Industrial equipment often fails under abrasive wear and harsh conditions in manufacturing, aerospace, and energy sectors, causing premature breakdowns that halt operations. These issues lead to high repair costs, lost production, and supply chain delays—one erosion spot can stop an entire line, eroding profits and competitiveness. Zirconia, an advanced ceramic, offers exceptional toughness and resistance, turning fragile parts into durable assets that extend uptime and cut failures, proven in technical applications.

What is Zirconia?

How Does Zirconia Form?

Zirconia, or zirconium oxide (ZrO₂), forms through sintering zirconium compounds at high temperatures, creating a dense ceramic from powder precursors.

Why Choose Stabilized Zirconia?

Pure zirconia shifts phases unstably, cracking under stress; stabilization locks it in a tough tetragonal or cubic form for reliable use.

What Stabilizers Enhance Zirconia?

Magnesia (MgO), yttria (Y₂O₃), and ceria (CeO₂) dopants prevent transformations, boosting strength in variants like MSZ, YTZP, and CSZ.

Key Takeaway: Zirconia serves as a foundational ceramic for high-performance parts, offering versatility across industrial needs.

| Aspect | Description | Benefit | |

|---|---|---|---|

| Base Material | Zirconium oxide ceramic | High baseline strength | |

| Stabilization Types | Magnesia, Yttria, Ceria | Prevents phase changes | |

| Common Forms | Dense or powder | Adaptable for custom fabrication |

Properties of Zirconia

What Makes Zirconia Tough?

Transformation toughening expands grains under stress, blunting cracks for fracture toughness up to 10 MPa·m¹/².

