Zircon sand has emerged as an essential material in advanced electronics, yet many decision-makers remain unaware of its significance. As industries evolve and technology advances, understanding the role of this mineral can address concerns about reliability, efficiency, and sustainability in electronic components. Earlier, materials were often chosen based on cost rather than performance, which sometimes led to issues.

This article offers detailed insights into how zircon’s unique properties can enhance the performance of electronic devices while providing a trustworthy guide for purchasing managers and professionals involved in material selection. By the end of this comprehensive piece, you will grasp the profound value of integrating this mineral into your products and see how it can elevate quality and sustainability in your operations.

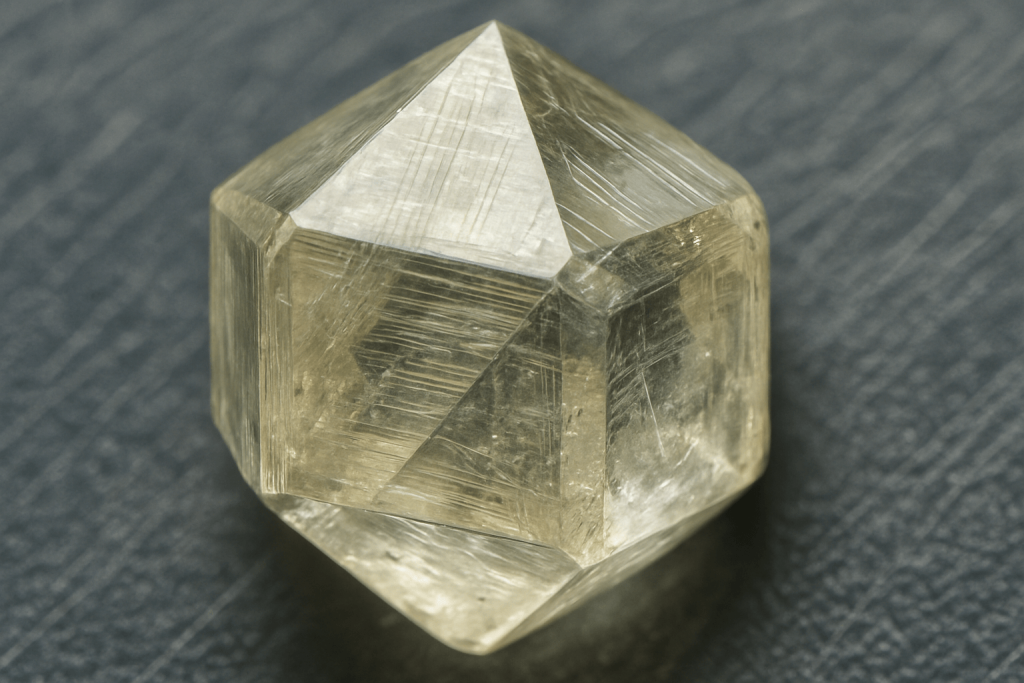

This image shows zircon sand grains magnified, highlighting their unique mineral structure.

WHAT IS ZIRCON SAND AND WHY IS IT IMPORTANT?

Zircon sand is a naturally occurring mineral primarily composed of zirconium silicate (ZrSiO4). Found in various geological formations, this mineral is extracted through mining processes and is associated with heavy mineral sands. Its crystal structure lends it remarkable properties, making it a highly valued material across numerous industries.

This mineral is prized for its high melting point, excellent electrical insulation properties, and resistance to chemical corrosion. These attributes make zircon particularly important in high-temperature applications, such as those found in advanced electronics. With its diverse applications ranging from foundries, ceramics, to advanced technologies in electronics, zircon sand has been utilized for centuries, showcasing its versatility and functional benefits.

Its importance to the electronics sector cannot be overstated, as the push for more durable, efficient, and compact electronic devices continues. The modern consumer demands devices that not only perform exceptionally but also withstand prolonged usage and extreme conditions. Zircon sand successfully meets these requirements, making it an indispensable material in the design and manufacturing of state-of-the-art electronics.

Why does it matter? The unique properties of this sand make it suitable for high-performance applications. For example, its thermal stability allows electronic devices to function at higher temperatures without degrading, which is increasingly critical in the face of miniaturization in technology. Additionally, zircon sand’s insulating properties help improve the reliability of various components, from capacitors to circuit boards.

