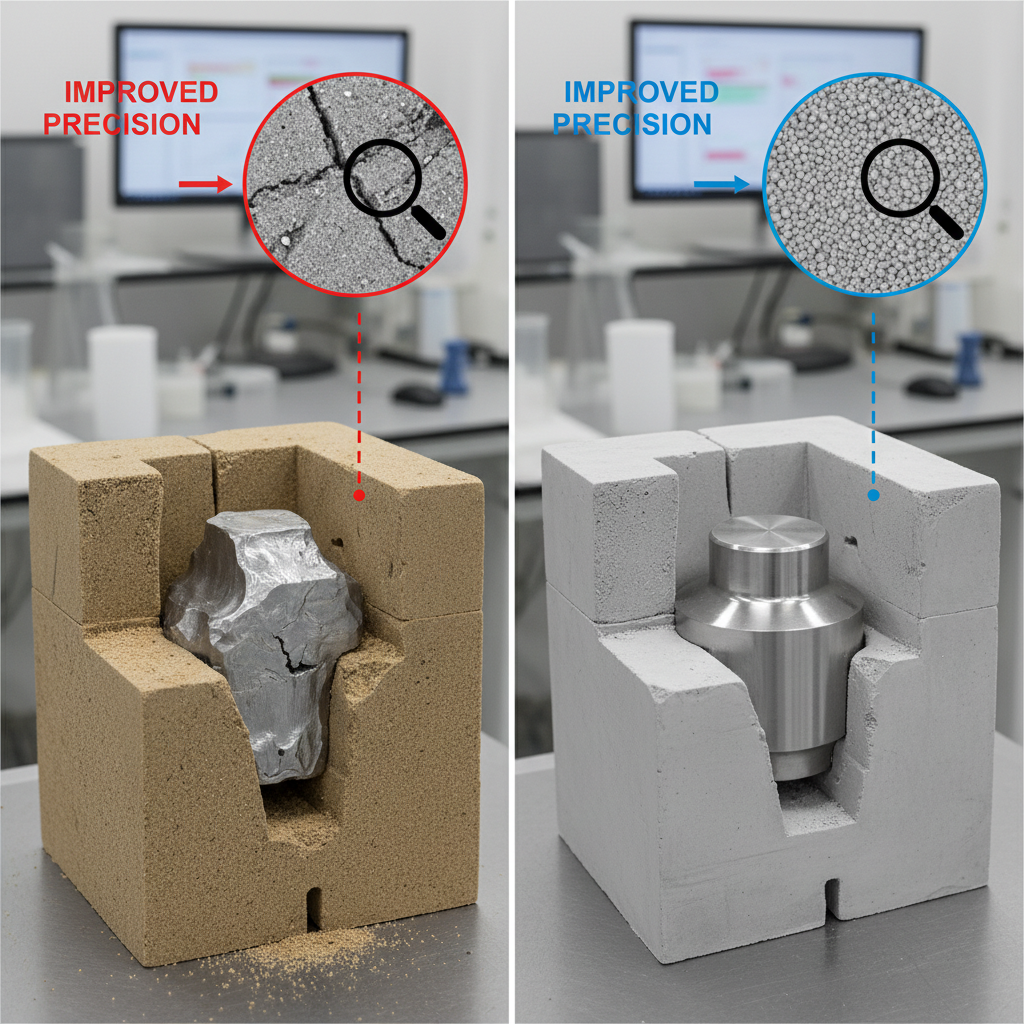

Precision steel casting faces constant, aggressive threats from extreme temperatures exceeding 1,600°C, molten metal penetration into mold substrates, and surface degradation. These issues invariably lead to costly defects like burn-on, veining, and porosity, resulting in high scrap rates and compromised structural integrity.

Here’s the deal: ignoring these surface issues results in a cascade of financial and operational failures. When molten steel penetrates the sand mold, the resulting “burn-on” forces your fettling team to spend hours manually grinding parts, consuming expensive abrasives and driving up labor costs. Worse, if a subsurface defect slips past QC and fails in the field—perhaps in an automotive engine or an oil rig valve—the reputational damage could be irreversible. You are not just losing materials; you are eroding your margins and client trust with every imperfect pour.

Zircon coatings offer a superior, high-density refractory barrier that withstands extreme heat and abrasion better than any silica or aluminosilicate alternative. By utilizing the unique atomic stability of Zirconium Silicate, foundries can ensure flawless surface finishes, drastically reduce cleaning room bottlenecks, and achieve the operational efficiency required by modern industry standards.

