Imagine a patient returning with a chipped porcelain-fused-to-metal bridge and a dark gray line at their gum margin. This failure creates frustration for the clinician and deep distrust in the patient, highlighting the need for materials that withstand stress without compromising beauty. Zirconia-bridges provide the definitive solution in 2025, offering a monolithic structure that eliminates metal fatigue while delivering superior biocompatibility. As an expert in ceramic materials, I will guide you through the technical reasons why transitioning to high-purity zirconia is the standard for modern restorative excellence.

What Makes Zirconia-Bridges the Top Choice in 2025?

Here is the deal: The dental industry has shifted decisively toward metal-free solutions, driven by patient demand for natural aesthetics and the clinical need for durability. Zirconia-bridges utilize Yttria-stabilized Tetragonal Zirconia Polycrystal (Y-TZP) to deliver high flexural strength that rivals metal substructures.

The Evolution of Bridge Materials

Dental materials have moved from gold alloys to PFM, and now to high-performance ceramics. 2025 marks the era of “smart” zirconia with varying translucency gradients that mimic natural dentition. This shift is powered by material science innovations, specifically phase transformation toughening which prevents crack propagation.

Current Industry Adoption

You might be wondering: Is the material versatile enough for every case? Modern formulations allow for both high-opacity frameworks to mask discolored stumps and high-translucency full-contour bridges. This versatility has made it the primary choice for labs worldwide.

Material Science Innovation

The core advantage lies in the crystalline structure of the material. By using high-quality Zirconia Powder , manufacturers ensure the microstructural density required to resist hydrothermal aging. This results in a restoration that remains stable in the wet oral environment.

Table 1: Industry Adoption Rates (2025)

| Material Type | Market Share Growth | Primary Indication | Failure Rate (5-Year) | |

|---|---|---|---|---|

| Zirconia-Bridges | +15% YoY | Posterior/Anterior | < 1.5% | |

| PFM Bridges | -8% YoY | Long-span posterior | ~4.0% | |

| Lithium Disilicate | +5% YoY | Anterior single units | ~2.5% |

Key Takeaway: The data indicates a clear displacement of PFM by zirconia, primarily due to the significantly lower failure rate and broader indication range.

How Do Zirconia-Bridges Outperform PFM Restorations?

But here’s the kicker: While PFM has been the gold standard for decades, its layered structure is its weak point. Zirconia-bridges eliminate the oxide layer and metal coping, removing the risk of porcelain delamination (chipping).

Structural Integrity Comparison

Full-contour zirconia resists chipping entirely because it is a monolithic material. There is no veneering porcelain to fracture off the substructure during heavy chewing. This makes it structurally superior to any layered restoration available today.

Thermal Conductivity Benefits

Patients often complain of sensitivity with metal-based restorations due to temperature transfer. Zirconia has lower thermal conductivity, acting as an insulator against hot and cold foods. This results in immediate post-operative comfort for the patient.

Esthetic Longevity

Think about this: Metal margins often cause “graying” of the gingiva over time. Zirconia is tooth-colored at the margin, ensuring that even if gum recession occurs, the aesthetics remain uncompromised.

Table 2: Physical Property Comparison

| Feature | PFM Bridge | Zirconia-Bridges | Advantage | |

|---|---|---|---|---|

| Flexural Strength | 800-1000 MPa (Metal) | 1000-1400 MPa | Higher fracture resistance | |

| Esthetics | Opaque core required | Translucent options | Natural light transmission | |

| Biocompatibility | Risk of metal allergy | 100% Biocompatible | Tissue health | |

| Preparation | Aggressive reduction | Conservative prep | Tooth preservation |

Key Takeaway: Zirconia offers superior strength with less invasive tooth preparation, preserving vital tooth structure while eliminating metal aesthetics.

Why Are Zirconia-Bridges Critical for Posterior Stability?

