In industries that require high-performance materials, zirconium silicate stands out as a vital component. Businesses often face challenges when seeking materials that offer both durability and efficiency within extreme conditions. The quest for refractory materials that can withstand extreme temperatures, resist wear and tear, and maintain their integrity over time is paramount. Zirconium silicate addresses these concerns effectively, offering a solution that not only meets but exceeds these rigorous demands. This article provides insights into how zirconium-based materials enhance refractories, offering solutions for improved performance in critical applications. With extensive expertise in the field, we present reliable information to help you make informed decisions about materials for your operations, ensuring that you integrate the best options into your processes.

How Does Zirconium Silicate Function in Refractory Applications?

Zirconium silicate plays a significant role in the performance of refractories. Its unique properties are key to understanding its effectiveness across varied applications.

First and foremost, zirconium silicate exhibits remarkable thermal resistance. This material is engineered to withstand high temperatures without breaking down or losing its structural integrity, making it particularly ideal for applications in furnaces, kilns, and other high-temperature environments. The ability of zirconium-rich refractories to operate efficiently at temperatures exceeding 2000°C showcases their importance in industries such as metal smelting, glass manufacturing, and other heat-intensive processes.

Next, the chemical composition of zirconium silicate adds to its stability. This material maintains its integrity even when exposed to corrosive environments, which are commonplace in many industrial settings. For instance, in glass production, materials are subjected to not only intense heat but also aggressive chemical interactions. Zirconium silicate’s ability to withstand such conditions without degradation ensures that manufacturing processes run smoothly without interruptions caused by material failure.

Moreover, zirconium silicate also provides excellent mechanical strength. This strength contributes to the overall durability of refractory linings, which are often exposed to physical wear during operations. The combination of thermal stability, chemical resistance, and mechanical strength effectively positions zirconium-based materials as an invaluable asset for high-performance refractories.

Let’s dig a little deeper. Alongside these properties, zirconium silicate contributes to better energy efficiency. When used in refractory linings, it minimizes energy loss during heating. And so, businesses experience not only fewer disruptions but also substantial cost savings through reduced energy consumption.

What Are the Primary Benefits of Zirconium Silicate?

Understanding the wide-ranging benefits that zirconium silicate brings to the table can help businesses make informed decisions and ultimately enhance operational performance.

First, zirconium silicate enhances durability significantly, extending the lifespan of refractories in challenging environments. Because it can withstand extreme conditions, materials that utilize zirconium silicate require fewer replacements over time. This capacity leads to reduced maintenance costs and less downtime, which is critical for operations that depend on consistent productivity.

Next, this remarkable material improves thermal conductivity. With better heat distribution characteristics, zirconium silicate facilitates more efficient energy use in industrial applications. This improvement not only optimizes the performance of the production equipment but also contributes to energy conservation, which aligns with current sustainability goals.

Another key advantage revolves around its resistance to thermal shock. This property allows zirconium silicate to endure rapid temperature changes without cracking or degrading. Such resilience is crucial in applications where materials often face sudden increases or decreases in temperature, such as during the pouring of molten metal into molds or while transitioning in glass forming processes.

So, what does this mean for your business? By adopting zirconium-silicate-based refractories, companies can see a remarkable positive impact on their bottom line. Enhanced performance translates into lower operational costs, making it a wise investment in today’s competitive industrial landscape.

| Benefit | Explanation |

|---|---|

| Enhanced Durability | Longer lifespan reduces replacement frequency and translation costs associated with failure. |

| Improved Thermal Conductivity | Better heat distribution leads to reduced energy consumption during production. |

| Resistance to Thermal Shock | Endurance against rapid temperature changes prevents cracking in high-stress areas. |

How Is Zirconium Silicate Manufactured?

The manufacturing process of zirconium silicate directly influences its quality and performance, and understanding this process can aid businesses in making informed purchasing decisions.

The production journey begins with the extraction of ores containing zircon. Various mining techniques are employed to ensure optimal recovery of the mineral resource. Once extracted, these ores undergo a series of processes including crushing, grinding, and refining to isolate zirconium from unwanted materials.

