Environmental regulations play a vital role in the manufacturing sector, particularly in the production of materials like zirconium silicate. Many companies face significant challenges in complying with these rules, often worrying about their operational flexibility and bottom line. The complexity of environmental regulations can create an environment of uncertainty, leading businesses to seek clarity on how to navigate compliance without sacrificing productivity.

In this article, we will explore the real and profound impact of environmental regulations on zirconium silicate production. By providing insights into regulatory requirements, industry best practices, and the role of technology, this content aims to equip businesses with the knowledge they need to thrive while maintaining compliance. We draw on industry expertise to offer valuable information that can enhance your understanding and guide you in effectively managing environmental regulations.

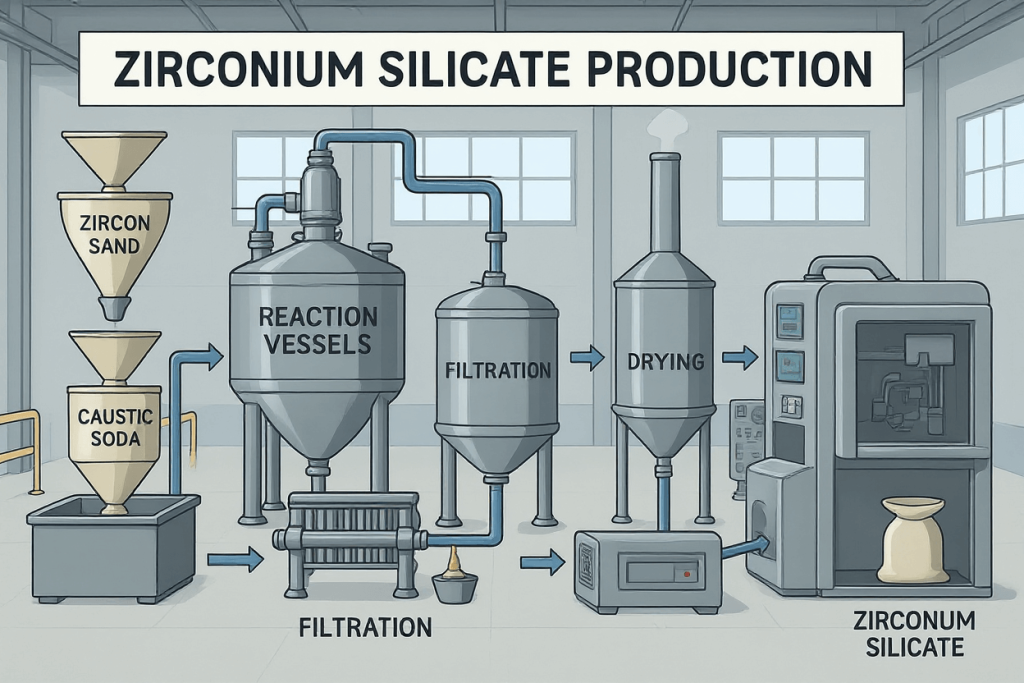

An image showcasing the zirconium silicate production process in a modern manufacturing facility.

What Are Environmental Regulations in Manufacturing?

Environmental regulations are a set of laws and guidelines designed to protect the environment from harmful industrial practices while balancing economic growth. These regulations aim to control pollution levels, manage resource usage, and promote sustainability in manufacturing processes. Established by governmental bodies at local, national, and international levels, these laws ensure that manufacturers operate responsibly and mitigate their environmental impact.

Different types of environmental regulations directly influence manufacturing activities. These include:

- Air Quality Standards: Regulations that control emissions of pollutants from manufacturing facilities to protect air quality. These standards often dictate permissible levels of various contaminants, requiring companies to implement emission control measures.

- Waste Management Regulations: Rules governing the disposal and treatment of hazardous and non-hazardous waste. Companies must adhere to specific protocols for waste segregation, recycling, and disposal to minimize environmental harm.

- Water Quality and Conservation Regulations: Legislation aimed at protecting water sources from contamination. Businesses must comply with standards that dictate how they manage wastewater and stormwater runoff.

Key regulatory bodies such as the Environmental Protection Agency (EPA) in the United States, the European Environment Agency (EEA) in Europe, and various local authorities play significant roles in setting and enforcing these regulations. They require manufacturers to monitor their environmental impact continuously and maintain compliance to help protect public health and ecosystems.