As industries strive to meet ever-increasing performance demands, the importance of zircon sand becomes even more evident. In light of accelerating technological advancements, it provides a reliable and robust base material that supports the continuous evolution of electronics, driving innovation and enhancing overall product quality.

HOW DOES ZIRCON SAND BENEFIT THE ELECTRONICS INDUSTRY?

Zircon sand offers multiple advantages when integrated into electronic components that are crucial for meeting the demands of modern technology. Firstly, its high melting point makes it ideal for high-temperature environments. This characteristic is particularly beneficial in applications involving power electronics or devices subjected to heavy thermal loads. As engineering teams strive to design more efficient and robust circuits, the heat-resilient nature of zircon sand enables them to push the boundaries of current technology without compromising performance. Have you ever considered how materials withstand the rigors of modern electronics?

Moreover, zircon sand contributes significantly to energy efficiency in electronic devices. Its excellent thermal conductivity helps dissipate heat effectively, which is vital in preventing overheating and associated failures. This property enhances the performance of semiconductors, which are responsible for effective energy transfer in various electronic applications. Many companies that have embraced zircon in their manufacturing processes report noticeable improvements in energy efficiency and overall performance metrics of their products.

Examples of properties influencing electronic applications:

- High thermal conductivity: This helps manage heat within electronic devices, allowing them to operate efficiently without overheating, which, in turn, extends their lifespan.

- Low thermal expansion: This characteristic ensures that components maintain their precise dimensions even under fluctuating temperatures, which is crucial for ensuring product reliability and performance consistency.

- Excellent electrical insulation: This property helps prevent short circuits and electrical failures, thus prolonging the life of electronic devices.

These advantageous features empower manufacturers to produce devices that not only function efficiently but also endure over extended periods. Consequently, incorporating zircon sand fosters a pathway to fewer product failures, reduced warranty claims, and ultimately lower replacement costs, creating value for both manufacturers and consumers alike.

WHAT ARE THE KEY APPLICATIONS OF ZIRCON SAND IN ELECTRONICS?

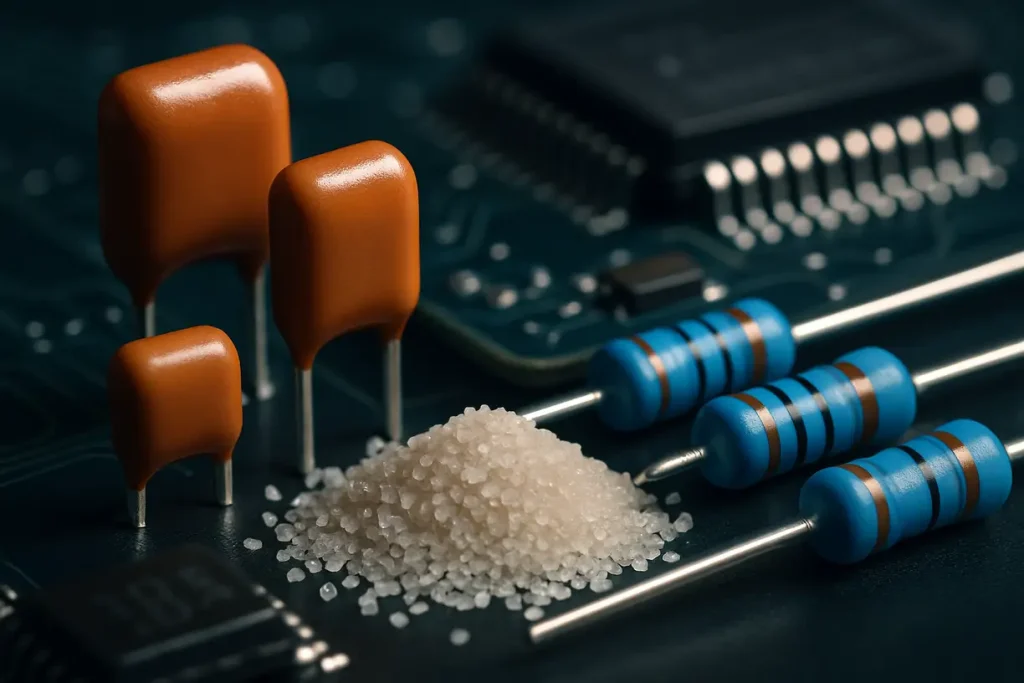

Zircon sand finds applications across various components in the electronics industry. From capacitors and resistors to circuit boards, its versatility shines through, providing tailored solutions to specific industry needs.