Next, these zircon materials are subjected to chemical reactions that convert them into zirconium silicate. The steps are critical and require precision to ensure that the material retains its desired properties throughout the transition. For instance, temperature control and timing during this chemical conversion are vital to achieving the ideal grain size and uniformity.

In addition, quality control measures are woven throughout the manufacturing process. These measures are instrumental in maintaining high-performance standards. Each batch of zirconium silicate is rigorously tested for purity, consistency, and physical properties before it is deemed fit for use. This meticulous attention to detail guarantees that the end product meets the exacting standards expected in high-performance applications.

Here’s an interesting fact: The refinement process not only enhances purity but also optimizes particle size, which is vital for its effectiveness in refractory applications. Proper granulation contributes to the performance characteristics we discussed earlier, facilitating better bonding during the installation of refractories.

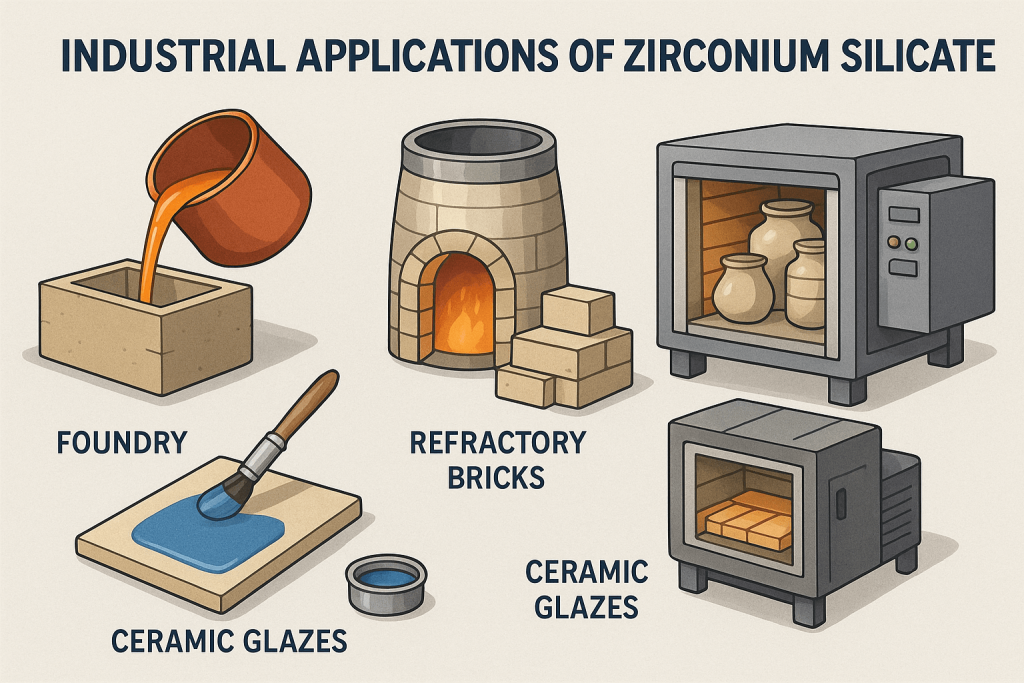

This image depicts various industrial applications of zirconium silicate, showcasing its versatile use in high-temperature environments.

| Step | Description |

|---|---|

| Mining | Extraction of zircon-rich ores utilizing sustainable practices where possible. |

| Refinement | Chemical processes that convert zircon materials into zirconium compounds with controlled conditions. |

| Quality Control | Ensuring material meets predetermined performance standards through rigorous testing. |

What Industries Utilize Zirconium Silicate Refractories?

Zirconium silicate refractories find numerous applications across various industries. Understanding these sectors can reveal where your business might benefit from this advanced material.

The metal industry relies heavily on these materials, particularly in the production of metals. They are critical in furnace linings where high temperatures and corrosive materials are commonplace. The ability to withstand extreme conditions while maintaining structural integrity makes zirconium silicate refractories invaluable in smelting operations.

Glass manufacturing is another major area where zirconium-based materials excel. The refractory linings in melting tanks experience not only intense heat but also aggressive chemical interactions with molten glass. Here, the material’s stability ensures that production processes remain uninterrupted.

