High-purity zirconia powder is becoming increasingly important across various industries. Professionals often face the challenge of identifying the best materials for their specific applications. This article addresses that concern, clarifying which industries gain the most from using high-purity zirconia powder. By examining key applications and benefits, we aim to provide valuable insights for purchasing managers and decision-makers. Trust in our expertise, as we delve into the significant implications this material presents for industries that are vital to modern economies.

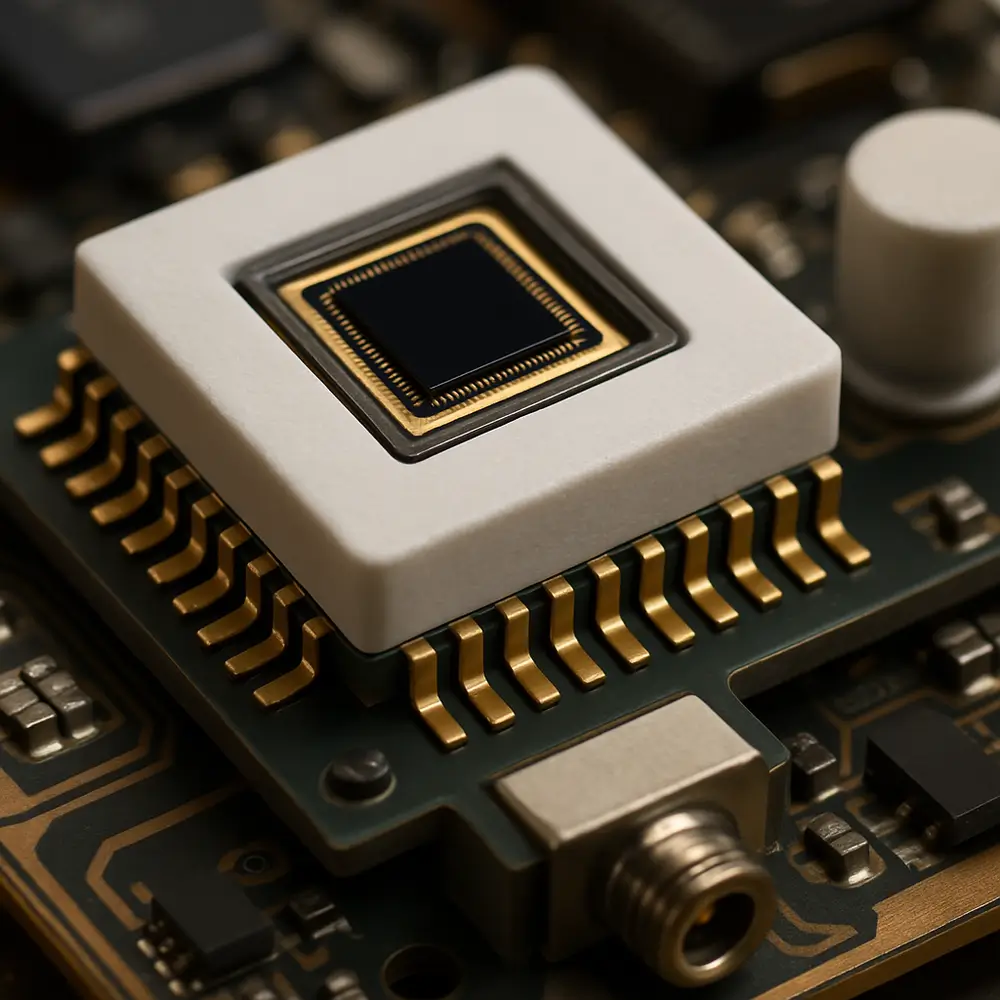

This image represents high-purity zirconia powder applications across multiple industries.

Which Industries Utilize High-Purity Zirconia Powder?

High-purity zirconia powder has found applications in numerous industries, each benefiting from its unique properties. A concise overview reveals that the sectors making substantial use of this material include healthcare, aerospace, electronics, automotive, construction, and energy.

