In today’s competitive environment, understanding which supplier certification standards matter most in zirconia powder procurement can be a game-changer for businesses. Many decision-makers, such as purchasing managers, face challenges when evaluating potential suppliers and ensuring product quality. This article aims to clarify the necessary certification standards and their significance in securing reliable high-quality zirconia powder. You will find actionable insights backed by industry knowledge, enabling you to make informed decisions that reinforce product integrity and supplier relationships.

What Are Supplier Certification Standards?

Supplier certification standards play a pivotal role in the procurement process. These are specifications and criteria that suppliers must meet to demonstrate they can provide quality products reliably and consistently.

The foundation of supplier certification lies in establishing trust between buyers and sellers. When a supplier holds a certification, it indicates they have undergone rigorous evaluations, confirming their management systems and processes align with industry standards. Consequently, businesses can confidently select suppliers who are committed to quality.

Different standards exist to ensure that suppliers adhere to best practices across various industries. These may relate to quality control, safety, or environmental management. Recognizing which certifications are pertinent to your industry can greatly affect procurement outcomes, ensuring the materials you source meet all necessary specifications.

The importance of supplier certification cannot be overstated. They help identify trustworthy suppliers while minimizing risks associated with procurement. By choosing certified suppliers, companies can expect better compliance with industry regulations and improved overall product quality.

Key Benefits of Supplier Certification Standards:

- Quality Assurance: Certifications often indicate a commitment to high production standards.

- Regulatory Compliance: Helps ensure adherence to local and international laws.

- Risk Mitigation: Reduces the likelihood of procurement issues related to product failure.

- Supplier Credibility: Established standards increase the trustworthiness of suppliers.

- Market Competitiveness: Certified materials often enhance your company’s reputation.

One key aspect to understand is the difference between national and international certifications. International standards, like ISO and ASTM, set a globally recognized benchmark, making them essential for businesses operating on a global scale. Therefore, knowing the various types of supplier certification standards is critical for ensuring a successful procurement strategy.

In summary, supplier certification standards are not just formalities; they represent a commitment to quality and consistency that is indispensable in today’s market.

This image illustrates the importance of supplier certification standards in procurement.

Why Do Supplier Certifications Matter in Zirconia Powder Procurement?

Supplier certifications are vital in zirconia powder procurement due to their direct impact on product quality and reliability. First, certified suppliers often maintain better quality control processes. This leads to consistent product performance and minimizes variations that could affect your end products.

Additionally, certifications help manage regulatory compliance, ensuring that suppliers adhere to relevant laws and guidelines. This proactive compliance not only reduces the liability risk for your business but also fosters a safer working environment for all stakeholders involved.

Another significant factor is the impact on supplier selection. By focusing on certified suppliers, businesses can streamline their procurement processes. Certified suppliers typically have established credibility within the industry; this can save time and resources in the long run, allowing for faster procurement cycles. Moreover, this selective approach helps build a network of trustworthy partners, thus enhancing supply chain reliability.

Furthermore, working with certified suppliers enhances your company’s reputation. Clients and customers increasingly demand proof of quality and ethical standards. Assurance that the products they purchase meet specific certification criteria can significantly impact their decision-making process. Using certified zirconia powder not only improves trust but also strengthens brand loyalty.

Key Benefits of Supplier Certifications in Zirconia Powder Procurement:

- Enhanced Quality Control: Consistent product performance through established quality processes.

- Regulatory Compliance: Reduced risk of legal issues and improved safety standards.

- Streamlined Supplier Selection: Faster procurement cycles by relying on reputable, certified partners.

- Improved Brand Reputation: Increased customer trust and loyalty through documented quality assurances.

In summary, embracing supplier certifications is not just about compliance; it’s an integral part of building a robust and reliable procurement strategy that propels business success.

Which Certification Standards Are Most Relevant for Zirconia Powder?

When it comes to zirconia powder procurement, several key certification standards stand out. Understanding these can guide your supplier evaluation effectively.

1. ISO Standards

The ISO (International Organization for Standardization) standards, particularly ISO 9001, focus on quality management systems. This ensures that suppliers have systematic processes to deliver consistent products. Adhering to ISO standards symbolizes a commitment to continuous improvement and customer satisfaction, enhancing overall trust.

Another essential standard is ISO 13485, which is particularly relevant if your powder will be used in medical applications. This standard assures that a supplier complies with the specific requirements for producing medical devices, ensuring that zirconia powder meets the safety and quality needed in such sensitive areas.

2. ASTM Standards

ASTM (American Society for Testing and Materials) standards also play an important role. For instance, ASTM F1151 outlines essential specifications for zirconia ceramic materials, focusing on mechanical properties, strength, and consistency. This standard is crucial for applications requiring high-performance materials, such as in aerospace or biomedical fields.