Takeaway: Understanding these regulations allows businesses to make informed decisions, leading to smoother operations and avoiding costly fines associated with non-compliance.

| Type of Regulation | Purpose | Example |

|---|---|---|

| Air Quality Standards | Manage emissions to protect air quality | Clean Air Act |

| Waste Management Laws | Control hazardous waste disposal | Resource Conservation and Recovery Act |

| Water Quality Standards | Ensure safe water discharge and usage | Clean Water Act |

How Do Environmental Regulations Affect Zirconium Silicate Production?

Zirconium silicate production is subject to various regulatory requirements that can significantly impact its processes and operational capabilities. Understanding these implications is essential for manufacturers seeking to remain compliant while achieving their production goals efficiently.

The production process of zirconium silicate typically involves several stages, each of which can be affected by specific environmental regulations. For example, this includes the extraction of zircon from mineral sands, the processing of this raw material, and the final production of zirconium silicate products. Compliance with regulations must be integrated at every stage to not only meet legal requirements but also ensure product safety, which is crucial for customer trust and market access.

Companies must prepare for regular inspections and audits by regulatory bodies to demonstrate adherence to environmental standards. This process may involve maintaining detailed records of operational activities, emissions data, and waste disposal practices. For instance, organizations should conduct periodic internal audits to verify compliance with air quality standards and engage trained professionals to assess compliance risks.

Noteworthy case studies reveal the profound effects of regulations on zirconium silicate companies. One well-known example involved a manufacturer in Australia who faced fines due to excessive emissions from its production facility. By investing in advanced emission control technologies and adopting greener production processes, the company not only resolved compliance issues but also reduced operational costs significantly. Such investments can yield improvements in efficiency through better resource management.

Key takeaway: Proactive compliance minimizes risks, enhances production quality, and can improve the overall efficiency of production operations.

| Stage of Production | Regulatory Challenge | Compliance Strategy |

|---|---|---|

| Mining | Land disturbance and waste management | Sustainable mining practices |

| Processing | Emissions and effluent control | Advanced filtration and monitoring |

| Final Product Storage | Hazardous waste regulations | Proper labeling and disposal methods |

What Are the Key Compliance Challenges for Producers?

Manufacturers of zirconium silicate face several compliance challenges. These challenges stem from complex regulations, which can vary by region and frequently change due to evolving environmental priorities and increased awareness.

Navigating the myriad of regulations often requires considerable time, expertise, and resources. Smaller or even medium-sized companies may struggle due to limited personnel who can stay updated on compliance requirements. Misinterpretations of regulations can lead to inadvertent non-compliance, with significant legal and financial penalties.

Common difficulties include:

- Maintaining Accurate Records: Companies must keep precise documentation of emissions, waste disposal, and compliance efforts. This can become overwhelming, especially without a streamlined system for data management.

- Understanding Complex Regulations: The evolving nature of regulations can lead to confusion. Companies may find it challenging to interpret the legal language and practical implications of various rules.

- Training Staff on Regulations: Ensuring that employees are informed about compliance protocols and the importance of adhering to regulations adds another layer of complexity. This is especially true in larger companies with multiple departments involved in the compliance process.

To address these challenges, companies should establish a clear internal compliance framework. This can include hiring environmental compliance officers who specialize in navigating regulatory complexity, conducting regular training sessions for employees about updated regulations, and utilizing compliance management software that centralizes documentation and reporting processes.

So what’s the solution? Building a structured compliance program with clearly defined roles and responsibilities is essential for any zirconium silicate production facility.

| Compliance Challenge | Impact on Production | Suggested Solution |

|---|---|---|

| Record-keeping | Risk of penalties for non-compliance | Implement efficient data management systems |

| Emergency Preparedness | Potential environmental disasters | Regular drills and contingency plans |

| Staff Training | Knowledge gaps on regulations | Ongoing employee training sessions |

How Can Companies Prepare for Regulatory Changes?

The regulatory landscape constantly evolves, prompting companies in zirconium silicate production to stay informed and prepared. Understanding the potential changes and proactively adapting ensures compliance and helps maintain operational efficiency.

Identifying potential regulatory changes involves a multi-faceted approach. Companies should keep an eye on industry news, participate in relevant workshops and conferences, and maintain relationships with industry associations that provide updates on pending regulations. Engaging with regulatory agencies through public comment periods can also provide early insights into proposed changes.

Developing internal policies tailored to address these regulations is crucial. This may include creating detailed standard operating procedures with actionable compliance steps, conducting regular risk assessments to identify vulnerabilities, and establishing clear reporting lines for compliance-related issues.

Training staff on the latest regulations is paramount. Holding workshops on compliance topics, including safety practices regarding emissions and resource usage, prepares employees to adapt to any changes effectively. Ongoing education ensures that everyone within the organization is informed about the significance of compliance and the potential ramifications of non-compliance.

