Patients frequently struggle with significant limitations inherent in traditional denture materials, facing issues like chipping acrylic or heavy metal frameworks that compromise facial esthetics. These outdated solutions often fail under daily stress, leading to embarrassment and costly repairs. Zirconia arches offer a revolutionary solution, providing a monolithic, high-strength restoration that delivers exceptional durability and lifelike translucency for full-mouth rehabilitation. As a leader in advanced materials, we understand that high-quality zirconia powder forms the critical foundation of every successful dental restoration, ensuring long-term patient satisfaction. Here is the deal: The quality of raw material dictates the longevity of a smile.

What Is a Zirconia Arch and How Does It Function?

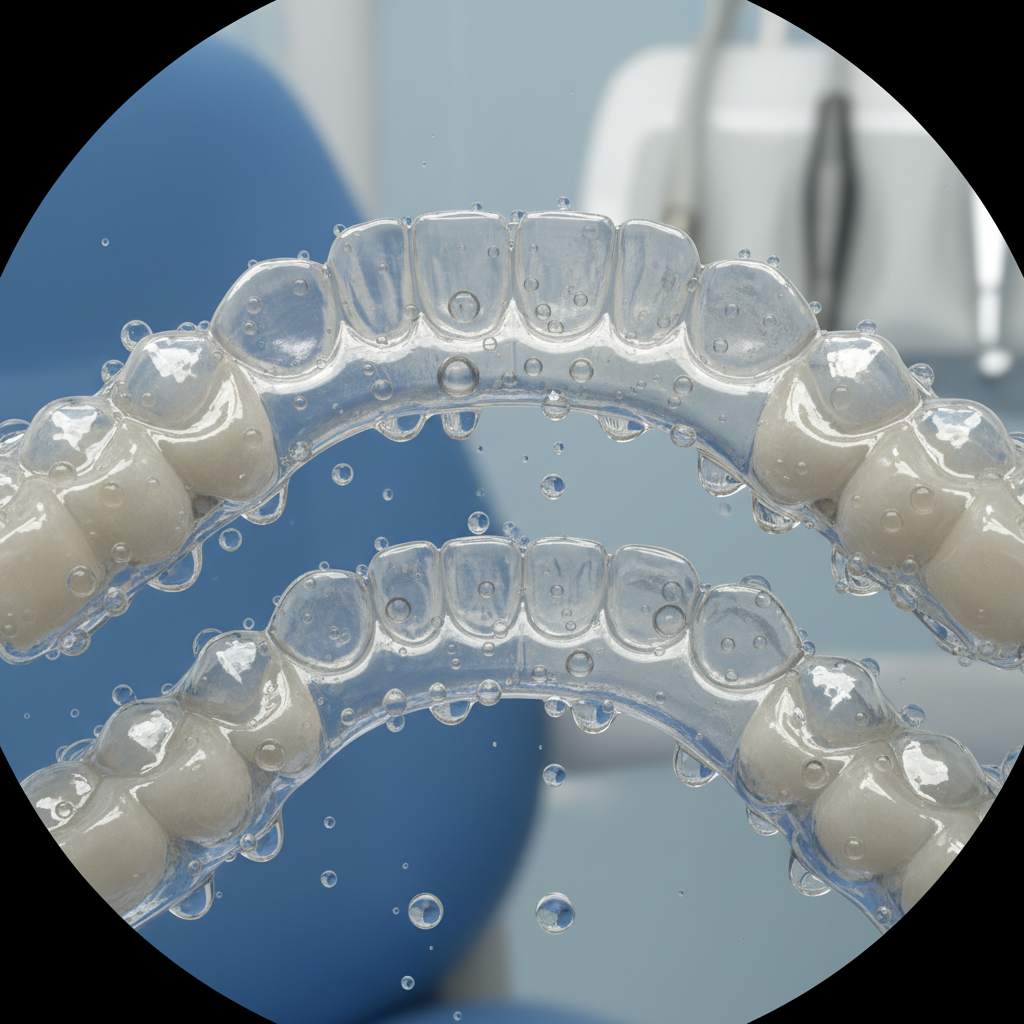

A zirconia arch represents the pinnacle of modern dental prosthetics, functioning as a solid, full-contour bridge designed specifically for All-on-4 or All-on-6 implant protocols. Unlike traditional hybrids that fuse porcelain to metal, this solution consists of a monolithic structure milled from a single block of zirconium oxide. This one-piece design eliminates common failure points, such as porcelain chipping off a metal substructure, which plagues older prosthetic models. Computer-Aided Design and Manufacturing (CAD/CAM) technology drives the creation process, ensuring a precise fit that screw-retains directly into dental implants. Zirconium oxide exhibits remarkable biocompatibility, promoting healthy gum tissue integration without the inflammatory responses often seen with porous acrylics.

The material functions by distributing occlusal forces evenly across the implant fixtures, protecting the underlying bone from resorption. Its high density prevents micro-movement and bacterial harbor, issues frequently observed in hybrid dentures. Clinicians favor this material because it combines the strength of metal with the esthetics of natural teeth. You might be wondering: how does such a hard material feel in the mouth? Patients report a smooth, glass-like texture that feels substantial yet natural.

