Zircon sand plays a critical role in improving material durability across various industries. Selecting the right materials that can withstand harsh conditions while maintaining consistent performance is a challenge many businesses face. This article highlights how zircon sand addresses these concerns, enhancing durability without compromising quality. By examining its unique properties and applications, you will understand why this particular sand is a superior choice for manufacturers seeking longevity and strength in their products.

Scientific backing supports the contributions of this material, establishing it as a dependable component in numerous applications. With the information provided, decision-makers like you will be equipped to make informed choices regarding material selection and improvements in your operational processes.

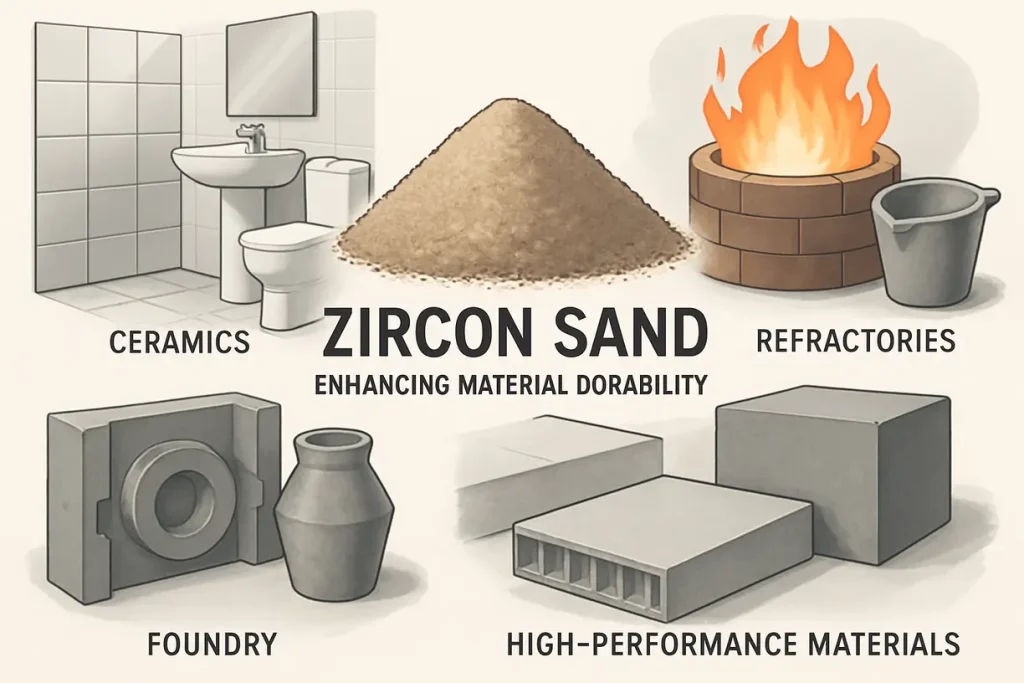

This image illustrates various industrial applications of zircon sand to highlight its versatility in enhancing material durability.

How Does Zircon Sand Improve Material Strength?

Zircon sand has several properties that notably boost material strength. Its primary component, zirconia, provides exceptional toughness and resistance to fracture. This characteristic is crucial in applications where materials undergo physical stresses, including the automotive sector and construction materials.

Here’s the deal: Strength is a vital factor for materials used in demanding environments. Zircon sand meets these needs, offering enhanced performance across a range of applications. The addition of zircon materials in formulations not only improves composite resilience but also prevents breakage and wear.

Zircon sand exhibits remarkable heat resistance, maintaining its structural integrity even at elevated temperatures. This feature is particularly advantageous for industries producing components subjected to intense heat, like aerospace or manufacturing.

Consider this example: A ceramic tile manufacturer applying zircon materials to their formulations enhances both the durability of the tiles and their aesthetic appeal due to improved surface finish. The improved performance translates to longer-lasting, more appealing products.

As such, here are additional properties of zircon that contribute to strength:

- Low Thermal Expansion: Helps maintain shape and structure under temperature variations.

- Chemical Stability: Resists degradation from environmental factors, increasing lifespan.

- Fine Particle Size: Enhances surface area, contributing to better bonding in composite materials.

| Property | Description | Impact on Durability |

|---|---|---|

| Toughness | High capacity to resist fracture | Reduces breakage risk |

| Heat Resistance | Maintains integrity at high temps | Extends material life |

| Aesthetic Finish | Enhanced surface smoothness | Increases market value |

What Are the Benefits of Using Zircon Sand in Manufacturing?

Incorporating this specific sand in manufacturing brings forth a multitude of advantages that extend beyond mere material performance. The most significant of these is its ability to enhance the overall quality of produced materials.