Defining High-Performance Zircon Coatings

High-performance zircon coatings are specialized refractory barriers defined by their high purity Zirconium Silicate (ZrSiO4) content and specific particle size distribution, designed to interface between molten steel and the sand mold. Unlike generic mold washes, these coatings are engineered suspensions that combine refractory flour with carrier liquids (water or alcohol) and binding agents to create a dense, impenetrable shell.

What is the chemical advantage?

You might be wondering… why this specific compound matters so much in metallurgy. The magic lies in the lattice structure of Zirconium Silicate. It possesses a naturally high density (4.6g/cm3) compared to silica (2.65g/cm3), allowing it to pack more refractory material into a thinner layer.

- Chemical Inertness: It resists reaction with iron oxide (FeO) and other slag components.

- Thermal Conductivity: It acts as a mild chill, promoting a fine grain structure at the surface.

- Refractoriness: It remains solid and stable well beyond the liquidus temperature of steel.

How does particle size affect performance?

Here is the reality: It is not just about the raw material; it is about the grind. High-performance coatings utilize a multimodal particle distribution—mixing coarse and fine flours. The fine particles fill the voids between coarse particles, creating a “brick and mortar” structure that prevents liquid metal from finding a path through the coating.

Key Takeaway: The atomic stability and high density of ZrSiO4 provide a primary defense that standard silica simply cannot physically achieve.

| Property | Zircon Coating | Silica Wash | |

|---|---|---|---|

| Reactivity | Chemically Inert | Reactive with FeO | |

| Density () | ~4.6 (High) | ~2.65 (Moderate) | |

| Wetting Angle | High (Repels Metal) | Low (Wets easily) |

Analysis: Zircon’s chemical inertness fundamentally alters the mold-metal interaction, effectively waterproofing the sand against liquid steel.

Why Precision is Critical?

Precision is critical because modern engineering tolerances in aerospace, automotive, and energy sectors have shrunk to micron levels, making any surface deviation a cause for immediate rejection. In the past, a foundry might have gotten away with a rough finish that could be machined down. Today, “near-net-shape” casting demands mean the part coming out of the mold must be virtually ready for assembly.

Can you afford surface errors?

But here’s the kicker… poor finishes destroy profit margins faster than any other production variable. If a casting surface has a Roughness Average (Ra) that exceeds specifications, it requires machining passes that were not budgeted for.

- Tolerance Demands: Turbine components often allow for zero deviations.

- Structural Integrity: Surface roughness can act as stress risers, leading to fatigue cracks.

- Aesthetics: For visible automotive parts, surface texture is a direct quality indicator.

What is the cost of failure?

Think about it: The cost of a casting defect increases exponentially the further it travels down the production line. A defect caught at shake-out costs dollars; a defect caught during customer machining costs thousands.

Key Takeaway: Surface fidelity is directly linked to profitability; precision is not a luxury, it is the baseline for entry.

| Defect Type | Consequence | Cost Implication | |

|---|---|---|---|

| Micro-cracking | Structural Failure | High (Scrap & Liability) | |

| Rough Finish | Extra Machining | Medium (Labor hours) | |

| Sand Inclusion | Tool Breakage | Medium (Customer Penalty) |

Analysis: Precision errors lead to exponential cost increases in post-processing, moving a part from profitable to a net loss.

Zircon Coatings vs. Chrome and Nickel

Zircon coatings outperform chrome and nickel alternatives by offering higher refractoriness and chemical inertness without the environmental toxicity associated with hexavalent chrome. While chromite sand and coatings have historically been used for their chilling properties, they pose significant environmental and health risks that modern foundries are moving away from.

Is chrome obsolete?

Let’s look at the facts… regarding material comparison. Chrome ore can oxidize into Hexavalent Chromium (Cr(VI)), a potent carcinogen. Zircon offers similar, if not superior, chilling capabilities and resistance to metal penetration without this toxicity profile. Furthermore, Nickel-based barriers often struggle with the highest temperature steel alloys, whereas Zircon remains stable.

- Wear Resistance: Zircon exhibits superior hardness (Mohs 7.5).

- Thermal Stability: Integrity maintained >1,500°C, whereas alternatives may soften.

- Safety: Zircon is non-hazardous compared to Chromite.

How does it compare on cost-performance?

You need to know this: While the raw material cost of Zircon coatings can be higher than silica or olivine, it is often comparable to or cheaper than high-grade chromite. When you factor in the disposal costs of hazardous chrome waste, Zircon becomes the clear economic winner.

