In the world of materials used for industrial applications, zircon sand holds a unique position due to its versatility and essential properties. As a result, it is utilized in a range of sectors, from ceramics and glass to foundry and even nuclear industries. However, many decision-makers and industry leaders harbor misconceptions about its usage and properties. These misunderstandings can lead to inefficiencies in sourcing and application, ultimately impacting both operational effectiveness and the bottom line.

This article serves to clarify these common myths surrounding zircon sand, presenting accurate, practical information to empower businesses in making informed decisions. We aim to provide insights that enhance your understanding and application of this valuable material, ensuring that your processes are optimized for the best possible outcomes.

This image shows samples of zircon sand, illustrating its gritty texture used in various industrial applications.

What Are the Misconceptions Surrounding Zircon Sand?

There are numerous myths about zircon sand that can mislead professionals and hinder informed decision-making. What are the key points to understand?

First, one common misconception is that zircon sand is primarily a cosmetic ingredient. This perspective can be restrictive, as zircon sand serves a myriad of functions across different industries, including ceramics, glass manufacturing, and even foundries. For instance, professionals in the ceramic industry value zircon sand for its ability to improve the quality of tiles and porcelain, which may illustrate its broader importance.

Next, let’s consider the terminology surrounding this mineral. Some individuals mistakenly equate zircon sand with zirconium. However, it is important to note that zircon sand is primarily composed of zirconium silicate. While zirconium can be extracted from zircon sand, they are not interchangeable terms. This distinction is crucial for professionals who must choose the right materials depending on specific needs and applications.

Lastly, environmental impact is often a topic of concern associated with zircon sand extraction. It is a common belief that mining these materials is inherently damaging to ecosystems. However, when responsible mining practices are implemented, the extraction process can be conducted with minimal environmental harm. As awareness of sustainability grows, it becomes increasingly important for professionals to recognize the economic and environmental advantages that responsible sourcing can offer.

In summary, recognizing and addressing these misunderstandings enhances the ability to make informed choices about zircon sand, leading to improved results across various applications.

Why Do Misconceptions About Zircon Sand Persist?

Why do these misconceptions continue to exist? The persistence of misunderstandings about zircon sand can largely be attributed to a few interconnected factors.

First, the historical context plays a significant role. For many years, zircon was underutilized, and as a result, limited education about its full potential became commonplace. Industries may have favored other materials that seemed simpler or were perceived as more reliable, further marginalizing zircon’s role.

Additionally, when marketing practices exaggerate or oversimplify claims regarding zircon products, they contribute to ongoing misunderstanding. In some cases, promotional materials may highlight particular applications while downplaying others, leading to misconceptions about the versatile nature of zircon itself.

Another critical factor is the complex nature of the industries that utilize zircon. Different applications may require varied forms of zircon, and without a clear understanding, professionals may mistakenly generalize its uses, overlooking crucial details that could alter their decisions.

Furthermore, the reliance on anecdotal evidence can be detrimental to the understanding of zircon. Many industry players share personal experiences that may not accurately reflect the overall capabilities and properties of this mineral. As a result, misinformation spreads through informal channels, compounding confusion and promoting outdated views.

Understanding these reasons adds context to the persistence of misconceptions and highlights the importance of thorough research when considering zircon products for any application, allowing for informed decision-making and optimized outcomes.

What Are the Key Misunderstandings About Zircon Sand?

What are the specific misunderstandings? There are several important misconceptions that professionals should be aware of to avoid pitfalls in their decisions.

Misconception 1: Zircon sand equals zirconium. This misunderstanding can lead to significant consequences, particularly in product formulation and material selection. While zirconium can be derived from zircon sand, the two should not be conflated. Understanding this difference is crucial for industries that require zirconium’s unique properties for applications such as aerospace and medical devices.

Misconception 2: Zircon sand is harmful to the environment. Many believe that mining zircon minerals inherently contributes to ecological degradation. However, contemporary mining techniques and ethical practices can minimize environmental damage. By focusing on sustainability and responsible sourcing, companies can align their operations with modern environmental standards, ensuring they meet both regulatory requirements and ethical business practices.

Misconception 3: Zircon sand is only for cosmetics. This view overlooks the material’s versatility and application across various sectors. It is extensively used in ceramics (think tiles, porcelain, and sanitary ware), glass production, and metal casting in foundries. In ceramics, it enhances durability and thermal stability, essential for high-performance applications, while in glass manufacturing, it contributes to the creation of strong, high-quality glass components.