You might be wondering about the economic benefits associated with zircon as a key ingredient. The material can substantially minimize production costs by reducing waste and enhancing material utility. Its unique properties enable companies to use less raw material while still achieving the desired strength, durability, and overall performance.

Furthermore, the versatility of zircon extends across various industries, making it a valuable asset. This natural mineral is employed in applications ranging from ceramics and glass to electronics and even dental products. Here’s a closer look at some specific applications:

- Dental Ceramics: Utilized in the manufacture of crowns and bridges, providing strength and aesthetic finish.

- Glass Manufacturing: Enhances clarity and provides a smooth finish to glass products, contributing to their visual appeal.

- Foundries: In mold-making processes, its heat resistance plays a crucial role in maintaining mold integrity under high temperatures.

Moreover, the availability of this natural resource facilitates consistent sourcing for manufacturers, ensuring that supply chains function efficiently. This reliability aids businesses in planning production schedules without unexpected delays or increased costs, thereby enhancing productivity.

In addition to these benefits, using zircon in manufacturing can also lead to increased customer satisfaction. High-quality, durable products established through the incorporation of zircon can enhance brand reputation and foster customer loyalty.

Overall, the combination of improved performance, versatility, and economic efficiency makes zircon an invaluable material in manufacturing processes.

| Benefit | Explanation | Industry Applications |

|---|---|---|

| Reduced Waste | Requires less material for durability | Ceramics, Glass |

| Versatility | Fields of use span multiple sectors | Electronics, Refractory |

| Abundant Sourcing | Readily available for manufacturing | General Manufacturing |

| Enhanced Quality | Improves durability and customer satisfaction | Dental, Automotive, Industrial Products |

How Does Zircon Sand Affect Thermal Stability?

Thermal stability is paramount in various industrial applications, where materials are consistently exposed to extreme conditions. The use of zircon in these contexts plays a significant role in ensuring thermal stability due to its high melting point and impressive resistance to thermal shock.

Manufacturers looking to create products capable of withstanding high temperatures often benefit from integrating this material, especially in sectors like automotive and aerospace. So, let’s break it down: Materials that maintain their integrity under extreme heat prevent failures, which can lead to costly downtime or production delays. The reliability of products made with zircon allows them to perform optimally over extended periods, even in harsh environments.

For instance, in applications like furnace linings or components used in jet engines, the demand for materials that endure extreme conditions makes zircon a compelling choice. Products manufactured with this material will not only withstand elevated temperatures but also provide safety and reliability in critical applications.

Further illustrating its thermal stability, zircon also offers:

- Thermal Conductivity: Efficient distribution of heat, preventing localized hot spots that could damage surface integrity.

- Temperature Range Capacity: This material remains effective at temperatures reaching up to 1700°C, significantly expanding its usability in high-performance applications.

- Longevity: A thermal stability that reduces the frequency of necessary replacements, leading to lower long-term costs for manufacturers.

| Application | Temperature Exposure | Zircon Sand Advantage |

|---|---|---|

| Furnace Linings | Up to 1700°C | Superior thermal stability |

| Jet Engine Components | High altitude temps | Maintains integrity under stress |

What Role Does Zircon Sand Play in Abrasion Resistance?

Materials often face abrasive forces in various settings, leading to damage, reduced lifespan, and higher maintenance costs. This particular sand significantly enhances abrasion resistance, making it an ideal choice for environments where robust materials are necessary.

Here’s the scoop: The inherent properties of zircon sand contribute to the formation of abrasion-resistant composites. This is particularly beneficial in industries like mining, construction, and manufacturing, where equipment and tools regularly encounter severe wear and tear.

For instance, consider the impact on concrete mixes. The integration of zircon sand can lead to improvements in the longevity and sustainability of the mixers, conveyors, and other machinery involved in production. Over time, this reduction in maintenance efforts translates to considerable cost savings, enhancing overall productivity.

Furthermore, improved abrasion resistance leads to fewer operational interruptions. This consistency in performance allows companies to maintain smooth workflows and focus on meeting production goals without excessive downtimes.

Here are key industries that reap the benefits of increased abrasion resistance:

- Construction: Use in concrete for enhanced durability of structures against harsh environmental conditions.

- Mining: Enhancements in tools and machinery that withstand extreme operational stresses.

- Automotive Parts: Improved performance of components encountered with friction and extensive use, extending their service life.

| Industry | Application | Zircon Materials Benefit |

|---|---|---|

| Mining | Equipment & Tools | Improved service life and efficiency |

| Concrete Production | Mix Enhancement | Reduced wear in machinery and tools |

How Can Zircon Sand Improve Environmental Performance?

