirconia powder comes with several core advantages that appeal to businesses.

First and foremost, zirconia offers a longer lifespan compared to many alternative materials. This longevity translates into cost savings over time, as users experience fewer replacements and repairs.

Second, zirconia’s performance in high-stress applications means better reliability. Whether in dental work or industrial tools, the durability of zirconia boosts confidence in the products created with it.

Additionally, zirconia powder often requires less processing than alternatives. This can lead to less energy consumption during manufacturing, aligning with sustainability goals many companies prioritize today.

Ultimately, the benefits of using zirconia powder establish it as a material that not only meets but exceeds industry standards.

| Benefit | Description | Financial Impact |

|---|---|---|

| Longer lifespan | Reduced replacement frequency | Cost savings over time |

| High reliability | Improved product performance | Increased customer satisfaction |

| Lower processing costs | Energy-efficient manufacturing | Reduced operational expenses |

Key Advantages to Businesses:

- Reduction in Overall Costs: Lower maintenance and replacement expenses.

- Increased Customer Trust: Improved product quality leads to higher customer satisfaction.

- Innovation Encouragement: Reliable materials foster innovation in product development.

- Compliance with Regulations: Meeting industry standards more easily with high-quality materials.

- Eco-friendly Options: Sustainability initiatives can be supported with effective sourcing.

How Does Technological Advancements Affect Zirconia Powder Usage?

Technological progress plays a significant role in shaping the applications of zirconia powder. Innovations in processing and manufacturing techniques have expanded the potential uses of this material.

Advancements in 3D printing technology have opened new doors for zirconia powder. This capability allows for bespoke designs and rapid prototyping, catering to specific industry needs with remarkable efficiency.

Furthermore, research continues into enhancing the properties of zirconia. New formulations and blends can lead to even better characteristics, making it suitable for emerging applications in industries such as renewable energy or advanced ceramics.

So, how should businesses respond to these advancements? Keeping track of technology trends can position companies to leverage zirconia and maintain a competitive edge.

| Advancement | Impact on Use | Future Potential |

|---|---|---|

| 3D Printing | Custom designs and rapid prototyping | Tailored solutions for niches |

| Enhanced Formulations | Improved properties for new applications | Expanding range of uses in industries |

Technological Impacts on Zirconia Powder:

- Precision Manufacturing: Enhanced accuracy in creating components.

- Material Optimization: Improved formulations leading to better performance.

- Faster Production Cycles: Reduced lead times in manufacturing processes.

- Innovation in Application: Development of new uses in technology and healthcare.

- Sustainability in Production: Advanced methods may lead to lower environmental impacts.

What Challenges Do Businesses Face with Zirconia Powder?