Here’s a brief list of the primary applications of zircon sand:

- Ceramics: Used to enhance the quality of tiles, porcelain, and sanitary ware.

- Glass Manufacturing: Key component in producing high-tech glass, such as optical glass.

- Foundries: Employed in metal casting to create molds and cores due to its thermal stability.

- Refractory Materials: Used in applications that require high resistance to heat and chemical attack.

Understanding these misconceptions allows decision-makers to make better-informed choices about utilizing zircon sand for their specific needs.

How Does Zircon Sand Compare to Other Materials?

How does zircon sand stack up against other materials? An effective comparison can reveal why this mineral is a preferred choice in many applications.

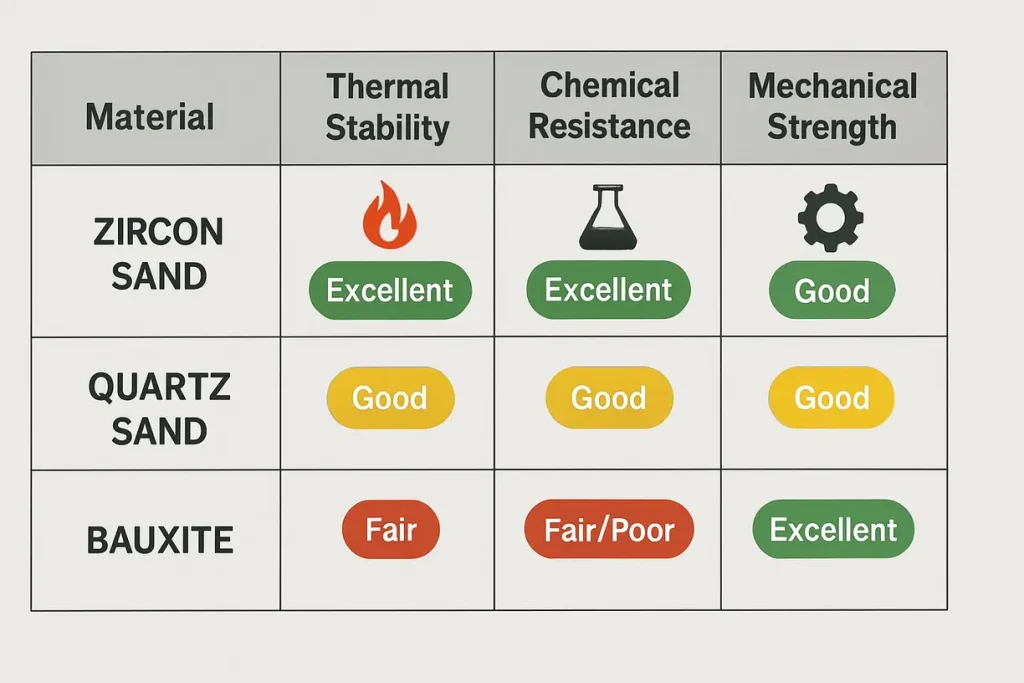

When comparing zircon sand to quartz sand, several distinct differences become evident. For example, zircon sand offers superior thermal stability, making it especially suitable for applications involving high temperatures. In contrast, quartz sand may not perform as optimally under extreme conditions, which can limit its viability in specific industrial environments.

Next, consider the chemical resistance of zircon sand. It outperforms many alternative materials, rendering it a standout option for performance in ceramics and glass applications. This property ensures longevity and reliability in products that operate under demanding conditions.

Moreover, zircon sand provides mechanical strength advantages over many alternatives, including alumina. The high-strength properties of zircon sand are particularly valuable in foundry processes, where metal casting molds must withstand rigorous thermal and mechanical strains.

In addition to these comparisons, consider factors such as:

- Cost and Sourcing: When determining the best material, not only should properties be considered, but also the cost of sourcing and any potential supply chain disruptions.

- Environmental Impact: The ecological footprint of the materials chosen is becoming increasingly significant. Sustainable sourcing options can enhance a business’s reputation and compliance with environmental regulations.

Here’s a quick comparison table illustrating these key points:

| Property | Zircon Sand | Quartz Sand | Alumina |

|---|---|---|---|

| Thermal Stability | High | Moderate | Moderate |

| Chemical Resistance | Superior | Moderate | High |

| Mechanical Strength | High | Low | Very High |

Given these attributes, zircon sand proves its worth as a versatile and effective material choice for various industrial applications, which professionals should keep in mind.