Environmental performance is an increasingly critical consideration for businesses aiming to adopt sustainable practices. The integration of zircon sand can significantly contribute to various eco-friendly approaches, aligning with corporate sustainability goals.

Let’s explore this topic further: Using zircon materials often allows manufacturers to replace more harmful alternatives in numerous applications. This substitution leads to a reduced carbon footprint, as zircon’s inherent durability ensures that products last longer, minimizing waste and the environmental impact associated with frequent replacements.

In addition to direct ecological benefits, these materials can also enhance production efficiency. When properly employed, zircon can streamline manufacturing processes, leading to lower energy consumption and resource use. This is particularly important as industries face escalating energy costs and stringent environmental regulations.

Here are several specific environmental advantages associated with using zircon:

- Resource Conservation: Durable products mean less frequent extraction of raw materials, preserving natural resources for future generations.

- Waste Reduction: The longevity of zircon-containing products contributes to less landfill waste, supporting a circular economy.

- Energy Efficiency: The processing of zircon can be optimized for reduced energy usage, translating to lower operational costs and a smaller environmental impact.

By integrating zircon into their operations, companies can not only improve their product quality but also align with global sustainability trends, making a positive contribution to environmental initiatives.

| Factor | Description | Environmental Impact |

|---|---|---|

| Replacement Material | Often less harmful than others | Decreases carbon footprint |

| Longevity of Products | Reduces need for replacements | Minimizes resource use |

What Are the Challenges of Implementing Zircon Sand?

Despite its many advantages, several challenges are associated with the implementation of zircon materials in manufacturing processes. Sourcing high-quality zircon can prove difficult due to fluctuating market conditions, varying levels of availability, and differences in supplier capabilities.

But do not fret: Engaging with reliable suppliers who focus on quality can help address these challenges. It is essential to establish partnerships with companies committed to consistency, thus assuring you receive premium materials that meet your operational demands and specifications.

Another hurdle involves the processing of zircon materials. Incorporating this component may require specialized techniques or equipment, which can lead to increased initial costs. While these investments may pose challenges, it is crucial to recognize that, once effectively integrated into production, the long-term benefits, such as enhanced product durability and reduced maintenance, typically outweigh these initial expenditures.

In addition to these factors, companies often face these common challenges when integrating zircon materials:

- Cost Variability: Fluctuations in market prices can affect budgeting and forecasting, making it essential to monitor buying patterns.

- Processing Complexity: Existing machinery may need to be adapted or upgraded to handle zircon materials effectively, requiring additional time and resources for training.

- Quality Control: Ensuring that the zircon meets specific performance standards is essential, necessitating regular testing processes to maintain quality assurance.

Addressing these challenges proactively can pave the way for successful integration of zircon components, ultimately leading to greater product performance and business efficiency.

| Challenge | Description | Solution |

|---|---|---|

| Sourcing Quality | Market variability may cause issues | Establish reliable partnerships |

| Processing Techniques | May need specialized equipment | Invest in proper machinery |

How to Integrate Zircon Sand into Existing Processes?

Integrating zircon sand into existing manufacturing processes can be accomplished smoothly with careful planning. The first step is to assess current formulations and production methods to identify where zircon sand can provide the most substantial benefits.

So, here’s what you need to know: Begin with small-scale trials to evaluate how this material interacts with existing components. Performance metrics gathered from these trials will provide valuable data to support larger-scale implementation.

Next, it’s vital to train staff on new processing techniques that may come into play. Investing in ongoing education ensures that the transition will run smoothly and maximizes the advantages of using zircon materials.

Lastly, collaborating with suppliers on specifications can refine the integration process further, aligning product requirements with production capabilities for optimal outcomes.

Here are key steps to ensure a successful integration:

- Conduct Comprehensive Testing: Evaluate interactions with existing materials before large-scale adoption.

- Develop Training Programs: Equip employees with the necessary knowledge for effective implementation.

- Monitor Performance Metrics: Regularly assess the impact of zircon sand on final product quality.

| Step | Description | Outcome |

|---|---|---|

| Assess Formulation | Identify potential areas for integration | Improved product quality |

| Conduct Trials | Test interactions with existing materials | Data-driven decision-making |

| Staff Training | Equip employees with knowledge | Smooth transition process |

What Trends Are Shaping Zircon Sand Usage in Industry?

Several evolving trends currently shape how industries utilize zircon materials. The strong push toward sustainability means that more manufacturers are seeking environmentally-friendly solutions, and zircon sand fits seamlessly within this framework.

Here’s what’s trending: Innovations in processing technology now make zircon sand more accessible than before, expanding its applications. Companies are embracing these advancements to develop new composites that function better than traditional materials.