Let’s face it: The biting forces in the posterior region are immense, often exceeding 700 Newtons. Zirconia-bridges are uniquely suited for this environment because they do not suffer from the fatigue cycles that cause ceramics to fail.

Handling Masticatory Force

These bridges are capable of withstanding bruxism and heavy occlusion without fracturing. The high density of the material allows it to absorb stress rather than transfer it destructively. This makes it the safest option for molar replacements.

Connector Design Freedom

The strength of zirconia allows for optimal connector dimensions without breakage. Technicians can create hygienic pontic designs that are still robust enough to handle load. This balance of hygiene and strength is difficult to achieve with weaker ceramics.

Wear Characteristics

Expert Note: Polished zirconia wears opposing enamel less than feldspathic porcelain. Using high-grade Zirconia Ceramic Structural Parts guarantees that the surface remains smooth and non-abrasive over years of function.

Table 3: Posterior Force Resistance

| Region | Avg. Bite Force (N) | Req. Material Strength | Zirconia-Bridges Rating | |

|---|---|---|---|---|

| First Molar | 400 – 800 N | > 800 MPa | Excellent (1200+ MPa) | |

| Premolar | 300 – 500 N | > 500 MPa | Superior | |

| Incisor | 100 – 200 N | > 300 MPa | Over-engineered |

Key Takeaway: Zirconia provides a safety factor of nearly 2x for the highest masticatory forces found in the human mouth.

Can Zirconia-Bridges Achieve Lifelike Anterior Esthetics?

You might think that strength comes at the cost of beauty. In the past, zirconia was “chalky” white, but today, zirconia-bridges utilize multilayer technology that mimics the natural gradient of the tooth.

Multilayer Technology

Color runs through the entire block, not just on the surface layer. This gradient shading mimics the transition from opaque dentin to translucent enamel. It eliminates the flat, monochromatic look of early generations.

Translucency Advances

New formulations like 4Y-TZP and 5Y-TZP offer glass-like optics. These materials allow light to pass through the incisal edge just like natural teeth. The result is a restoration that blends seamlessly with adjacent dentition.

Customization Potential

Ready for the good part? Labs can stain and glaze these bridges using Zirconium Silicate based systems for characterization. This allows for the replication of calcification spots, cracks, and mamelons for hyper-realistic results.

Table 4: Esthetic Parameters

| Attribute | Solid Zirconia (Old) | Layered/Multi Zirconia (2025) | Natural Enamel | |

|---|---|---|---|---|

| Translucency | < 30% | 45-49% | ~50% | |

| Shade Stability | Permanent | Permanent | Variable | |

| Fluorescence | Low | Medium-High | High | |

| Surface Texture | Smooth | Detailed/Anatomical | Textured |

Key Takeaway: The gap between zirconia and natural enamel has closed significantly, making it viable for the “smile zone.”

