Zircon sand plays a vital role in various industries, including ceramics, glass, and metal production. However, purchasers often face challenges concerning the impurities found in zircon sand and their effects on product quality. Understanding these impurities is essential for ensuring optimal outcomes for manufacturing processes. Identifying the contaminants allows businesses to choose better sources, enhance their end products’ performance, and reduce the likelihood of costly recalls or complaints. This article will provide a comprehensive overview of the impurities in zircon sand, their implications for different applications, and effective strategies for addressing these concerns, all backed by solid industry insights.

What Are the Common Impurities in Zircon Sand?

Zircon sand is primarily valued for its unique properties, which make it a preferred material in various applications. However, it often contains impurities that can vary depending on the source or processing methods employed. Some of the most common impurities include:

- Iron: This element is often found in zircon sand, and its levels can vary based on the extraction and processing techniques used. High iron content can lead to discoloration in many applications, particularly ceramics, where aesthetic appearance is essential.

- Titanium: While titanium is sometimes present naturally, it can affect the thermal and electrical properties of zircon products. In sectors where electrical efficiency is paramount, minimizing titanium impurities becomes critical to avoid compromised product performance.

- Silica: Although silica itself is a common component in many materials, its excess concentration can dilute the quality of pure zircon. This dilution can impair thermal stability and make the material less effective for specific applications, especially in high-temperature environments.

Understanding these impurities is crucial because they can influence product quality as well as processing efficiency. Depending on where zircon sand is sourced, contamination levels can fluctuate, so it is essential for businesses to stay vigilant about purity standards.

Now, let’s consider this: The presence and composition of these elements can change the physical and chemical performance of zircon in significant ways. For instance, an excess of iron in zircon sand can reduce the mechanical strength of ceramics, while high levels of titanium can significantly affect electricity conductivity, leading to inefficiencies in products designed for electronic applications.

This image depicts a comparison between pure zircon sand and zircon sand with high iron content, indicating the impact of impurities.

Why Are Impurities Significant in Zircon Sand?

The significance of impurities in zircon sand extends beyond mere composition. Quality control is particularly crucial in manufacturing, where the impact of these contaminants can ripple through the entire production process. Understanding how impurities affect products is key for businesses aiming to produce reliable and high-quality outputs.

Purity is intrinsically linked with product reliability; the more impurities present, the greater the risk of compromised performance. For instance, if iron levels exceed acceptable limits in a ceramic application, the resultant products can become brittle or exhibit unsightly discolorations. Industries that prioritize aesthetics, such as those in home decor and luxury goods, cannot afford to compromise on quality, making it essential to maintain stringent purity standards across the board.

Different industries have specific purity requirements to meet their unique product specifications. For example, a ceramics manufacturer might prioritize low iron content to ensure color fidelity, while a glass manufacturer may focus on minimizing titanium levels to preserve optical clarity.

| Industry | Key Impurity Concerns | Quality Consequence |

|---|---|---|

| Ceramics | High iron content | Brittle products; aesthetic issues |

| Glass Manufacturing | Excess titanium | Reduced transparency and clarity |

| Electronics | High levels of iron or silica | Performance and efficiency issues |

In summary, the presence of impurities is crucial because these contaminants can directly affect product integrity, performance, and ultimately, customer satisfaction. Understanding these factors allows organizations to make informed decisions about material selection and processing methods, ensuring that quality remains at the forefront of production.

How Do Different Impurities Affect Zircon Sand Quality?

The specific effects of impurities in zircon sand vary depending on the type of impurity, and their implications can be extensive and significant.

- Iron can cause discoloration and significantly reduce the durability of finished ceramics. When ceramics are used for high-end applications, such as decorative tiles or kitchenware, tracking iron concentration becomes critical for maintaining aesthetic appeal as well as functional integrity.

- Titanium can alter the electrical conductivity of zircon, which is vital in industries focusing on electronic components. High titanium concentrations might lead to challenges during manufacturing processes, making it essential for manufacturers to develop tailored approaches for impurity management.

- Silica, although not inherently harmful, can dilute the effective zircon content, reducing overall yield and impacting thermal stability. This dilution can hinder performance in applications that demand consistent heat resistance, such as in high-temperature furnaces.