- Capacitors: By improving dielectric performance, zircon sand ensures efficient energy storage and retrieval in capacitors, which helps regulate power flow in electronic circuits.

- Resistors: The mineral’s high resistance ensures that current levels remain stable, effectively reducing variability in electronic responses which can lead to device malfunction.

- Circuit boards: Enhanced thermal performance helps prevent overheating, maintaining the integrity and reliability of circuit boards in various electronic devices.

- Display technologies: Its applications in displays can improve resolution and clarity, providing consumers with a superior visual experience, which is essential in today’s competitive market.

The diverse applications illustrate how zircon can serve as a backbone for cutting-edge electronics. Are you ready to consider how these applications can benefit your products?

| Application | Benefits | Key Characteristics |

|---|---|---|

| Capacitors | Improved energy storage efficiency | High dielectric strength |

| Resistors | Enhanced stability | Excellent electrical insulation |

| Circuit boards | Better thermal management | High melting point |

| Display technologies | Enhanced quality | Low thermal expansion |

This image illustrates the various applications of zircon sand across electronic components like capacitors and resistors.

HOW DOES ZIRCON SAND IMPACT PERFORMANCE IN ELECTRONICS?

Zircon sand plays a vital role in improving the overall performance of electronic components. What specific aspects does it influence?

First and foremost, its thermal stability allows devices to withstand an increase in temperature without compromising performance. This characteristic becomes particularly important in high-demand scenarios where overheating can lead to catastrophic device failure, disrupting both functionality and user experience. Furthermore, zircon sand can also enhance electrical conductivity, which contributes to faster data transmission times, making it ideal for high-speed applications where every millisecond counts.

Key impacts of zircon sand on performance:

- Enhanced thermal conductivity: The ability to efficiently dissipate heat reduces the risk of overheating, ensuring that electronic devices function optimally under various conditions.

- Reduced electrical resistance: This feature translates into improved efficiency and battery life for portable devices, enabling longer usage times between charges, which is crucial in today’s fast-paced world.

- Improved durability and lifespan: Components incorporating zircon sand often outlast competitors, leading to fewer replacements and, ultimately, increased customer satisfaction and brand loyalty. The robustness of these components makes them suitable for both consumer electronics and industrial applications, where reliability is paramount.

Overall, the integration of zircon leads to components that are not only more efficient but also longer-lasting, translating to lower operational costs for businesses and higher profitability through reduced replacement rates. By investing in zircon-enhanced technology, manufacturers position themselves for a competitive advantage in the ever-evolving electronics market.

WHAT CHALLENGES EXIST WITH ZIRCON SAND USAGE?

Despite its many benefits, the use of zircon sand does come with challenges that need to be acknowledged. What obstacles should businesses consider?

One primary concern is sourcing. With global demand for this mineral on the rise, ensuring a dependable supply chain becomes essential. If disruptions arise due to geopolitical issues or natural disasters, companies could face delays that impact production schedules. Businesses must evaluate potential suppliers closely to mitigate risks associated with supply interruptions and ensure that they can maintain consistent material availability throughout their operations.

Environmental impact associated with zircon mining is another significant challenge. As public awareness grows regarding ecological sustainability, many firms are pressed to implement sustainable practices that minimize environmental harm during extraction. Suboptimal mining practices can lead to habitat destruction, water pollution, and other detrimental effects on local ecosystems. Failure to comply with these growing expectations can lead to reputational damage and operational fines, further complicating a company’s prospects in a market that increasingly values sustainable approaches.

Lastly, quality control in production is vital. Variability in mineral quality can dramatically affect the performance of electronic components produced. Inconsistent material properties can result in unreliable components, ultimately leading to product recalls or warranty claims that can tarnish a brand’s reputation. Businesses need to implement rigorous testing protocols to ensure material consistency and reliability, which adds another layer of complexity to their operations.

| Challenge | Description | Mitigation Strategies |

|---|---|---|

| Sourcing | Difficulty in maintaining a consistent supply | Partner with verified, reliable suppliers |

| Environmental impact | Concerns over mining practices | Invest in sustainable sourcing methodologies |

| Quality control | Variability affecting product performance | Implement strict quality assurance processes |

By acknowledging these challenges upfront, companies can take proactive steps to navigate them, ensuring a smoother integration of zircon sand into their electronic components and maintaining their competitive edge in the market.