Moreover, ceramics production benefits profoundly from the characteristics that zirconium silicate provides. The strength and resistance to thermal shock make it a preferred component in tiles and advanced ceramics that undergo high-temperature firing processes.

Don’t overlook applications in petrochemical processes, where refractories require extreme heat resistance and chemical stability. In these environments, the materials also encounter fluctuating temperatures and process conditions, further exemplifying the versatility of zirconium silicate refractories.

| Industry | Application |

|---|---|

| Metal Manufacturing | Furnace linings for casting, smelting, and refining metals under intense heat. |

| Glass Production | Linings in melting tanks, ladles, and other critical equipment requiring heat resistance. |

| Ceramics Production | Strong materials for tiles, sanitary ware, and high-fire ceramics. |

| Petrochemical | Refractories for reactors and heat exchangers operating under harsh conditions. |

How Do Zirconium Silicate Refractories Compare to Alternatives?

Evaluating zirconium silicate against alternative materials reveals essential insights that can significantly impact operational effectiveness.

When compared to alumina refractories, zirconium-based materials typically display superior thermal stability. While alumina is a popular choice in the industry, it often falls short under extreme temperatures and when encountering corrosive substances. This limitation can be particularly critical during high-temperature metal processing where material failure could lead to production delays or quality issues.

Silica refractories also present their own challenges. While they are cost-effective, they often cannot withstand thermal shock as effectively as zirconium silicate. This vulnerability can lead to cracks and failures, especially in industries that rapidly cycle through extreme temperature changes.

Here’s the bottom line: Choosing zirconium silicate can enhance operational efficiency and product quality. The longevity and durability contribute to lower total costs when contrasted with using alternative materials. Additionally, the ability to integrate zirconium silicate into existing systems with minimal disruption provides a strategic advantage.

| Material | Pros | Cons |

|---|---|---|

| Zirconium Silicate | High thermal stability, corrosion resistance | Typically carries a higher initial cost compared to alternatives |

| Alumina | Good thermal shock resistance | Less effective at extreme temperatures |

| Silica | Generally lower cost | Lower stability and performance at high temperatures |

What Are the Environmental Considerations of Using Zirconium Silicate?

In today’s manufacturing landscape, environmental considerations are becoming increasingly vital for both ethical and practical reasons.

Zirconium silicate can be produced with sustainable practices in mind. Companies that prioritize environmentally friendly methods can minimize their impact on natural resources. By utilizing more efficient mining and processing techniques, manufacturers can limit energy consumption and waste generation.

