Imagine selecting ceramics for a high-wear engine component, only to face failures from poor thermal resistance or brittleness, leading to costly downtime in manufacturing. These missteps not only inflate repair expenses but erode reliability in critical applications like aerospace or automotive, where one wrong choice risks safety and efficiency. This guide compares Zirconia and Silicon Nitride, highlighting key properties to empower you with confident selections for durable, high-performance solutions. For a deeper look at the material’s use in related fields, read our article on the Application of Zirconium Silicate in Ceramics. As an expert in advanced ceramics, you’ll gain insights to optimize material choices effectively.

Zirconia Properties Overview

Core Mechanical Traits of Zirconia

Zirconia boasts exceptional hardness exceeding 9 Mohs, ideal for wear-intensive uses.

- High fracture toughness at 13 MPa·m¹/² prevents cracking under stress. You might wonder how this stacks against daily demands—Zirconia endures mechanical loads superbly. You can rely on its compressive strength of 2500 MPa for robust parts.

Thermal Resistance in Zirconia

Zirconia handles temperatures up to 500°C in air without degrading.

- Low thermal conductivity of 2.7 W/m-K minimizes heat transfer. Here’s the deal: Sudden shocks up to 360°C won’t shatter it. You benefit from stable performance in fluctuating environments.

Key Takeaway: Zirconia vs. Silicon Nitride Basics

Zirconia excels in toughness over Silicon Nitride’s superior heat tolerance.

| Property | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Hardness (Mohs) | >9 | 8-9 | |

| Max Temp (°C) | 500 | 1200 | |

| Fracture Toughness | 13 | 6-7 |

Zirconia’s balanced profile suits versatile industrial needs, outperforming in impact scenarios.

Zirconia in High-Wear Applications

Can Zirconia Handle Cutting Tools?

Zirconia shines in high-speed cutting tools due to its wear resistance.

- Resists abrasion from metals and composites effectively. What’s the catch? It maintains edges longer than softer ceramics. You save on replacements through extended tool life.

Zirconia for Pump Seals and Valves

Pump seals made from Zirconia withstand corrosive fluids seamlessly.

- Impervious to acids, alkalis, and solvents. But here’s the kicker: Tight seals prevent leaks in harsh pumps. You ensure operational continuity with minimal maintenance.

Key Takeaway: Wear Performance Edge

Zirconia outperforms Silicon Nitride in chemical resistance for seals.

| Application | Zirconia Advantage | Silicon Nitride Fit | |

|---|---|---|---|

| Cutting Tools | Superior hardness | High-speed tolerance | |

| Seals/Valves | Chemical inertness | Thermal stability |

Analysis: Zirconia’s edge in abrasion makes it preferable for dynamic wear environments.