| Feature | Monolithic Zirconia | Traditional Metal-Ceramic | |

|---|---|---|---|

| Structure | Single solid piece | Porcelain fused to metal | |

| Chipping Risk | Minimal / None | High (Porcelain shear) | |

| Biocompatibility | Excellent (Tissue friendly) | Good (Potential metal sensitivity) | |

| Fabrication | CAD/CAM Milled | Casting & Layering |

Why Are Zirconia Arches Superior to Acrylic Hybrids?

Comparing zirconia against traditional acrylic titanium hybrids reveals a stark contrast in hygiene, longevity, and structural integrity. Acrylic hybrids function essentially as high-impact plastic fused to a titanium bar, a design that inevitably absorbs fluids, bacteria, and odors over time. Zirconia, conversely, remains impervious to fluids, ensuring the prosthesis stays stain-free and odor-neutral even after years of use. This hygienic advantage significantly reduces the risk of peri-implantitis, a condition that threatens implant stability. Esthetically, acrylic tends to look opaque and flat, whereas zirconia mimics the translucency and light-scattering properties of natural tooth enamel.

Durability stands as another major differentiator between these two popular material choices. Acrylic teeth wear down relatively quickly against natural opposing dentition or even porcelain, leading to a loss of vertical dimension. A zirconia arch maintains its shape and occlusal detail indefinitely, resisting wear even in patients with heavy bruxism. Here’s the kicker: Acrylic bridges often require tooth replacement or resurfacing every few years, while zirconia serves as a permanent solution.

How Is the Manufacturing Process of Zirconia Controlled?

