Zircon sand plays a vital role in various industrial applications, but the challenge of waste management raises a significant concern for purchasing managers. Manufacturers are increasingly facing pressures from both economic and environmental perspectives. Addressing how the recycling of zircon sand can be done efficiently is key to mitigating these concerns. This article aims to outline effective recycling methods that can alleviate waste, lower costs, and meet sustainability goals. By presenting reliable solutions based on industry practices, we aim to establish trust and provide valuable insights for decision-makers in manufacturing and other sectors.

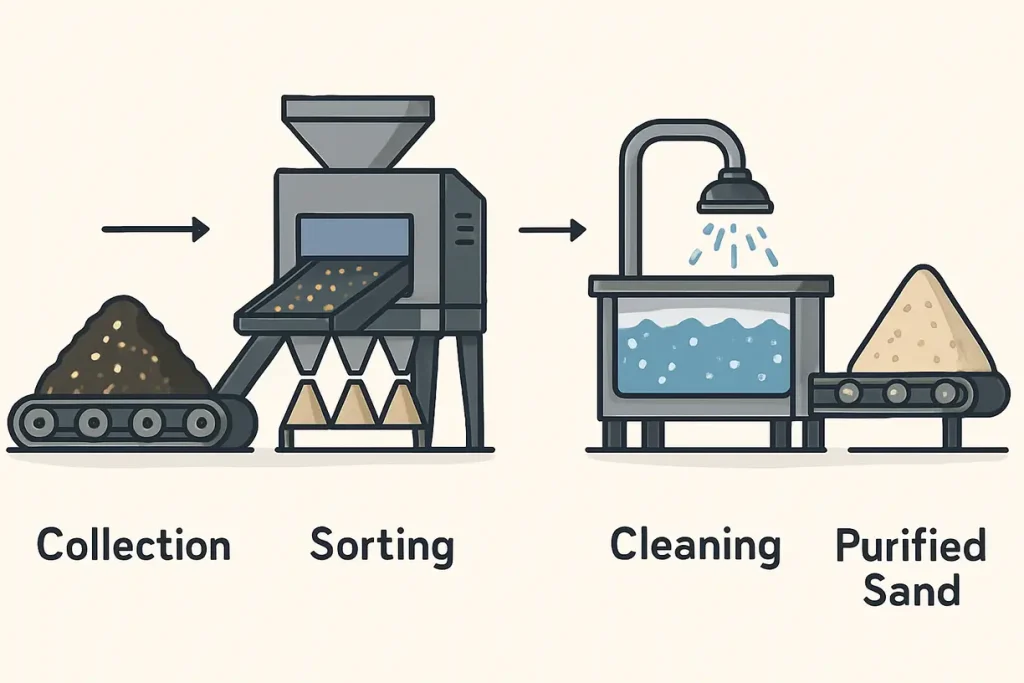

This image illustrates the steps involved in the zircon sand recycling process, highlighting sorting and cleaning stages.

How Can Zircon Sand Be Recycled Efficiently?

Recycling zircon sand involves several critical processes that significantly reduce waste while still delivering high-quality material for industrial use. The recycling process typically begins with collecting and processing waste from factories, which can include remnants from ceramic production or casting operations. These remnants often contain valuable zircon that can be rejuvenated.

Once collected, the sand undergoes various treatment stages designed to remove impurities and restore its original properties. Here’s the scoop: mechanical processes serve as the foundational approach to recycling zircon materials. These processes often include screening and washing to eliminate contaminants like dust and dirt. After cleaning, the sand may be further processed through thermal methods to remove any residual chemicals or coatings that may affect its quality in final use.

Another option is chemical treatment, which can help enhance the quality of recycled zircon sand. By stabilizing and refining the material, companies can maintain high-performance standards in their manufacturing processes, ensuring that the recycled product meets strict industry specifications.

Ultimately, an efficient recycling process not only benefits the environment but also decreases dependence on newly mined resources. This supports a more sustainable manufacturing framework—something that modern business practices must embrace in today’s world.

| Recycling Process | Description |

|---|---|

| Collection and Sorting | Gathering zircon sand waste from production |

| Mechanical Processing | Screening and washing to remove contaminants |

| Chemical Treatment | Enhancing quality through chemical methods |

| Thermal Processing | Additional measures to purify the sand |

What Are the Benefits of Recycling Zircon Sand?

