Struggling to achieve consistent whiteness and durability in your ceramic products? This common manufacturing hurdle leads to high rejection rates, wasted materials, and a compromised reputation for quality. You are often forced to choose between aesthetic perfection and structural integrity, a trade-off that limits your product’s potential. Zirconium Silicate is the definitive solution, a multi-functional additive that delivers superior opacity, strength, and thermal stability in one powerful material.

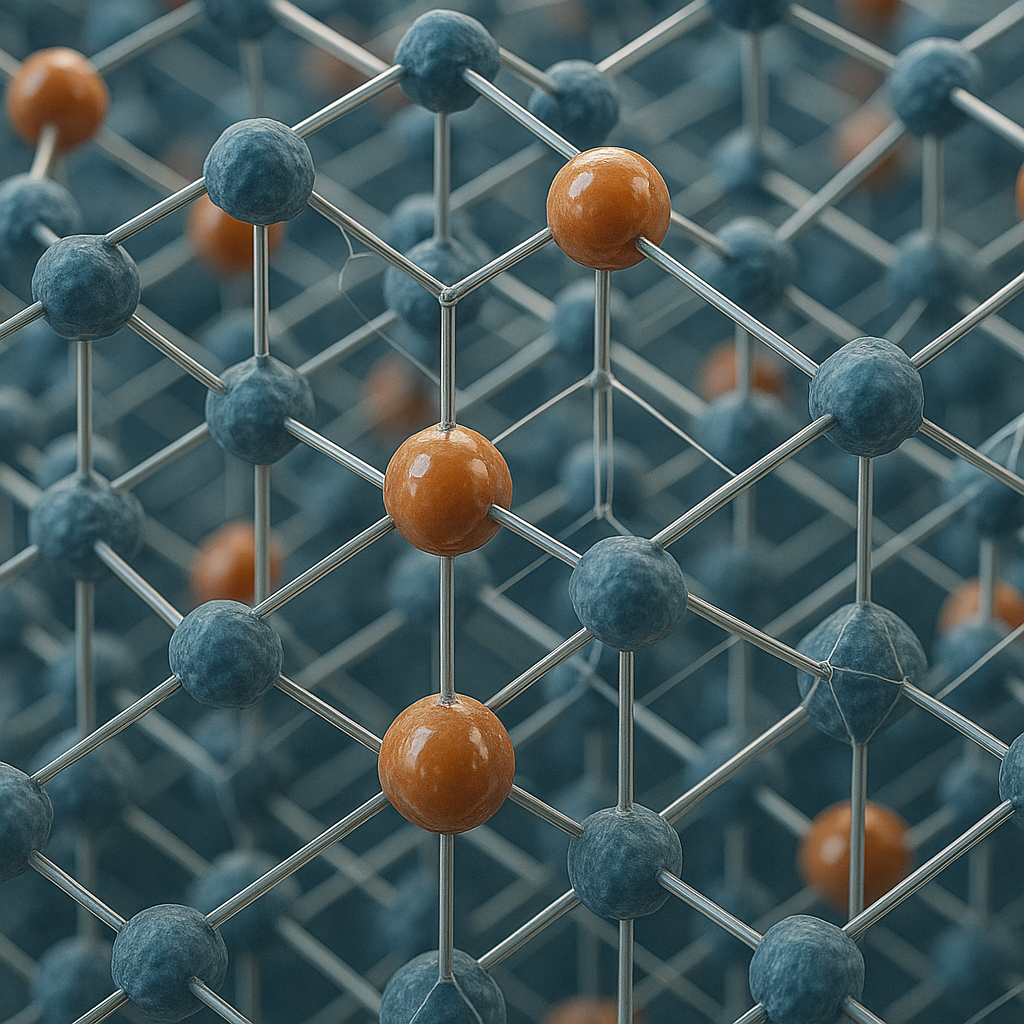

What are Zirconium Silicate’s core properties?

Its core properties are a high refractive index, exceptional chemical stability, and low thermal conductivity. These traits make it an invaluable material for modern ceramic manufacturing. It provides brilliant opacity and resilience against harsh chemical and thermal conditions.

What are its core characteristics?

This material is known for its hardness, high melting point, and excellent resistance to abrasion. These features contribute directly to the final product’s longevity and performance. It ensures your ceramics can withstand daily use and harsh environments.