In the healthcare sector, high-purity zirconia is used in medical devices, dental ceramics, and surgical tools. Its biocompatibility and strength make it ideal for implants and prosthetics.

Moving to aerospace, this powder is crucial in producing components capable of withstanding extreme conditions. It enhances fuel efficiency and reduces weight, which are essential factors in aircraft design.

In the electronics industry, high-purity zirconia serves as an insulator in capacitors and other electronic components, contributing to performance enhancement.

The automotive industry employs high-purity zirconia in fuel cells and sensors, delivering effective solutions for modern engines.

Finally, construction utilizes this material in producing durable and high-strength building materials, effectively enhancing structural performance.

Understanding the diverse applications of high-purity zirconia powder highlights its versatility and relevance in today’s industrial landscape.

| Industry | Applications | Key Benefits |

|---|---|---|

| Healthcare | Medical devices, dental ceramics | Biocompatibility, durability |

| Aerospace | Components for aircraft | Lightweight, efficiency |

| Electronics | Insulators for components | Performance enhancement |

| Automotive | Fuel cells, sensors | Efficient engine solutions |

| Construction | High-strength building materials | Enhanced durability |

What Makes High-Purity Zirconia Powder Valuable?

The value of high-purity zirconia powder stems from its unique characteristics. These properties include its exceptional strength, thermal stability, and chemical resistance.

First, strength is a defining feature. High-purity zirconia can withstand harsh conditions while maintaining its structural integrity. This makes it ideal for demanding applications in various sectors, particularly where reliability is paramount.

Next, thermal stability is crucial in industries exposed to extreme temperatures. High-purity zirconia does not degrade easily under heat, making it suitable for aerospace and automotive applications where thermal endurance is critical.

Additionally, chemical resistance allows high-purity zirconia to be used in corrosive environments. This is particularly important in healthcare, where sterilization and cleanliness are crucial.

Ultimately, these properties enhance the overall performance of products using high-purity zirconia powder. Companies can trust that solutions incorporating this material will deliver exceptional results.

| Property | Importance | Industry Applications |

|---|---|---|

| Strength | Withstands harsh conditions | Aerospace, automotive |

| Thermal Stability | Maintains integrity under heat | Aerospace, electronics |

| Chemical Resistance | Effective in corrosive environments | Healthcare, industrial |

How Does High-Purity Zirconia Powder Impact the Healthcare Sector?

In the healthcare sector, high-purity zirconia powder plays a critical role in a variety of applications. Medical devices made from this material ensure safety and durability, which are vital for patient trust and health outcomes.

For dental applications, high-purity zirconia is a preferred choice for crowns and bridges. Its ability to mimic the appearance of natural teeth while providing strength makes it a go-to material for dental professionals.

In surgical tools, the use of high-purity zirconia ensures longevity and optimum performance. Its resistance to wear and tear translates to lower replacement costs over time, providing hospitals and clinics with significant savings.

Moreover, implants crafted from high-purity zirconia are biocompatible and help reduce rejection rates. This advantage not only leads to better patient outcomes but also enhances surgical success rates.

Benefits of Using High-Purity Zirconia in Healthcare

- Biocompatibility: Minimizes rejection and enhances healing.

- Durability: Reduces wear and enhances tool longevity.

- Aesthetic Appeal: Mimics natural anatomy for dental applications.

These applications illustrate high-purity zirconia powder’s vital contribution to healthcare, reinforcing the importance of selecting quality materials in medical solutions.

| Application | Benefits | Impact on Healthcare |

|---|---|---|

| Dental Crowns | Aesthetic appeal, strength | Enhanced patient satisfaction |

| Surgical Tools | Durability, performance | Cost savings over time |

| Implants | Biocompatibility, lower rejection rates | Improved surgical success |

What Role Does High-Purity Zirconia Play in Aerospace and Defense?

High-purity zirconia is gaining traction in the aerospace and defense sectors, where its unique attributes lead to enhanced performance and safety.