3. Industry-Specific Certifications

In addition to ISO and ASTM standards, several industry-specific certifications may be important. These certifications focus on the unique requirements of sectors like automotive, aerospace, and dental applications.

- Automotive Standards: Certifications such as IATF 16949 ensure that suppliers meet the rigorous quality management requirements prevalent in the automotive sector.

- Aerospace Standards: AS9100 certification ensures that the manufacturing processes comply with aerospace quality standards.

- Medical Device Certifications: In the healthcare industry, Biocompatibility standards may apply to ensure the safety of materials used in medical applications.

Summary Table of Key Certification Standards

| Certification Standard | Focus Area | Application |

|---|---|---|

| ISO 9001 | Quality Management | General procurement and manufacturing |

| ISO 13485 | Medical Applications | Medical devices and healthcare products |

| ASTM F1151 | Mechanical Properties | High-performance ceramics |

| IATF 16949 | Automotive Quality Management | Automotive components |

| AS9100 | Aerospace Quality Management | Aerospace and defense products |

By understanding these certification standards, you can effectively assess potential suppliers, ensuring compliance, quality, and reliability in your zirconia powder procurement.

How Can Certifications Impact Your Procurement Process?

The impact of certifications on the procurement process can be profound. First, having a certified supplier can facilitate smoother negotiations. When suppliers have recognized certifications, it provides a level of assurance that their products meet quality benchmarks. This can lead to fewer conflicts and a more straightforward buy-sell relationship.

Moreover, certifications can enhance supply chain transparency. Suppliers with certifications often provide documentation proving their compliance. This fosters trust and opens the door for better collaboration between you and your suppliers. A transparent relationship allows for more effective communication and quicker problem resolution when issues arise.

In the long term, working with certified suppliers pays off in terms of reliability. You can count on consistent product quality, which ultimately translates to fewer disruptions in your supply chain. This is particularly crucial during times of peak demand when you rely on timely delivery and consistent performance.

Additionally, using certified suppliers minimizes risks associated with quality failures and non-compliance. Businesses can avoid costly recalls or legal repercussions, ultimately protecting their bottom line.

Lastly, utilizing certified suppliers can lead to enhanced innovation within your supply chain. Suppliers that are committed to maintaining their certifications often invest in research and development, resulting in improved product offerings.

| Benefit of Certification | Description |

|---|---|

| Smoother Negotiations | Streamlined discussions due to defined standards. |

| Enhanced Trust | Clear documentation promotes confidence. |

| Reduced Supply Chain Disruption | Consistent quality minimizes operational hiccups. |

| Lower Risk of Legal Issues | Compliance avoids costly penalties and recalls. |

| Catalyst for Innovation | Investing partners lead to improved products. |

By prioritizing supplier certifications, you can reap significant benefits that enhance your procurement process and contribute to long-term business success.

What Challenges Can Arise with Supplier Certifications?

While supplier certifications offer many benefits, challenges can arise in verifying those certifications. One common issue is the authenticity of claims made by suppliers. Some may present misleading information or outdated certifications, leading to potential risks in procurement. It’s crucial to be vigilant in scrutinizing the certifications to ensure they are current and valid.

Addressing discrepancies in certification can be challenging, especially if you have established a relationship with a supplier who claims compliance. This is why due diligence in supplier evaluation is essential. Conducting thorough checks and regular audits can help mitigate these risks.

Another problem can arise from changes in regulations or standards themselves. Certifications that were once relevant might become obsolete, necessitating a reevaluation of your suppliers to ensure ongoing compliance. It’s vital to stay informed about any industry changes that could affect supplier certification requirements.

Additionally, some smaller suppliers may struggle to meet required certification standards due to resource constraints. This limitation could result in fewer options and potential delays in finding adequate suppliers. It’s important to balance the drive for certified suppliers with the flexibility to work with promising smaller businesses that have strong potential but may not yet have all certifications in place.

Here are some challenges to consider:

- Verification of Claims: Ensuring that suppliers are not misleading in their certification statuses.

- Regulatory Changes: Keeping up with evolving regulations that may impact existing certifications.

- Resource Constraints: Smaller suppliers may have difficulty achieving or maintaining certifications.

To mitigate these risks, you must incorporate a thorough verification process during supplier selection and maintain regular reassessments of their compliance status.

| Challenge | Potential Consequence |

|---|---|

| Misleading Supplier Claims | Increased risk of quality issues |

| Regulatory Changes | Non-compliance leading to legal penalties |

| Limited Options from Smaller Suppliers | Potential delays in procurement |

By being aware of these challenges, businesses can develop strategies to enhance their procurement processes, ensuring that they only engage with reliable and certified suppliers.