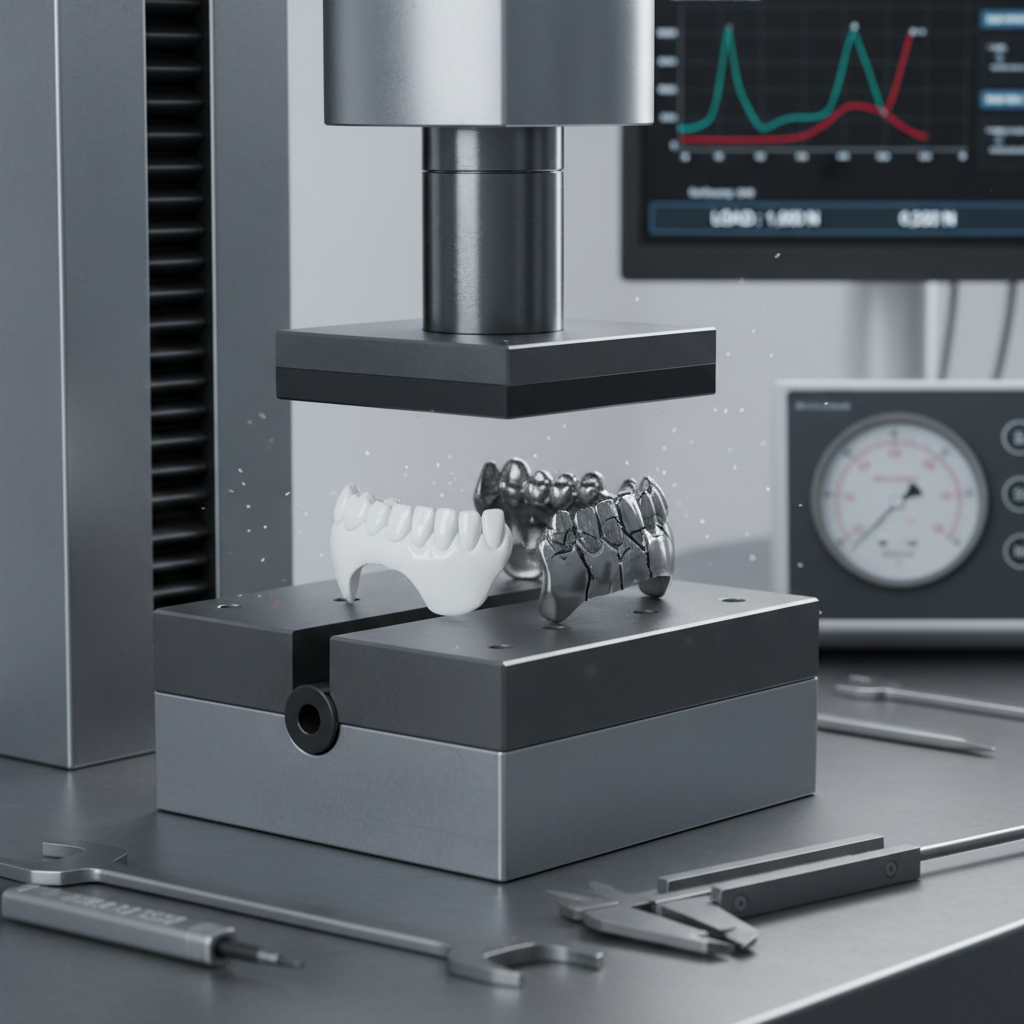

How Does CAD/CAM Improve Zirconia-Bridges Precision?

Here is the secret: The success of zirconia-bridges is intrinsically linked to the digital workflow. Unlike lost-wax casting, digital milling eliminates expansion and contraction errors associated with investment materials.

The Digital Workflow Advantage

Intraoral scanners capture margin details within microns. This digital impression is instantly transferred to design software. It removes the variables of impression material distortion and stone expansion.

Software Optimization

Design software optimizes connector thickness and pontic design automatically. It ensures the minimum thickness requirements are met for structural safety. This eliminates human error in estimation.

Milling Consistency

5-axis milling units carve the bridge from a presintered block with zero distortion. Using high-quality milling tools and stable raw materials like Zircon Powder ensures that the margins remain chip-free during the “green state” milling phase.

Table 5: Precision Tolerance

| Fabrication Method | Marginal Gap (Microns) | Internal Fit | Production Time | |

|---|---|---|---|---|

| CAD/CAM Zirconia | 20 – 40 µm | Consistent | < 2 Hours | |

| Traditional Cast Metal | 50 – 100 µm | Variable | 2 Days | |

| Press Ceramic | 40 – 60 µm | Good | 1 Day |

Key Takeaway: Tighter margins mean less cement dissolution and significantly lower risk of secondary caries.

Are Zirconia-Bridges Biocompatible for Sensitive Gums?

Think about this: Many patients suffer from sub-clinical inflammation around dental restorations. Zirconia-bridges are chemically inert, meaning they do not trigger immune responses or attract plaque accumulation.