- High refractive index (~1.93-2.01)

- Excellent chemical inertness

- Mohs hardness of 7.5

How does its chemical stability help?

Its chemical stability prevents reactions with other glaze components or corrosive agents. Here’s the deal: This means your glazes will not discolor or degrade over time. It maintains the integrity of the product even when exposed to acidic or alkaline substances.

- Resists corrosion from acids and alkalis

- Prevents unwanted chemical reactions during firing

- Ensures color stability in glazes

What is the impact of its low thermal conductivity?

Low thermal conductivity improves the thermal shock resistance of ceramic bodies. Think about it this way: Your products can endure rapid temperature changes without cracking. This is particularly useful for manufacturing items like cookware or industrial refractories. The Key Takeaway is that Zirconium Silicate’s fundamental properties provide a robust foundation for creating high-quality, durable, and visually appealing ceramics.

| Property | Benefit in Ceramics | |

|---|---|---|

| High Refractive Index | Creates brilliant whiteness and opacity. | |

| Chemical Stability | Prevents corrosion and discoloration. | |

| Low Thermal Conductivity | Improves thermal shock resistance. |

How is Zirconium Silicate manufactured?

It is made by processing natural zircon sand through calcination, grinding, and refinement. This process transforms the raw mineral into a high-purity, fine powder suitable for diverse industrial uses. High-temperature roasting is a critical step to optimize its properties for ceramic applications.

The manufacturing process explained.

The process begins with mining zircon sand, which is then purified to remove impurities like iron and titanium. Afterwards, the sand is milled into an ultra-fine powder to ensure uniform distribution in ceramic bodies. This precision grinding is key to its performance as an opacifier.

- Mining and purification of zircon sand

- Calcination at high temperatures

- Fine-milling to specific particle sizes

Is high-temperature roasting required?

Yes, high-temperature roasting, or calcination, is a necessary step in the process. But what does this mean for you? It decomposes the zircon into zirconium oxide and silica, which enhances its refractive index and opacifying power. The Key Takeaway is that this controlled manufacturing process is what unlocks the material’s full potential for ceramic enhancement.

| Manufacturing Step | Purpose | |

|---|---|---|

| Purification | Removes impurities that cause discoloration. | |

| Calcination | Enhances opacifying properties. | |

| Grinding | Ensures uniform particle size for smooth finishes. |

How does Zirconium Silicate improve ceramics?

Zirconium Silicate improves overall ceramic quality by acting as a superior opacifier and strengthening agent. It greatly enhances both the aesthetic appearance and the internal structural quality of the finished product. The result is a more valuable, durable, and visually consistent item.

Its role as a flux in production.

In some formulations, it can act as a flux, reducing the melting temperature of other components. This allows for lower firing temperatures, which saves energy and reduces production costs. For more details on glazes, see our article on glaze smoothness. It helps create a denser, less porous ceramic body during vitrification.

- Lowers the required firing temperature

- Reduces energy consumption

- Improves vitrification

Enhancing appearance and internal quality.

It scatters light effectively, creating a bright, white, and opaque finish. Here’s the deal: This masks the color of the underlying ceramic body, giving you a clean canvas for glazes. The Key Takeaway is that it simultaneously improves the visual appeal and the physical robustness of your ceramic ware.

| Enhancement | Effect | |

|---|---|---|

| Opacification | Produces a bright, consistent white color. | |

| Fluxing Agent | Lowers energy costs and improves density. | |

| Strengthening | Increases hardness and wear resistance. |

Does Zirconium Silicate affect transmittance?

Yes, it is used specifically to reduce light transmittance, serving as a powerful opacifying agent. This quality is what creates a brilliant and uniform white appearance in ceramic bodies and glazes. It achieves this by efficiently scattering any light that attempts to pass through the ceramic matrix.