Remember: Being proactive in regulatory preparedness is far more effective than reacting only when compliance issues arise.

| Preparation Strategy | Description | Expected Outcome |

|---|---|---|

| Regulatory Monitoring | Regularly review upcoming regulatory changes | Staying compliant and informed |

| Internal Policy Development | Create tailored procedures for new regulations | Streamlined compliance management |

| Staff Training Initiatives | Offering workshops on new compliance topics | Improved employee knowledge and readiness |

What Are the Potential Financial Impacts of Regulations?

Financial implications of environmental regulations can significantly affect zirconium silicate producers, altering their budgetary allocations and overall financial health. Compliance costs can pose a financial burden, especially for smaller businesses operating on tight margins.

The initial costs of compliance vary widely and can include investments in emission control technologies, waste management systems, and other compliance measures. While these expenses might deter some from pursuing full compliance, failing to do so can lead to far greater costs in terms of penalties and operational disruptions.

However, the benefits of compliance often outweigh the initial outlays in the long run. Reducing penalties through compliance safeguards a company’s financial future. Moreover, adhering to sustainable practices enhances brand reputation and can attract customers who prioritize environmental responsibility in their purchasing decisions.

Businesses should regularly evaluate their compliance strategies from a financial perspective. This involves assessing both short-term and long-term financial impacts, exploring funding opportunities for sustainability projects, and identifying potential cost savings through improved operational efficiency.

Key takeaway: Effective compliance contributes to financial stability while opening avenues for potential growth opportunities.

| Financial Impact | Description | Strategy for Mitigation |

|---|---|---|

| Compliance Implementation Costs | Initial expenses on systems and technologies | Budget for compliance in planning |

| Penalties for Non-Compliance | Financial repercussions from violations | Maintain transparent operations with accurate records |

| Long-term Savings | Potential cost savings through sustainable practices | Invest in technologies that improve efficiency |

How Can Technology Assist in Compliance Efforts?

Technology plays a pivotal role in meeting and maintaining compliance with environmental regulations in zirconium silicate production. Utilizing various software solutions and technological advancements simplifies compliance processes and makes them more efficient.

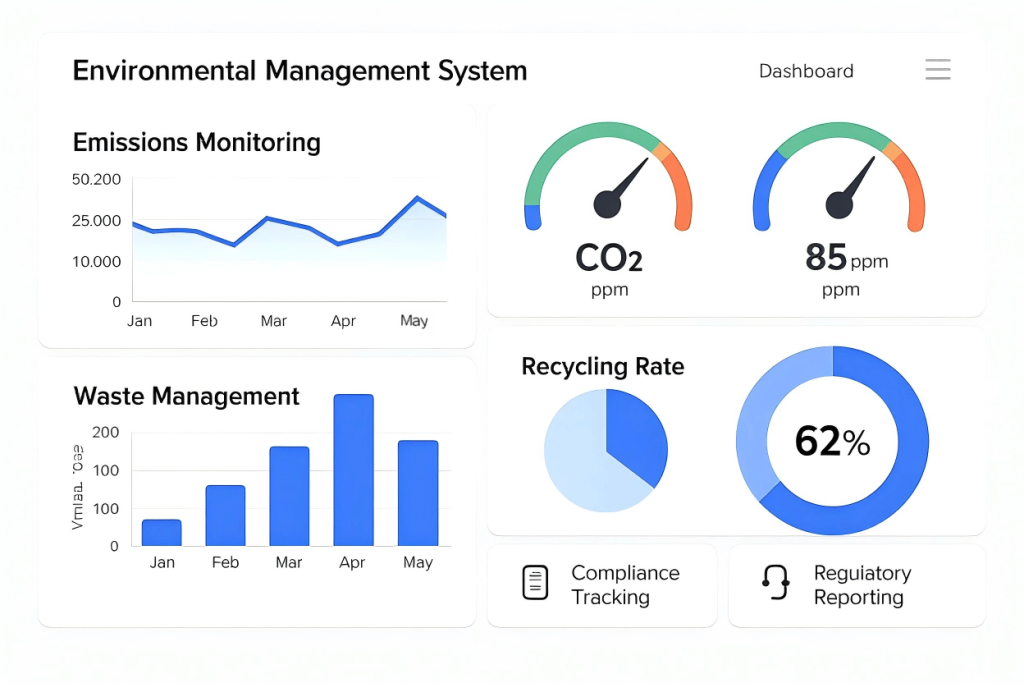

Environmental management systems (EMS) help companies continuously monitor their environmental performance. These systems enable real-time tracking of emissions, waste management, and compliance with applicable laws, ensuring that manufacturers can quickly respond to situations before they escalate.