Recycling zircon sand offers multiple benefits that extend beyond simple waste management. Consider this: one of the primary advantages is the significant environmental impact reduction. By engaging in recycling processes, organizations can lower their carbon footprint, decrease landfill waste, and help in conserving natural resources. This meets the growing sustainability demands from customers and regulatory bodies, allowing companies to portray themselves as responsible stewards of the environment.

Additionally, recycling zircon materials can facilitate compliance with increasingly strict environmental regulations. Companies that proactively reduce waste through recycling practices are likely to enhance their reputations among consumers and stakeholders who prioritize sustainability.

Furthermore, the economic advantages are substantial. By recycling, firms can substantially cut down on procurement costs associated with virgin materials. For instance, the cost savings from recycling can be redirected toward improving production capacity or enhancing employee training. This allocation of resources can lead to improved operational efficiencies and better profitability overall.

List of economic benefits from recycling zircon sand:

- Lower operational costs due to decreased material procurement

- Enhanced budgeting through predictable supply availability

- Increased funding for innovation and workforce development

Resource conservation is another critical advantage of recycling practices. By reusing materials, businesses maintain a stable supply of essential resources, which can help to reduce fluctuations in cost and availability. Companies that adopt robust recycling initiatives foster sustainability, ensuring long-term viability in their operations and positively impacting their bottom line.

| Benefits | Details |

|---|---|

| Environmental Impact | Reduces carbon footprint and landfill waste |

| Cost Savings | Lowers procurement costs for materials |

| Resource Conservation | Maintains stability in material supply |

What Are the Common Methods for Recycling Zircon Sand?

Numerous methods are employed for the recycling of zircon sand, each offering its own unique benefits and challenges. Take a look at some of the most common techniques and how they impact the recycling process.

Mechanical processes dominate the recycling landscape. These include screening to separate larger particles from smaller ones, washing to remove dirt, and crushing to refine particle size. Each method aims to restore the sand to a usable state. Mechanical recycling, while generally effective, requires ongoing maintenance and can involve substantial investment in equipment that ensures quality.

Chemical processes represent another vital recycling avenue. These methods often involve treating the sand with various acids or alkaline solutions to remove impurities. While effective at achieving high purity levels, these methods can be more expensive than mechanical alternatives. They also present environmental risks if not managed properly, which necessitates careful handling and appropriate disposal of any harmful byproducts.

Thermal processes utilize heat to clean and purify zircon sand. These high-temperature treatments can effectively eliminate contaminants and deliver high purity for the recycled raw material. However, given the significant energy demands associated with these techniques, businesses must weigh the costs against the benefits carefully.

In sum, industries should evaluate which recycling methods are best aligned with their specific needs and budget, balancing operational effectiveness with overall costs.

| Recycling Method | Advantages | Challenges |

|---|---|---|

| Mechanical Processing | Cost-effective and widely used | Equipment maintenance required |

| Chemical Treatment | High purity achievable | Expensive and potentially harmful |

| Thermal Processing | Effective in removing contaminants | High energy usage and overall costs |

How Do Industries Implement Zircon Sand Recycling?

Implementing zircon sand recycling practices requires a structured and strategic approach. Here’s the key: companies should begin by thoroughly assessing their current waste streams. Conducting a waste audit helps identify potential sources of recyclable zircon material. This assessment can reveal valuable insights into where waste occurs, ultimately leading to better recovery techniques.

After mapping waste sources, the next step is establishing clear, actionable procedures for collecting and processing the sand. Detailed guidelines can help streamline the recycling process and ensure that all employees are on the same page.

Collaboration with recycling facilities can significantly enhance efficiency. Many businesses partner with specialized providers who manage the entire recycling chain, enabling firms to focus on their core operations. This collaboration can also help ensure adherence to environmental standards and regulatory requirements.

Training employees on effective recycling practices fosters greater awareness and active participation in the company’s sustainability efforts. By cultivating a culture of recycling, businesses are likely to see increased engagement and a stronger commitment from their staff.

Finally, companies need to track the outcomes of their recycling initiatives. By measuring success in terms of cost savings, waste reduction, and environmental impact, organizations can refine their strategies continuously, optimizing their recycling efforts for improved outcomes.

| Implementation Steps | Description |

|---|---|

| Assess Current Waste Streams | Identify sources of zircon sand waste |

| Establish Clear Procedures | Create guidelines for collection and processing |

| Partner with Facilities | Collaborate with specialized recycling providers |

| Train Employees | Educate staff on best practices for recycling |

| Track Results | Measure progress and success in savings and waste reduction |

What Are the Quality Control Measures for Recycled Zircon Sand?

