Zirconia powder has garnered significant attention in various industrial applications, especially in manufacturing advanced materials. However, buyers often seek to understand how recent breakthroughs in research and development might affect their choices. The challenges of selecting the right materials in an evolving market can be daunting. This article will provide insights into recent R&D advancements that are enhancing zirconia powder applications. By highlighting these innovations, this piece aims to empower decision-makers with the knowledge needed to adapt to changing industry demands. With the growing importance of zirconia, understanding its latest developments could provide vital competitive advantages.

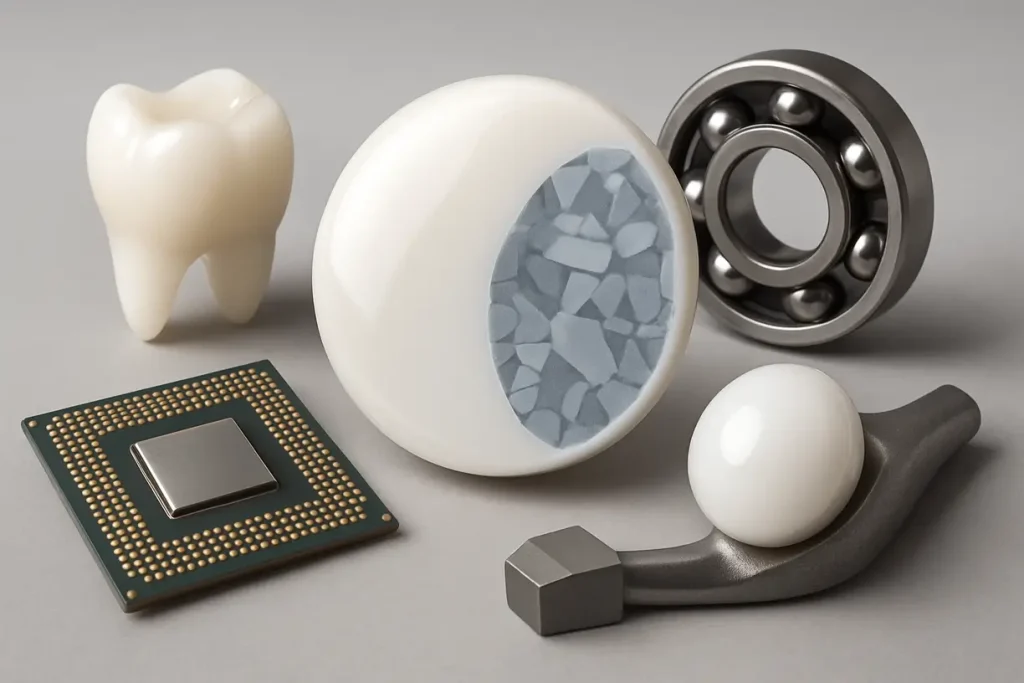

This image illustrates various applications of zirconia powder in multiple industries, showcasing its versatility and significance.

1. What Are Zirconia Powders and Their Uses?

Zirconia powder, known scientifically as zirconium dioxide (ZrO2), is a ceramic material valued for its unique and advantageous properties. Why should you care about it? Its applications span multiple industries, making it essential for various manufacturing processes.

In dental applications, zirconia is renowned for its role in creating crowns and bridges. Its biocompatibility ensures that it is safe for patients, while its aesthetic qualities closely mimic natural teeth. This dual advantage has made zirconia a preferred choice among dentists and patients alike.

Aerospace is another industry where zirconia shines. Its ability to withstand extreme temperatures is crucial for components that operate under severe conditions, ensuring performance and safety in flight. Additionally, zirconia’s lightweight characteristics help reduce overall aircraft weight, which contributes to fuel efficiency.

Zirconia is not just limited to dental and aerospace fields. It also plays a significant role in ceramic coatings, which provide wear resistance in various applications. In the electronics sector, its insulating properties make it suitable for components in fuel cells and sensors, where reliability is paramount.

Key Uses of Zirconia Powder:

- Medical Devices: Used in prosthetics and implants due to its durability and biocompatibility.

- Automotive: Employed in fuel cells for cars, enhancing energy conversion efficiency.

- Consumer Products: Found in high-performance kitchenware for non-stick applications.