For example, a manufacturer producing high-end ceramic tiles may find that elevated iron content renders their porcelain products less appealing due to discolorations or weaknesses. Conversely, in glass manufacturing, if the zircon contains too much titanium, it may result in delays, additional costs, and loss of credibility in the market due to inconsistent product quality.

Thus, understanding these impacts is critical. This knowledge can lead to improved sourcing strategies and help businesses avoid costly and time-consuming rectifications later in their manufacturing process.

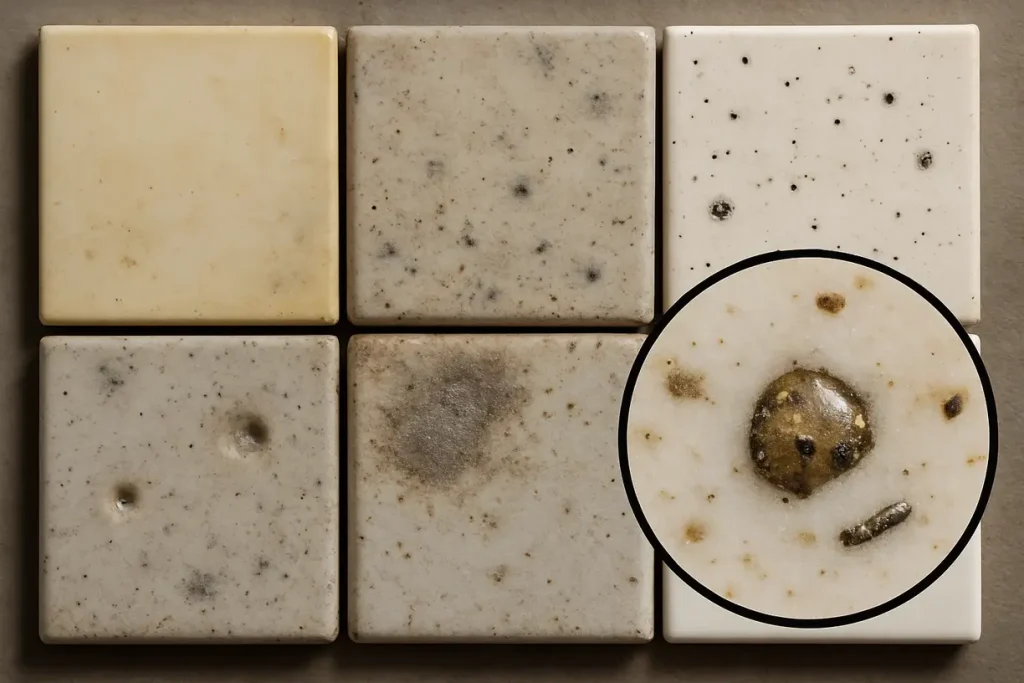

This image shows ceramic tiles impacted by various impurities, illustrating differences in color and finish quality.

What Testing Methods Are Used for Impurities Analysis?

Reliable testing methods for analyzing impurities in zircon sand are essential for ensuring product quality and compliance with industry standards. Different techniques exist, each serving its specific purpose and providing unique benefits.

- X-ray fluorescence (XRF) is one popular method. It is widely used for rapid and non-destructive analysis of elemental composition, allowing for onsite testing in several cases. This approach minimizes material waste and speeds up the analysis process.

- Scanning electron microscopy (SEM) allows for detailed imaging of the sand’s structure, revealing the presence of impurities at a microscopic level. SEM can also provide insight into the morphology of zircon particles and any associated contaminants, which can guide processing adjustments.

- Chemical analysis techniques, such as ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry), quantify various elements present in the sand. This technique offers high sensitivity and accuracy, making it particularly useful for detecting trace contaminants that might influence product quality.

Companies often utilize a combination of these methods to gain a comprehensive understanding of impurity levels within their materials. For instance, SEM might reveal structural defects associated with high impurity levels, while XRF quantifies specific elements accurately.

Ultimately, selecting the right testing methods is crucial for gaining a clear picture of the purity quality of zircon sand, helping companies meet their standards for operational excellence and product performance.

| Testing Method | Key Feature | Benefits |

|---|---|---|

| X-ray Fluorescence (XRF) | Rapid, non-destructive | Quick analysis of elemental composition |

| Scanning Electron Microscopy (SEM) | Detailed imaging | Insight into microstructures |

| ICP-OES | Quantitative analysis | Accurate elemental quantification |

How Can Companies Reduce Impurities in Zircon Sand?