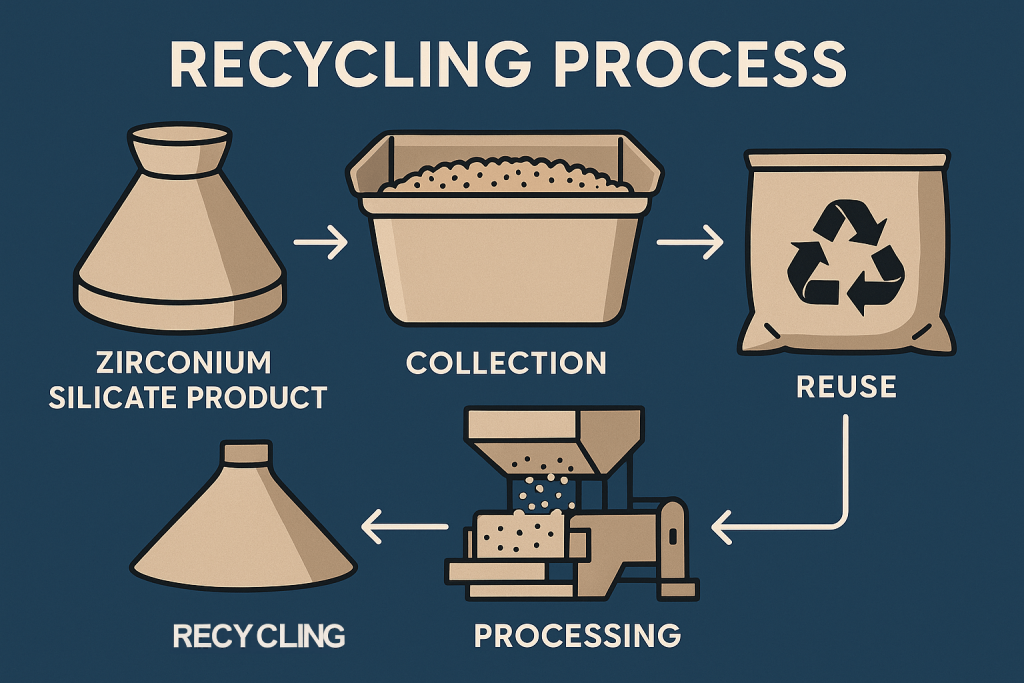

Additionally, zirconium-based refractories can often be recycled at the end of their lifecycle. This recycling capability aligns with sustainability initiatives, promoting a circular approach to material use. When old refractories are repurposed or reused, less material ends up in landfills, benefiting both the environment and the bottom line.

Let’s emphasize that these materials can be processed and repurposed into various applications once they reach the end of their useful life. This capability reduces landfill waste and exemplifies the growing trend toward sustainable practices in manufacturing.

| Environmental Factor | Details |

|---|---|

| Sustainable Production | Focus on eco-friendly mining and processing methods that conserve resources. |

| Recyclability | Many products can be recycled and repurposed for secondary uses. |

| Compliance | Meeting regulatory standards for environmental protection and sustainability. |

This image shows the recycling process of zirconium silicate products, demonstrating their sustainability in manufacturing.

How Can Businesses Choose the Right Zirconium Silicate Product?

Choosing the right zirconium silicate product requires careful consideration of multiple factors that will drive performance and return on investment.

First, companies should evaluate their specific application requirements. Different environments may demand distinct features from refractories. Understanding the thermal, mechanical, and chemical demands of your processes will guide you toward the most suitable product.

Next, supplier credibility plays a significant role in ensuring quality and performance. Engaging with reputable manufacturers who adhere to strict quality control practices can make a substantial difference. Look for suppliers that provide transparency regarding their production processes and have a proven track record in the industry.

Furthermore, options for customization can add significant value. Some suppliers offer tailored solutions that cater specifically to the operational needs of different industries. Investigating these customization options can lead to improved performance and cost-effectiveness. Most importantly, proper consultation with your supplier can ensure that the materials used align perfectly with the operational demands.

| Selection Factor | Consideration |

|---|---|

| Application Requirements | Analyze the specific conditions and challenges to select the best refractories. |

| Supplier Reputation | Confirm quality control standards and the reliability of sourcing. |

| Customization Options | Explore tailored solutions that can sustainably address unique needs. |

What Are Common Misconceptions About Zirconium Silicate?

Addressing common misconceptions helps businesses make more informed choices when considering materials for high-performance applications.

One prevalent belief is that zirconium silicate is prohibitively expensive for many operations. While it may have a higher initial acquisition cost compared to other materials, the long-term benefits often outweigh this investment. The durability and performance lifecycle can significantly reduce total operational costs through fewer replacements and improved efficiencies.

Another misconception is the belief that zirconium silicate lacks effectiveness compared to other refractories. In reality, extensive research has supported its performance advantages under extreme conditions. This evidence indicates that businesses can trust in zirconium silicate’s reliability, especially in critical applications where failure is not an option.

It’s essential to clarify these misconceptions as they can hinder businesses from realizing the potential benefits. Educating teams about the features and real-world effectiveness of zirconium silicate can lead to better decision-making and increased operational success.

| Misconception | Reality |

|---|---|

| High Initial Cost | Long-term savings and performance reliability typically offset the upfront expense. |

| Ineffective Performance | Extensive evidence supports strong performance advantages in extreme conditions. |

What Future Trends Are Emerging in Zirconium Silicate Usage?

Emerging trends indicate a dynamic future for the use of zirconium in refractory applications.

