Zirconia ceramics are celebrated for their remarkable characteristics, which include exceptional strength, enhanced toughness, and impressive biocompatibility. These qualities make them invaluable in various high-performance applications, from medical devices to cutting tools. However, despite their advantages, producing zirconia ceramics comes with its fair share of challenges, particularly during the sintering process. One of the most pressing issues is the development of cracks and warping, which can severely compromise the integrity and functionality of the final product. This article addresses these common concerns and offers actionable solutions to mitigate defects throughout the zirconia ceramic manufacturing process.

By focusing on critical factors such as the selection of powder materials, optimizing forming processes, and carefully managing sintering conditions, manufacturers can significantly enhance the quality and reliability of their zirconia products. With a deep understanding of both the technical and material challenges involved in sintering, you can implement effective strategies that not only minimize defects but also lead to improved performance in end-use applications. Rely on our expertise as we provide you with valuable insights aimed at enhancing the quality of zirconia ceramics in your production processes.

This image illustrates the diverse applications and strength properties of zirconia ceramics in various industries.

What Challenges Arise During Zirconia Sintering?

The process of sintering zirconia ceramics presents numerous challenges that require careful consideration. At the heart of these issues is the transformation of zirconia from a tetragonal to a monoclinic phase, which is sensitive to thermal conditions. This transformation can occur under rapid temperature changes during the sintering process, inducing internal stresses that may lead to cracking. The significance of temperature control cannot be overstated; fluctuations in temperature can cause irreversible damage to the material’s structure, impacting not only the appearance but also the functional integrity of the ceramic.

Apart from phase transformation, the quality of the zirconia powder itself plays a pivotal role in determining the success of the sintering process. Impurities such as oxides and metallic contaminants can introduce vulnerabilities within the ceramic matrix. These contaminants may not only weaken the material but can also interfere with the sintering process itself, leading to uneven densification. Understanding the origin of these impurities and employing stringent quality control measures during powder selection are vital steps in mitigating defects.

Moreover, the handling and processing of the zirconia powder significantly influence the outcome. Poor batching practices or inadequate storage conditions can expose the powder to moisture or contaminants, which can compromise its purity and impact the final ceramic product. The importance of using high-purity powder cannot be overstated when it comes to achieving consistent and reliable sintering results.

In summary, recognizing the multifaceted nature of challenges that arise during the sintering of zirconia ceramics, from phase transformations to material quality control, is crucial for any production facility. This holistic understanding is a key first step in addressing potential issues before they escalate into defects in the final product.

How Do You Choose the Right Zirconia Powder?

Choosing the right zirconia powder is a foundational step to achieving optimal results in sintering processes. The purity of the zirconia powder significantly influences its performance during sintering. High-purity zirconia minimizes the risk of developing defects that often arise from the presence of impurities. These impurities can create stress points within the material, increasing the likelihood of cracking and warping during thermal cycling. Carefully selecting powders with certified purity levels ensures that the starting material is conducive to producing defect-free ceramics.