Reducing impurities in zircon sand involves a combination of sourcing high-quality materials and implementing effective purification strategies. Here’s how companies can approach contamination reduction:

- Sourcing: Opt for suppliers who adhere to strict quality standards and have a proven track record of providing high-purity zircon materials. Conduct thorough evaluations and testing of material samples to assess impurity levels before making purchasing decisions. This proactive measure can save businesses from significant quality control issues later on.

- Purification Techniques: Companies can invest in state-of-the-art filtration systems or chemical treatments to minimize impurities. Processes such as magnetic separation can effectively remove iron impurities, while chemical leaching methods might be applicable for other contaminants.

- Technology Adoption: Utilizing modern technologies helps enhance impurity detection and removal. For instance, automated monitoring systems can provide real-time data on impurity levels during production, allowing for quick interventions if necessary. This can significantly improve production consistency.

By adopting these approaches, companies can ensure that their zircon sand meets or exceeds industry standards, ultimately improving the quality and performance of their final products.

Consequently, prioritizing impurity reduction enhances overall product reliability and customer satisfaction, creating a competitive edge for businesses in an increasingly demanding market.

| Strategy | Description | Expected Outcome |

|---|---|---|

| Sourcing Suppliers | Partner with reputable suppliers | Higher initial purity levels |

| Filtration Techniques | Conduct magnetic or chemical filtration | Minimized impurities in the sand |

| Technology Investment | Implement real-time monitoring systems | Enhanced compliance and quality assurance |

What Are the Economic Implications of Impurities?

Understanding the economic implications of impurities in zircon sand can shape strategic decisions for businesses, impacting their overall longevity and competitiveness.

Low-quality zircon sand can lead to several negative financial impacts. Manufacturers may face increased production costs due to the need for additional treatments to correct product flaws caused by impurities. These corrections can lead to unexpected delays and increased labor costs, which strain operating budgets and reduce profit margins.

Furthermore, high impurity levels often result in lower selling prices. Products that fail to meet high-quality standards might require significant markdowns to sell, directly impacting profit margins and overall business sustainability. Thus, the cost of opting for low-quality raw materials extends well beyond initial procurement expenses.

In light of this, investing in high-quality zircon sand can yield significant long-term financial benefits, directly supporting continued business growth and operational efficiency. Ensuring high product quality can lead to higher customer satisfaction, fostering long-term loyalty and repeat business.

| Economic Impact | Description | Long-term Effects |

|---|---|---|

| Increased Production Costs | Need for additional processing | Lower profit margins |

| Selling Price Reduction | Flawed products selling at discounted rates | Decreased revenues |

| Vendor Relationships | Quality issues strain supplier partnerships | Longer-term cost instability |

What Regulations Surround Zircon Sand Purity Standards?

Regulations regarding zircon sand purity standards continue to evolve and vary by region and industry. These regulations are designed to ensure that businesses maintain the highest quality outputs in their manufacturing processes.

Globally, industries are guided by specific regulatory bodies and standards that dictate acceptable impurity levels. For example, the American National Standards Institute (ANSI) and various regional regulatory agencies establish guidelines for zircon used in ceramics, electronics, and other applications. Adhering to these regulations is crucial for businesses, as they help maintain not just product quality but also market integrity.

Compliance with these regulations helps companies avoid costly fines, potential product recalls, and reputational damage. It is essential for businesses to stay informed about changes in regulations and proactively adjust their processes and sourcing strategies accordingly.

Ultimately, adherence to established regulations not only ensures product quality but also protects companies from potential legal repercussions, thereby enhancing long-term operational stability.

| Regulatory Body | Region | Key Focus |

|---|---|---|

| ANSI | United States | Standards for production |

| ISO | International | Quality assurance requirements |

| EEC | European Union | Environmental and safety standards |

How Do Different Industries Utilize Zircon Sand?

Zircon sand’s unique physical and chemical properties make it vital across various industries. Understanding the specific uses and purity requirements helps manufacturers align their sourcing efforts with market needs.

- Ceramics: Zircon finds extensive use in producing ceramic glazes and whitewares. Here, purity is critical to ensure strength, durability, and color fidelity. Subpar zircon may lead to products that are less aesthetically pleasing or structurally sound.

- Glass Manufacturing: In glass production, zircon sand helps prevent devitrification and enhances thermal stability. Low impurity levels contribute to clearer glass with fewer defects, which is essential for high-value applications like eyewear.