Quality control is vital in the recycling process of zircon sand, ensuring that the recycled product meets or exceeds industry standards. Here’s the bottom line: maintaining high standards is essential for reliability and performance in the end-use applications.

First, companies typically employ standardized testing methods to evaluate the purity of recycled sand. Common tests include moisture content analysis, particle size distribution measurements, and contaminant assessments. These tests help assure manufacturers that the final product performs effectively in a range of applications, aligning with clients’ expectations.

In addition to testing, companies should also consider implementing a robust quality assurance framework. This can include:

- Regular Equipment Calibration: Ensuring machinery used in processing is calibrated correctly to maintain consistent quality levels.

- Supplier Assessments: Regularly evaluating the performance and reliability of suppliers who provide recycling services or raw materials.

- Employee Training Programs: Providing ongoing training for employees involved in the recycling process to emphasize the importance of quality and efficient practices.

Moreover, regular audits of the entire recycling process can identify potential issues before they escalate into significant problems. Adopting a Total Quality Management (TQM) approach fosters a culture of continuous improvement and drives long-term reliability in product quality.

Furthermore, seeking certifications for recycled materials can communicate quality assurance to potential clients. Obtaining recognition from reputable industry standards builds trust and reinforces the commitment to high-quality practices.

| Quality Control Measures | Description |

|---|---|

| Standardized Testing | Conduct purity and contamination analyses |

| Regular Audits | Inspect and assess recycling processes |

| Total Quality Management (TQM) | Implement ongoing improvements for reliability |

| Certifications | Attain industry recognition for quality assurance |

How Does Zircon Sand Recycling Impact Production Efficiency?

The effect of zircon sand recycling on production efficiency is considerable. Consider this: when organizations integrate recycled materials, they can streamline operations while simultaneously reducing operational costs.

Recycled sand often requires less energy to process than virgin materials, leading to significant energy savings over time. Additionally, businesses frequently experience shorter lead times because recycled zircon tends to be more readily available, helping them to meet production schedules more effectively.

Moreover, using recycled materials typically results in less wear and tear on machinery due to their improved quality. This translates into reduced maintenance costs and prolonged equipment lifespan, which is crucial in maintaining overall productivity.

Lastly, having stable access to recycled materials can help mitigate the price fluctuations that often accompany newly mined zircon. This stability allows firms to adopt a more predictable budgeting process, thereby ensuring consistent quality and reliability in their production.

| Impact on Production Efficiency | Description |

|---|---|

| Energy Savings | Less energy required for processing |

| Shorter Lead Times | More readily available materials |

| Reduced Wear and Tear | Improved quality leads to extended equipment life |

| Price Stability | Minimizes fluctuations in material costs |

This image depicts the industrial setup for processing zircon sand, showcasing machinery and handling operations.

What Regulations Govern Zircon Sand Recycling?

Achieving regulatory compliance is crucial in the recycling sector. Let’s break this down: various laws and standards dictate how recycled materials must be processed, handled, and documented throughout their lifecycle.

Local and international regulations frequently set quality, safety, and environmental impact standards. It is vital that companies remain informed about these regulations to avoid potential fines and to ensure they meet customer expectations.

One key regulation is the Resource Conservation and Recovery Act (RCRA) in the United States, which outlines essential guidelines for waste management practices, including those that impact the recycling of industrial materials. Similar legislation exists internationally, making it imperative for businesses to remain compliant across different jurisdictions to avoid legal ramifications.

Additionally, engaging with legal experts and industry associations can help companies navigate the intricacies of regulatory requirements effectively. This proactive approach not only mitigates risks but also promotes responsible practices and fosters a positive reputation in the marketplace.

| Regulations | Description |

|---|---|

| Local Regulations | Vary by region, often targeting waste and recycling practices |

| International Regulations | Encompass global standards for safety and quality |

| Resource Conservation Act (RCRA) | U.S. law governing waste management practices |

| Engagement with Experts | Consulting legal professionals for guidance |

How Is Zircon Sand Recycling Evolving?

The recycling landscape for zircon sand is undergoing rapid transformation. Pay attention: advancements in technology and methods have dramatically improved recycling efficiency along with the quality of recycled products.