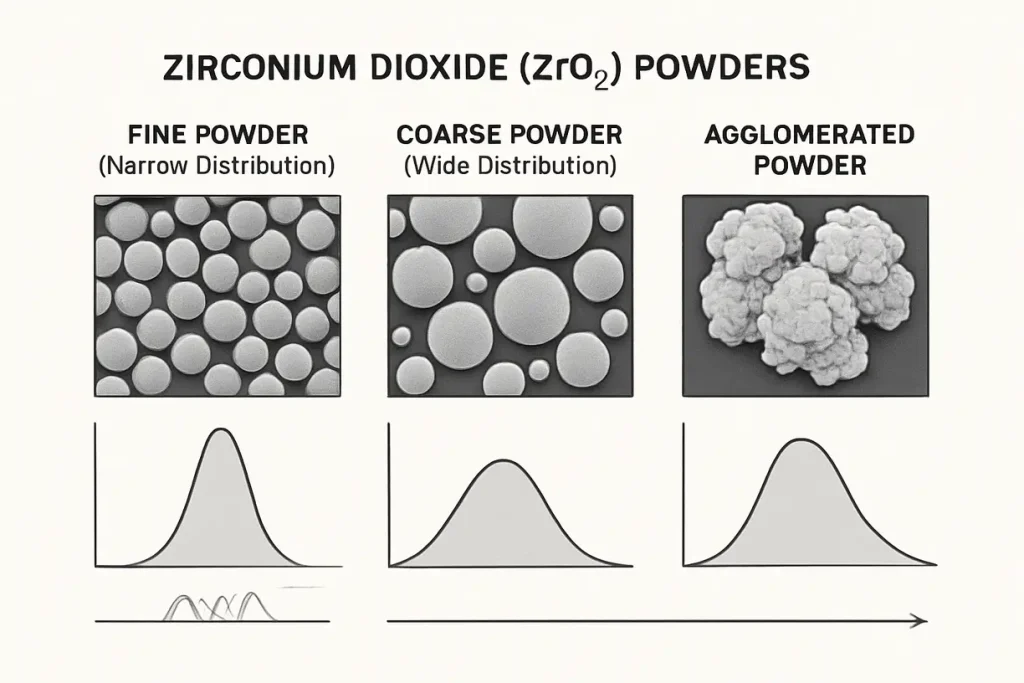

Equally crucial is the consideration of particle size distribution (PSD). A narrow and consistent PSD promotes uniform shrinkage and density during the sintering process. When the powder contains a significant number of fines or coarse particles, it leads to unpredictable behavior in the sintering outcome. For example, a higher concentration of fine particles might lead to excessive densification, while coarse particles could cause localized areas of low density. A well-balanced particle size distribution facilitates the formation of a cohesive ceramic body, ultimately leading to improved mechanical properties in the final product.

The choice of binders and additives also warrants careful attention. An optimized binder system is crucial in ensuring that the binder burns out efficiently and completely before the densification stage begins. If the binder does not burn out effectively, it can leave behind residual materials that compromise the structural integrity of the ceramic. This can result in defects such as internal voids, bloating, or a weakened final product. Manufacturers should consider the thermal properties of the binder, as well as its compatibility with the zirconia powder being used.

When exploring the options for zirconia powder, consider using products like our [Your Product Series, e.g., ZP-Pro series]. Specifically engineered for performance, our powders are produced with a focus on maintaining consistent particle size and minimizing impurities. The manufacturing process has been designed to ensure a balanced PSD and to adhere to strict purity standards, thus promoting a more predictable and successful sintering outcome.

| Parameter | Significance |

|---|---|

| Purity | Reduces risk of defects |

| Particle Size Distribution | Ensures uniformity and predictability |

| Binder System | Affects burnout and final structure |

This image displays a comparison of various zirconia powders, highlighting differences in particle size distribution.

What Best Practices Should Be Implemented in Green Body Formation?

Ensuring the quality of the green body is a vital step in producing defect-free zirconia ceramics. The formation of a flawless green body—un-sintered part—is critical for successful sintering. Key practices must be implemented to achieve this goal. One of the most important factors is the application of uniform pressure during pressing and molding processes. Non-uniform pressure can lead to density gradients within the green body, making certain areas more susceptible to warping during the subsequent sintering phase.

In processes like cold isostatic pressing (CIP), careful attention must be paid to how pressure is distributed across the mold. If certain areas experience higher pressure than others, it can lead to increased density in those regions, while lighter-pressured areas remain less dense. This variation is a significant driver of warping, as the material will not shrink uniformly during sintering, resulting in structural imbalances.

Debinding, the process of removing the binder before sintering, is another critical stage that requires precision. The rate of heating during debinding must be carefully controlled. If the heating rate is too rapid, trapped gases may form and create internal stresses, leading to cracks in the final product. A gentle ramp rate—typically in the range of 1-2°C per minute when traversing through the 200-400°C range—is often necessary. This pace allows for a more gradual transition and ensures that any gases trapped within the binder have ample time to escape safely.

By implementing these best practices, manufacturers can create a stable green body that can withstand the complexities of sintering. It is also beneficial to perform thorough inspections throughout the green body formation process to identify any inconsistencies early on, allowing for necessary adjustments before proceeding to the more complex sintering phase.

| Step | Best Practice |

|---|---|

| Pressing | Apply uniform pressure |

| Molding | Ensure consistent density |

| Debinding | Use slow heating rates |

How Do You Control the Sintering Curve?

Gaining a comprehensive understanding of the sintering curve is essential for controlling the overall process effectively. The sintering curve encompasses several phases, each of which plays a vital role in determining the final properties of zirconia ceramics.

Phase 1: Initial Heating Ramp is the first step in the sintering process. During this phase, it is pivotal to adopt a gradual heating rate. Rapid increases in temperature can lead to thermal shock, whereby the material experiences rapid changes in internal stress, resulting in cracks. Ideally, heating rates should be controlled to ensure that there is a smooth transition into the sintering temperature range, thereby mitigating the risk of thermally induced defects.