- Foundries: Zircon sand is commonly employed in metal casting due to its high refractoriness. Foundries require highly pure zircon to ensure the quality of cast metal products. Contaminated zircon can lead to flawed castings, increased scrap rates, and wasted resources.

Different industries will have unique tolerances for impurities, so understanding these nuances helps businesses adapt their sourcing and processing methods to meet specific industry needs effectively.

In summary, recognizing how various sectors utilize zircon sand enables more informed production choices and helps pinpoint industry-specific requirements, ultimately fostering business growth and stability.

| Industry | Key Application | Purity Requirements |

|---|---|---|

| Ceramics | Glazes and whitewares | High purity for color fidelity |

| Glass | Prevents devitrification in glass production | Minimum impurities for clarity |

| Foundries | Metal casting | Critically pure for casting quality |

What Are the Future Trends in Zircon Sand Purity?

Monitoring future trends in zircon sand purity is essential for staying competitive in today’s evolving market landscape. Emerging technological advancements are shaping how industries approach impurity detection and management.

- Automation: The rise of automated quality monitoring systems improves real-time detection of impurities, allowing quicker responses to quality issues. This technological shift can lead to increased operational efficiency and reduced manual error.

- Enhanced Testing Methods: Developments in testing technologies, such as advanced spectroscopy and real-time analytics, are leading to more precise impurity measurements. Manufacturers can gain insights far more quickly than ever before, facilitating better production decisions.

- Sustainable Sourcing: As industries focus on sustainability, organizations will increasingly seek ethical and environmentally friendly sources of zircon sand that minimize impurities. This trend not only appeals to consumers but can also enhance brand credibility.

The accumulation of data over time will help companies anticipate trends and prepare their operations for necessary adjustments. By staying ahead of the curve, businesses can seize opportunities for quality improvements, cost reductions, and new product developments.

Clearly, by keeping abreast of these trends, businesses can strategically position themselves for success in an increasingly competitive market.

| Trend | Description | Industry Impact |

|---|---|---|

| Automation | Implementing automated quality monitoring | Faster issue resolution |

| Enhanced Testing | Advanced techniques improve accuracy | Better compliance and product quality |

| Sustainable Sourcing | Prioritizing ethical sourcing | Improved reputation and customer trust |

Conclusion

In summary, understanding the impurities present in zircon sand and their varied impacts is crucial for any business involved in its processing and utilization. By focusing on maintaining high purity levels, companies can improve product quality, enhance operational efficiency, and ultimately increase profitability. A deliberate shift towards strategic sourcing and compliance with established purity regulations not only leads to better product reliability but also fosters customer trust and loyalty. For those looking to optimize their procurement process and ensure access to high-quality materials, partnering with Global Industry is the logical next step. Connect with us today to explore our commitment to providing top-tier zircon sand solutions, ensuring your success in a competitive market.

FAQ Section

Q1: What types of impurities are commonly found in zircon sand?

Common impurities in zircon sand include iron, titanium, and silica. These elements often vary in concentration based on the mineral source and processing methods used, and understanding their presence is crucial for assessing zircon’s quality for specific applications.

Q2: How do impurities impact the quality of zircon products?

Impurities can negatively affect the performance, aesthetic appeal, and durability of zircon-based products. For example, high iron levels can lead to discoloration in ceramics, while increased silica content can weaken structural integrity, ultimately impacting product reliability and customer satisfaction.

Q3: What testing methods measure impurities in zircon sand?

Various methods, such as X-ray fluorescence (XRF), scanning electron microscopy (SEM), and chemical analysis techniques like ICP-OES, are used to measure impurities. These methods provide valuable insights into the elemental composition and quality of zircon sand, enabling companies to meet their purity standards effectively.

Q4: How can companies ensure high-quality zircon sand sourcing?

To secure high-quality zircon sand, companies should implement rigorous supplier evaluations, conduct comprehensive testing of material samples, and establish partnerships with reputable sources. This proactive approach reduces the risk of impurities and helps ensure that their end products maintain the desired quality.

Q5: What are the legal standards for zircon sand purity?

Legal standards for impurity levels in zircon sand can vary across regions and industries. Standards set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) guide acceptable purity levels to ensure safety, quality, and consistency in zircon-based applications. Being compliant with these regulations is crucial for market competitiveness.