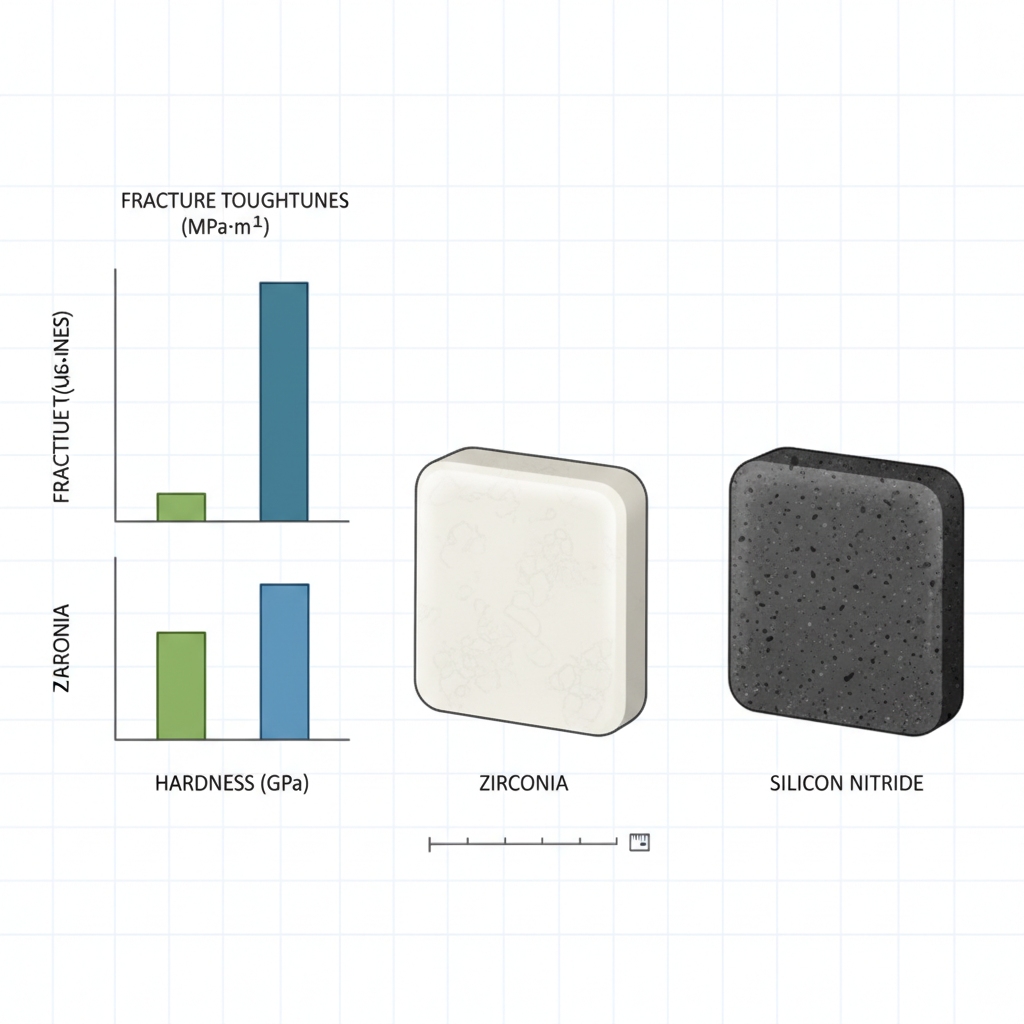

Comparing Zirconia and Silicon Nitride Strength

What’s Zirconia Toughness Like?

Zirconia delivers fracture toughness far beyond many ceramics at 13 MPa·m¹/².

- Absorbs shocks without brittle failure. You might be wondering: Does it bend or break? It flexes under stress reliably. You gain durability in impact-prone setups.

Silicon Nitride vs. Zirconia Hardness

While both hard, Zirconia edges out with >9 Mohs versus Silicon Nitride’s 8-9.

- Better for surface abrasion resistance. Ready for the good part? Zirconia holds up in grinding applications. You select it for precision machining needs.

Key Takeaway: Strength Selection Criteria

Opt for Zirconia when toughness trumps pure heat resistance.

| Strength Metric | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Compressive (MPa) | 2500 | 3000 | |

| Toughness (MPa·m¹/²) | 13 | 6-7 |

Zirconia’s higher toughness reduces failure risks in mechanical stress.

Zirconia for Thermal Shock Resistance

How Does Zirconia Resist Heat Shocks?

Zirconia manages thermal shocks up to 280-360°C effortlessly.

- Ideal for rapid heating in engines. This is where it gets interesting: No cracking during cycles. You deploy it confidently in variable temp zones.

Zirconia in Engine Components

Jet and diesel engines favor Zirconia for its stability.

- Withstands molten metals without erosion. Here’s the deal: Low expansion coefficient of 11 µm/m-°C aids fit. You enhance engine longevity substantially.

Key Takeaway: Shock Handling Comparison

Zirconia suits moderate shocks; Silicon Nitride for extremes.

| Shock Factor | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Delta T (°C) | 280-360 | 800+ | |

| Conductivity (W/m-K) | 2.7 | 20-30 |

Short analysis: Zirconia’s insulation properties shine in controlled thermal swings.

Electrical Properties of Zirconia

Can Zirconia Insulate Transistors?

Zirconia’s dielectric strength of 9 kV/mm protects electronics.

- High resistivity >10¹⁴ Ω·cm blocks currents. What’s the real story? It supports high-voltage setups safely. You integrate it for reliable circuit isolation.

Zirconia Dielectric Constant Explained

At 26 (1 MHz), Zirconia stores energy efficiently in capacitors.

- Stable across temperatures. But here’s the kicker: Outperforms in compact designs. You optimize space in semiconductor parts.

Key Takeaway: Insulation Advantages

Zirconia provides balanced electrical performance over Silicon Nitride’s conductivity.

| Electrical Trait | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Dielectric Strength (kV/mm) | 9 | 10-15 | |

| Constant (1 MHz) | 26 | 8 |

Analysis: Zirconia’s properties favor insulating roles in electronics.

