In the realm of biomedical applications, the functionality of zirconia powder is paramount. Purchasing managers and decision-makers often face challenges related to the effectiveness of this material in medical devices. The right coating technologies can significantly improve the performance characteristics of zirconia, making it more suitable for various applications. This article provides insights into how specific coating methods improve zirconia powder functionality in biomedicine, offering practical knowledge to help you make informed decisions for your organization. Our aim is to equip you with actionable information backed by research, allowing you to enhance the performance of your products effectively.

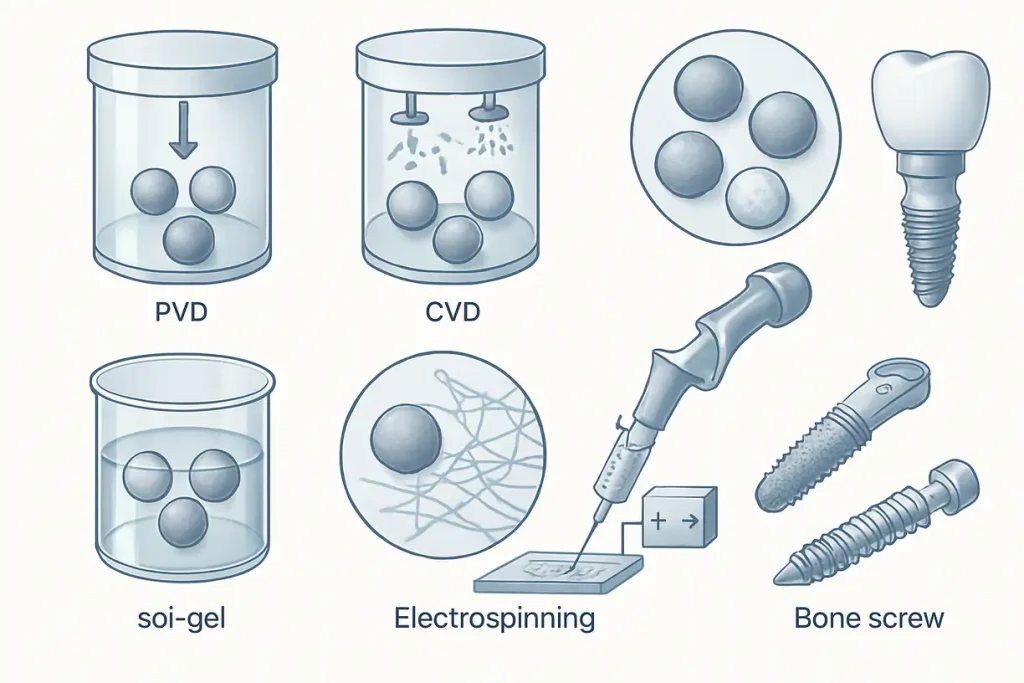

This image illustrates the various coating technologies used for enhancing zirconia powder in biomedical applications.

How Do Coating Technologies Work for Zirconia Powder?

Coating technologies play a critical role in optimizing zirconia powder for biomedical applications. These technologies involve applying a thin layer of material onto the zirconia surface. This coating process can significantly alter the physical and chemical properties of the zirconia, enhancing its overall performance for specific uses.

When zirconia is coated, it undergoes changes that improve its interaction with biological tissues. Such transformations are essential in ensuring that zirconia-based products are not only sturdy but also compatible with the human body. Coatings can enhance numerous attributes, including:

- Biocompatibility: Improved integration with biological tissues reduces the risk of rejection.

- Surface Roughness: Altering roughness can promote better cell adhesion and tissue integration.

- Chemical Resistance: Enhanced coatings can protect against corrosive bodily fluids.

Various methods of coating include chemical vapor deposition (CVD) and physical vapor deposition (PVD). CVD utilizes chemical reactions to create a solid material on the surface of zirconia. This method allows for precise control over the coating’s thickness and composition, which is vital for specific applications.

Conversely, PVD employs physical techniques such as evaporation or sputtering to deposit a thin layer onto the zirconia. This method is known for producing strong and uniform coatings, significantly benefiting the integrity of biomedical devices.

Moreover, these techniques can be tailored to achieve specific properties aligned with application requirements. For instance, some coatings may be designed to enhance hydrophilicity, thereby supporting better cell attachment—crucial for implants aiming for optimal integration with bone and tissue.