Key Takeaway: Zircon provides a wider safety margin for thermal spikes and regulatory compliance compared to legacy heavy minerals.

| Feature | Zircon | Chrome/Chromite | |

|---|---|---|---|

| Max Temp | ~2,550°C | ~1,900°C | |

| Acid Resistance | High | Moderate | |

| Environmental | Inert/Safe | Toxic Risk () |

Analysis: Zircon outperforms legacy materials in extreme thermal environments and simplifies environmental compliance.

Preventing Specific Defects

Zircon coatings specifically prevents defects by forming an impenetrable barrier that stops molten steel from interacting with the silica sand substrate or penetrating interstitial voids. Steel casting is particularly aggressive; the high temperatures cause silica sand to expand rapidly and chemically attack the metal oxides. Zircon acts as the shield.

Does it stop penetration?

What’s the real story? Metal penetration happens when the pressure of the liquid metal (ferrostatic head) forces it between the sand grains. Zircon flour, milled to mere microns, fills these tiny gaps.

- Burn-On: Prevents the chemical fusion of sand to metal (iron silicate formation).

- Veining: Mitigates the “rat-tail” defects caused by the rapid expansion of silica sand.

- Erosion: Resists the scouring action of molten metal during the pour.

How does it handle thermal expansion?

Consider this: Silica sand has a non-linear thermal expansion curve (the quartz inversion). Zircon coatings specifically prevents defects by forming an impenetrable barrier that stops molten steel from interacting with the silica sand substrate or penetrating interstitial voids. Steel casting is particularly aggressive; the high temperatures cause silica sand to expand rapidly and chemically attack the metal oxides. Zircon acts as the shield. has a very low, linear expansion coefficient. By coating the mold with Zircon, you physically constrain the sand and insulate it from the initial thermal shock, preventing the mold surface from cracking and creating veins on the casting.

Key Takeaway: Zircon acts as a physical seal and a thermal buffer, not just a cosmetic surface wash.

| Defect | Prevention Mechanism | |

|---|---|---|

| Burn-on | Chemical Barrier (Inertness) | |

| Veining | Thermal Insulation/Stability | |

| Penetration | Pore Filling (High Density) |

Analysis: High-density coverage eliminates the path for molten metal infiltration, effectively solving the physics of penetration.

The Application Process

The application process is a multi-step technical protocol involving density checks, multipass spraying, and controlled drying to ensure coating integrity. A bucket of high-quality Zircon wash is useless if applied incorrectly. The goal is a uniform layer thickness (typically 200-400 microns) that is free of runs, drips, or bubbles.

Is surface prep that critical?

Here is the process… that ensures safety. You cannot paint over dirt. The mold surface must be free of loose sand.

- Grit Blasting/Air Blowing: Removes loose particles that would prevent adhesion.

- Mixing: Coatings are thixotropic; they must be sheared (mixed) to reach the right viscosity for application.

- Baumé Check: Operators must verify the specific gravity (density) before every shift.

Is drying actually important?

Why does this matter? If you pour molten steel into a mold with a damp coating, the water instantly flashes to steam, expanding 1,600 times in volume. This causes “scabs” or dangerous blowouts. Controlled drying—whether by tunnel ovens, torching (for alcohol bases), or dehumidified air—is non-negotiable.

- Technique: Controlled thermal spraying or flow coating.

- Layering: Two thin coats are often better than one thick coat to prevent mud-cracking.

- Inspection: Dry film thickness gauges verify the coverage.

Key Takeaway: Moisture control and viscosity management are as critical as the coating material itself.

| Step | Critical Action | Risk of Failure | |

|---|---|---|---|

| Prep | Remove loose sand | Coating Delamination | |

| Mix | High-shear mixing | Uneven protection | |

| Cure | 100% Moisture removal | Steam Blowouts |

Analysis: Adherence to strict application protocols prevents steam-related blowouts and ensures mechanical bonding.

Key Industry Applications

Key industry applications span sectors requiring extreme reliability, such as high-pressure valves in oil & gas and critical rotating components in aerospace. In these fields, the material properties of Zircon coatings specifically prevents defects by forming an impenetrable barrier that stops molten steel from interacting with the silica sand substrate or penetrating interstitial voids. Steel casting is particularly aggressive; the high temperatures cause silica sand to expand rapidly and chemically attack the metal oxides. Zircon acts as the shield. are not just preferred; they are specified by engineering standards.

Why does aerospace need it?

Why does this matter? In aerospace, a “superalloy” turbine blade or a stainless steel structural ring cannot have surface inclusions. A micro-defect acts as a crack initiation site under high cyclic loading. Zircon coatings ensure the ceramic shell or sand mold does not react with these expensive, reactive alloys.

- Aerospace: Turbine blades, structural rings, landing gear components.