In aerospace applications, this powder is used to manufacture turbine blades and components that require high-temperature performance. Its ability to maintain strength and stability at elevated temperatures contributes significantly to fuel efficiency and overall aircraft performance.

In the defense industry, high-purity zirconia powder is employed in various applications, including armor systems. Its high hardness offers effective protection while remaining lightweight, a crucial factor in military operations.

Another significant application is in thermal barrier coatings, which protect components from extreme heat. This use showcases how high-purity zirconia enhances safety and reliability in both aerospace and defense applications.

Key Applications in Aerospace and Defense

- Turbine Blades: Critical for engine efficiency.

- Armored Vehicles: Provides weight-efficient protection.

- Thermal Barrier Coatings: Insulates components from high temperatures.

Overall, the benefits of high-purity zirconia are evident in the advanced technology found in these sectors. Investing in materials with such properties can significantly impact operational success.

| Aerospace Application | Benefit | Defense Application |

|---|---|---|

| Turbine Components | High-temperature performance | Armor systems |

| Thermal Barrier Coatings | Effective protection | Lightweight solutions |

How Are Electronics Manufacturers Benefiting from High-Purity Zirconia?

The electronics manufacturing industry is leveraging high-purity zirconia powder in numerous applications, leading to improved performance and efficiency.

One of the key uses is in capacitors, where high-purity zirconia enhances the dielectric properties, resulting in better energy storage capabilities. This leads to more efficient electronic devices.

Another application is in insulating layers for various components. High-purity zirconia serves as a reliable insulator, preventing short circuits and ensuring durability in electronic circuits.

Furthermore, its thermal stability provides protection against heat generated by electronic components, helping them operate at optimal levels. This ensures that devices perform better and last longer.

Advantages of High-Purity Zirconia in Electronics Manufacturing

- Enhanced Dielectric Properties: Improves energy efficiency.

- Reliable Insulation: Prevents short circuits in critical components.

- Thermal Stability: Protects against component overheating.

As the demand for efficient electronic devices grows, high-purity zirconia continues to play a vital role in the advancement of technologies in this sector.

| Application | Benefit | Result |

|---|---|---|

| Capacitors | Improved dielectric properties | More efficient energy storage |

| Insulating Layers | Reliable insulation | Reduced risk of short circuits |

| Thermal Protection | Optimal component operation | Increased durability of electronic devices |

This image depicts high-purity zirconia applications within the electronics industry.

What Advantages Does High-Purity Zirconia Offer in the Automotive Industry?

In the automotive industry, high-purity zirconia powder is making waves with its diverse applications that enhance overall vehicle performance.

One important use is in fuel cells, which are becoming essential for developing clean energy vehicles. High-purity zirconia aids in the efficient electrochemical reactions required for hydrogen fuel cell operation, promoting a more sustainable future.

Moreover, high-purity zirconia is implemented in sensors that monitor various vehicle systems, ensuring optimal performance and safety. These sensors help maintain fuel efficiency and reduce emissions by providing critical data to control systems.

In addition, brake components made from high-purity zirconia offer improved performance and longevity, crucial for modern vehicles that demand high safety standards.

Automotive Applications Using High-Purity Zirconia

- Fuel Cell Components: Enhances efficiency of hydrogen fuel cells.

- Electrical Sensors: Critical for monitoring performance and emissions.

- Brake Systems: Offers durability and enhanced performance.

Overall, high-purity zirconia presents significant advantages, making it an essential material for innovation in the automotive sector.

| Application | Advantage | Outcome |

|---|---|---|

| Fuel Cells | Efficient electrochemical reactions | Promotion of clean energy |

| Sensors | Enhanced monitoring capabilities | Optimal vehicle performance |

| Brake Components | Improved durability and performance | Higher safety standards |

Which Industries Benefit from High-Purity Zirconia in Construction?

The construction industry benefits significantly from high-purity zirconia powder, particularly in developing innovative building materials.