The surface modifications achieved through these coatings can lead to enhanced characteristics such as increased biocompatibility and improved mechanical strength. With the appropriate coating, zirconia is better equipped to integrate with biological tissues, solidifying its status as a preferred material for dental implants and orthopedic devices. So, when considering zirconia powder, understanding the impact of coating technologies is essential.

This initial step of applying coatings marks a pivotal moment in enhancing the usability and effectiveness of zirconia in the field of biomedicine, setting the stage for future innovations.

What Are the Key Benefits of Enhanced Zirconia Coating?

Coating zirconia powder optimizes its properties for biomedical uses in several significant ways. The primary benefits include improved biocompatibility, enhanced mechanical attributes, and increased wear resistance.

1. Improved Biocompatibility

One of the most critical advantages of enhanced zirconia coatings is their capacity to promote biocompatibility. Coatings can facilitate better integration with human tissues, effectively reducing the likelihood of adverse reactions. For instance, coatings designed with bioactive materials can encourage cellular activity, further enhancing tissue integration.

2. Enhanced Mechanical Attributes

Another notable benefit is the improvement of zirconia’s mechanical properties. Coated zirconia exhibits greater strength, toughness, and fracture resistance, essential for enduring the rigorous demands of biomedical applications, such as dental implants and orthopedic devices. The coatings can also distribute stress more evenly across the zirconia surface, minimizing the risk of failure.

3. Increased Wear Resistance

Wear resistance is vital, especially for coatings in applications like dental crowns and hip replacements. Successfully coated zirconia significantly outperforms uncoated alternatives when resisting wear and tear from friction and pressure. This durability ensures that the components remain effective and maintain their performance standards over time.

Summary of Benefits

| Benefit | Description | Impact on Biomedical Applications |

|---|---|---|

| Improved Biocompatibility | Enhances integration with biological tissues | Reduces rejection rates in implants |

| Enhanced Mechanical Attributes | Increases strength and fracture resistance | Suitable for load-bearing applications |

| Increased Wear Resistance | Provides durability against friction | Prolongs lifespan of dental and orthopedic devices |

In summary, enhanced zirconia coatings provide significant advantages, making them a vital consideration in the development of biomedical devices. These benefits not only improve the product’s performance but also lead to better patient outcomes, enhancing overall satisfaction with medical interventions.

Which Coating Techniques Are Most Effective?

Several coating techniques are proven effective for improving zirconia powder, and understanding these methods can aid in making informed choices.

1. Physical Vapor Deposition (PVD):

This method is favored for its ability to create a strong bond between the coating and the base material. PVD can produce coatings with excellent physical properties, such as hardness and wear resistance. The process involves evaporating the coating material in a vacuum environment and allowing it to condense on the zirconia surface. This technique is especially useful when a durable coating is required for high-stress applications.

2. Chemical Vapor Deposition (CVD):

CVD is ideal for producing uniform coatings on complex shapes. This method involves introducing gaseous precursors that chemically react, resulting in a solid coating forming on the surface of the zirconia. CVD can also modify the chemical properties of zirconia, enhancing its bioactivity and promoting cell adhesion. This makes it particularly advantageous for applications where biological interaction is critical.

3. Sol-Gel Coating Techniques:

These techniques involve creating a gel that adheres to the surface before transitioning to a solid state. Sol-gel processes are attractive due to their versatility, allowing for the incorporation of various functional materials. The coatings produced can offer composite properties, such as improved bioactivity and tailored surface characteristics.

All these techniques have their unique advantages, but the choice often depends on specific application needs. The following table summarizes some key aspects of these methods.

| Coating Technique | Key Benefits | Application Suitability |

|---|---|---|

| Physical Vapor Deposition | Excellent hardness, strong adhesion; ideal for high-demand environments | Load-bearing implants, dental applications |

| Chemical Vapor Deposition | Uniformity and customization; enhances bioactivity | Orthopedic implants, critical surgical devices |

| Sol-Gel Coating | Versatile and adaptable; potential for functional incorporation | Coatings requiring specific bioactive traits |

So, when evaluating coating options, consider the specific qualities required for your biomedical applications. Understanding the nuances of each coating technique can significantly influence the success of zirconia-based products in the medical field.

How Do Coatings Impact Zirconia in Biomedical Devices?