How Do You Evaluate Supplier Certifications Effectively?

When evaluating supplier certifications, a structured approach can yield the best results. Start by developing a checklist that outlines essential certification requirements based on your industry and specific needs.

Key factors to include are:

- Verification of certification documents

- The geographical relevance of the certifications

- The reputation of the certifying body

It’s also important to conduct site visits or audits. This provides firsthand insight into the supplier’s operations and their commitment to maintaining standards.

Other evaluation methods include seeking customer references and case studies that highlight the supplier’s past performance. This qualitative data can enhance your confidence in their certifications.

Lastly, do not overlook third-party verification services. These organizations specialize in confirming the authenticity of various certifications and can serve as valuable resources during evaluation.

| Evaluation Criteria | Purpose |

|---|---|

| Certification Verification | Confirm authenticity |

| Site Audits | Assess operational compliance and culture |

| Customer References | Gain insights into past performance |

What Role Does Regulatory Compliance Play in Certifications?

Regulatory compliance is a significant driver of supplier certifications, especially in industries where safety and quality are paramount. The procurement of zirconia powder, particularly for applications in the medical and automotive fields, necessitates adherence to strict regulations. This compliance is essential for preventing accidents and ensuring that products are not only effective but also safe for use.

Certifications help underline a supplier’s commitment to following these regulations, providing assurance to clients that they are partnering with responsible organizations. For instance, suppliers with ISO or ASTM certifications commonly adhere to established safety and quality benchmarks recognized internationally. This commitment helps protect your business from potential liabilities that may arise from the use of non-compliant materials.

Moreover, companies that emphasize regulatory compliance through supplier certifications are better positioned in the market. They can respond more swiftly to changes in regulatory requirements, ensuring they stay compliant and avoid disruptions in their supply chains.

Key Points on Regulatory Compliance and Certifications:

- Protects Against Legal Risks: Non-compliance may result in fines or legal actions.

- Enhances Credibility: Certified suppliers build trust with customers and regulatory bodies alike.

- Facilitates Market Access: Compliance enables entry into various international markets, which may have specific requirements.

- Promotes Sustainable Practices: Adhering to regulations often aligns with sustainable and ethical business practices.

To maintain compliance effectively, companies should continually monitor changes in regulations and engage in regular reviews of supplier certifications. This proactive approach ensures that not only are you meeting current standards, but you are also anticipating future requirements.

In summary, regulatory compliance is a cornerstone of supplier certifications, fostering safer practices and enhancing the credibility of both suppliers and businesses alike.

Which Industries Benefit Most from Certified Zirconia Powder?

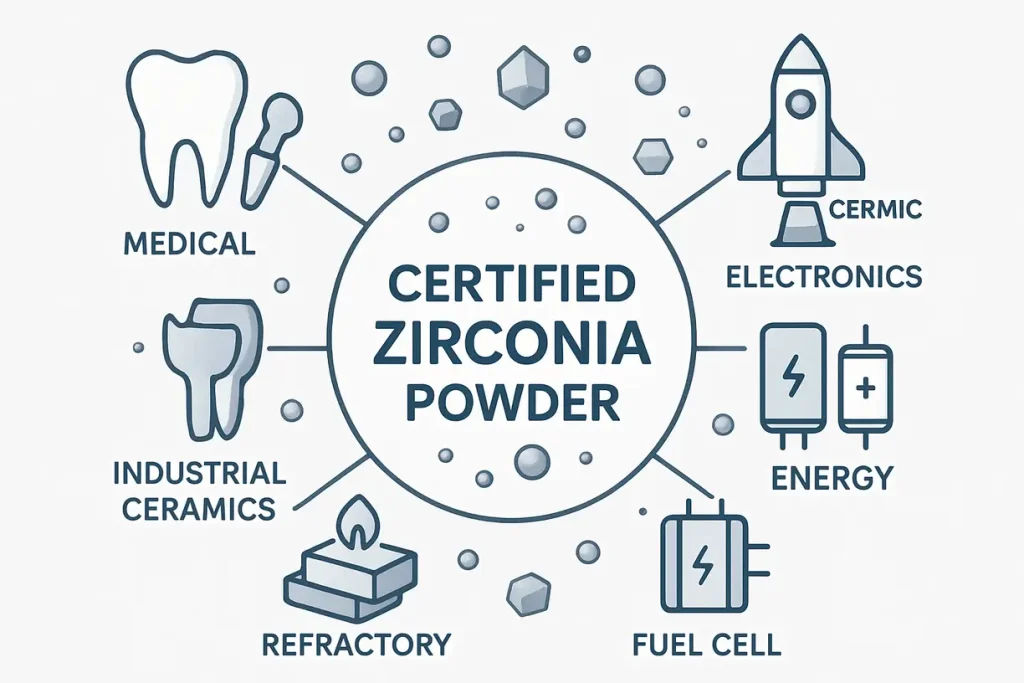

Various industries leverage the advantages of certified zirconia powder. The medical field is one of the most significant sectors benefiting from high-quality zirconia. Surgical instruments that use zirconia must meet stringent standards to ensure safety and effectiveness, making certifications crucial for minimizing risks associated with surgical procedures.

