In the fast-paced world of oil and gas, companies constantly seek ways to enhance efficiency and performance. One material that is gaining attention for its benefits is zirconium silicate, a compound notable for its unique properties. Many industry professionals face challenges related to material performance and operational costs, making the need for effective solutions critical. The good news is that integrating zirconium silicate into various processes can significantly address these pressing concerns. By providing exceptional durability and thermal stability, this material enhances operational efficiency and reliability. This article will offer valuable insights into the numerous ways zirconium silicate can benefit your projects, ensuring you are well-equipped to make informed decisions backed by credible information.

How Does Zirconium Silicate Work in Oil and Gas?

Zirconium silicate possesses unique properties that make it highly valuable in oil and gas applications. Here’s the deal: this compound contains high thermal stability which allows it to withstand extreme temperature environments that are common in oil and gas extraction and processing. Its molecular structure contributes to its ability to resist thermal degradation, making it ideal for high-pressure applications where other materials might falter. This characteristic is especially important for processes such as drilling and extraction, where materials frequently encounter intense heat, rendering them less effective over time.

The mechanism of action for zirconium silicate is straightforward yet effective. Acting both as a stabilizing agent and an enhancer of mechanical strength, this compound plays a pivotal role in drilling fluids. For instance, when zirconium silicate is added to these fluids, it helps improve the viscosity while maintaining consistent performance across varying operational conditions. This stability is crucial for efficient drilling operations, which can often be hindered by fluctuations in temperature and pressure. Unlike some traditional alternatives that may degrade or react negatively with other constituents in drilling fluids, zirconium silicate maintains its integrity, ensuring reliable performance.

In summary, integrating this compound into oil and gas operations can provide reliable, high-performance materials necessary for the demanding environments typical in the industry. The advantages of employing zirconium silicate translate not just to enhanced efficiency, but also to improved safety and operational reliability.

This image depicts an oil extraction operation, reflecting the harsh conditions where zirconium silicate is utilized.

What Are the Key Benefits of Zirconium Silicate?

When considering materials for oil and gas applications, it is vital to understand the extensive benefits that zirconium silicate can provide. You might be surprised at how its advantageous properties translate into real-world gains for companies in this sector. First and foremost, its thermal stability permits operations to run smoothly without the risk of material failure, even under strenuous conditions. This durability is a game-changer, particularly when projects are under tight deadlines and any downtime can lead to significant financial losses.

Moreover, the mechanical strength of this compound minimizes equipment wear and tear, directly impacting the lifespan of critical machinery. Increased durability reduces the frequency of maintenance checks and repairs, saving companies considerable amounts of money over time. Rather than needing constant replacements of critical parts due to wear, businesses can expect their equipment to last longer, leading to more sustainable operations.

Additionally, zirconium silicate boasts strong resistance to corrosion, which is especially useful in environments where other materials would quickly succumb to the harsh effects of chemicals and extreme temperatures. This feature not only serves to prolong the life of operational equipment but also aligns well with environmental regulations aimed at reducing harm associated with emissions and waste. Companies that invest in materials that comply with sustainability standards often find themselves more competitive in a market increasingly aware of ecological impact.