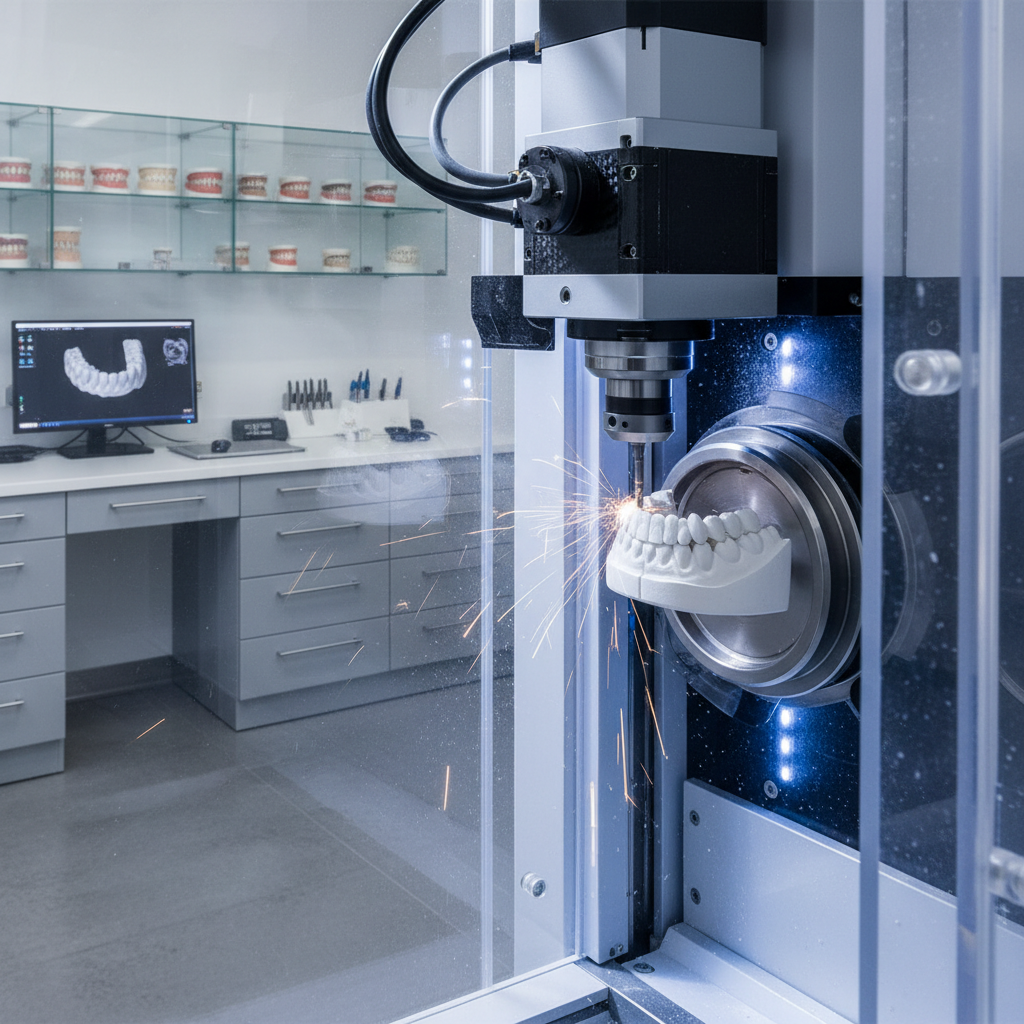

Control over the manufacturing zirconium field determines the ultimate fracture resistance and fit of the final dental bridge. Zirconia pucks used in dental laboratories originate from industrial-grade powder that undergoes rigorous processing to ensure purity. Isostatic pressing compacts this powder into discs, distributing pressure centrally from all directions to create a uniform density free of internal flaws. Any inconsistency in particle size or binder distribution can lead to catastrophic cracking during the sintering phase. Sintering involves heating the milled soft zirconia to temperatures around 1,500°C, causing it to shrink by approximately 20% and reach full hardness.

Labs must calculate this shrinkage factor with extreme precision to ensure the screw channels align perfectly with the implants in the patient’s mouth. Advanced manufacturing protocols monitor parameters like heating rates and cooling times to prevent thermal shock. It turns out: even a microscopic variance in the raw powder composition affects translucency and strength. High-end manufacturers utilize colloidal processing to achieve a homogeneity that cheaper alternatives cannot match.

| Manufacturing Step | Purpose | Critical Factor | |

|---|---|---|---|

| Powder Prep | Create uniform particle size | Purity & Binder Mix | |

| Isostatic Pressing | Form dense pucks (discs) | Uniform Density | |

| Pre-Sintering | Chalk-like state for milling | Softness for Tools | |

| Final Sintering | Achieve full hardness | Temp Control (1500°C) |

What Are the Esthetic Benefits of Full-Arch Zirconia?

Modern “Prettau” style zirconia and multilayered pucks have revolutionized the esthetic potential of full-arch restorations. Early generations of zirconia appeared bone-white and opaque, earning a reputation for looking artificial. Today, gradient technology allows manufacturers to produce discs with varying translucency levels, shifting from more opaque at the gingival (gum) area to highly translucent at the incisal (biting) edge. This gradient mimics the natural structure of a tooth, where dentin provides color and enamel provides light transmission. You might be wondering: Can an opaque material really look like natural teeth?