High-purity zirconia is used in concrete mixtures, providing enhanced strength and durability. When added to concrete, it improves the composite material’s overall performance, leading to safer structures.

Additionally, this powder finds applications in ceramic tiles and elements. High-purity zirconia contributes to the aesthetic and functional qualities of tiles, making them more appealing and longer-lasting.

Another application is in producing insulating materials for energy efficiency in buildings. High-purity zirconia enhances thermal insulation properties, promoting sustainability in construction projects.

Benefits of High-Purity Zirconia in Construction

- Strengthened Concrete: Increases durability in structures.

- Aesthetic Improvement: Elevates the appearance of tiles and fixtures.

- Energy Efficiency: Provides superior insulation for buildings.

The result is a range of construction materials that not only meet safety standards but also cater to contemporary needs for energy efficiency and aesthetics.

| Application | Benefit | Contribution to Construction |

|---|---|---|

| Concrete Mixtures | Enhanced strength | Safer structures |

| Ceramic Tiles | Improved aesthetics and durability | Long-lasting materials |

| Insulating Materials | Better thermal insulation | Energy efficiency in buildings |

This image reflects high-purity zirconia’s use in various construction applications.

How Is High-Purity Zirconia Powder Used in the Energy Sector?

In the energy sector, high-purity zirconia powder plays a crucial role in developing sustainable and efficient energy solutions.

High-purity zirconia is commonly used in solid oxide fuel cells (SOFC), which convert chemical energy into electrical energy with high efficiency. This application supports the transition toward renewable energy sources and reduces reliance on fossil fuels.

Additionally, this powder is used in photovoltaic cells, improving the efficiency of solar energy applications. High-purity zirconia contributes to better performance by enhancing the electrical and thermal properties of these cells.

Furthermore, its use in energy storage systems is becoming more prevalent. High-purity zirconia increases the stability and lifespan of energy storage solutions, allowing for more reliable renewable energy systems.

Energy Sector Contributions of High-Purity Zirconia

- Solid Oxide Fuel Cells: High efficiency in energy conversion.

- Photovoltaic Cells: Helps improve solar energy capture.

- Energy Storage: Enhances longevity and reliability of systems.

Investing in high-purity zirconia for energy applications not only promotes sustainability but also contributes to technological advancements that are crucial for the future.

| Application | Role | Impact |

|---|---|---|

| Solid Oxide Fuel Cells | Efficient energy conversion | Supports renewable energy growth |

| Photovoltaic Cells | Enhances efficiency | Improves solar energy performance |

| Energy Storage Systems | Increases stability and lifespan | Ensures reliable renewable solutions |

What Challenges Are Faced in Sourcing High-Purity Zirconia?

Sourcing high-purity zirconia powder comes with its set of challenges that professionals must navigate.

One major challenge is the supply chain. Fluctuations in availability can impact production timelines. Companies must establish reliable suppliers to maintain consistent quality and access to the material.

Additionally, quality control is critical. High-purity zirconia must meet specific industry standards to ensure performance in demanding applications. This necessitates rigorous testing and certification processes, which can be resource-intensive.

Another consideration is the cost of high-purity zirconia. While it offers numerous benefits, the price can sometimes pose budgetary constraints for companies. Organizations must weigh the value it provides against their financial limitations.

Key Challenges in Sourcing High-Purity Zirconia

- Supply Chain Reliability: Consistent access to materials is essential.

- Regulatory Compliance: Adhering to industry standards can be challenging.

- Cost Management: Balancing material quality with budget constraints.

By addressing these challenges effectively, businesses can secure a reliable source of high-purity zirconia that meets their specific needs while ensuring consistent quality.

| Challenge | Description | Solution |

|---|---|---|

| Supply Chain | Fluctuations in availability | Establish reliable suppliers |

| Quality Control | Must meet specific industry standards | Implement rigorous testing processes |

| Cost | Budget constraints | Weigh benefits against costs |

How Can B2B Buyers Make Informed Decisions on High-Purity Zirconia?