Phase 2: Dwell/Soak Time at the peak sintering temperature significantly influences the final density and grain structure of zirconia components. When soaking at the peak temperature, it is crucial to remain vigilant regarding the duration. Too short a soak time can prevent sufficient particle bonding, leading to residual porosity in the ceramic. Conversely, overly prolonged soaking can allow excess grain growth, which negatively impacts toughness and mechanical strength. Finding the balance within this phase is essential, as both ends of the spectrum can result in compromised material properties.

Phase 3: The Cooling Phase is perhaps the most critical in avoiding catastrophic failures. During this phase, the tetragonal-to-monoclinic phase transformation occurs around 1170°C. If cooling transitions through this temperature range are too rapid, the internal stresses generated can lead to cracking. Slower cooling rates should be implemented, particularly during this transition, allowing for a more controlled and stable shift between phases.

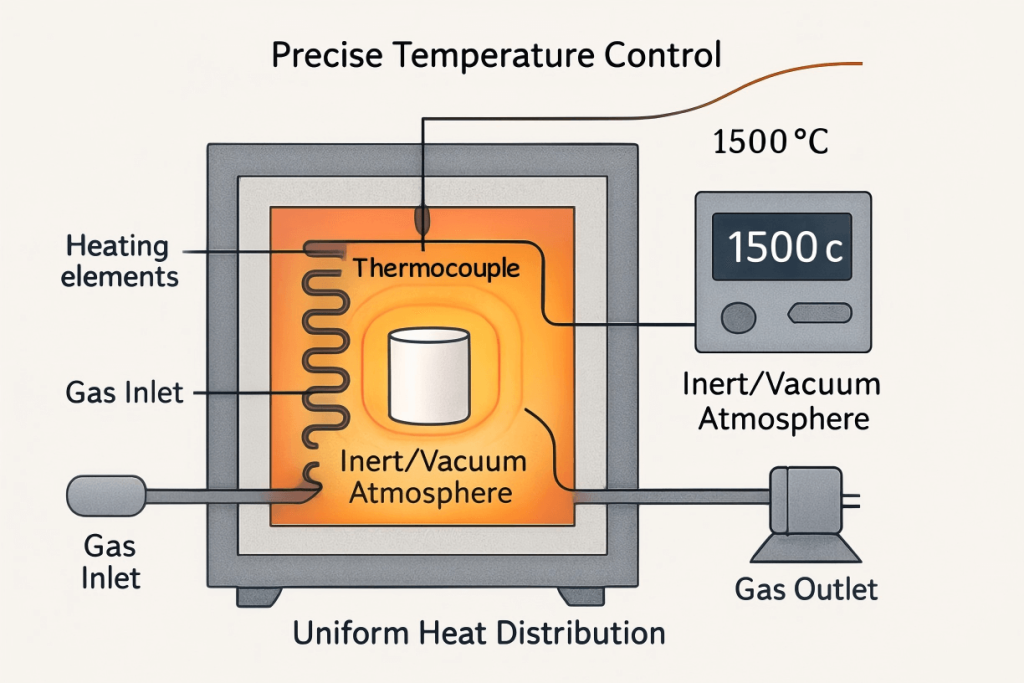

Additionally, controlling the furnace atmosphere is essential. The atmosphere in which the sintering occurs—whether in air or in a vacuum—can have a profound impact on the properties of the final product. An oxidizing environment can lead to unwanted reactions that can affect material properties and performance. Therefore, ensuring proper atmospheric conditions will facilitate achieving the desired characteristics in the zirconia ceramics.

| Phase | Key Considerations |

|---|---|

| Initial Heating Ramp | Gradual increase to prevent thermal shock |

| Dwell/Soak Time | Balance time for density and grain control |

| Cooling Phase | Slow cooling to prevent cracking |

What Are Common Defects and Their Remedies?

Identifying and troubleshooting common defects during the sintering process is a critical aspect of achieving high-quality zirconia ceramics. Here, we examine frequent defects along with their respective causes and proposed remedies.

Defect 1: Surface Cracks.

- Likely Causes: Surface cracks often result from thermal shock experienced during rapid heating or cooling. Additionally, residual stress from the molding process can exacerbate this issue.

- Solutions: Implement strategies such as reducing ramp rates for heating and cooling processes. Regular checks on the uniformity of the density within the green body are also essential. This ensures that stress concentrations do not occur, which might lead to cracks.

Defect 2: Warping/Distortion.

- Likely Causes: Warping can stem from non-uniform density in the green body, leading to uneven shrinkage during sintering. Insufficient support within the furnace and uneven heating can also contribute to this issue.