Recent trends indicate a shift toward the development of more effective mechanical and chemical processes that yield higher purity levels. Innovations in treatment technology allow for the better removal of contaminants, thereby enhancing the overall quality of the recycled zircon product.

Moreover, artificial intelligence (AI) and automation are becoming increasingly integrated into recycling processes. This technological infusion allows companies to monitor and optimize their recycling operations, enhancing productivity, lowering costs, and ensuring adherence to stringent quality standards.

Looking toward the future, as demand for sustainable practices evolves, recycling practices for zircon materials are expected to grow in importance. Companies that proactively embrace these trends will find themselves well-positioned to compete in a marketplace increasingly focused on sustainable practices and materials.

| Evolutionary Trends | Description |

|---|---|

| Improved Processes | Innovative techniques yield purer materials |

| AI and Automation | Enhance efficiency and reduce processing costs |

| Growing Demand | Increasing emphasis on sustainability practices |

| Future Outlook | Higher focus on adopting effective recycling solutions |

How Can Companies Collaborate for Better Recycling Practices?

Collaboration is an essential component in enhancing zircon sand recycling practices. Here’s what to remember: industry partnerships can drive innovation, share resources, and ultimately improve operational efficiency.

Companies can work together and with recycling facilities to establish best practices and improve access to recycled materials. Such partnerships often lead to cost-sharing opportunities, enabling businesses to implement new technologies without shouldering the entire financial burden.

Participating in industry associations also grants access to valuable resources, insights, and networking opportunities. Building relationships within the industry fosters knowledge sharing, enabling companies to learn from one another’s successes and challenges.

Finally, engaging directly with customers about their sustainability preferences can also shape product offerings. As more clients demand recycled materials, companies can align their strategies accordingly, creating a win-win situation for both the business and the environment.

| Collaboration Opportunities | Description |

|---|---|

| Partnerships | Collaborate to enhance access and drive innovation |

| Industry Associations | Share best practices and valuable resources |

| Customer Engagement | Adjust offerings to meet evolving sustainability demands |

Conclusion

In summary, recycling zircon sand is crucial in today’s industrial landscape where sustainability and economic efficiency are paramount. The various environmental, economic, and quality benefits make an undeniable case for its implementation. By minimizing waste and lowering the reliance on newly mined resources, companies can significantly reduce their carbon footprint and contribute to a more sustainable future.

Organizations that integrate efficient recycling practices stand to gain substantial cost savings while enhancing their sustainability profile and meeting regulatory obligations. These practices not only optimize resource usage but also foster a positive company image among environmentally conscious consumers.

Global Industry encourages businesses to take immediate action toward adopting effective recycling solutions. By forging partnerships with industry leaders and implementing best practices, organizations can chart a path toward sustained success in their environmentally friendly initiatives. Engaging with this evolving practice not only supports individual corporate goals but also contributes to broader environmental objectives, creating a win-win scenario for businesses and the planet alike.

FAQ Section

Q1: What is zircon sand used for?

Zircon sand is primarily used in ceramics, foundry molds, and furnace linings due to its high melting point and chemical stability. It’s also utilized in the production of zirconium metal, which is vital for several advanced applications, including nuclear reactors and surgical instruments.

Q2: How does recycling zircon sand reduce waste?

Recycling helps divert zircon materials from landfills by reprocessing waste generated during industrial applications. This minimizes the extraction of new resources and lowers the environmental footprint associated with mining activities, promoting more sustainable practices in industries reliant on zircon.

Q3: What challenges exist in zircon sand recycling?

Common challenges include contamination from various materials during the recycling process and logistical issues related to collecting and transporting zircon waste. Additionally, companies must ensure that recycled content meets industry quality standards, which requires robust quality control measures.

Q4: Are there specific industries that benefit more from recycled zircon?

Industries such as ceramics, metal casting, and glass manufacturing heavily leverage recycled zircon due to its excellent thermal and mechanical properties. These sectors benefit from lower material costs while enhancing their sustainability profiles by using recycled content in their products.

Q5: What role do technology and innovation play in the recycling of zircon sand?

Technological advancements, such as automated sorting and chemical processing methods, significantly enhance the efficiency and effectiveness of zircon recycling. Innovations in machine learning and data analysis also help monitor and optimize recycling processes, ensuring consistent high-quality output and reduced operational costs.