This image illustrates a comparison chart showcasing properties of different industrial materials, including zircon sand, quartz, and alumina.

What Are the Real Applications of Zircon Sand?

What real applications does zircon sand have? Understanding its diverse applications can help industries appreciate its value and maximize its utility.

In the ceramics industry, zircon sand plays a crucial role in producing materials like tiles, porcelain, and sanitary ware. It significantly enhances the quality of these products by improving their whiteness, strength, and durability.

In glass manufacturing, zircon serves as an essential ingredient in high-technology glass used for electronic applications and optics. Manufacturers prefer zircon due to its excellent thermal stability and chemical resistance, making it ideal for creating strong, long-lasting glass products.

In foundries, zircon sand is particularly valuable for metal casting, where it is used to create durable molds and cores. The properties of zircon sand allow for unique designs and high-precision components in various industries, including automotive and aerospace.

Here’s a list of other industries where zircon sand plays a vital role:

- Energy Sector: Used in the production of high-performance materials for turbine blades.

- Construction: Employed in high-quality concrete blends and specialty coatings.

- Environmental Applications: Utilized in filters and sorbents due to its ability to capture pollutants.

Here’s a summarizing table of these applications:

| Industry | Application | Benefits |

|---|---|---|

| Ceramics | Tiles, porcelain, sanitary ware | Enhances quality and performance |

| Glass Manufacturing | High-technology glass | Excellent thermal and chemical properties |

| Foundries | Metal casting | Durable molds for high-performance parts |

Identifying and understanding these applications helps illustrate why zircon sand is essential in various sectors and supports its widespread use as a key material.can make more informed decisions about when and where to use zircon sand, leading to improved product quality and operational efficiency.

What Quality Standards Exist for Zircon Sand?

What quality standards should professionals know about? Ensuring high-quality zircon sand is vital for achieving optimal results in all applications.

Industry standards dictate the quality of zircon sand based on specific needs. Different sectors have varying requirements, and understanding these becomes essential for professionals throughout the supply chain.

One critical standard is the ZrO2 content in zircon sand. This component is directly linked to performance, with high-quality zircon sand usually containing a minimum of 65% zirconium oxide (ZrO2). Regulations may vary by region, but consistent quality should always be a priority.

Additionally, minimizing impurities is crucial; excessive contaminants can significantly degrade the performance of the finished product. Regular testing and certification by accredited labs ensure compliance with industry standards, thus bolstering consumer confidence.

Beyond these specifics, consider the importance of:

- Consistent Sourcing: Establishing long-term relationships with reliable suppliers can enhance the quality and regularity of zircon sand procurement.

- Sustainability Certification: Look for certifications that showcase a supplier’s commitment to environmental and social governance.

Professionals must prioritize sourcing zircon sand that meets these and other emerging quality standards. This vigilance helps ensure reliable results, promotes best practices, and enhances overall product quality.

How Can Businesses Effectively Use Zircon Sand?

How should businesses effectively use zircon? Maximizing the potential benefits of zircon requires thoughtful planning and strategic frameworks.

First and foremost, selecting the right supplier is crucial. Businesses should assess potential suppliers based on their reliability and consistency in delivering high-quality zircon. Key factors to evaluate include certifications, reputation within the industry, and previous customer reviews or case studies that highlight their performance in real-world applications.

Next, integrating zircon into production processes should be accompanied by careful monitoring and necessary adjustments to operational parameters. When introducing zircon sand as a substitute for other materials, it’s critical to reassess manufacturing conditions to ensure that the final product meets the desired specifications and leverages the mineral’s unique properties effectively.

Lastly, collaborating with industry experts can empower companies to make well-informed decisions. Providing education and training for staff members with respect to zircon’s properties, handling, and potential uses not only enhances knowledge but improves operational efficiency as well. This training ensures that employees can confidently utilize zircon in ways that optimize results.

Here’s a brief table summarizing these strategies:

| Strategy | Description |

|---|---|

| Supplier Evaluation | Assess suppliers for quality and reliability |

| Production Integration | Adjust production parameters for optimal results |

| Staff Training | Enhance understanding of zircon properties |

Applying these strategies will help businesses make the most of their zircon purchases, ultimately enhancing product quality and operational efficiency.

What Are the Future Trends for Zircon Sand?

What future trends should professionals keep an eye on concerning zircon? Being aware of emerging trends can strategically position businesses for future success.