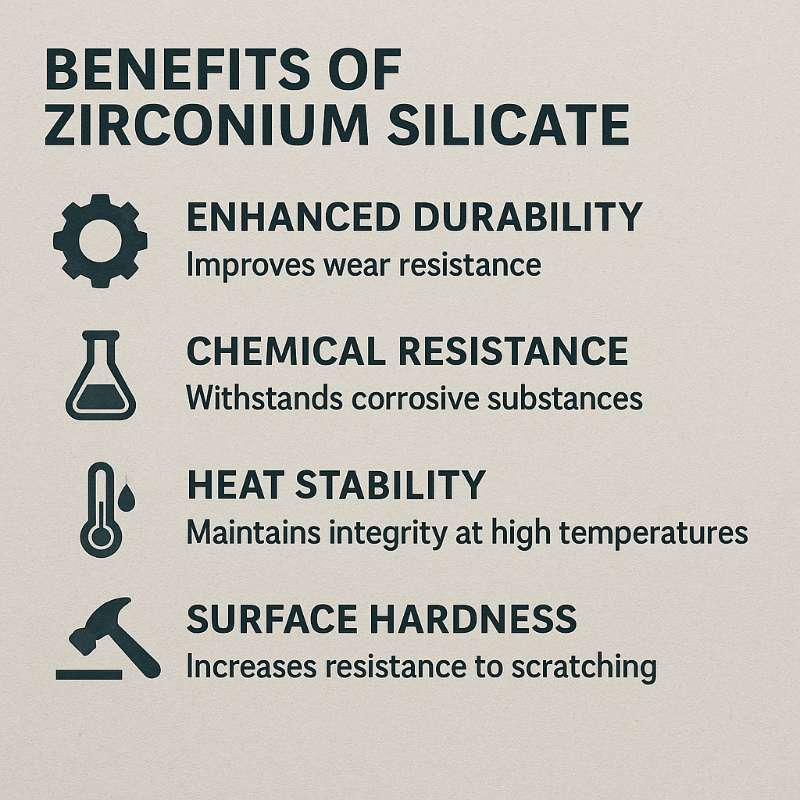

Here’s a quick overview of the benefits of zirconium silicate:

- High thermal stability: Ensures equipment functions effectively under extreme conditions without degradation.

- Improved mechanical strength: Reduces wear and tear on machinery, enhancing their lifespan.

- Corrosion resistance: Protects equipment from harsh chemicals, increasing sustainability efforts.

Incorporating this compound into oil and gas operations results in tangible benefits such as improved performance, dependable material quality, and long-term cost savings, creating an essential asset for businesses.

This image depicts the various benefits of zirconium silicate in industrial settings.

How Can Integrating Zirconium Silicate Reduce Costs?

Integrating zirconium silicate can have a substantial impact on cost management in oil and gas projects. Let’s highlight a few points regarding how it can lead to financial savings. Initially, its thermal stability allows for more efficient operations, significantly reducing the potential for material failure during critical processes like drilling and extraction. In high-stakes environments where every second counts, minimizing downtime translates directly into financial benefits.

Moreover, the material’s inherent mechanical strength contributes to lower maintenance requisites. Because zirconium silicate is less prone to wear and damage, companies not only save on immediate repair costs but also increase their overall operational efficiency. For instance, a reduction in equipment downtime means that projects can stay on schedule, further optimizing productivity and income.

Case studies showcase operations that have seen actual reductions in costs after integrating this important material. Companies report experiencing up to 20% reductions in maintenance expenditures by utilizing zirconium silicate. This percentage translates to significant financial savings in the long haul, allowing organizations to channel resources into other critical areas of operations or technology advancements.

To dive into specifics, here’s how embracing zirconium silicate can sharpen the cost perspective:

| Cost Factors | Before Integration | After Integration | Savings |

|---|---|---|---|

| Maintenance Cost | $100,000 | $80,000 | $20,000 |

| Equipment Replacement Frequency | Every 6 months | Every 12 months | Reduced |

| Downtime Loss | 100 hours | 50 hours | 50 hours |

In the long run, the advantages amassed from using this compound present financial returns that support its integration into oil and gas operations, demonstrating that an investment in quality materials can yield impressive economic benefits.

What Applications Benefit Most from Zirconium Silicate?

Zirconium silicate finds its niche across various applications in the oil and gas sector. So, let’s break this down: specific processes gain more value from its unique properties than others. For instance, when it comes to drilling fluids, the compound is particularly effective in maintaining viscosity under high temperatures and pressures. This ability is crucial in ensuring that drilling operations remain effective even under the most challenging conditions.

In addition to its role in drilling fluids, zirconium silicate is also utilized in different stages of production. Its resilience allows it to function effectively during extraction, refining, and transportation phases. This ensures that equipment operates safely and efficiently, directly contributing to a productive workflow.

Moreover, zirconium silicate has applications in the formation of advanced ceramics used for downhole components. These ceramics benefit significantly from improved thermal and mechanical properties, ensuring they can withstand the extreme conditions encountered in deep drilling operations. The ability of zirconium silicate to be integrated into multifunctional components further solidifies its position as a go-to material in the oil and gas industry.

In summary, its various applications in drilling fluids, production stages, and component manufacturing demonstrate the versatility and effectiveness of zirconium silicate within the complexities of the oil and gas landscape.

