Zircon sand is a key mineral used across multiple industries, from ceramics and refractories to foundry applications. Buyers and procurement managers often find themselves puzzled by the many sources of zircon sand and the variations in quality they bring. Finding the right supplier can be tricky, especially when faced with conflicting information and concerns about product reliability. This article answers that challenge by laying out the main zircon sand sources, discussing how these sources impact quality and performance, and sharing practical insights that help B2B buyers make informed decisions. At Global Industry, we have years of experience in sourcing and quality control, and we’re here to share that knowledge in this guide.

What Are Zircon Sand and Its Key Uses?

Zircon sand, a natural mineral, is rich in zirconium silicate. This mineral’s unique properties make it a trusted choice in manufacturing processes and technical applications. Its high melting point and thermal stability are just two reasons why industries use it extensively.

The sand’s physical structure is also impressive. It stands up well to high temperatures, making it reliable in foundry work and as a refractory material. Ceramics manufacturers value it for its ability to add whiteness and opacity to glazes and enamels.

So, why do these qualities matter so much? Here’s why: industries like precision casting and glass production depend on materials that don’t break down or alter under extreme heat. Zircon sand delivers on that need, providing a consistent and trusted performance.

The sand’s uses are widespread. Ceramics manufacturers rely on it to create strong and bright tiles. Foundries use it for mold coatings. In the glass industry, it strengthens glass products and helps create smooth, finished surfaces.

Many technical industries also favor zircon sand. It’s a base material in certain types of refractory bricks that line high-temperature furnaces. In precision casting, it acts as a mold coat that resists thermal shock.

Its versatility comes from a straightforward combination of heat resistance and chemical stability. For B2B buyers, that means predictable results in applications where failure can be costly.

Zircon sand used in ceramics, highlighting its whiteness and heat resistance.

The global market sees high demand for zircon sand because it performs so reliably. However, not all zircon sand is the same. That brings us to the next topic.

What Are the Major Global Sources?

Zircon sand comes from mineral sands deposits found worldwide. The most significant sources are located in Australia, South Africa, China, and the United States. Each region has distinct mining practices and production volumes.

Australia ranks at the top of the list. Its large coastal deposits along the east and west coasts have supplied zircon sand for decades. These deposits contain high-purity zircon, making them attractive to buyers worldwide.

South Africa follows close behind. Its deposits lie mainly along the coast in the Eastern and Western Cape provinces. Mining operations there focus on heavy mineral sands, which include zircon and rutile.

China’s deposits are smaller in scale but still significant. Located in inland provinces, they serve both domestic and regional markets.

The United States has smaller operations in states like Florida and Georgia. Though not as large as Australia’s or South Africa’s, these sources provide local industries with a steady supply of zircon sand.

But here’s something you may not know: the quality and mineral content of zircon sand can differ based on the geological setting and the extraction process used. This makes it critical for buyers to understand what’s on offer from each region.

Here’s a breakdown of where zircon sand comes from:

| Country | Main Production Regions | Estimated Share of Global Market |

|---|---|---|

| Australia | East & West coastal mineral sands | ~40% |

| South Africa | Eastern & Western Cape coasts | ~30% |

| China | Inland provinces | ~15% |

| United States | Florida, Georgia | ~5% |

| Others | Small producers in Asia & Europe | ~10% |

These numbers can shift due to market demand and mining conditions. However, this snapshot gives you a sense of where most zircon sand comes from today.

Mining methods also differ across these regions. Australia’s open-pit mining contrasts with some underground or hybrid techniques used in other countries. These variations can affect consistency and cost, both important factors for industrial buyers.

A mining operation in Australia, showing the scale and processing involved in zircon sand extraction.

What Factors Influence the Quality of Zircon Sand?

Not all zircon sand is created equal. Let’s break it down. Several key factors influence the quality of zircon sand. These include geological formation, extraction processes, and mineral composition.

The geological environment sets the stage. Zircon forms in heavy mineral sands alongside other minerals like rutile and ilmenite. Over time, natural forces like water and wind sort these minerals by weight and size. The resulting deposits contain varying levels of zircon purity.

Extraction processes matter, too. Some producers use advanced separation techniques to remove impurities like iron oxides or clay minerals. These extra steps lead to a higher-purity zircon product. Lower-purity sands often contain more residual minerals, affecting how the sand performs in high-temperature applications.

The mineral composition is another factor. Here’s what’s important: zircon sand typically contains trace elements such as hafnium and titanium. While these can be beneficial in some technical applications, they might be unwanted in others. Consistency in these trace elements is key for predictable results.