Automated reporting tools save time and reduce administrative burdens by simplifying the generation of compliance documentation. These tools enhance accuracy and allow environmental officers to focus on strategic compliance efforts rather than getting bogged down in paperwork.

Predictive analytics can foresee potential compliance breaches by analyzing data trends, enabling organizations to implement corrective actions proactively. This reduces the risk of non-compliance and fosters a culture of vigilance regarding environmental responsibilities.

Investing in technology not only enhances compliance efforts but also creates opportunities for operational efficiency. Companies that embrace these advancements can remain agile and responsive to changes in regulatory requirements while maintaining productivity and profitability.

To sum it up: Leveraging technology can significantly improve compliance efforts and operational efficiency, leading to more streamlined production processes.

| Technology Type | Benefits | Examples |

|---|---|---|

| Environmental Management Systems | Continuous monitoring of compliance | ISO 14001 certified systems |

| Automated Reporting Tools | Reduces manual errors in documentation | Software like Envirosite |

| Predictive Analytics | Foresees compliance issues | Data analytics platforms |

Visualization of an environmental management system monitoring emissions and waste, showcasing technological support for compliance.

What Are Best Practices for Sustainable Zirconium Production?

Adopting sustainable practices in zirconium silicate production not only helps ensure compliance with environmental regulations but also improves overall ecological impact. It is increasingly crucial for companies to incorporate sustainability into their operations for long-term viability and growth.

The journey begins with responsible mining practices. This may involve reducing land disturbances, protecting biodiversity, and rehabilitating mined areas. Engaging with local communities is also a best practice, ensuring that operations align with environmental priorities and community standards.

Energy efficiency plays a vital role in sustainability. Using renewable energy sources like solar or wind not only reduces carbon footprints but also can lead to lower energy costs over time. Additionally, implementing energy-efficient processes throughout production can decrease waste generation significantly.

Regular reviews of production processes are essential for identifying areas where sustainability can be improved. Companies may seek to implement closed-loop systems that recycle materials and minimize waste. Emphasizing corporate social responsibility throughout the supply chain can encourage suppliers to adopt similar sustainable practices.

Here’s an important note: Sustainable methods not only help meet compliance demands but also differentiate companies in an increasingly competitive market.

| Sustainable Practice | Description | Benefits |

|---|---|---|

| Responsible Mining Practices | Reducing land disruption and rehabilitating previously mined areas | Improved public perception |

| Energy Efficiency Initiatives | Utilizing renewable energy and energy-efficient processes | Lower operating costs |

| Waste Reduction Strategies | Implementing recycling and waste minimization programs | Environmental impact reduction |

A visual representation of sustainable mining practices, highlighting rehabilitation and responsible land use techniques.

How Do Regulations Affect Competitive Advantage?

Adhering to environmental regulations can provide a significant competitive advantage in the zirconium silicate market. Companies that prioritize compliance and sustainability often outperform those that do not focus on these areas.

Compliance fosters trust and transparency, enhancing brand reputation among customers. Companies that actively showcase their environmental responsibility often attract businesses that prioritize sustainability in their supply chains. This growing trend means offering compliant and eco-friendly products can expand market reach and customer loyalty.

Moreover, the marketplace is becoming increasingly scrutinous about environmental practices. Those compliant with regulations can position themselves as industry leaders, appealing to environmentally-conscious buyers and investors alike. They benefit from positive public relations that highlight their commitment to responsible operations.

By investing in sustainable practices, firms can differentiate themselves from competitors. Leveraging marketing strategies that highlight compliance and environmental commitment enables companies to strengthen their market position while reducing regulatory risks.

Strategies to Leverage Compliance for Competitive Advantage:

- Promote Sustainability Initiatives: Share success stories around sustainability efforts in marketing.

- Engage in Industry Partnerships: Collaborate with organizations that support environmental responsibility.

- Educate Customers: Provide transparency about processes and compliance measures to foster customer trust.

In summary: Compliance is not merely an obligation; it serves as a pathway for companies to enhance their visibility and competitiveness in the industry.

| Competitive Advantage | Highlight | Marketing Strategy |

|---|---|---|

| Brand Trust and Reputation | Enhanced public image through compliance | Promoting sustainability initiatives |

| Access to Green Certifications | Meeting standards to obtain environmental certifications | Targeting businesses focused on sustainability |

| Differentiation from Competitors | Establishing a unique market position | Capitalizing on compliance in marketing |

What Resources Are Available for Navigating Regulations?