Another key trend involves the globalization of supply chains. As demand for zircon rises, businesses are forming relationships with international suppliers to stabilize sourcing options. This enhances competitiveness within the global market and ensures supply reliability.

To further elaborate on trends:

- Increased Regulatory Standards: Stricter environmental regulations push companies to adopt sustainable materials.

- Investment in Research and Development: Companies are focusing on developing new applications and formulations.

- Consumer Demand for Sustainability: End-users are increasingly favoring durable, eco-friendly products.

| Trend | Description | Implications |

|---|---|---|

| Sustainability | Increased focus on eco-friendly materials | Broader acceptance |

| Processing Innovations | New methods to enhance access | Expanded applications |

How Does Zircon Sand Compare to Other Materials?

When evaluating materials for durability, it is essential to consider how zircon materials compare to competitor options. Many alternatives exist, but few offer the same blend of properties and benefits.

You might find this surprising: While certain materials may provide high strength, they can often fall short in thermal stability or abrasion resistance—or they might be cost-prohibitive. Zircon materials consistently deliver a commendable balance of performance and cost-effectiveness.

Comparing zircon sand to other options, such as alumina or silica, reveals notable advantages. In many cases, products enhanced with zircon can result in product longevity while also lowering overall manufacturing costs.

Here’s a quick comparison of strengths and weaknesses:

- Alumina: Offers high strength but has lower thermal resistance compared to zircon.

- Silica: Economical for specific applications but lacks the durability of zircon sand.

- Zircon: Combines thermal resistance, strength, and longevity, making it a balanced choice.

| Material | Strength | Thermal Stability | Cost-Effectiveness |

|---|---|---|---|

| Zircon Sand | High | Excellent | Competitive |

| Alumina | Moderate | Low | Higher overall costs |

| Silica | Low | Moderate | Variable |

What Expert Opinions Exist on Zircon Sand Applications?

Expert perspectives on zircon sand applications provide valuable insights into its potential. Industry professionals emphasize its versatility and durability, asserting that zircon sand remains among the best choices for various sectors.

Let’s highlight key opinions: Experts often recommend zircon materials for companies focusing on innovative manufacturing processes. Not only does zircon sand support product longevity, but it also contributes to an overall enhancement of brand reputation through improved quality.

Supporting this viewpoint, case studies from satisfied manufacturers reinforce these claims. Success stories illustrate how integrating zircon has revolutionized the performance of various products.

Often, experts cite the following advantages:

- Longevity: Increased service life of finished goods due to durability.

- Cost Savings: Reduced need for replacements translating to lower operational costs.

- Innovative Applications: Opening doors for novel uses across different industries.

| Expert | Opinion | Supporting Evidence |

|---|---|---|

| Material Scientist | Endorses its versatility | Multiple industry applications |

| Production Manager | Highlights cost-effectiveness | Successful case studies |

The image represents expert consultations and case study highlights to support zircon sand’s advantages in manufacturing.

Conclusion

In summary, zircon sand significantly enhances material durability, offering strengths in resistance to heat, abrasion, and overall longevity. The measurable benefits of using zircon materials include reduced production costs and improved performance. Global Industry is ready to assist you in leveraging these advantages within your manufacturing processes. Take the next step by consulting with our experts to determine how zircon materials can suit your specific operational needs. Together, we can build a lasting partnership that drives your company’s success.

FAQ Section

Q1: What industries benefit most from zircon sand?

Zircon sand is widely utilized in industries such as ceramics, where it enhances the durability and finish of tiles and sanitary ware. It’s also crucial in refractories used for furnace linings, metal casting molds, and even foundry applications where heat resistance and strength are paramount.

Q2: How does zircon sand enhance thermal stability?

Zircon sand’s unique composition allows it to maintain structural integrity under high temperatures, making it ideal for applications in industries like aerospace and automotive. Its high melting point helps products resist thermal shock and prevent deformation, ensuring reliable performance over time.

Q3: Are there any environmental concerns with zircon sand?

While zircon sand offers several benefits, its extraction can raise environmental and ethical concerns, particularly regarding mining practices. Responsible manufacturers focus on sustainable sourcing, employing methods that minimize ecological impact and adhere to regulations to promote environmental stewardship.

Q4: What challenges arise when using zircon sand in production?

Challenges include fluctuating market prices for zircon, which can impact budgeting, and the need for specialized processing equipment. Companies must also ensure consistent quality in sourcing to avoid production delays, which can affect overall efficiency.

Q5: Who are the key players in the zircon sand market?

Major players typically include global mining companies, processing facilities, and suppliers that specialize in zircon products. These companies often focus on innovation and developing new applications, helping to drive demand across various industries while ensuring product quality and availability.