WHAT INNOVATIONS ARE EMERGING WITH ZIRCON SAND?

Exciting innovations are making their mark concerning zircon and its applications within electronics. What trends are sExciting innovations are making their mark concerning zircon and its applications within electronics. What trends are shaping this field?

Recent advancements have refined processing techniques, leading to enhanced purity and consistency of zircon materials used in manufacturing. The industry has witnessed significant progress in methods to extract and process zircon sand to meet rigorous standards required for high-performance electronics. This purification not only enhances the quality but also broadens the scope of applications where zircon can be utilized effectively.

Research is underway to explore new forms of zircon, such as nanostructured varieties, which have shown promise in further enhancing performance across specific applications, particularly in high-tech areas. These nanoscale materials can exhibit unique characteristics, such as increased surface area and improved reactivity, making them suitable for various advanced applications, including next-generation semiconductors and flexible electronics.

For instance, researchers are exploring the potential of zircon-based materials in next-generation batteries. With demands for faster charging, greater energy storage capabilities, and overall efficiency rising, these innovations could directly contribute to enhanced performance in electronic devices, particularly in the growing electric vehicle market and renewable energy storage solutions.

Examples of innovations:

- Advances in purification processes leading to superior material quality and consistency.

- Development of zircon-based nanomaterials that offer enhanced performance characteristics, including improved conductivity and thermal stability.

- Increased research into applications in battery technology, which could support the growing market for electric vehicles and renewable energy technologies.

As these trends become more widely accepted, zircon sand is positioned to become even more essential in the landscape of electronics manufacturing. The integration of these innovative materials is not just about enhancing performance but also about driving the industry towards greater sustainability, efficiency, and adaptation to future technological demands, pushing the industry toward greener solutions and improved product offerings.

HOW TO CHOOSE THE RIGHT ZIRCON SAND SUPPLIER?

Selecting the right zircon sand supplier is crucial for ensuring that your organization can maintain high quality and reliability standards. What factors should businesses consider?

First, it is essential to evaluate a supplier’s reputation. Look for companies that have a proven track record of delivering quality materials and reliable service. Trust in a supplier often translates to confidence in your components. This can be assessed through reviews, testimonials, and industry endorsements, which collectively give insights into the supplier’s performance history.

Next, proper certification is vital. Suppliers that maintain high industry standards demonstrate their commitment to quality assurance, which can help mitigate risks in your production process. Certifications can also ensure compliance with regulatory requirements, which is especially important in industries where safety and reliability are paramount.

Moreover, consider the potential for long-term partnerships. Building relationships with trusted suppliers can pave the way for more successful collaborations and enhanced terms in the future. A supplier who understands your specific needs and can adapt to changing circumstances is invaluable. Successful partnerships often lead to further innovations and improvements in material usage, helping your company stay competitive.

Lastly, assess the supplier’s capacity for consistent delivery. A reliable supplier should have robust logistics in place to ensure that materials are delivered on time, minimizing disruptions in your production schedule. This aspect is particularly crucial as the demand for zircon sand continues to grow alongside advancements in the electronics industry.

| Supplier Assessment Criteria | Importance |

|---|---|

| Reputation | Indicates reliability and the quality of service |

| Certification | Ensures compliance with critical industry standards |

| Partnership potential | Facilitates long-term collaboration opportunities |

| Logistics and reliability | Ensures timely delivery of materials to maintain production flow |

HOW CAN COMPANIES TRANSITION TO USING ZIRCON SAND?

Transitioning to zircon entails careful planning. What steps should organizations take to implement this change effectively?

Initially, businesses should assess their current material usage and identify areas where zircon may offer distinct advantages. This evaluation might include conducting cost-benefit analyses to understand potential impacts on production and pricing strategies.

Following this assessment, researching reliable suppliers and understanding the cost implications is necessary. This phase is critical to minimize disruptions in your manufacturing processes while integrating this mineral.

Conducting a pilot program to evaluate the practicality and performance of zircon sand in real-world applications can provide valuable insights into the material’s benefits and any challenges that might arise.