Innovations in production technologies are likely to enhance the efficiency and sustainability of the manufacturing process for zirconium compounds. New methods that focus on reducing energy use and minimizing environmental impacts can play a pivotal role in making zirconium silicate more accessible and affordable.

Moreover, anticipated advancements in the performance features of zirconium-based materials are on the horizon. Researchers are continuously exploring ways to enhance the properties of these materials, such as improving thermal resistance and mechanical strength. These advancements will likely expand the applicability of zirconium silicate into even more demanding environments.

Keeping an eye on market trends will prove beneficial in this context. As industries respond to changing demands, the need for high-performance materials like zirconium silicate is expected to grow, leading to new applications and opportunities. Being at the forefront of these trends can position businesses for greater success and technological relevance.

| Trend | Description |

|---|---|

| Innovative Production | New technologies being adopted for greater efficiency and environmental sustainability. |

| Advancements in Performance | Research continues to improve thermal and mechanical properties of materials. |

| Rising Demand | As industries evolve, the need for high-performance materials will become more pronounced. |

How Can Companies Optimize Their Use of Zirconium Silicate Refractories?

Optimizing the use of zirconium silicate refractories is crucial for enhancing operational efficiency and realizing return on investment.

First, implementing best practices during installation can maximize performance. Utilizing a qualified workforce familiar with zirconium applications can ensure correct placement and alignment, reducing the likelihood of future failures.

Next, ongoing maintenance should not be overlooked. Establishing regular assessments can help identify any wear or damage before they escalate into costly problems. Creating a maintenance schedule that aligns with operational demands can streamline this process, making it efficient and effective.

Finally, consider periodic upgrades to incorporate new technologies or formulations. Staying informed about developments in refractory materials allows companies to enhance their operational efficiency. Businesses that invest time in optimizing their processes, while keeping pace with the latest innovations, are likely to see improved performance outcomes over the long term.

| Optimization Strategy | Benefits |

|---|---|

| Best Installation Practices | Increases reliability and performance longevity. |

| Regular Maintenance | Early detection of issues minimizes downtime and repair costs. |

| Periodic Upgrades | Access to innovative advancements ensures continued efficiency. |

Conclusion

In summary, zirconium silicate offers numerous benefits for high-performance refractories. Its unmatched durability, thermal stability, and resistance to corrosive environments make it the material of choice for industries demanding reliability and efficiency. By integrating zirconium-based materials into operations, businesses can expect long-term cost savings and improved product quality. Identify how Global Industry can assist you in leveraging these materials to optimize your operations. Reach out today to discover the best strategies and solutions tailored for your specific needs.

FAQ Section

Q1: What makes zirconium silicate a preferred choice for refractories?

Zirconium silicate is favored for its remarkable thermal stability and high resistance to corrosion. These properties enable it to withstand extreme temperatures and aggressive chemical environments, which are critical in industries like metal processing and glass manufacturing. Its durability also extends the lifespan of refractory linings, reducing maintenance needs.

Q2: Are zirconium silicate refractories environmentally friendly?

Yes, zirconium silicate refractories can be produced using sustainable practices that minimize resource depletion and waste generation. Additionally, many of these products are recyclable, contributing to a more circular economy. By reusing materials, businesses can reduce their environmental impact while maintaining operational efficiency.

Q3: How does zirconium silicate compare to traditional materials like alumina?

Compared to alumina, zirconium silicate typically offers superior thermal stability and resistance to thermal shock. While alumina can suffice in some high-temperature applications, it may not stand up as reliably under corrosive conditions. This makes zirconium silicate a more effective choice for demanding applications in sectors such as metallurgy and ceramics.

Q4: What industries benefit most from zirconium silicate refractories?

Zirconium silicate refractories are advantageous in industries such as metal manufacturing, glass production, ceramics, and petrochemicals. Each of these sectors requires materials that can withstand high temperatures and harsh chemical environments, making zirconium silicate a critical component in their processes.

Q5: Can zirconium silicate be customized for specific applications?

Absolutely. Many suppliers offer customized zirconium silicate solutions tailored to meet the unique requirements of various applications. This customization may include adjustments to particle size, formulation, or thermal properties, ensuring that the materials align perfectly with the specific needs of a given process or environment.