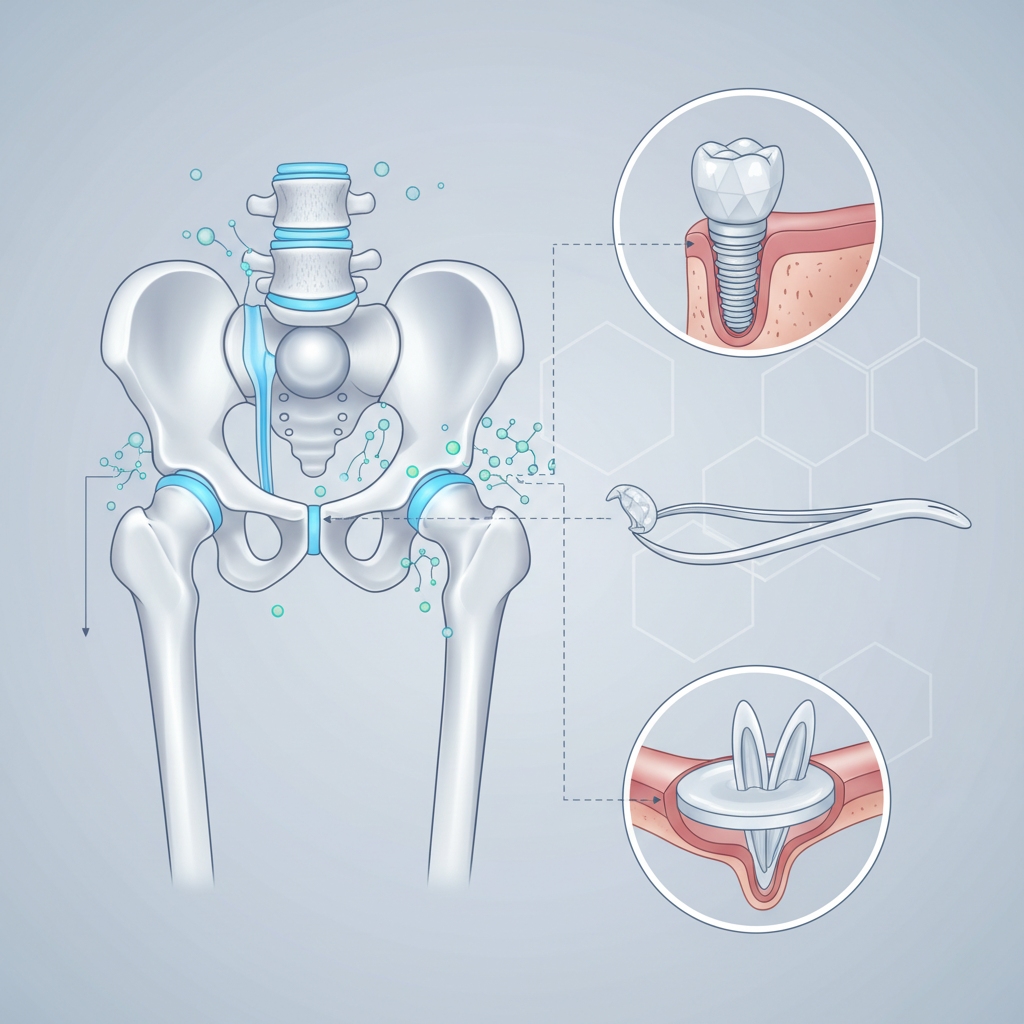

Zirconia in Medical and Dental Uses

Is Zirconia Biocompatible for Implants?

Zirconia offers full biocompatibility for dental implants.

- Corrosion-free in bodily fluids. You might wonder: Will it last? Its hardness ensures decades of wear. You trust it for patient safety.

Best Way to Use Zirconia in Prosthetics?

Craft prosthetics with Zirconia for precise, smooth finishes.

- High strength supports load-bearing. Ready for the good part? Reduces allergic reactions effectively. You deliver superior medical outcomes.

Key Takeaway: Medical Fit Assessment

Zirconia leads in biocompatibility versus Silicon Nitride’s industrial focus.

| Medical Aspect | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Biocompatibility | High | Moderate | |

| Wear Resistance | Excellent | Good |

Zirconia’s inertness makes it ideal for implants. Its properties are also key in achieving high-quality finishes, such as those discussed in our guide on How to Boost Ceramic Glaze Whiteness.

Selecting Zirconia for Automotive Parts

Can I Use Zirconia for Sensors?

Automotive sensors thrive with Zirconia’s chemical resistance.

- Endures exhaust gases and fuels. This is where it gets interesting: Maintains accuracy in heat. You improve vehicle diagnostics reliably.