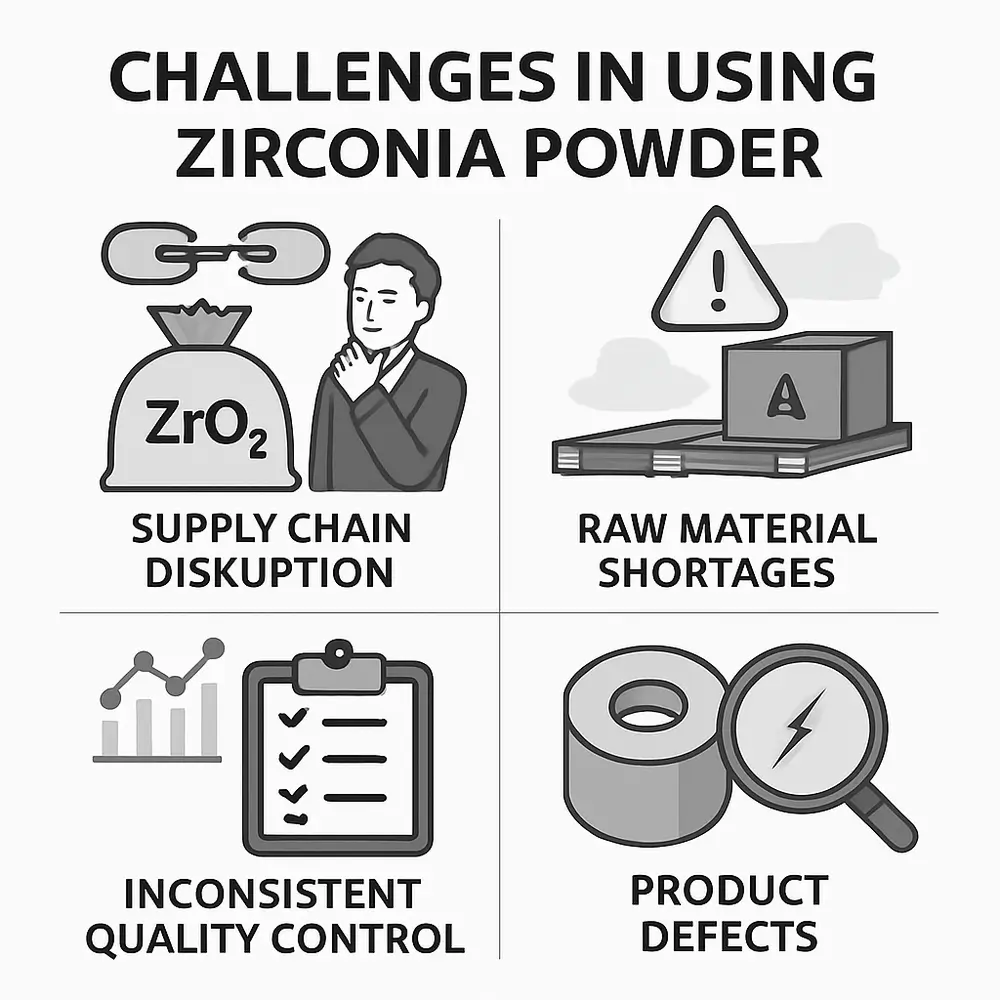

While zirconia powder offers numerous benefits, businesses must also navigate challenges related to its use.

Supply chain complexities can create hurdles. As demand grows, securing consistent, high-quality materials becomes vital. Companies in this space need to establish reliable sourcing strategies to mitigate risks.

Additionally, quality control is paramount. Variations in zirconia powder can affect performance, leading to dissatisfaction among customers. Maintaining stringent quality assurance protocols ensures that products meet industry standards.

Lastly, regulatory compliance can pose challenges. Different regions have varying standards for materials used in manufacturing, particularly in healthcare. Staying informed about these regulations is critical to avoiding potential setbacks.

In conclusion, addressing these obstacles strategically positions businesses for future success in leveraging zirconia powder.

| Challenge | Description | Mitigation Strategies |

|---|---|---|

| Supply Chain Complexity | Difficulty in obtaining consistent quality | Develop strong supplier relationships |

| Quality Control | Variability in material performance | Implement stringent QA protocols |

| Regulatory Compliance | Variability in regulations across regions | Stay informed on local standards |

This image highlights the challenges businesses face when using zirconia powder, focusing on supply and quality issues.

Common Challenges to Address:

- Supplier Reliability: Finding consistent suppliers can be difficult.

- Material Variability: Quality fluctuations can lead to inconsistent products.

- Regulatory Navigation: Keeping up with varied regulations can be cumbersome.

- Cost Pressures: Rising raw material costs require strategic budgeting.

- Technological Changes: Rapid advancements may require constant updates to operations.

How Can Companies Effectively Source Zirconia Powder?

Effective sourcing of zirconia powder is vital for companies looking to capitalize on its advantages.

First, businesses should conduct thorough market research to identify potential suppliers. Evaluating supplier reputation, experience, and product quality is essential during this process.

Second, forming strong relationships with suppliers can result in better pricing and prioritization in supply chains. Establishing long-term partnerships enhances security in sourcing practices.

Lastly, it is crucial to assess quality assurance measures offered by potential suppliers. Understanding their testing and certification processes can help ensure consistent material quality.

So, what’s the takeaway? Adopting a proactive sourcing approach leads to reliable and high-quality zirconia powder availability.

| Sourcing Strategy | Description | Benefits |

|---|---|---|

| Market Research | Investigating potential suppliers | Informed decision-making |

| Supplier Relationships | Building strong connections | Better pricing and priority access |

| Quality Assessment | Evaluating supplier QA measures | Ensures consistent product quality |

Sourcing Tips for Zirconia Powder:

- Diversify Suppliers: Reduce risk by not relying on a single source.

- Verify Certifications: Ensure suppliers meet industry standards and certifications.

- Engage in Negotiations: Optimize purchasing terms and conditions.

- Monitor Market Trends: Stay informed about fluctuations in prices and demand.

- Conduct Audits: Regularly check supplier practices to maintain quality assurance.

What Should Be Considered in the Sustainable Use of Zirconia Powder?

Sustainability is at the forefront of many industries today. When utilizing zirconia powder, businesses should consider its environmental impact.

First, companies must evaluate the sustainability of their sourcing practices. Choosing suppliers that prioritize environmentally friendly processes contributes to overall sustainability goals.

Second, minimizing waste during production is essential. Techniques like recycling zirconia or optimizing material usage can reduce environmental footprints.

Finally, companies should remain compliant with evolving regulations that govern materials and their environmental impact. Being proactive in understanding and adapting to these standards is crucial.

Ultimately, integrating sustainability into the use of zirconia powder not only complies with regulations but also meets customer expectations for environmentally responsible practices.

| Sustainability Measure | Description | Impact |

|---|---|---|

| Responsible Sourcing | Choosing eco-friendly suppliers | Reduces overall environmental impact |

| Waste Minimization | Implementing recycling and resource efficiency | Supports sustainability goals |

| Regulatory Compliance | Adhering to material regulations | Builds trust among consumers and stakeholders |

Sustainable Practices in Using Zirconia Powder:

- Eco-friendly Sourcing: Partner with suppliers who focus on sustainability.

- Green Manufacturing: Implement clean production technologies to minimize waste.

- Lifecycle Analysis: Assess the environmental impact from sourcing to disposal.