Skilled technicians apply specialized stains and glazes to further characterize the restoration, adding subtle details like mamelons, cracks, and gum tissue shading. Pink porcelain layering is often utilized on the gingival portion of the bridge to replicate soft tissue, creating a seamless transition between the prosthesis and the patient’s natural gums. This artistic approach results in a smile that looks indistinguishable from natural dentition, boosting patient confidence significantly.

Are There Downsides Like Clicking Sounds with Zirconia?

One frequently cited concern regarding zirconia involves a distinct “clicking” or “clacking” sound that occurs when teeth contact each other. This phenomenon results from the extreme hardness and density of ceramic structural parts , which lack the shock-absorbing properties of natural periodontal ligaments or softer acrylics. Patients transitioning from natural teeth or acrylic dentures may find this auditory feedback surprising initially. The sound is most improved when opposing arches are both restored with zirconia, creating a hard-on-hard contact.

However, this issue rarely affects daily quality of life and often diminishes as the patient adapts neurologically to the new prosthesis. Clinicians can mitigate this effect by meticulously adjusting the occlusion to ensure simultaneous contact points, preventing premature striking. But there is a catch: Ignoring occlusion can lead to joint pain. Prescribing a hard-soft occlusal guard for nighttime use protects the restoration and dampens forces, safeguarding the temporomandibular joint.

How Durable Is a Zirconia Arch Under Daily Stress?

Zirconia boasts a flexural strength that frequently exceeds 1,000 to 1,200 MPa, making it virtually unbreakable under normal physiological forces. To put this in perspective, the average human bite force in the posterior region rarely exceeds 700 Newtons, well within the material’s safety margin. This exceptional toughness allows zirconia arches to withstand the repetitive cycles of chewing, grinding, and clenching without fatigue. Unlike metal-ceramic bridges that may suffer from delamination, a monolithic zirconia structure has no layers to separate.

Long-term studies indicate survival rates for zirconia full-arch prostheses remaining extremely high over five to ten-year periods. Failures, when they do occur, typically stem from laboratory design errors, such as inadequate connector thickness, rather than material weakness. Ready for the good part? You can eat virtually anything. The material resists abrasion from coarse foods, maintaining its smooth surface and preventing wear on opposing natural teeth if polished correctly.

| Material | Flexural Strength (MPa) | Fracture Risk | |

|---|---|---|---|

| Zirconia | 1000 – 1200+ | Very Low | |

| Porcelain | 90 – 120 | Moderate | |

| Acrylic | 80 – 100 | High (Wear/Breakage) | |

| Gold Alloy | 400 – 500 | Low (Bends vs Breaks) |

Who Is the Ideal Candidate for Zirconia Restorations?

Ideal candidates for zirconia restorations include patients exhibiting high bite forces or those with a history of bruxism who destroy lesser materials. Bruxers often pulverize acrylic teeth within months, necessitating a stronger solution that can endure significant parafunctional habits. Individuals seeking a permanent, non-removable replacement for dentures find zirconia particularly appealing due to its fixed nature and low maintenance. Candidates must possess adequate bone volume to support the requisite number of implants, usually four to six per arch, to distribute the load effectively.

Evaluation involves assessing the vertical dimension of occlusion, ensuring enough space exists for the material thickness required for strength. What’s the real story? Not everyone qualifies immediately. Patients with limited inter-arch space might require bone reduction surgery to accommodate the zirconia height without compromising esthetics. Clinicians also screen for parafunctional habits that might require specific design modifications, such as reinforced cantilever areas.

How Do You Maintain and Clean Zirconia Arches?

Maintaining a zirconia arch requires a dedicated hygiene protocol, as plaque accumulates around implants just as it does natural teeth. Although the material itself is non-porous and hydrophobic, resisting bacterial adhesion, the interface between the bridge and the gum tissue remains vulnerable. Patients must utilize water flossers daily to flush out debris from beneath the pontic areas where a toothbrush cannot reach. Using Superfloss or specialized bridge threaders helps clean the abutments effectively.