Zirconia in High-Wear Auto Components

Exhaust and fuel system parts benefit from Zirconia’s durability.

- Resists thermal cycling. Here’s the deal: Lowers failure rates significantly. You cut maintenance costs over time.

Key Takeaway: Automotive Choice Guide

Choose Zirconia for wear; Silicon Nitride for high-heat engines.

| Auto Application | Zirconia Strength | Silicon Nitride Edge | |

|---|---|---|---|

| Sensors | Chemical resistance | Heat tolerance | |

| Wear Parts | Toughness | Strength |

Analysis: Zirconia’s versatility boosts automotive efficiency.

Zirconia vs. Silicon Nitride in Aerospace

What’s Best for Jet Engine Zirconia Parts?

Zirconia fortifies jet components against thermal stress.

- Toughness handles vibrations. What’s the catch? It insulates better than metals. You achieve lighter, stronger designs.

Comparing Aerospace Material Limits

Silicon Nitride edges in max temp, but Zirconia wins toughness.

- Both resist corrosion. You might be wondering: Which for turbines? Zirconia fits moderate exposures. You balance performance needs.

Key Takeaway: Aerospace Decision Factors

Zirconia prioritizes impact resistance in aerospace.

| Aerospace Metric | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Max Temp (°C) | 500 | 1200 | |

| Toughness | High | Moderate |

Short analysis: Zirconia’s profile enhances aerospace safety margins.

Custom Zirconia Fabrication Tips

How to Customize Zirconia Components?

Tailor Zirconia via CNC for precise tubes and rods.

- Supports small-batch prototyping. But here’s the kicker: Achieves tight tolerances easily. You accelerate development cycles.

Best Practices for Zirconia Machining

Grind Zirconia carefully to preserve properties.

- Use diamond tools for accuracy. Ready for the good part? Ensures surface smoothness vital for seals. You produce high-quality parts consistently.

Key Takeaway: Fabrication Efficiency

Zirconia machines well for custom needs, unlike denser Silicon Nitride.

| Fabrication Aspect | Zirconia | Silicon Nitride | |

|---|---|---|---|

| Machinability | Good | Fair | |

| Prototyping Speed | Fast | Slower |

Analysis: Zirconia’s ease streamlines custom production.

Final Selection: Zirconia or Silicon Nitride?

When to Choose Zirconia Over Alternatives?

Select Zirconia for applications needing toughness and biocompatibility.

- Ideal for wear and moderate heat. This is where it gets interesting: Avoids Silicon Nitride’s higher cost for non-extreme uses. You optimize budgets effectively.

Assessing Overall Cost-Benefit

Zirconia’s longevity offsets initial expenses.

- Lower replacement frequency. Here’s the deal: Balances performance with economy. You make informed procurement decisions.

Key Takeaway: Ultimate Comparison

Zirconia fits versatile, impact-heavy roles; Silicon Nitride for ultra-high temps.

| Overall Factor | Zirconia Winner | Silicon Nitride Winner | |

|---|---|---|---|

| Versatility | Yes | No | |

| Cost-Effectiveness | Moderate use | High-heat only |

Analysis: Zirconia’s broad applicability simplifies selections.

Conclusion

Struggling with ceramic choices that cause downtime or excess costs? This guide equips you to select Zirconia confidently for toughness-driven applications, solving wear and compatibility pains. Contact us for expert consultation to tailor solutions that advance your projects. Our vision: Empowering industries with precision materials for innovative, reliable performance.

FAQ

Can I use Zirconia for high-temperature engines? Yes, but limit to 500°C; its toughness suits moderate heat better than extremes where Silicon Nitride excels due to 1200°C tolerance.

What’s the best way to compare Zirconia and Silicon Nitride? Evaluate based on toughness needs versus thermal limits—Zirconia for impact resistance, Silicon Nitride for prolonged high heat, ensuring application-specific matching.

How do I know if Zirconia fits my wear application? Check for >9 Mohs hardness requirements; Zirconia’s superior fracture toughness confirms suitability over Silicon Nitride in abrasive, chemical-exposed settings.

Can Zirconia replace Silicon Nitride in electronics? Often yes for insulation—its 9 kV/mm strength provides reliable barriers, though Silicon Nitride offers better conductivity in specialized circuits.

What’s the best selection criterion for medical uses? Prioritize biocompatibility; Zirconia’s corrosion resistance and strength make it preferable to Silicon Nitride’s more industrial profile.