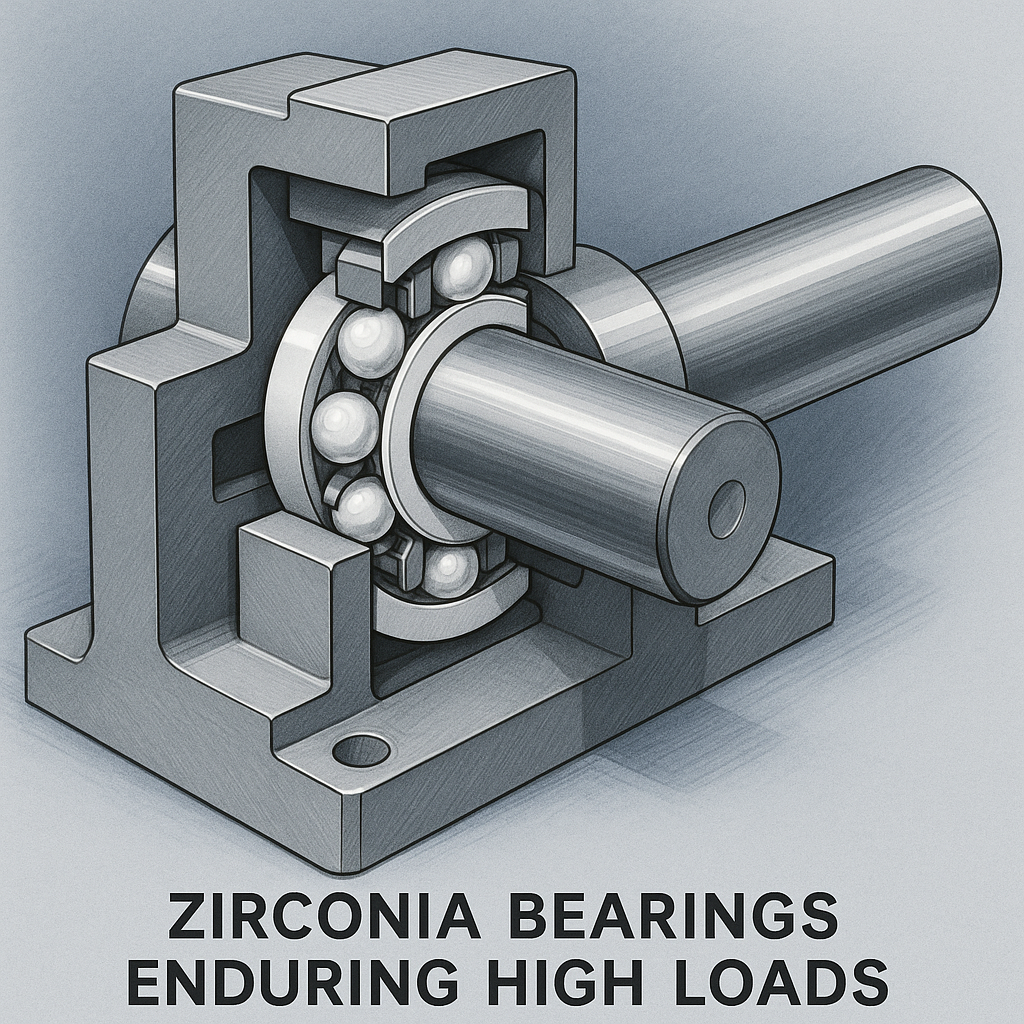

How Does Zirconia Resist Wear?

Its hardness exceeds metals, with low friction reducing abrasion in high-load scenarios like bearings.

Why is Zirconia Corrosion-Proof?

Stable oxides resist acids, bases, and steam, unlike metals that erode in chemical flows.

Key Takeaway: Zirconia’s properties like high strength and low thermal conductivity make it ideal for demanding B2B applications.

| Property | Value | Industrial Impact | |

|---|---|---|---|

| Flexural Strength | Up to 1200 MPa | Reduces breakage risk | |

| Fracture Toughness | 8-10 MPa·m¹/² | Enhances longevity | |

| Wear Resistance | Superior to metals | Cuts maintenance costs |

Magnesia Stabilized Zirconia

What Defines MSZ?

MSZ uses 8-10% magnesia to stabilize cubic phases, yielding ivory or yellow material with heterogeneous grains.

How Does MSZ Handle Heat?

It withstands over 220°C without degradation, ideal for thermal mismatch in metal-ceramic joins.

Why Use MSZ in Pumps?

Its toughness suits wear sleeves and pistons in moist, high-heat downhole tools.

Key Takeaway: MSZ excels in high-temperature, moist settings, providing reliable components for tough operations.

| Feature | MSZ Advantage | Application Example | |

|---|---|---|---|

| Temperature Stability | Up to 220°C+ | Downhole tools | |

| Microstructure | Heterogeneous for toughness | Wear sleeves | |

| Color Variants | Ivory for purity | Precision seals |

Yttria Stabilized Zirconia

What Powers YTZP Strength?

3-5% yttria creates fine tetragonal grains, delivering top flexural strength via phase stability.

How Does YTZP Prevent Cracks?

Stress triggers tetragonal-to-monoclinic shift, expanding to compress cracks and halt propagation.

Why Limit YTZP to 500°C?

Above this, strength drops; water vapor at 200-300°C causes low-temp degradation.

Key Takeaway: YTZP delivers peak mechanical performance in precision and wear-intensive roles.

| Characteristic | YTZP Spec | Use Case | |

|---|---|---|---|

| Phase Structure | Tetragonal fine-grain | Cutting tools | |

| Toughening Mechanism | Transformation under stress | Oxygen sensors | |

| Chemical Resistance | Excellent against acids | Valve seats |

Ceria Stabilized Zirconia

What Stabilizes CSZ?

12% ceria fills vacancies in the lattice, maintaining cubic structure for steam endurance.

How Does CSZ Thrive in Steam?

It resists degradation in high-pressure vapor, unlike YTZP, via stable oxygen sites.

Why Pick CSZ for pH Extremes?

Superior acid/base resistance suits corrosive processing without phase shifts.

Key Takeaway: CSZ offers stability in aggressive chemical environments, broadening material options.

| Attribute | CSZ Benefit | Scenario | |

|---|---|---|---|

| Degradation Resistance | Fills vacancies | High-pressure steam | |

| Toughness Type | Transformation | Acid/base exposure | |

| Temperature Range | High endurance | Corrosive processing |

Zirconia Toughened Alumina

What Blends ZTA?

10-20% zirconia particles in alumina matrix enhance toughness cost-effectively.

How Does ZTA Boost Alumina?

Transformation expands zirconia inclusions, raising fracture toughness 20-30%.

Why Choose ZTA for Cost Savings?

It matches zirconia’s gains over alumina at lower prices for structural parts.