Lastly, employee training is essential. Ensuring that operational teams understand zircon properties and uses can facilitate smoother integration and reduce the learning curve associated with adapting to this material. This training can help maximize the benefits derived from incorporating zircon into existing systems.

WHAT ARE THE COST IMPLICATIONS OF ZIRCON SAND USAGE?

While zircon offers numerous benefits, understanding its financial implications is vital for effective budgeting. How does this mineral fit into the broader financial picture?

While implementing zircon in production may initially increase material costs, the long-term benefits typically outweigh these expenses. For companies eager to innovate, the reduced frequency of product failures and lower maintenance needs can enhance the bottom line.

Additionally, the enhanced performance of products can justifiably allow for higher retail prices, contributing positively to overall revenue streams. Taking advantage of these performance aspects can lead to a substantial boost in market competitiveness.

| Cost Consideration | Impact |

|---|---|

| Initial material expenses | Higher upfront costs |

| Long-term savings | Decreased repair and replacement expenses |

| Potential price premiums | Higher product retail prices due to performance |

HOW DOES ZIRCON SAND ALIGN WITH FUTURE TRENDS IN ELECTRONICS?

As the electronics industry continues to evolve, zircon remains a relevant and adaptable component within the production landscape. What future trends connect with this mineral’s role?

One significant trend is the increasing focus on sustainability in manufacturing processes. The natural origins of zircon and its potential recycling capabilities make it an appealing choice for organizations aiming to deliver eco-friendly products and practices.

Additionally, advancements in electronic technology, particularly the ongoing shift toward greener energy solutions, create exciting opportunities for this mineral. Its unique properties can support new applications, ranging from solar panels to components in electric vehicles, which are often central to discussions about the future of energy consumption.

To summarize, zircon sand not only adapts to technological advancements but actively contributes to more sustainable practices in the electronics industry, aligning with contemporary consumer and regulatory expectations.

Conclusion

This article has thoroughly explored the multifaceted role of zircon in advanced electronics. From its valuable properties to its diverse array of applications and emerging trends, it’s clear that this mineral significantly impacts the industry’s financial viability and sustainability efforts. By understanding and considering zircon materials, companies can improve both their product performance and environmental responsibility, ultimately enhancing customer satisfaction and loyalty. Global Industry invites you to reach out for reliable sourcing solutions, ensuring that your business thrives in an ever-changing marketplace. Invest in zircon today, and watch your electronic components excel in performance and sustainability.

This image depicts futuristic electronic devices that integrate zircon for enhanced performance and sustainability.

FAQ Section

Q1: What properties make zircon sand valuable for electronics?

Zircon sand’s unique properties, such as its high thermal stability, exceptional electrical insulation, and resistance to chemical corrosion, make it highly sought after in electronics. These characteristics ensure that electronic components can operate efficiently in high-temperature environments while maintaining reliability and preventing electrical failures.

Q2: What are the environmental concerns related to zircon sand mining?

Mining zircon sand can lead to habitat destruction, water quality issues, and soil erosion, which may disrupt local ecosystems. Additionally, the release of dust and pollutants during extraction can affect air quality. Therefore, it is critical for companies to adopt sustainable practices, such as responsible sourcing and rehabilitation of mining sites, to mitigate these concerns.

Q3: How does zircon sand compare to alternative materials used in electronics?

Compared to alternative materials like quartz or other ceramics, zircon often outperforms them in thermal resistance and electrical insulation properties. This means that electronic components made from zircon can achieve greater reliability under harsh operating conditions, leading to fewer failures and longer product lifespans, which is crucial for consumer satisfaction.

Q4: What should companies consider before switching to zircon sand?

Before transitioning to zircon sand, companies should evaluate factors such as the quality of the material, potential suppliers’ reliability, and any necessary modifications to production processes. It’s also important to conduct a detailed cost analysis that assesses both upfront material costs and potential long-term savings from improved product performance and reduced failure rates.

Q5: What is the future outlook for zircon sand in electronics?

The future of zircon sand in the electronics industry looks promising as technology continues to evolve. With the growing emphasis on sustainable manufacturing practices and the demand for high-performance electronic devices, zircon sand’s unique properties will likely become increasingly crucial. This mineral is well-positioned to support advancements in various applications, including renewable energy technologies and smart devices, leading to enhanced product quality and environmental responsibility.