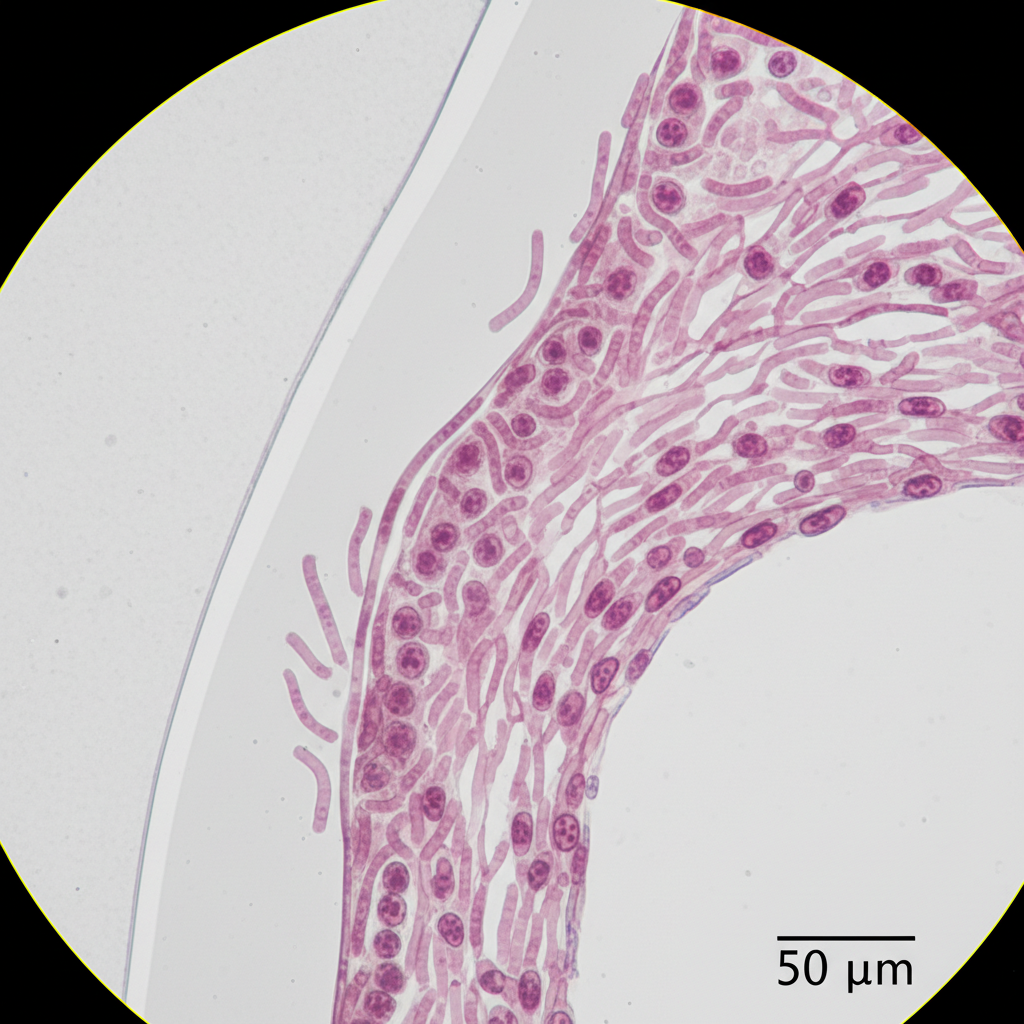

Tissue Response Benefits

Gum tissue can attach to polished zirconia via hemodesmosomes. This biological seal protects the underlying bone and tooth structure. It mimics the natural attachment of gum to enamel.

Plaque Resistance

The surface charge of zirconia repels bacteria. This hydrophobicity prevents the biofilm accumulation common on metal and resin surfaces. Patients find it easier to keep these restorations clean.