Key Takeaway: ZTA provides enhanced strength over alumina at lower costs, optimizing budgets for structural needs.

| Element | ZTA Improvement | Practical Gain | |

|---|---|---|---|

| Strength Increase | 20-30% | Standoffs and insulators | |

| Toughening Process | Volume expansion | Pump pistons | |

| Cost Efficiency | Below pure Zirconia | Fluid systems |

Applications of Zirconia

Where Does Zirconia Fit in Aerospace?

Lightweight bearings and guides reduce weight while handling high loads reliably.

How Zirconia Aids Medical Devices?

Biocompatible implants and sensors offer durable, corrosion-free performance.

Why Zirconia for Energy Tools?

Nozzles and seals endure erosion in harsh energy extraction and processing.

Key Takeaway: Zirconia’s applications span industries, helping innovate in structural and precision components.

| Industry | Zirconia Role | Outcome | |

|---|---|---|---|

| Aerospace | Bearings and guides | Reduced weight, high reliability | |

| Medical | Implants and sensors | Biocompatible durability | |

| Energy | Nozzles and seals | Extended service life |

Limitations of Zirconia

What Causes YTZP Degradation?

Water vapor at low temps (200-300°C) triggers monoclinic phase, weakening structure.

How Do Temperature Caps Affect Zirconia?

Strength falls above 500-1500°C; hybrids mitigate for extreme heat.

Why Avoid Zirconia in Certain Moistures?

Humid heat degrades YTZP/CSZ; controls or MSZ variants counter this.

Key Takeaway: Understanding limits allows selecting variants matching operational challenges.

| Limitation | Affected Type | Mitigation | |

|---|---|---|---|

| Low-Temp Degradation | YTZP above 200°C in vapor | Switch to MSZ | |

| Strength Drop | All above 500-1500°C | Hybrid designs | |

| Moisture Sensitivity | CSZ/ZTA in humid heat | Environmental controls |

Zirconia vs. Metals and Ceramics

How Does Zirconia Outperform Metals?

50% lower erosion and better corrosion in acids, outlasting in wear.

What Edges Zirconia Over Alumina?

20-30% higher toughness prevents brittle failures in impacts.

Why Zirconia Beats Plastics in Extremes?

Tolerates 1500°C and abrasion where plastics deform or melt.

Key Takeaway: Comparing Zirconia positions it as superior for longevity against alternatives.

| Material | Zirconia Edge | Key Metric | |

|---|---|---|---|

| Metals | Higher corrosion resistance | Erosion rate lower by 50% | |

| Alumina | 20-30% tougher | Fracture toughness higher | |

| Plastics | Better heat tolerance | Operating temp up to 1500°C |

Advanced Zirconia Innovations

What New Forms Enhance Zirconia?

Nano-structured and hybrid composites refine grains for precision.

How Zirconia Integrates in Sensors?

YTZP enables accurate oxygen detection in fuel cells and probes.

Why Explore Custom Zirconia Blends?

Tailored stabilizers cut R&D, fitting niche B2B needs like valves.

Key Takeaway: Emerging advancements equip tailored solutions for future-proof strategies.

| Innovation | Description | Business Value | |

|---|---|---|---|

| Hybrid Composites | ZTA expansions | Cost-effective upgrades | |

| Nano-Structured | Finer grains for precision | Improved sensor accuracy | |

| Custom Stabilizers | Tailored for niches | Reduced R&D time |

Conclusion

Zirconia resolves high-wear issues by cutting downtime and enhancing reliability in operations. Ready to upgrade? Its properties, variants, and applications deliver real value. For custom solutions, contact for tailored B2B engineering. Lead with unbreakable components—drive innovation ahead.

FAQ

Can I use Zirconia in high-moisture environments? Yes, select MSZ or CSZ. These resist degradation better than YTZP due to stable microstructures preventing phase shifts in humid conditions, ensuring longer part life.

What’s the best Zirconia for cutting tools? YTZP excels. Its flexural strength and transformation toughening stop crack growth, yielding sharper, durable edges outperforming metals in abrasives.

How do I know if Zirconia suits my pump components? If facing abrasion or corrosion, yes. For temps under 500°C, YTZP’s wear resistance reduces replacements, saving costs per your specs.

Can I blend Zirconia with other ceramics cost-effectively? Yes, ZTA blends alumina for value. It gains 20-30% strength at lower prices than pure zirconia, suiting budget upgrades.

What’s the best way to test Zirconia durability? Use property charts and prototypes. Its toughness shows in stress tests, with proven erosion resistance confirming fit pre-deployment.