- Waste Management Techniques: Employ recycling practices to repurpose materials.

- Community Engagement: Collaborate with local communities on sustainability initiatives.

How Do Market Dynamics Influence Zirconia Powder Prices?

Understanding market dynamics is crucial for businesses to navigate pricing strategies for zirconia powder.

Several factors influence prices in this sector. Supply and demand fluctuations, production costs, and geopolitical factors all play a role in determining market prices.

For example, if demand for zirconia spikes due to increased production in certain industries, prices may rise. Conversely, if new suppliers enter the market and increase availability, prices could stabilize or decrease.

Therefore, keeping an eye on these market trends is essential for effective pricing strategies and budgeting.

| Factor | Influence on Pricing | Strategic Response |

|---|---|---|

| Supply & Demand | Higher demand can increase prices | Monitor trends and adjust forecasts |

| Production Costs | Changes in raw material costs affect prices | Optimize production processes |

| Geopolitical Factors | International conflicts can disrupt supply chains | Diversify suppliers to reduce risk |

Key Price Influencers:

- Global Economic Trends: Economic growth in key regions can heighten demand.

- Material Availability: Shortages in raw materials can push prices up.

- Technological Improvements: Advances in manufacturing can reduce production costs.

- Trade Policies: Tariffs and trade agreements can impact sourcing strategies.

- Market Competition: New entrants into the market can drive prices down.

What Future Trends Should Be Monitored for Zirconia Powder?

As industries evolve, monitoring future trends for zirconia powder is vital for informed decision-making.

One significant trend is the increasing adoption of advanced applications in emerging technologies, such as energy storage and bioengineering. These developments could open new markets for zirconia powder, driving demand further.

Additionally, sustainability continues to shape the industry. Companies focusing on eco-friendliness will likely adopt zirconia for its potential environmental benefits.

Lastly, staying updated on regulatory changes is crucial. As stringent standards continue to evolve, businesses must adapt to keep up with compliance needs.

So, how prepared are you to embrace these trends? Keeping a close watch now will position your business for future growth.

| Trend | Implications | Action Required |

|---|---|---|

| Advanced Applications | New markets for zirconia | Invest in research and development |

| Sustainability Focus | Increase in demand for eco-friendly materials | Adjust sourcing and production practices |

| Evolving Regulations | Need for compliance adaptation | Stay informed on regulatory updates |

Conclusion

In summary, zirconia powder is poised for growth across various industries due to its unique properties and wide-ranging applications. By considering its benefits and challenges, companies can harness this material effectively. Engaging with Global Industry can keep you informed about the latest developments and innovations in zirconia powder. Together, we can position your business to thrive in this dynamic environment.

FAQ Section

Q1: What makes zirconia powder unique compared to other materials?

Zirconia powder possesses exceptional hardness, thermal stability, and biocompatibility, making it suitable for a wide range of industrial applications. Its unique crystalline structure contributes to its strength and resistance to wear and deformation, which is not commonly found in other ceramic materials. Additionally, it’s non-reactive, allowing it to maintain its properties in harsh environments, making it particularly valuable in fields like dental, biomedical, and high-temperature applications.

Q2: Which industries are the largest consumers of zirconia powder?

Industries such as healthcare, manufacturing, and electronics are the primary consumers of zirconia powder due to the material’s versatility and reliability. Specifically, in healthcare, it is widely used for dental crowns and implants because of its aesthetic appeal and strength. In manufacturing, zirconia is essential for producing cutting tools and other industrial components that require high wear resistance. Meanwhile, in the electronics sector, its insulating properties are crucial in producing capacitors, sensors, and semiconductor components.

Q3: How has the demand for zirconia powder changed in recent years?

The demand for zirconia powder has surged over the past decade, driven by advancements in technology and increased applications across various sectors. Factors such as the rise of electric vehicles, improvements in dental technology, and the growth of wearable electronics have spurred the need for zirconia-based materials. Additionally, the push for sustainable and high-performance materials in industries such as renewable energy and advanced manufacturing has further fueled demand for zirconia powder.

Q4: What challenges do businesses face when sourcing zirconia powder?

Businesses encounter several challenges when sourcing zirconia powder, including ensuring consistent quality and maintaining strong supplier relationships. Variability in zirconia powder quality can affect the performance of final products, which is particularly important in regulated industries like healthcare. Additionally, managing logistics and supply chain disruptions can lead to increased costs and project delays. Organizations must also navigate the complexities of compliance with varying regulations across different regions, which can complicate sourcing efforts.

Q5: How can companies prepare for future trends in the zirconia powder market?

To prepare for future trends in the zirconia powder market, companies should focus on continuous market research and monitor emerging technologies that could influence demand. Investing in innovation and R&D can help businesses develop new zirconia applications and improve existing products. Furthermore, fostering strategic partnerships with suppliers can enhance resource availability and secure competitive pricing. Staying adaptive to regulatory changes and consumer preferences will also be essential for maintaining a leadership position in this evolving industry. Additionally, companies should consider implementing sustainable practices to align with the growing demand for eco-friendly materials.