When selecting high-purity zirconia, B2B buyers can make informed decisions by considering several key factors.

First, it is important to evaluate supplier reputation. Researching potential suppliers and seeking reviews or testimonials can provide insight into their reliability and quality assurance practices.

Next, buyers should ensure quality assurance processes are in place. Understanding the testing and certification standards that suppliers adhere to will help buyers choose materials that meet their specific application requirements.

Finally, assessing previous client testimonials can also guide decision-making. References from other businesses can shed light on a supplier’s performance and the quality of their products.

Recommendations for B2B Buyers

- Conduct In-Depth Research: Look into potential suppliers and their product offerings.

- Request Certifications: Ensure materials meet industry standards.

- Utilize Client References: Get feedback from prior customers for insights.

By carefully considering these factors, B2B buyers can confidently select high-purity zirconia that meets their needs and aligns with their operational goals.

| Consideration | Importance | Recommended Action |

|---|---|---|

| Supplier Reputation | Insight into reliability | Research and read reviews |

| Quality Assurance Processes | Ensures product reliability | Understand testing standards |

| Client Testimonials | Provides first-hand insights | Seek references from other businesses |

Conclusion

In summary, high-purity zirconia powder stands as a critical material for various industries, including healthcare, aerospace, electronics, and construction. By understanding its specific applications and benefits, professionals can make informed choices. One significant takeaway is that investing in high-purity zirconia can lead to enhanced performance and sustainability across numerous applications. For valuable partnerships and exceptional sourcing solutions, turn to Global Industry for high-quality materials tailored to your needs.

FAQ Section

Q1: What industries can use high-purity zirconia powder?

High-purity zirconia powder is utilized across a broad spectrum of industries due to its unique properties. Key sectors include healthcare, where it’s used in dental ceramics and surgical instruments; aerospace, for components that can withstand extreme temperatures; electronics, in capacitors and insulators; automotive, in fuel cells and sensors; and construction, in high-strength materials. Its versatility makes it an indispensable material in various high-performance applications.

Q2: How does high-purity zirconia powder enhance product performance?

High-purity zirconia powder significantly boosts product performance through its exceptional properties. Its high strength ensures durability and reliability in demanding applications. Thermal stability allows components to maintain their performance under extreme temperatures, making it ideal for aerospace and automotive use. Additionally, its chemical resistance makes it suitable for environments that require sterilization or protection against corrosion, ensuring longevity and consistent performance.

Q3: Are there specific certifications for high-purity zirconia powder?

Yes, high-purity zirconia powder often needs to meet specific certifications and quality standards, depending on the industry it serves. Common certifications include ISO standards, which ensure quality management and consistency, and ASTM (American Society for Testing and Materials) standards for material specifications. These certifications verify that the zirconia powder is suitable for its intended applications, ensuring manufacturers and consumers can trust in its performance and safety.

Q4: What are the typical applications of high-purity zirconia powder?

High-purity zirconia powder finds diverse applications across multiple fields. In healthcare, it is commonly used for dental crowns, implants, and surgical instruments due to its biocompatibility. In aerospace, it is used in turbine blades and thermal barrier coatings. The electronics industry employs it in capacitors and insulating layers, while in the automotive sector, it is used in sensors and fuel cells. Additionally, in construction, high-purity zirconia contributes to concrete reinforcement, insulation materials, and ceramic tiles.

Q5: How can businesses choose the right supplier for high-purity zirconia?

Choosing the right supplier for high-purity zirconia involves several critical considerations. First, evaluate the supplier’s reputation by researching their history and client reviews. It’s important to verify their quality assurance processes to ensure adherence to industry standards. Request certifications that demonstrate compliance with relevant quality benchmarks. Additionally, seeking testimonials or references from previous clients can provide insight into a supplier’s reliability and product quality, helping businesses make informed purchasing decisions. Regular communication with potential suppliers is also essential to clarify any specific requirements or concerns.