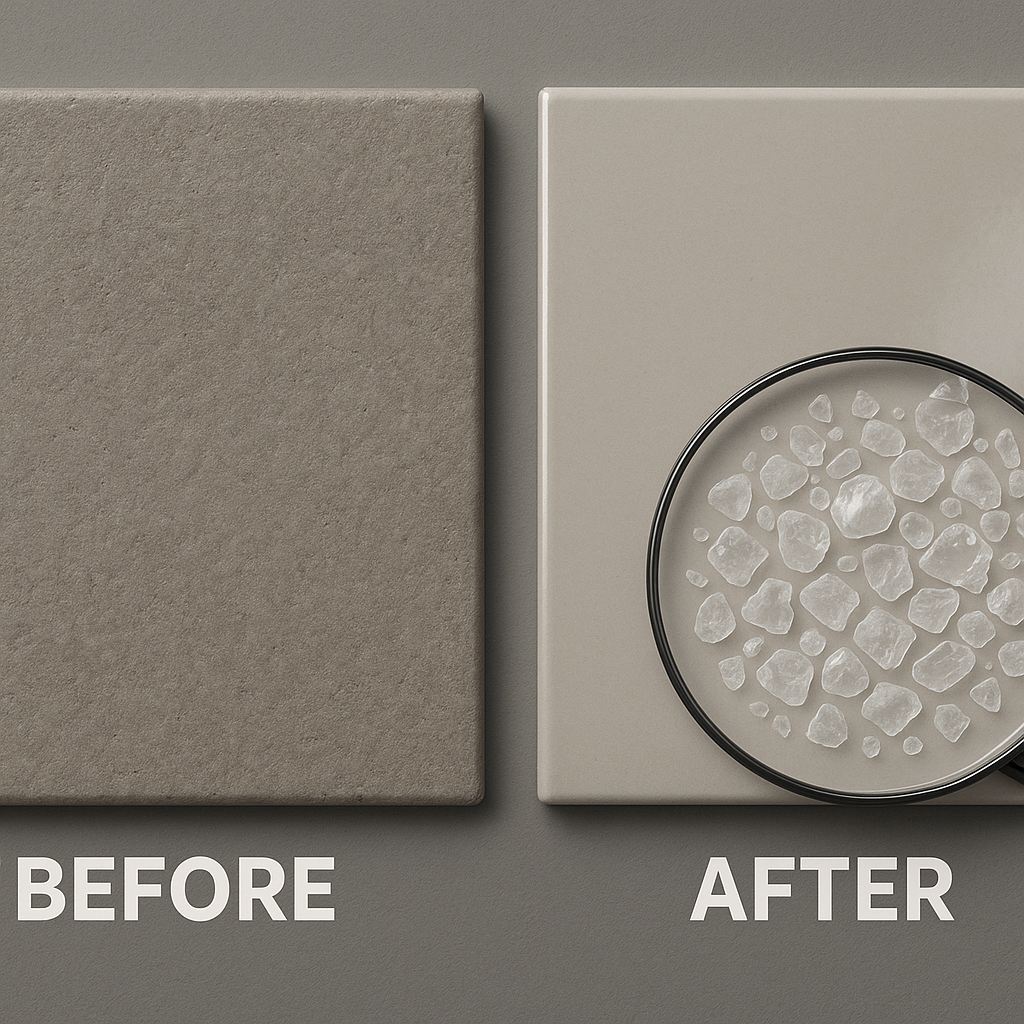

Achieving a smoother ceramic surface.

The fine particles of zirconium silicate fill microscopic pores on the ceramic surface. This results in a smoother, less permeable finish that is easier to clean. This smoothness also contributes to a higher-quality feel and appearance.

- Fills in surface imperfections

- Reduces porosity

- Creates a uniform texture

How does it act as a permeability enhancer?

It enhances the surface by reducing permeability, which improves stain resistance. But what does this mean for you? Your products become more hygienic and durable, especially for tableware and sanitary ware applications. The Key Takeaway is that Zirconium Silicate is the key to creating an opaque, impermeable, and flawlessly smooth ceramic surface.

| Feature | Impact on Transmittance | |

|---|---|---|

| Opacity | Blocks light, creating a solid white appearance. | |

| Smoothness | Reduces surface scattering for a clean finish. | |

| Permeability | Prevents stains from penetrating the surface. |

Can Zirconium Silicate boost heat resistance?

Absolutely, its high melting point and low coefficient of thermal expansion make it ideal for boosting heat resistance. This allows your ceramic products to maintain complete structural integrity at very high temperatures. It is a go-to material for any application that demands superior thermal stability.

Enabling use at higher temperatures.

By incorporating Zirconium Silicate, you can formulate ceramics that perform reliably in demanding environments. This includes applications like kiln furniture, refractory bricks, and industrial crucibles. The material does not deform or degrade under thermal stress.

- Increases the maximum service temperature

- Improves thermal shock resistance

- Maintains structural form when heated

Why is its high melting point important?