No Galvanism

Here is the deal: Zirconia eliminates “battery effect” shocks common with mixed metals. Patients with amalgam fillings or gold crowns elsewhere in the mouth will not experience galvanic pain. It creates a neutral oral environment.

Table 6: Biocompatibility Metrics

| Material | Bacterial Adhesion | Cytotoxicity | Gingival Response | |

|---|---|---|---|---|

| Zirconia | Very Low | None | Healthy/Pink | |

| Base Metal Alloy | High | Moderate (Ni release) | Inflammation | |

| Gold Alloy | Low | None | Healthy | |

| Resin | High | Low | Receding |

Key Takeaway: Zirconia is the most biologically friendly material available for subgingival margins.

What is the Cost-Benefit Analysis of Zirconia-Bridges?

What’s the real story? While the initial material cost of zirconia blocks might seem higher than wax and metal, the reduction in labor and the elimination of “remakes” make it the most cost-efficient option for B2B dental labs and clinics.

Labor Savings

There is no waxing, investing, casting, or divesting required. The manual labor involved in traditional bridges is cut by over 80%. This allows technicians to focus on finishing and artistry.

Speed and Turnover

Same-day sintering options allow for faster turnover. Labs can produce more units per day with the same number of staff. This scalability is impossible with analog casting methods.

Durability ROI

Expert Insight: Fewer warranty replacements occur for fractured units. Sourcing from a reliable partner like QGlobal Industry ensures consistent pricing and material quality, stabilizing overhead costs.

Table 7: Lab Production Costs (Estimated)

| Cost Driver | PFM Bridge | Zirconia-Bridges | Savings | |

|---|---|---|---|---|

| Material Cost | Medium (Alloy dependent) | Moderate | Neutral | |

| Labor Hours | 3-4 Hours | 0.5 Hours | High | |

| Equipment Use | Casting/Porcelain Furnace | Mill/Sinter Furnace | Efficiency | |

| Remake Rate | 4-6% | < 1% | High |

Key Takeaway: The drastic reduction in manual labor hours makes zirconia significantly more profitable for dental businesses.

How Durable Are Zirconia-Bridges Under High Stress?

This is where it gets interesting: Zirconia exhibits a property called “transformation toughening.” When a crack attempts to start, the crystalline structure expands to seal the crack, effectively self-repairing at a microscopic level.

Fatigue Resistance

These bridges can withstand millions of chew cycles without degrading. Unlike metal which can fatigue, or porcelain which micro-cracks, zirconia remains stable. It is the only ceramic with this self-repairing capability.

Impact Strength

They are highly resistant to accidental trauma. Whether from a sports injury or biting on a cherry pit, zirconia is less likely to fail catastrophically. This provides peace of mind for active patients.

Connector Size Efficiency

You might be wondering: Does strength require bulk? No, zirconia requires less bulk than glass-ceramics to achieve the same strength. This allows for better hygiene access under the connectors.

Table 8: Wear and Strength Data

| Property | Value | Implication | |

|---|---|---|---|

| Fracture Toughness | 5-10 MPa·m^1/2 | Resists crack propagation | |

| Vickers Hardness | 1200 HV | Resists surface scratches | |

| Antagonist Wear | 2-3 µm/year | Similar to natural enamel wear | |

| Water Absorption | 0% | No degradation over time |

Key Takeaway: Zirconia balances extreme hardness with a wear-friendliness that protects opposing natural teeth.

What Maintenance Do Zirconia-Bridges Require?

Don’t overlook this: While zirconia-bridges are decay-proof, the tooth structure underneath is not. Proper maintenance protocols are vital for long-term success.

Hygiene Protocols

Superfloss or water flossers must be used under pontics daily. Patients should be educated that the bridge is only as strong as the supporting teeth. Plaque removal is critical to prevent recurrent decay at the margins.

Prophylaxis Considerations

Hygienists should use non-abrasive pastes to maintain the glaze. Using coarse prophy paste can dull the surface luster over time. Plastic or carbon fiber scalers are preferred over steel to prevent metal transfer.