- Oil & Gas: Pump casings, impellers, and valves handling corrosive slurries.

- Energy: Kaplan and Francis turbine runners for hydroelectric power.

What about heavy industry?

Look at the scale: In mining and earthmoving equipment, castings are massive. The ferrostatic pressure at the bottom of a 20-ton casting is immense. Standard coatings would wash away or suffer penetration. Zircon’s high hot strength withstands this pressure, ensuring the bottom of the casting is as clean as the top.

Key Takeaway: High-risk, high-value industries require the reliability of zircon to mitigate catastrophic failure risks.

| Sector | Application Example | Critical Need | |

|---|---|---|---|

| Aerospace | Engine Components | Zero Defects/Inclusions | |

| Oil & Gas | High-Pressure Valves | Corrosion Resistance | |

| Heavy Rail | Bogie Frames | Structural Fatigue Life |

Analysis: Zircon is mandatory where component failure is not an option and operating conditions are extreme.

Impact on Operational Costs

The impact on operational costs is a net reduction, as the initial investment in premium coating materials is vastly outweighed by savings in the fettling and cleaning room. Foundry economics are often misunderstood; managers focus on the cost per gallon of the coating, rather than the cost per shipped ton of casting.

Is the upfront cost worth it?

Ready for the good part? Fettling (grinding, welding, and finishing) is traditionally the bottleneck of the foundry. It is labor-intensive, dangerous, and slow. By switching to Zircon, the casting peels away from the sand cleanly.

- Reduced Fettling: Reduces grinding time by up to 50%.

- Consumables: Lowers consumption of grinding wheels and welding rods.

- Throughput: Parts move through the finishing room faster, increasing plant capacity.

What is the ROI?

Do the math: If Zircon coating costs 2moreperpartbutsaves 50 in grinding labor and prevents a $500 scrap event, the Return on Investment is immediate.

Key Takeaway: Higher material costs are heavily offset by labor savings and increased throughput.

| Item | Cost Impact | Explanation | |

|---|---|---|---|

| Coating Material | +15% Cost | Premium raw material price | |

| Fettling Labor | -40% Savings | Reduced grinding/chipping | |

| Abrasives | -30% Savings | Longer wheel life |

Analysis: The reduction in finishing labor drives the total cost of ownership down, making Zircon the “cheaper” option in the long run.

Thermal Stability Limits

Thermal stability limits of Zircon extend well beyond the pouring temperatures of steel, maintaining solid phase integrity up to dissociation points near 2,550°C. Most foundry sands (silica) begin to soften or chemically change around 1,400°C-1,600°C. Zircon remains a refractory fortress.

Can it handle thermal shock?

This is where it gets interesting… When molten steel at 1,600°C hits a room-temperature mold, the thermal shock is violent. Materials with high thermal expansion crack. Zircon possesses a low coefficient of thermal expansion (4.5×10−6/°C).

- Melting Point: Dissociation occurs at ~2,550°C, far above steel temps.

- Chilling Power: Zircon absorbs heat effectively, creating a thin solidified skin on the metal quickly.

- Chemical Stability: It does not dissolve in the liquid metal oxides formed during the pour.

Why is the melting point important?

Consider the physics: If the coating softens, the weight of the steel washes it away (erosion). Because Zircon stays hard, it maintains the mold geometry perfectly, ensuring dimensional accuracy even in massive, thick-walled sections that stay liquid for hours.

Key Takeaway: Thermal stability prevents expansion-related cracking and erosion, preserving the casting’s geometry.

| Property | Value | Significance | |

|---|---|---|---|

| Melt Point | ~2,550°C | No softening during pour | |

| Expansion | Low (Linear) | Resists thermal shock cracking | |

| Heat Capacity | High | Promotes directional solidification |

Analysis: Zircon remains stable well beyond the pouring temperature of steel, ensuring the mold face survives the most critical phase of casting.

Environmental Safety

Environmental safety is significantly improved with Zircon because it eliminates the risk of silicosis associated with silica flour and reduces hazardous waste generation. As regulations like the OSHA Respirable Crystalline Silica standard become stricter, foundries must look for safer alternatives to silica-based washes.

Is it safer for workers?

Think about it… The fine dust generated when spraying or mixing silica flour is a direct respiratory hazard. Zircon is considered a nuisance dust rather than a fibrogenic carcinogen like crystalline silica.

- Silicosis Reduction: Replaces the primary source of fine silica dust in the dipping room.

- Cleaner Floor: High-density coatings drip less and are easier to clean up.