The automotive industry is another sector demanding high-performance materials. Components such as fuel injectors, valves, and brake parts utilize zirconia for its durability, heat resistance, and mechanical properties. Certifications provide assurance that these materials will perform reliably under varying conditions, which is essential for vehicle safety.

This image highlights various industries that benefit from certified zirconia powder applications.

Additionally, the ceramics and electronics industries extensively use zirconia powder. In ceramics, applications range from advanced dental crowns to durable tableware, requiring consistent quality to maintain aesthetic and functional attributes. Meanwhile, in electronics, zirconia is incorporated into sensors, capacitors, and insulators, where precise electrical properties are crucial for device performance.

Here’s a brief overview of key industries benefiting from certified zirconia powder:

| Industry | Application | Certification Importance |

|---|---|---|

| Medical | Dental implants, surgical tools | Ensures patient safety |

| Automotive | Engine components, brake pads | Guarantees performance reliability |

| Electronics | Sensors, capacitors | Maintains electrical efficiency |

| Ceramics | Dental crowns, decorative tiles | Ensures durability and quality |

In summary, certified zirconia powder offers high reliability across a diverse range of industries, positioning it as a preferred material for many applications.

How Can Supplier Certifications Enhance Product Quality?

Supplier certifications are closely tied to product quality and performance. First, certified suppliers typically have more robust quality control systems in place. This leads to consistent manufacturing processes, producing higher-quality zirconia powder.

For example, companies using certified materials often see fewer defects in their final products. They experience lower rates of return and higher customer satisfaction—both valuable metrics in building brand trust.

Case studies involving certified zirconia powder reveal noteworthy improvements in performance metrics across various applications. Companies report that their end products, like dental crowns or surgical components, show superior characteristics when produced with certified materials.

Moreover, leveraging certified suppliers can result in enhanced innovation. Suppliers committed to maintaining certifications tend to invest in research and development, leading to new and improved product formulations.

| Industry | Product Quality Impact | Example |

|---|---|---|

| Medical | Higher reliability in surgical products | Dental crowns |

| Automotive | Reduced failure rates and enhanced safety | Engine components |

| Electronics | Improved performance in devices | Sensors and circuits |

What Strategies Can Companies Use for Certification Compliance?

To maintain compliance with supplier certifications, companies must adopt effective strategies. Firstly, regular training for employees involved in procurement can enhance understanding of certification requirements. This ensures everyone is on the same page regarding compliance needs.

Another approach is to establish firm guidelines for supplier assessment. Create a documented process for evaluating supplier certifications and ensuring they remain current.

Incorporating technology solutions can also aid compliance. Software that tracks certification statuses and reminds you of renewal timelines can streamline the process.

Moreover, fostering open communication with your suppliers plays a key role. Encourage suppliers to share updates regarding their certifications and any changes in compliance status. This transparency can help you adjust your procurement strategies proactively.

By acting on these strategies, you can enhance your company’s reliability and strengthen supplier relationships.

Conclusion

In summary, understanding and prioritizing supplier certification standards in zirconia powder procurement can significantly improve product quality and compliance. By focusing on recognized standards such as ISO and ASTM, businesses can mitigate risks while enhancing supplier relationships. Using certified materials leads to tangible benefits like increased reliability and better overall product performance. For your next procurement project, partner with Global Industry to access certified zirconia powder and elevate your supply chain integrity. Connect with us today for insights that will keep your business ahead.

FAQ Section

Q1: What are the key supplier certification standards for zirconia powder? Understanding the core standards like ISO and ASTM is essential for assessing quality and compliance.

Q2: How do I verify a supplier’s certification claims? Conduct thorough evaluations and seek third-party verification to ensure authenticity.

Q3: Why should I prioritize certified suppliers? Certified suppliers generally offer consistent quality, mitigate risk, and conform to regulatory standards.

Q4: What impact do certifications have on procurement budgets? Investing in certified suppliers may incur higher upfront costs but leads to long-term savings through quality and reliability.

Q5: How often should supplier certifications be reviewed? Regular reviews, at least annually, are recommended to maintain compliance and quality assurance.