Coatings significantly influence zirconia’s performance in biomedical devices. Their impact can be observed in various applications, such as dental implants, orthopedic devices, and prosthetics. The effectiveness of these coatings directly correlates to the success of the medical procedures in which they are utilized.

In dental implants, coated zirconia can better integrate with surrounding bone and soft tissue, improving the success rate of these procedures. This integration is facilitated by enhanced surface characteristics that promote cellular attachment and growth, thereby minimizing the chance of implant failure. Coated zirconia also demonstrates improved mechanical properties, allowing it to withstand the dynamic forces of chewing and biting.

Orthopedic applications benefit similarly from enhanced zirconia coatings. For joint replacements, for instance, the wear resistance of coated zirconia ensures durability under significant loading conditions—extending its service life. Furthermore, the coatings can be engineered to reduce friction, which is critical in reducing wear on both the implant and the surrounding biological tissues.

For prosthetics, the aesthetic quality of zirconia coatings is equally critical. Coatings can provide a more natural appearance, which is vital for patient satisfaction. Additionally, the coatings may offer the ability to be customized in color and translucency, making prosthetic devices more lifelike.

Key Impacts of Coatings on Zirconia in Biomedical Devices:

- Improved Integration: Enhanced surface roughness promotes better osseointegration.

- Increased Durability: Coatings enhance wear resistance for load-bearing applications.

- Aesthetic Appeal: Customizable coatings improve the cosmetic appearance of prosthetics.

- Reduced Friction: Coatings minimize wear in high-motion applications.

Ultimately, the application of coatings can lead to improved performance and longevity of zirconia-based devices, ensuring better outcomes for patients. Moreover, understanding the specific needs of each application will guide manufacturers in selecting the most effective coatings for their zirconia products, thereby maximizing both function and patient satisfaction.

What Factors Influence the Selection of Coating Technology?

When selecting coating technologies for zirconia powder, several factors must be considered. These include material compatibility, desired mechanical properties, and cost implications.

1. Material Compatibility:

It’s essential to ensure that the coating material works well with zirconia. Incompatibilities can lead to delamination or reduced performance, which may compromise the success of the biomedical application. Evaluating the chemical and physical properties of both the coating and zirconia is critical before proceeding.

2. Desired Mechanical Properties:

Depending on the application, different mechanical properties may be prioritized. For instance, implants require high strength and durability to withstand physiological stress, while aesthetic applications need coatings that enhance visual qualities without compromising structural integrity.

3. Cost Implications:

Budget constraints can affect the choice of coating technologies. More advanced techniques may yield superior results but at a higher cost. It’s crucial to balance quality and budget to find the most suitable solution for your specific needs. Remember that investing in the right coating can lead to long-term savings by reducing the need for replacements or adjustments.

Thus, a thorough evaluation of these factors will guide the decision-making process regarding coating technologies.

| Factor | Considerations |

|---|---|

| Material Compatibility | Ensure compatible materials |

| Desired Mechanical Properties | Identify key properties needed |

| Cost Implications | Balance budget with quality expectations |

How Do Surface Characteristics Affect Zirconia Functionality?

Surface characteristics are fundamental in determining the effectiveness of zirconia in biomedical applications. Key attributes include surface roughness, chemical properties of the coatings, and how these affect biological interactions.

Surface Roughness:

Rougher surfaces can promote better cell adhesion, which is critical for implants. Conversely, overly rough surfaces may lead to wear issues over time.

Chemical Properties:

The chemistry of the coating plays a significant role in biocompatibility. Certain coatings can be engineered to release ions that promote healing, making them particularly beneficial in surgical applications.

Biological Interactions:

Coated surfaces influence how cells and tissues respond. Better integration with biological structures can lead to improved healing and reduced recovery times.

In summary, understanding and optimizing surface characteristics are essential for maximizing zirconia’s functionality in medical applications.