- Non-Toxic: Unlike Chrome, it releases no heavy metal toxins into the water table or air.

Does it help with compliance?

Here is the bottom line: Switching to Zircon can lower your facility’s average airborne silica levels, potentially saving costs on air filtration systems and medical surveillance programs. It is an engineering control that solves a safety problem at the source.

Key Takeaway: Zircon supports both worker safety and environmental compliance, reducing long-term liability.

| Hazard | Zircon Benefit | Regulatory Impact | |

|---|---|---|---|

| Silica Dust | Significant Reduction | Helps meet OSHA PEL | |

| Hexavalent Chrome | Complete Elimination | Avoids hazmat disposal | |

| Waste Water | Inert Solids | Simplified filtration |

Analysis: Switching to zircon aids in meeting modern occupational health standards and reducing insurance liabilities.

The Future of Foundry Tech

The future of foundry tech relies on Zircon’s consistency to enable additive manufacturing and fully automated robotic coating lines. As Industry 4.0 transforms the foundry floor, variables must be eliminated. Zircon’s predictable rheology makes it the perfect candidate for automation.

Is automation the next step?

Bottom line? Robots need consistency. If the viscosity of a coating fluctuates or if the material settles too quickly, a robotic arm will spray an uneven coat. Zircon coatings are engineered for stability, allowing for “lights-out” manufacturing where robots dip and spray molds 24/7 without human intervention.

- Robotic Spraying: High-density material pumps reliably.

- 3D Printed Molds: Zircon adheres exceptionally well to the resin-bonded sand used in binder jetting.

- Data Integration: Consistent coating usage allows for precise cost tracking.

How does it fit with 3D printing?

Future-proofing: 3D printed sand molds often have complex internal geometries that cannot be reached by a brush. Zircon flow coatings can penetrate these complex runners and risers, ensuring protection even in designs that were previously impossible to cast.

Key Takeaway: Zircon is the enabler for next-generation automated casting and additive manufacturing integration.

| Trend | Zircon Role | Benefit | |

|---|---|---|---|

| Robotics | Consistent Feed | Process Reliability | |

| 3D Print | High Flowability | Covers complex internal passages | |

| Smart Factory | Predictable Usage | Accurate inventory/costing |

Analysis: Automation requires predictable materials, and zircon delivers the consistency needed for the digitized foundry.

Conclusion & Next Steps

Zircon coatings provide superior thermal properties, cost-efficiency, and defect prevention compared to traditional methods. While the initial price per kilogram is higher than silica or aluminosilicate alternatives, the holistic reduction in scrap rates, fettling labor, and environmental risk makes Zircon the economically superior choice. As manufacturing tolerances tighten and the demand for complex, high-integrity steel castings grows, Zircon is no longer a luxury—it is a necessity for any competitive steel foundry aiming for zero defects.

Take Action: Do not let burn-on and rework eat your margins for another quarter. Assess your current defect rates today. If your cleaning room costs are exceeding budget or your scrap rate on premium steel parts is over 3%, it is time to upgrade. Evaluate your coating supplier and transition to high-performance Zircon materials to secure your foundry’s future.

FAQ

Q1: Can I use Zircon coatings for all metal types?While Zircon is compatible with most metals, it is technically “overkill” for low-melting-point metals like aluminum or magnesium. It is most cost-effective and necessary for high-temperature ferrous alloys (steels, iron) and heavy copper-base alloys where thermal shock and penetration are significant risks.

Q2: Do these coatings really save money despite higher prices?Yes. The calculation is based on Total Cost of Ownership (TCO). Zircon drastically reduces expensive fettling labor (which often accounts for 30-40% of casting production costs) and scrap rates. Saving just one complex casting from scrap often pays for a drum of coating.

Q3: Can I apply this using my existing equipment?Typically yes. Zircon coatings can be applied via brushing, swabbing, spraying, or flow coating. However, because Zircon is heavier (higher density) than standard washes, you may need to adjust the agitation in your dip tanks to prevent settling and use spray guns with appropriate fluid tips for the higher solids content.

Q4: Will this help with “burn-on” defects?Absolutely. Burn-on is caused by the chemical reaction between silica sand and iron oxides. Zircon creates a chemically inert barrier that prevents this reaction entirely. It also creates a physical barrier preventing mechanical penetration, ensuring the sand peels away cleanly at shake-out.

Q5: Is Zircon safer than Silica wash?Yes. Zircon (Zirconium Silicate) does not contain free crystalline silica, which is the cause of silicosis. By replacing silica washes with Zircon, you significantly reduce the amount of respirable silica dust in your facility, helping you meet OSHA and environmental safety standards.