Emerging markets around the globe are showing an increased demand for zircon. Countries with developing industries are quickly recognizing the benefits of this material, leading to new opportunities for growth in zircon applications. This trend suggests that suppliers and businesses may see amplified demand not just locally, but also internationally.

Moreover, innovation is driving significant advances in zircon processing technology. Methods that enhance the extraction and purification of zircon are being developed, improving efficiency in its processing and reducing the overall cost of acquiring high-quality materials.

Additionally, regulatory changes could shape the way zircon is mined and utilized in the future. As sustainability becomes a higher priority for governments and businesses alike, stricter environmental regulations may emerge, compelling industries to adopt greener mining practices. This shift not only ensures compliance but also addresses ecological concerns, ultimately promoting more sustainable business practices.

To summarize the trends, here’s a table demonstrating the factors at play:

| Trend | Description |

|---|---|

| Emerging Markets | Increased demand from developing nations |

| Innovation | Advances in extraction and purification processes |

| Regulatory Changes | Stricter laws encouraging sustainable practices |

Keeping an eye on these trends will provide insights that may help businesses remain competitive and adaptable in the evolving zircon market.h a competitive advantage. By being proactive and adapting to market changes, you position your organization for long-term success.

How Does Zircon Sand Impact Sustainability Efforts?

What role does zircon play in sustainability initiatives? The pursuit of sustainable practices is essential for the future of various industries relying on this material.

Mining for zircon can be conducted responsibly, with minimal environmental impact when best practices are adopted. Companies that commit to sustainable approaches can mitigate potential ecological disturbances associated with mineral extraction. This commitment not only meets regulatory requirements but also aligns with the growing consumer demand for eco-friendly products.

Furthermore, industry leaders are increasingly working on recycling initiatives aimed at promoting the reuse of zircon sand in various applications. By finding innovative ways to repurpose this material, businesses can drastically reduce the need for fresh extraction and help minimize waste overall.

Finally, a focus on transparency is becoming more prevalent. By clearly communicating sourcing methods and cultivation practices, companies can reassure consumers that they prioritize sustainable practices and ethical product origins. This transparency builds trust and enhances brand loyalty and consumer confidence in the mining and materials sector.

Here’s a table summarizing sustainability efforts related to zircon:

| Effort | Description |

|---|---|

| Sustainable Mining | Responsible extraction with minimal ecological impact |

| Recycling Initiatives | Promoting reuse and reducing waste |

| Transparency | Open sharing of sourcing and processing methods |

Understanding how zircon impacts sustainability can enhance corporate responsibility and address market demands, helping businesses align with evolving consumer expectations while also contributing positively to environmental preservation.

Conclusion

Throughout this article, we examined the various misconceptions associated with zircon sand. By clarifying its real applications, contrasting it with alternative materials, and considering the standards that govern its usage, we have provided insights that are crucial for informed decision-making. Recognizing the true value of zircon sand can enhance resource allocation and operational integrity, leading to significant competitive advantages. For additional partnership opportunities and expert advice regarding zircon sand, consider reaching out to Global Industry, where we specialize in effective sourcing and offer knowledgeable insights tailored to your business needs.

FAQ Section

Q1: What are the primary benefits of using zircon sand?

Zircon sand is renowned for its high stability and excellent thermal properties, making it suitable for demanding industrial applications. Additionally, its resistance to corrosion and various chemicals enhances the durability and performance of products made with this material, such as ceramics and glass.

Q2: Is zircon sand environmentally friendly?

While zircon sand itself does not pose any direct environmental harm, the sustainability of its extraction and processing practices is vital. When sourced responsibly, mining operations can minimize negative impacts on ecosystems, promoting eco-friendly practices throughout the supply chain.

Q3: How does zircon sand influence the quality of ceramics?

The inclusion of zircon sand significantly improves the thermal stability and overall strength of ceramic products. These enhanced properties are crucial for items that must withstand high temperatures and mechanical stress, resulting in a higher quality, more durable final product.

Q4: What industries rely heavily on zircon sand?

Zircon sand plays a crucial role in several industries, including ceramics, glass manufacturing, and foundries. Its unique properties make it an essential component in producing tiles, porcelain, durable glass, and reliable molds for metal casting processes.

Q5: Are there alternatives to zircon sand?

While there are alternative materials available, such as quartz and alumina, they often lack the specific properties required for certain applications. Zircon sand’s superior chemical resistance and thermal stability make it the preferred choice for industries that demand high performance and reliability in their products.