- Solutions: Prioritize optimizing the pressing process to guarantee consistent density throughout the green body. Utilizing flat setter plates made of sturdy materials, such as alumina, can provide adequate support during the sintering process. Ensuring consistent heating within the furnace will help maintain uniform density and prevent warping.

Defect 3: Internal Voids or Bloating.

- Likely Causes: These defects typically arise from incomplete binder burnout during the debinding phase or from overheating during heating ramp-up.

- Solutions: It’s crucial to extend the holding period at the debinding temperature, allowing for complete binder removal. Adjusting the initial ramp rate to a slower pace will also reduce the likelihood of these issues occurring during the sintering process.

A systematic approach to identifying defects will not only help in rectifying current problems but will also guide future manufacturing practices towards higher quality outputs.

| Defect | Cause | Solution |

|---|---|---|

| Surface Cracks | Thermal shock, residual stress | Slower ramp rates, check green body density |

| Warping/Distortion | Uneven density, poor support | Optimize pressing, use setter plates |

| Internal Voids or Bloating | Incomplete binder burnout | Longer hold at debinding temperature |

How Can You Achieve Sintering Success with a Holistic Approach?

Achieving success in the sintering of zirconia ceramics requires a comprehensive understanding of the various interconnected factors that influence the process. The quality of raw materials is of utmost importance; high-purity powders result in improved stability and predictable performance during sintering.

Furthermore, careful preparation of the green body is essential. An optimal green body will directly correlate to the success of the sintering process. Attention to detail in the handling of materials, temperature control, and monitoring of environmental conditions within the sintering furnace will all contribute to better outcomes.

By implementing a collaborative approach that incorporates high-quality materials, precise manufacturing techniques, and effective process controls, you can achieve significant improvements in the final product’s quality. It is essential to view these efforts as interconnected components of a larger system, where success in one area contributes to overall performance.

For those facing hurdles in their sintering processes, partnering with Global Industry can provide valuable support. Our technical team has worked with clients across various sectors, helping them optimize their production processes to yield higher quality products consistently. Contact us today for a complimentary consultation or to request a sample of our high-performance zirconia powder.

This image represents a sintering furnace, highlighting the controlled environment necessary for the sintering of zirconia ceramics.

FAQ Section

Q1: What are the most common issues during zirconia sintering?

Cracking and warping are frequent issues that arise due to several factors. Cracking typically occurs as a result of thermal stress during rapid heating and cooling or from residual stresses remaining in the material after the forming process. Warping, on the other hand, is often linked to uneven density distributions within the green body, which can lead to non-uniform shrinkage during the sintering phase. It’s essential to carefully manage temperature profiles and ensure uniform pressure application during pressing to mitigate these risks.

Q2: How can impurities in zirconia powder affect the final product?

The presence of impurities in zirconia powder can lead to significant challenges in achieving a defect-free final product. Impurities can create stress points within the material that may initiate cracks during sintering. Moreover, they may disrupt the uniformity of the sintering process, leading to variations in density and mechanical properties. Consequently, it’s crucial to select high-purity raw materials and rigorously monitor for contaminants to ensure optimal performance in the final ceramic product.

Q3: What heating rates are recommended during sintering?

Recommended heating rates during the sintering process typically range from 1 to 5°C per minute, depending on the specific formulation and geometries involved. Controlled rate increases allow for gradual elimination of moisture and other volatiles, thereby reducing the risk of thermal shock and defects. It’s vital to tailor these heating rates based on the characteristics of the zirconia powder and the complexity of the part being sintered. Implementing a strategy that emphasizes gradual increases can greatly enhance the overall quality of the sintered ceramic.

Q4: How can I improve the consistency of my green bodies?

To improve the consistency of green bodies, start by employing uniform pressure application during the forming processes, such as cold isostatic pressing or dry pressing. It’s essential to ensure that the mold and tooling are calibrated correctly to promote uniform density throughout. Additionally, assessing the binder system for compatibility and performance can be beneficial. A well-optimized binder not only aids in maintaining green body integrity but also ensures effective debinding, contributing to a more consistent sintering performance.

Q5: What should I do if I notice surface cracks in my products?

If surface cracks appear in your products, it’s important to first evaluate the overall sintering process for any rapid temperature changes that could induce thermal shock. Additionally, closely inspect the green body before sintering to ensure uniform density and absence of defects. Implementing strategies such as slowing down ramp rates during both heating and cooling can significantly reduce the likelihood of cracks reoccurring. Monitoring the entire production process—from powder selection to forming and sintering—can help to identify root causes and implement the necessary adjustments.