Occlusal Protection

Here is the deal: Nightguards are recommended for bruxers to protect the TMJ. Even though the bridge won’t break, the jaw joint still absorbs the force. Using smooth, high-density materials like Zircon Sand derivatives in polishing helps create a surface easy to clean.

Table 9: Cleaning Protocol Comparison

| Tool/Method | Recommended for Zirconia? | Reason | |

|---|---|---|---|

| Ultrasonic Scaler | No (with metal tip) | Can leave gray marks/scratches | |

| Plastic/Carbon Scaler | Yes | Safe for ceramic surface | |

| Air Polishing | Yes (Glycine powder) | Gentle biofilm removal | |

| Acidulated Fluoride | No | Can etch the glaze |

Key Takeaway: Specific hygiene protocols prevent surface damage and ensure the longevity of the restoration.

Why Should Labs Source High-Purity Powder for Zirconia-Bridges?

Here’s the bottom line: Not all zirconia is created equal. The purity of the raw powder directly dictates the translucency, strength, and hydrothermal stability of the final bridge.

The Role of Raw Materials

High-quality processing removes trace radioactive elements like uranium and thorium. This ensures the material is safe for long-term placement in the body. Cheap powders often skip this expensive purification step.

Particle Size Importance

Nanometric powders ensure higher density and lower sintering temperatures. Uniform particle size leads to predictable shrinkage rates (usually 20%). This accuracy is what delivers the perfect marginal fit.

Binder Distribution

Global Industry specializes in supplying premium Zirconia and silicate materials that meet stringent ISO standards. Uniform binders prevent warping during the sintering process, ensuring the bridge seats passively.

Table 10: Powder Quality Impact

| Parameter | Low-Quality Powder | High-Purity Powder | Result | |

|---|---|---|---|---|

| Particle Size | Inconsistent | Uniform Nano-scale | Better fit/density | |

| Impurities | High (Al, Fe) | Trace only | Pure color/No aging | |

| Sintering | Unpredictable | Controlled shrinkage | Perfect fit | |

| Aging | Rapid degradation | Stable | Long-term success |

Key Takeaway: The foundation of a perfect bridge lies in the chemical purity of the raw material.

Key Takeaway

In 2025, zirconia-bridges represent the pinnacle of restorative dentistry, combining the strength of steel with the aesthetics of natural porcelain. For dental laboratories and clinicians, the choice is clear: transitioning to high-purity zirconia improves clinical outcomes, enhances patient satisfaction through superior biocompatibility, and optimizes business efficiency through digital workflows. Ensuring the source of your material is reliable is the final step in guaranteeing quality. Contact us to find reliable suppliers!

FAQ

Q1: What is the main advantage of Zirconia-Bridges over traditional PFM?Zirconia-bridges offer superior esthetics and biocompatibility by eliminating the metal substructure. They provide equal or greater fracture resistance while ensuring no dark lines appear at the gumline over time.

Q2: How does the manufacturing process ensure the fit of Zirconia-Bridges?They are manufactured using CAD/CAM technology, which mills the bridge from a single block of material with micron-level precision. This eliminates the distortion common in casting and ensures a passive fit.

Q3: Are Zirconia-Bridges suitable for patients with metal allergies?Yes, zirconia is a metal-free, chemically inert ceramic material. It is fully biocompatible and hypoallergenic, making it the ideal choice for patients with sensitivity to nickel or other metals found in traditional alloys.

Q4: Can Zirconia-Bridges be repaired if they chip?While chipping is rare due to the monolithic strength of the material, minor chips can be polished smooth. However, significant fractures usually require the replacement of the bridge, emphasizing the need for correct design.

Q5: What is the expected lifespan of a Zirconia-Bridge?With proper oral hygiene and regular check-ups, a zirconia bridge can last 15 years or more. Its resistance to wear and fracture makes it one of the most durable dental restorations available today.