Are There Any Environmental Benefits?

As industries become more environmentally conscious, the potential for this compound to benefit sustainability efforts is noteworthy. For example: its unique properties contribute to reducing harmful emissions during extraction processes, aligning with global movements towards greener practices. The resistance to thermal degradation aids in ensuring that operations can remain efficient without generating excess waste or pollution.

The integration of zirconium silicate enhances energy efficiency not only by improving the performance of equipment but also by allowing processes to complete more quickly. This efficiency often leads to lower emissions associated with machinery operation, cementing the material’s role in eco-friendly business practices.

Furthermore, utilizing this compound can help companies comply with stringent environmental regulations often imposed by local governments and international bodies. Companies that adhere to such regulations tend to enjoy enhanced reputational benefits and reduced costs associated with potential fines. These efforts do not just reflect a commitment to sustainability; they also resonate with consumers and stakeholders who prioritize responsible operations.

Ultimately, integrating zirconium silicate can align business operations with modern environmental standards, demonstrating a commitment to sustainability that supports both operational efficacy and positive public perception.

This image shows a sustainable oil extraction process, highlighting eco-friendly practices in the industry.

How Much Zirconium Silicate is Required?

Determining the right amount of zirconium silicate for your operations involves several influential factors. Let’s clarify how to approach this issue more effectively. The dosage often depends on the specific application and the desired results. Understanding equipment specifications, as well as the conditions under which the material will be used, is fundamental to achieving optimal performance.

Key factors influencing the quantity required include:

- Temperature and pressure conditions: Operations conducted under higher extremes will need more stabilizing agents to maintain efficacy.

- Type of drilling fluid or material being formulated: Different formulations may demand varying concentrations to achieve the desired viscosity and performance characteristics.

- Desired viscosity and performance outcomes: The specific requirements of the project will dictate the careful adjustment of dosages to ensure effective outcomes.

Typically, operators may begin with a baseline quantity recommended by industry standards, followed by adjustments based on performance monitoring during use. Regular assessments help pinpoint the correct dosage for optimized performance across operations effectively.

| Conditions | Recommended Dosage |

|---|---|

| Low temperature/pressure | 2-4% of total formula |

| Medium temperature/pressure | 4-6% of total formula |

| High temperature/pressure | 6-8% of total formula |

Determining the precise amount can help companies fine-tune their operational processes and ensure they achieve the best results when incorporating this compound into their workflows.

What Are the Challenges of Using Zirconium Silicate?

While the incorporation of this compound offers many advantages, several challenges come along with its usage. Consider this: handling and processing zirconium silicate requires specific attention and expertise. One of the primary challenges involves compatibility. In some instances, the compound may not interact favorably with other materials used in certain formulations, leading to suboptimal performance. Conducting compatibility tests beforehand can proactively resolve potential issues, safeguarding the integrity of all materials involved.

Another challenge stems from sourcing high-quality zirconium silicate. Not all suppliers adhere to the same standards, so conducting thorough research and vetting options is paramount. Ensuring that the material is pure and sourced from reputable suppliers helps avoid operational headaches down the line.

Training for workers handling zirconium silicate is another critical consideration. Adequate education on safe handling procedures not only ensures compliance with safety regulations, but it also enhances operational effectiveness. Investing in training programs can equip employees with the necessary knowledge to manage this compound confidently and efficiently.

Addressing these challenges head-on will make the transition smoother, allowing operations to maximize the potential benefits of using zirconium silicate.

How Does Zirconium Silicate Compare to Alternatives?

When evaluating materials for oil and gas applications, it is essential to consider how zirconium silicate measures up against alternatives. Let’s break it down: zirconium silicate offers uniquely higher thermal stability compared to many traditional materials. Its mechanical strength often exceeds that of conventional options, making it a top choice for demanding applications.

Here’s a concise comparison of zirconium silicate versus some commonly used alternatives:

| Material | Thermal Stability | Mechanical Strength | Corrosion Resistance | Cost Effectiveness |

|---|---|---|---|---|

| Zirconium Silicate | Excellent | High | Good | Competitive |

| Traditional Clay | Moderate | Moderate | Fair | Low |

| Barite | Low | Low | Poor | Moderate |

While some alternatives may come at a lower upfront cost, the long-term benefits of zirconium silicate often lead to greater cost-effectiveness and durability. Investing in materials that perform well under extreme conditions can prevent costly operational disruptions and equipment failures.