Professional maintenance schedules typically involve visits every six months for cleaning and screw inspection. But there is a catch: Even the strongest teeth fail if gums are neglected. Peri-implantitis can lead to bone loss and implant failure regardless of the bridge material. Hygienists use plastic or titanium scalers to clean the prosthesis without scratching the glazed surface, ensuring the zirconia remains smooth and plaque-resistant.

| Tool | Frequency | Purpose | |

|---|---|---|---|

| Water Flosser | Daily | Flush debris under bridge | |

| Superfloss | Daily | Clean around implants | |

| Soft Brush | 2x Daily | Surface cleaning | |

| Professional Exam | 6 Months | Check screws & bone level |

What Is the Cost Analysis of Zirconia vs. Metal-Ceramic?

Zirconia restorations generally command a higher initial laboratory fee compared to traditional metal-ceramic or acrylic hybrid options. This cost reflects the advanced CAD/CAM technology, expensive milling equipment, and the premium price of high-purity zirconia discs. However, the long-term cost analysis often favors zirconia due to significantly reduced maintenance expenses. Acrylic hybrids frequently require denture tooth replacement, relining, or repair of fractured bases, accumulating costs that eventually surpass the initial savings.

Clinicians also benefit from reduced chair time associated with adjustments and repairs. Think about it: A “cheaper” bridge that breaks twice costs more than one that lasts forever. Patients engaging in a cost-benefit analysis should consider the value of their time and the psychological benefit of a worry-free smile. We encourage you to contact our experts to understand the specific investment structure for your lab or clinic.

What Future Trends Are Shaping Zirconia Manufacturing?

The future of zirconia manufacturing is rapidly shifting from subtractive milling to additive manufacturing, utilizing 3D printing technologies. Printing zirconia structures eliminates the significant material waste associated with milling pucks, where up to 70% of the block is discarded as dust. This advancement allows for even more complex internal geometries and finer marginal adaptation. Gradient technology continues to evolve, with new materials offering a seamless blend of high-strength opaque cores and hyper-translucent enamel layers within a single print.

Research focuses on improving the fracture toughness of highly translucent zirconia formulations, which historically traded strength for esthetics. This is where it gets interesting: Smart materials are on the horizon. Future zirconia formulations may possess self-healing properties or integrated sensors to monitor occlusal forces and pH levels in the mouth.

Conclusion

Zirconia arches have fundamentally transformed the landscape of restorative dentistry, offering a superior alternative to failing acrylics and heavy metals. By combining the industrial strength of zirconium oxide with advanced artistic staining, patients receive a smile that is both indestructible and beautiful. The initial investment pays dividends through reduced maintenance, improved hygiene, and enhanced quality of life. As manufacturing technology evolves, these restorations will only become more accessible and lifelike. Here is the bottom line: choosing the right material is the most critical decision in full-arch rehabilitation. Connect with us today to discuss your needs and contact our experts for a consultation.

FAQ Section

Q1: What is a zirconia full-arch bridge?A zirconia full-arch bridge is a complete set of upper or lower replacement teeth made from a single block of solid zirconium oxide, offering superior strength and esthetics for dental implant patients.

Q2: How does the manufacturing quality affect the bridge?High-purity zirconia powder and precise sintering processes are critical; impurities or uneven particle sizes can lead to micro-cracks and eventual failure of the restoration.

Q3: Can zirconia arches break under pressure?While extremely rare due to flexural strength exceeding 1000 MPa, fracture is possible if the material is too thin or if the bite is improperly balanced during the design phase.

Q4: Is zirconia heavy compared to other materials?Zirconia is denser and heavier than acrylic, but most patients adapt quickly to the weight, often interpreting the solidity as feeling more like “real” teeth.

Q5: How long do zirconia implant bridges last?With proper oral hygiene and regular check-ups, zirconia bridges are designed to be a permanent solution, often lasting 10 to 20 years or more without significant wear.