Numerous resources exist to help businesses navigate the complexities of environmental regulations related to zirconium silicate production. Understanding where to find these resources is invaluable for ensuring compliance and effective operations.

Government agencies such as the EPA and EEA continually publish guidelines and updates regarding relevant regulations. Their websites often provide access to comprehensive regulatory databases, offering tools and resources to help companies remain compliant.

Industry associations also provide rich information on compliance resources. Groups like the American Ceramic Society or similar organizations in other countries share best practices, case studies, and tools specifically designed for businesses in the ceramic and materials sectors. These associations often provide members with access to workshops, training sessions, and critical updates concerning regulatory changes.

Webinars, workshops, and conferences hosted by both government and industry bodies delve into regulatory issues, offering presentations by experts in the field. Many companies also offer specialized consulting services to assist manufacturers with their unique compliance challenges, improving the quality and timeliness of compliance efforts.

For manufacturers, these resources can equip them with essential knowledge and support in regulatory compliance, making the path towards adherence clearer and more accessible.

| Resource Type | Description | Notable Examples |

|---|---|---|

| Government Resources | Guidelines and regulations from official sources | EPA and EEA websites |

| Industry Associations | Best practice sharing and network support | American Ceramic Society |

| Consulting Services | Professional assistance in compliance | Environmental consultancy firms |

How Can Stakeholders Influence Regulatory Outcomes?

Stakeholders play significant roles in shaping environmental regulations affecting zirconium silicate production. Understanding their roles and leveraging their influence can help companies navigate the regulatory process more effectively.

Businesses can advocate for practical and feasible regulations by voicing concerns and suggestions during public consultations or stakeholder meetings. Active participation in industry meetings can help align business needs with regulatory expectations, promoting a collaborative approach to compliance.

Community members also have a vital voice in regulatory discussions. Engaging local residents in environmental impact assessments fosters transparency and builds trust. Listening to community concerns can lead to better regulatory outcomes that consider externalities and societal impacts.

Furthermore, aligning with industry groups amplifies the voices of specific sectors regarding important regulatory issues. Grassroots advocacy initiatives can lead to changes that better support both environmental responsibility and business interests.

To maximize their influence on regulations, companies should establish relationships with industry regulators and participate in lobbying efforts. By engaging stakeholders effectively, organizations can significantly shape regulatory frameworks while meeting sustainability goals.

| Stakeholder Type | Role in Regulation | Influence Method |

|---|---|---|

| Businesses | Advocating for practical regulations | Engaging in regulatory consultations |

| Communities | Participating in impact assessments | Providing local insights |

| Industry Groups | Strengthening collective influence | Lobbying efforts |

Conclusion

This comprehensive examination of the impact of environmental regulations on zirconium silicate production emphasizes that businesses face a complex landscape of compliance challenges. The discussion has highlighted critical aspects such as regulatory implications, the role of technology, and sustainable practices. Each of these elements plays a pivotal role in helping companies optimize processes while ensuring compliance with regulatory standards.

A key benefit of actively managing compliance is the potential for improved financial stability and enhanced corporate reputation. At Global Industry, we offer valuable resources and tailored support to help your business thrive in a constantly evolving regulatory environment. For further assistance or to schedule a consultation, reach out today, and let us partner together to strengthen your compliance strategy.

FAQ Section

Q1: What are the main environmental regulations affecting Zirconium production? There are several key regulations related to emissions, waste disposal, and resource usage that affect Zirconium production. Stakeholders must comply with local, national, and international environmental standards to ensure sustainable operations while minimizing their impact.

Q2: How can producers reduce costs related to compliance? Producers can reduce costs by investing in efficient technologies, streamlining processes, and implementing internal audits. These practices help identify and rectify compliance issues early, ultimately leading to cost savings through improved operations.

Q3: What technologies can assist with compliance monitoring? Technologies such as environmental management systems, automated reporting tools, and predictive analytics software can significantly aid in monitoring compliance with environmental regulations, ensuring businesses stay informed and proactive in their efforts.

Q4: How do environmental regulations impact the supply chain? Regulations can affect sourcing, logistics, and production schedules. Companies must assess their supply chains to ensure compliance at every stage, which may involve making necessary adjustments in supplier partnerships and procurement strategies.

Q5: What role do stakeholders play in shaping environmental regulations? Stakeholders, including businesses, regulators, and community members, can collaborate effectively to influence the development and enforcement of environmental regulations by providing feedback, sharing best practices, and advocating for practical approaches that balance sustainability with economic growth.