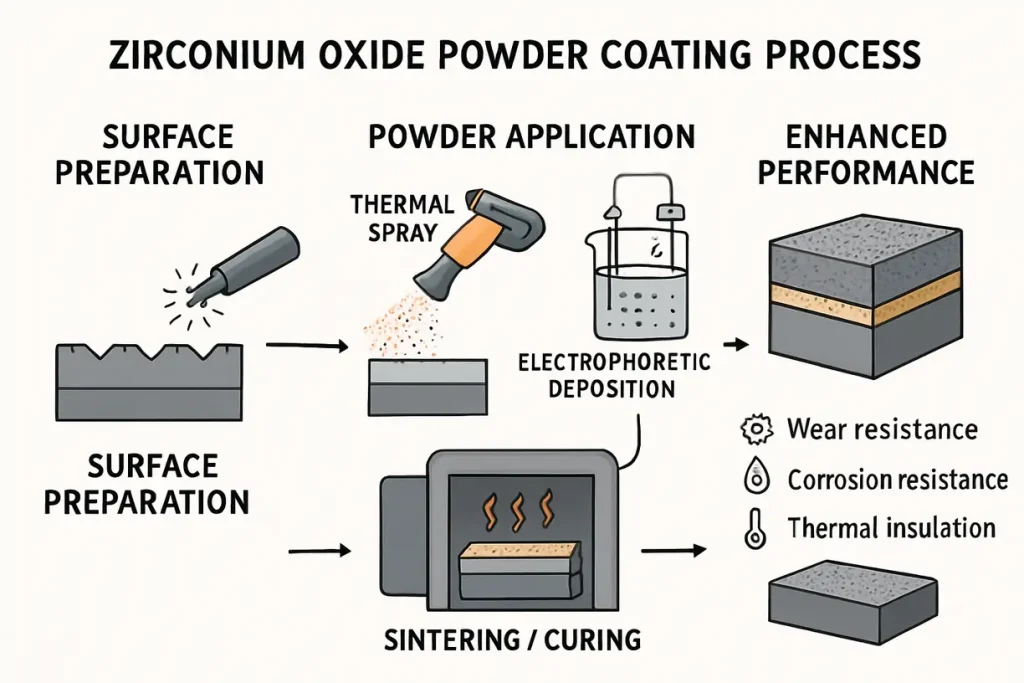

This image depicts the surface characteristics of zirconia, highlighting the importance of coatings in medical applications.

What Innovations Are Emerging in Coating Technologies?

The field of coating technologies is continually evolving, leading to new opportunities for enhancing zirconia powder. Recent innovations include the development of bioactive coatings, nanotechnology, and smart coatings.

Bioactive Coatings:

These coatings can interact with the body to promote healing and integration. For example, some bioactive coatings can stimulate bone growth, making them ideal for orthopedic implants.

Nanotechnology:

Using nanomaterials in coatings can enhance properties such as strength and bioactivity without significantly increasing weight. Nanostructured coatings can offer a great deal of promise in improving the efficiency of zirconia in biomedical applications.

Smart Coatings:

This new wave of coatings can respond to environmental changes, such as temperature or pH levels. These coatings can provide real-time feedback on the condition of the implant, aiding in patient management.

Overall, these innovations present exciting opportunities for advancing zirconia powder applications in the biomedical field.

| Innovation | Description | Benefits |

|---|---|---|

| Bioactive Coatings | Promote healing and integration | Enhanced bone growth around implants |

| Nanotechnology | Utilize nanomaterials for coatings | Improved strength without added weight |

| Smart Coatings | Respond to environmental changes | Provide feedback on implant conditions |

How Can Coatings Improve Longevity of Zirconia-Based Products?

Coatings contribute to the longevity of zirconia products by enhancing their durability and resistance to wear and corrosion. Improved coatings can protect zirconia from the harsh conditions found in various applications, ultimately prolonging the service life of medical devices.

Durability Assessments:

Regular evaluations of coated zirconia products can reveal insights into wear patterns and performance. These assessments help ensure that the coatings maintain their beneficial properties over time.

Long-Term Performance Metrics:

Monitoring how coatings hold up under stress can inform future design choices. Understanding which coatings perform best over time is critical for continuous improvement.

Strategies for Optimizing Lifespan:

Implementing the right maintenance techniques and selection of coatings plays a vital role in ensuring zirconia products remain effective throughout their expected lifespan.

Thus, investing in quality coatings and regular assessments can lead to significant returns in terms of reliability and patient outcomes.

What Are the Challenges in Coating Zirconia Powder?

While the benefits of coating zirconia powder are noteworthy, certain challenges remain. Adoption and implementation of coating technologies can present obstacles that must be considered.