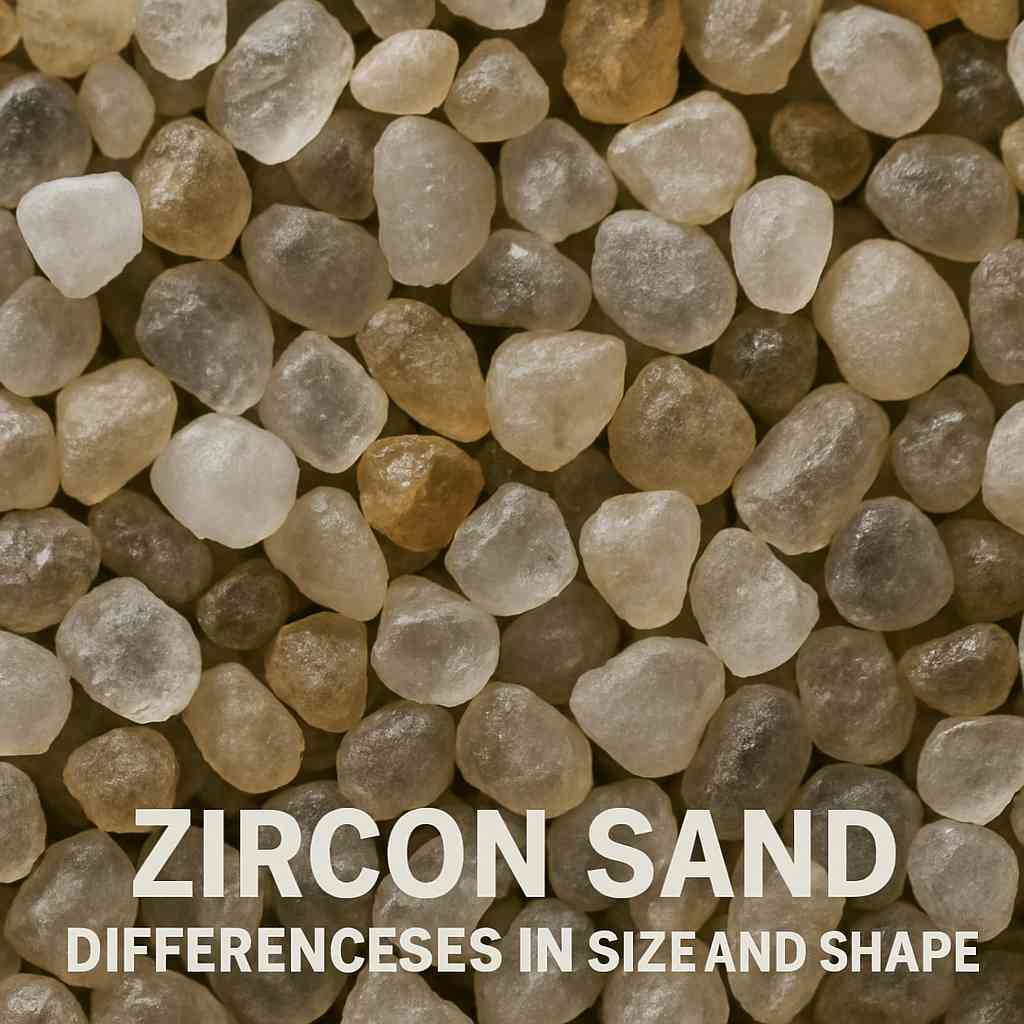

Physical characteristics also count. Grain size distribution affects how the sand packs in molds or mixes in ceramic slurries. Angular grains may bond differently than rounded grains. In foundry work, these small differences can mean higher yields and fewer defects.

To give buyers a quick reference, here’s a summary:

| Quality Factor | Why It Matters |

|---|---|

| Purity (% zircon) | Affects thermal stability and melting point |

| Grain size | Impacts how the sand packs and flows |

| Trace elements | Can change color, melting behavior, or performance |

| Moisture content | Impacts handling and shelf life |

A close look at zircon sand grains, highlighting differences in size and shape that affect performance.

This means: before making a purchase, it’s wise to review these factors in detail with suppliers. That way, you’re not just buying zircon sand—you’re buying consistent performance for your production lines.

How Do Sources Affect Quality and Performance?

Different zircon sand sources bring different advantages and challenges. Let’s walk through this. Australia’s zircon sand is well-known for its high purity, often above 65% zircon by weight. This makes it a favorite in ceramics and refractories, where reliability and heat resistance are non-negotiable.

South Africa’s sand often has slightly lower zircon content, around 50-60%, but still performs well in foundry applications. The lower purity doesn’t always mean lower quality—it depends on what the buyer needs. For some foundry uses, the slight variation in mineral content can improve mold coatings.

China’s zircon sand is usually mid-grade in purity. It works well for regional ceramics producers or foundries that don’t require ultra-high purity levels.

The United States, while smaller in output, has sands that meet local demand for industrial and ceramics applications. Buyers close to these sources value the reduced transport costs.

Here’s something to remember: buyers must align product quality with application needs. For instance, tile makers aiming for bright, uniform finishes prefer Australian zircon. Foundries using zircon as a mold coat might find South African or Chinese sands more cost-effective.