Its high melting point of over 2,500°C (4,532°F) ensures it remains stable long after other elements have melted. Think about it this way: It acts as a structural skeleton within the ceramic body during firing and use. The Key Takeaway is that Zirconium Silicate is indispensable for creating ceramics that can withstand extreme heat without failure.

| Thermal Property | Advantage | |

|---|---|---|

| High Melting Point | Provides structural stability during firing. | |

| Low Thermal Expansion | Prevents cracking from temperature changes. | |

| Heat Resistance | Enables use in high-temperature applications. |

Does Zirconium Silicate increase strength?

Yes, it substantially improves the mechanical strength and hardness of all types of ceramic products. Its ultra-fine particles effectively fill microscopic voids within the ceramic matrix, creating a much denser and more robust structure. This reinforcement directly reduces brittleness and enhances wear resistance.

Improving mechanical strength in ceramics.

The addition of Zirconium Silicate increases the flexural strength and impact resistance of ceramics. This makes products like tiles and tableware less likely to chip or break during handling and use. It fortifies the ceramic body from within.

- Increases flexural strength

- Reduces chipping and cracking

- Enhances overall durability

What about its insulation properties?

Its low thermal conductivity also contributes to its excellent electrical insulation properties. Here’s the deal: This makes it a valuable component in producing ceramics for the electronics industry, such as substrates for circuits. The Key Takeaway is that Zirconium Silicate is a dual-purpose additive, providing both mechanical reinforcement and effective insulation.

| Strength Aspect | Benefit | |

|---|---|---|

| Mechanical Strength | Improves durability and reduces breakage. | |

| Hardness | Increases resistance to scratches and abrasion. | |

| Insulation | Provides excellent electrical and thermal insulation. |

How is Zirconium Silicate used in glazes?

It is used in glazes primarily as an opacifier to produce brilliant, white, and non-transparent finishes. By carefully controlling the particle size of the Zirconium Silicate, you can achieve a wide range of surface effects. It combines easily with other raw materials to create customized, high-performance glazes.

How is it used to produce glazes?

It is added to the glaze formulation before firing, typically in amounts ranging from 5% to 15%. During firing, the Zirconium Silicate particles remain suspended in the molten glaze. They scatter light, which prevents the color of the clay body from showing through.

- Acts as a primary opacifying agent

- Suspends within the glaze matrix

- Creates a uniform, white base

Creating high-gloss and high-hardness finishes.

When milled to an ultra-fine particle size, it helps create a very smooth, high-gloss surface. But what does this mean for you? This not only improves aesthetics but also increases the surface hardness, making the glaze more resistant to scratches and chemical attack. The Key Takeaway is that it allows you to precisely control the opacity, gloss, and durability of your glaze finishes.

| Glaze Application | Result | |

|---|---|---|

| Opacification | Achieves a bright, consistent white. | |

| Particle Size Control | Allows for matte or high-gloss finishes. | |

| Hardness | Creates a scratch-resistant and durable surface. |

Why use Zirconium Silicate in tableware?

You use Zirconium Silicate in high-end tableware to achieve a superior level of whiteness, a perfectly smooth surface, and exceptional durability. These qualities are essential for meeting the high aesthetic and functional standards of premium ceramic dining products. It also significantly improves resistance to cutlery marks and damage from frequent washing.

Improving light transmittance in tableware.

In this context, it is used to block light transmittance, thereby increasing opacity. This gives tableware a bright, clean, and high-quality appearance. It ensures the color is a brilliant white rather than a dull off-white.

- Creates a pure, bright white look

- Masks imperfections in the clay body

- Provides a uniform color base

Increasing surface smoothness and wear resistance.

The material contributes to a non-porous, smooth glaze that resists staining and is easy to clean. Think about it this way: This makes the tableware more hygienic and durable enough for both home and restaurant use. The Key Takeaway is that Zirconium Silicate is the ingredient that gives premium tableware its signature look and feel of luxury and longevity.

| Tableware Benefit | Practical Advantage | |

|---|---|---|

| Whiteness | Provides a premium, high-end aesthetic. | |

| Smoothness | Resists staining and is easy to clean. | |

| Wear Resistance | Prevents scratches from cutlery. |

Can Zirconium Silicate be used in refractories?