Adhesion Issues:

Achieving strong adhesion between the coating and the zirconia substrate is critical. Poor adhesion can lead to coating failure, reducing the overall effectiveness of the product.

Limitations of Current Techniques:

Each coating method has inherent limitations. Some may not provide the desired uniformity, while others may be too expensive for widespread adoption.

Regulatory Considerations:

Navigating regulatory requirements can be a major hurdle. Coating technologies must meet strict guidelines to ensure safety and effectiveness for medical applications.

Ultimately, addressing these challenges is essential for the successful integration of coatings into zirconia-based products.

This image illustrates the coating process for zirconia powder, showcasing the steps involved in enhancing its properties.

How Do Coatings Enhance Processing Methods for Zirconia?

Coatings contribute to the longevity of zirconia products by enhancing their durability and resistance to wear and corrosion. Improved coatings can protect zirconia from the harsh conditions found in various applications, ultimately prolonging the service life of medical devices.

Influence on Sintering and Processing:

Coatings can help lower the sintering temperature of zirconia, making the manufacturing process more energy-efficient. This reduction can lead to significant cost savings over time and improve production efficiency. Furthermore, by optimizing the sintering conditions, coated zirconia can achieve better microstructural characteristics, leading to improved mechanical properties.

Modifications in Powder Handling:

Improved coating methods can streamline how zirconia powders are managed and processed. Enhanced flow characteristics may result in easier handling during production, which can minimize waste and improve product uniformity. Coated powders are often less prone to clumping and segregation, facilitating a smoother mixing process with other materials.

Optimization of Production Processes:

By adopting advanced coating techniques, manufacturers can optimize their production line, leading to higher throughput and lower defect rates. This optimization might include the integration of automated systems that work in tandem with the coating processes to ensure consistency and quality.

To summarize the benefits of coatings in processing zirconia powder, consider the following aspects:

| Benefit | Description |

|---|---|

| Lower Sintering Temperatures | Enhances energy efficiency and reduces costs |

| Improved Flow Characteristics | Facilitates smoother handling and processing |

| Increased Production Efficiency | Leads to higher throughput and quality assurance |

In summary, effective coatings can lead to significant improvements in the processing and manufacturing of zirconia products, offering both quality enhancements and cost efficiencies. These advantages help manufacturers stay competitive in a rapidly evolving biomedical landscape, ensuring that they can meet the growing demands for reliable and high-performance medical devices.

Conclusion

In summary, effective coatings can lead to significant improvements in the processing and manufacturing of zirconia products, offering both quality enhancements and cost efficiencies.

In conclusion, the exploration of how coating technologies improve zirconia powder in biomedicine reveals critical insights for professionals in the field. Key takeaways include the enhanced biocompatibility, improved mechanical properties, and increased longevity of coated zirconia products. By understanding these benefits, organizations can significantly improve their biomedical applications. Partner with Global Industry to discover advanced coating solutions tailored to your specific needs. For more information on our offerings, visit our website and take the next step in enhancing your products’ performance.

FAQ Section

Q1: What specific applications utilize zirconia powder coatings?

Zirconia powder coatings are frequently utilized in applications such as dental implants, where they enhance integration with bone, as well as orthopedic devices designed for joint replacement. Additionally, they are employed in prosthetic components to improve their durability and aesthetic appeal.

Q2: How do different coating techniques compare for effectiveness?

Each coating technique, such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), offers unique advantages. PVD is known for creating a uniform layer that provides excellent wear resistance, while CVD can produce coatings with a strong bond to the substrate and controlled chemical properties, making them suitable for specific biological applications.

Q3: What role do coatings play in improving the mechanical properties of zirconia?

Coatings enhance the mechanical properties of zirconia by increasing its resistance to wear, improving toughness, and preventing crack propagation. This is particularly important for implants and devices that are subjected to significant mechanical stress during use.

Q4: Are there any downsides to coating zirconia powder?

Potential downsides to coating zirconia powder include challenges related to achieving strong adhesion between the coating and substrate, the complexity of the coating processes, and the need to meet regulatory requirements that can complicate production timelines.

Q5: How can one assess the effectiveness of zirconia coatings?

Effectiveness can be assessed using various methods, including mechanical testing to gauge strength and wear resistance, biocompatibility evaluations to ensure safety, and long-term performance metrics to track wear and degradation over time. Regular quality assessments during manufacturing can also help uphold standards.