Let’s compare these source-based properties:

| Source | Typical Zircon Content | Typical Use Cases |

|---|---|---|

| Australia | 65-70% | Ceramics, refractories |

| South Africa | 50-60% | Foundry, general ceramics |

| China | 55-60% | Regional ceramics, some foundry |

| United States | 50-60% | Local industrial applications |

Each source offers a balance of performance and cost. The trick is matching the source to your specific industrial needs.

This diagram shows how zircon content and quality can differ by region, which matters for buyers.

What Challenges and Considerations Are There for Buyers?

Buying zircon sand isn’t always straightforward. Here’s the deal: B2B buyers face a few recurring challenges.

One is supply stability. Since zircon sand comes from mineral sands operations, disruptions in mining or shipping can create sudden shortages. Events like floods, strikes, or transport bottlenecks can ripple through the supply chain.

Another issue is environmental compliance. Regulations on mining and waste handling vary worldwide. Some buyers want assurance that their zircon sand comes from responsible producers who follow international standards.

Price fluctuations can also be tough to manage. Demand swings in ceramics and foundry markets can drive up prices fast. Bulk buyers often use long-term contracts or multiple supplier sources to balance risks.

Buyers must also consider handling and storage. High-quality zircon sand must be stored in dry, secure conditions to keep moisture content low. This prevents clumping and maintains free-flowing material, which is vital for consistent manufacturing results.

Here’s a list of common challenges:

- Supply chain stability: disruptions in mining and shipping

- Regulatory requirements: environmental, safety, and labor concerns

- Price volatility: driven by demand swings

- Storage and handling: moisture control and safe storage

Understanding these factors helps procurement managers plan ahead. A proactive approach to sourcing and verification keeps your production lines steady and efficient.

| Key Challenge | Potential Impact |

|---|---|

| Supply disruptions | Shortages and production delays |

| Regulatory compliance | Reputation and legal risks |

| Price changes | Budget unpredictability |

| Moisture control | Flow and consistency in usage |

How to Choose the Right Zircon Sand Source?

Choosing the right zircon sand source requires more than just looking at price. Here’s what smart buyers do: they start by defining their technical needs. For ceramics, consistent high zircon content matters. In foundry work, some variations may be acceptable.

Supplier credibility is also key. Buyers should request product samples and check lab results for purity, grain size, and trace elements. Certifications can help confirm these claims.

Many buyers rely on third-party testing. This provides confidence that the sand will perform in high-temperature or precision processes. Clear communication about product needs helps both buyers and sellers avoid misunderstandings.

Here are some best practices for buyers:

- Ask for a detailed product specification sheet.

- Request samples and lab test reports.

- Check supplier track record and customer reviews.

- Discuss transport and storage options upfront.

This approach reduces risk and helps build long-term supplier relationships. For industries where consistency matters, this level of scrutiny can make or break production success.

| Step | Why It Matters |

|---|---|

| Product specs review | Confirms technical suitability |

| Sample and lab testing | Verifies performance claims |

| Supplier reliability check | Reduces supply risks |

| Storage and transport plans | Maintains product quality |

What Are Future Trends in Zircon Sand Sourcing?

The zircon sand industry is changing fast. Let’s see what’s ahead. New mining projects in Africa and Southeast Asia may shift production balances in the coming years. These regions have shown potential for high-grade zircon deposits.

Sustainability is also gaining attention. Buyers want to know their sand comes from mines that protect workers and local communities. Producers adopting better mining practices often get preference from global buyers.

Technology is playing a role too. More advanced separation and purification processes can improve sand quality and reduce waste. These changes could make lower-grade sands more usable in higher-end applications.

For buyers, these trends mean new choices and new challenges. Being aware of what’s next can help B2B decision-makers secure better deals and protect their long-term supply lines.

| Future Trend | Implication for Buyers |

|---|---|

| New mining regions opening | Fresh sourcing opportunities |

| Sustainability focus | Increased supplier scrutiny |

| Technology improvements | Expanded use of lower-grade sands |

Conclusion

This guide has outlined the key zircon sand sources, the factors affecting quality, and the challenges buyers face. Knowing where zircon sand comes from and how each source performs helps you make more confident purchasing decisions. At Global Industry, we’ve spent years helping manufacturers and buyers source zircon sand with the consistency and reliability they need. If you’re looking for a supplier that understands your requirements and speaks your language, we’re ready to help. Reach out today to request a sample or speak with one of our technical advisors.

FAQ

Q1: How is zircon sand formed in nature?

Zircon sand forms slowly from the cooling of magma containing zirconium silicate over millions of years.

Q2: What industries rely most on zircon sand?

The ceramics, foundry, and refractories industries are the main users of zircon sand.

Q3: Does the country of origin really affect the quality?

Yes, different geological formations and extraction methods create varied purity and performance levels.

Q4: Can recycled zircon sand meet quality standards?

Recycled zircon sand can sometimes meet standards, depending on the intended use and reprocessing method.

Q5: What certifications are typically used to confirm zircon sand quality?

Certifications include ISO standards and independent lab tests, which verify zircon sand meets required specifications.