Yes, it is a key raw material for high-performance refractory products because of its extremely high melting point and excellent thermal shock resistance. Its inherent chemical stability ensures reliable performance in corrosive, high-temperature industrial environments. It is ideal for manufacturing items like refractory bricks, coatings, and kiln furniture.You can learn more about preventing cracks in ceramics in our blog. The Key Takeaway is that its use in refractories is a testament to its exceptional thermal and chemical resilience.

A key raw material for refractory products.

It is used to produce zircon-based refractories that are essential for industries like steel and glass manufacturing. These materials must contain molten metals and glass without degrading. Zirconium Silicate provides the necessary non-reactive and heat-resistant properties.

- Used for glass and steel contact refractories

- Ideal for kiln linings and furniture

- Forms a component of specialty cements

Why is it suited for refractory applications?

It is perfectly suited for refractories due to its combination of thermal and chemical resilience. Here’s the deal: It does not react with molten metals or slag, preventing contamination and extending the service life of the furnace lining. The Key Takeaway is that its stability under extreme conditions makes Zirconium Silicate a critical component for any industry reliant on high-temperature processes.

| Refractory Property | Industrial Benefit | |

|---|---|---|

| Thermal Stability | Withstands extreme process temperatures. | |

| Chemical Inertness | Prevents reaction with molten materials. | |

| Thermal Shock Resistance | Endures rapid heating and cooling cycles. |

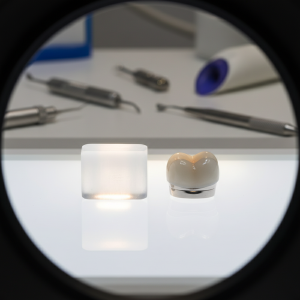

Are there other uses for Zirconium Silicate?

Yes, beyond its primary role in ceramics, it has important applications in the electronics and biomedical fields. Its unique combination of physical strength, biocompatibility, and dielectric properties makes it an incredibly versatile material. This adaptability continues to open doors for new and innovative uses.

Applications in the electronics industry.

Due to its low thermal conductivity and high electrical resistivity, it is used as an insulating material. It can be found in specialized electronic components and as a filler in epoxy molding compounds. It helps manage heat and prevent electrical leakage.

- Electrical insulators

- Filler for electronic packaging

- Substrates for specific circuits

What are its biomedical uses?

Its excellent biocompatibility and wear resistance make it a prime candidate for medical applications. But what does this mean for you? It is used in creating durable and non-reactive artificial joints, bones, and dental implants that the human body does not reject. The Key Takeaway is that the same properties that make Zirconium Silicate great for ceramics also make it valuable for advanced technological and medical devices.

| Industry | Application | |

|---|---|---|

| Electronics | Electrical and thermal insulation. | |

| Biomedical | Artificial joints and dental implants. | |

| Dentistry | Component in artificial teeth and crowns. |

Are you ready to solve inconsistencies in your ceramic production and create stronger, more beautiful products? Integrating Zirconium Silicate eliminates problems with opacity, strength, and heat resistance, giving you a decisive competitive advantage. We can help you select the precise grade and particle size of Zirconium Silicate to meet your specific manufacturing goals. Our vision is to drive industry progress by supplying superior materials that empower our partners to achieve unmatched quality and innovation.

Frequently Asked Questions (FAQ)

Q1:Can I use Zirconium Silicate to improve the strength and heat resistance of my ceramic products?Yes, its fine particles reinforce the ceramic body to improve mechanical strength, while its high melting point significantly increases heat resistance.

Q2:What’s the best way to use Zirconium Silicate for a smoother, high-gloss glaze finish?Use an ultra-fine, milled grade of Zirconium Silicate in your glaze formulation. The small particle size minimizes light scattering at the surface, which promotes a smooth, high-gloss finish.

Q3:Is Zirconium Silicate effective for improving the light transmittance of porcelain?No, it is used for the opposite effect. It is a powerful opacifier that blocks light transmittance to create a brilliant, uniform white appearance.

Q4:What’s the primary role of Zirconium Silicate when used as a ceramic additive?Its primary role is to act as an opacifier, providing a bright white and opaque quality to ceramic bodies and glazes, thereby masking the color of the clay underneath.

Q5:Can I use Zirconium Silicate for applications outside of traditional ceramics, like refractories?Absolutely. Its high melting point and chemical stability make it a key raw material for high-performance refractory products used in the steel and glass industries.