In essence, the choice of material will impact not only immediate operational efficiency but also long-term viability in oil and gas applications.

What Should Companies Consider Before Integrating It?

Before integrating zirconium silicate into your operations, several crucial considerations must be taken into account. Let’s highlight these factors: first, companies should evaluate the costs associated with sourcing high-quality zirconium silicate against the potential returns on investment. This type of analysis helps firms determine whether the initial costs will be compensated by the operational savings achieved through improved performance.

Understanding the scope of projects is also of utmost importance. Assess how zirconium silicate fits into current operational frameworks and existing materials. This assessment ensures that the introduction of the new material occurs without disrupting established processes.

Furthermore, companies should recognize the requirement for training personnel in handling the material safely and effectively. Providing staff with instruction on maintenance and operational best practices will lead to smoother transitions and enhanced workplace safety.

Lastly, staying informed of industry trends and technological advancements related to zirconium silicate will keep companies competitive in a rapidly evolving market. Continuous improvement is vital to maintaining an edge in the oil and gas industry.

How to Source Zirconium Silicate Efficiently?

Finding the right suppliers of zirconium silicate requires diligence and precision. Here’s what you need to know: initially, you should research the reputation of potential suppliers. Look for those specializing in industrial minerals with a proven track record in the oil and gas sector. High-quality materials from reputable sources often have a significant impact on overall performance.

Next, pay close attention to the quality of zirconium silicate that suppliers offer. Request samples to scrutinize for purity and performance attributes in alignment with your operational requirements. Furthermore, ensure that suppliers provide relevant certifications demonstrating adherence to quality protocols and industry standards.

While price is certainly a factor in any purchasing decision, it is essential to ensure that you do not compromise on quality. Striking the right balance allows companies to benefit from high-performing materials without exceeding budget limitations. Often, investing a bit more upfront in quality zirconium silicate will pay off through improved operational outcomes and reduced long-term costs.

By carefully sourcing this compound, companies can ensure they are utilizing the best materials available, capable of supporting their operations on multiple fronts.

Conclusion

In summary, incorporating zirconium silicate into oil and gas operations offers a plethora of advantages that can transform business outcomes. From the markedly improved material performance to the substantial reduction in operational costs, the benefits are tangible and impactful. Companies that strategically embrace this material position themselves to enhance efficiency and profitability, bringing lasting success to their projects. At Global Industry, we encourage you to reach out for tailored guidance on integrating zirconium silicate into your operations. Partnering with us fosters innovation and growth for your organization.

FAQ Section

Q1: What is zirconium silicate used for in oil and gas?

Zirconium silicate is primarily used in oil and gas operations to enhance performance and efficiency. Its exceptional heat resistance and mechanical strength make it ideal for applications such as drilling fluids and downhole components, ensuring operations run smoothly under challenging conditions.

Q2: How does zirconium silicate improve production efficiency?

Zirconium silicate improves production efficiency by increasing temperature stability and mechanical properties in various applications. This allows for better processing, minimized downtime, and reduced equipment wear, ultimately enhancing the overall productivity of oil and gas operations.

Q3: What safety considerations are there with this compound?

When working with zirconium silicate, it is essential to follow proper handling procedures to minimize risks associated with dust inhalation and skin contact. Additionally, reviewing safety data sheets (SDS) provides critical information on safe usage, disposal, and any potential hazards linked to the material.

Q4: Where can I purchase zirconium silicate for my operations?

Zirconium silicate can be purchased from specialized suppliers who focus on high-quality industrial minerals suitable for the oil and gas sector. It’s advisable to conduct thorough research, compare various vendors, and request samples before making a purchase to ensure the material meets your operational needs.

Q5: What trends are emerging regarding the use of zirconium silicate in the industry?

Emerging trends include a growing focus on sustainability and the push for more efficient materials in oil and gas operations. Innovations in material science, improved formulations, and enhanced processing techniques are driving increased interest in zirconium silicate, further promoting its adoption in the industry.