As industries continuously seek to improve manufacturing efficiency and product performance, understanding zirconia powder’s versatile applications is essential. By leveraging these properties, businesses can enhance their products and processes.

| Industry | Zirconia Application |

|---|---|

| Dental | Crowns, bridges, and dental implants |

| Aerospace | High-temperature parts and thermal barriers |

| Ceramics | Coatings for wear resistance |

| Electronics | Insulators and sensors |

2. What R&D Breakthroughs Have Recently Emerged?

In recent years, a wave of research has brought forth significant advancements in zirconia technology. Want to know what’s new? These breakthroughs are expanding the usability of zirconia powder across various sectors, leading to enhanced performance and cost-effectiveness.

One noteworthy development is the refinement of zirconia’s microstructure. Researchers have achieved finer control over the particle size and distribution, allowing for the engineering of zirconia that exhibits improved strength and flexibility. This improvement not only enhances the material’s mechanical properties but also optimizes its performance in demanding applications, resulting in longer-lasting components.

Another area gaining traction is the exploration of doped zirconia. By incorporating elements like yttria or ceria, scientists can tailor the mechanical and chemical properties for specific uses. For instance, doped zirconia has shown improved ionic conductivity, which is vital for applications in fuel cells and electrochemical systems where efficiency is key.

Additionally, advancements in manufacturing processes have significantly reduced production costs. Innovative techniques such as additive manufacturing and advanced sintering methods allow for the mass production of high-quality zirconia powder. This accessibility supports a broader range of applications and encourages innovation in product design.

Here are a few emerging trends in zirconia research:

- Bioactive Zirconia: Enhancements are being developed for use in medical applications, particularly in bio-implants to promote better integration with bone tissue.

- Nano-Zirconia: The development of nano-scale zirconia offers new opportunities for achieving higher performance in coatings and catalysts.

- Environmental Sustainability: New methods are being explored to recycle zirconia, further promoting eco-friendly practices in industries that utilize this material.

In summary, these R&D breakthroughs are positioning zirconia as a more attractive option for many industries, addressing both performance metrics and cost efficiency effectively.

| Breakthrough | Description |

|---|---|

| Microstructure refinement | Enhanced particle size control for better strength |

| Doped zirconia innovations | Tailored properties for specific applications |

| Cost-effective manufacturing | Scalable production methods for better accessibility |

3. How Are Innovations Changing Zirconia Powder Properties?

Innovations in zirconia research are leading to significant changes in its properties, making it an increasingly attractive material for various applications. Curious about how this affects you? These improvements enhance the performance and extend the usability of zirconia across multiple industries.

One major change involves the mechanical properties of zirconia. Advances in processing techniques allow manufacturers to produce zirconia with superior toughness and strength. This enhancement is invaluable in dental applications, where durability and resistance to chipping or cracking are paramount for patient satisfaction.

Additionally, improvements in chemical stability have been noted. Zirconia is being treated to increase its resistance to acids and bases. This enhances its suitability for use in harsher environments, such as chemical processing or as protective coatings in various industrial applications.

Thermal expansion characteristics have also been modified. With innovations in dopant materials, zirconia now exhibits a reduced thermal expansion coefficient. This property becomes crucial when zirconia components are subjected to varying temperatures, ensuring longevity and performance stability.

Furthermore, recent research has started to explore the concept of functionally graded zirconia. This involves creating layers of zirconia with varying compositions or properties, enabling customized performance for specific applications.

In summary, these innovations are transforming zirconia from a useful material to a crucial one for high-performing applications across various sectors.

| Property Change | Impact |

|---|---|

| Enhanced mechanical strength | Improved durability in dental applications |

| Increased chemical stability | Better performance in harsh environments |

| Reduced thermal expansion | Longer-lasting components under temperature shifts |

- Other potential benefits include:

- Improved ion conductivity for applications in batteries.

- Enhanced wear resistance, making zirconia ideal for high-friction environments.

- Greater flexibility in design through customized formulations for specific needs.

These ongoing innovations ensure that zirconia remains at the forefront of material science, catering to diverse and demanding industrial requirements.

The image depicts technological innovations in zirconia research, illustrating advancements in material properties and their applications.

4. What Industrial Requirements Are Being Met by New Developments?

New developments in zirconia technology are addressing specific industrial needs. What does this mean for your business? It translates into enhanced efficiency, performance, and adaptability, essential for maintaining a competitive edge.

In the dental industry, the demand for materials that not only look good but also perform well under stress is high. Recent advancements ensure that zirconia can meet these aesthetic and mechanical requirements, thus providing patients with both durability and visual appeal. This combination of aesthetic quality and strength makes zirconia a standout option for dental restorations.

In the aerospace sector, weight reduction is a critical concern. New zirconia formulations help reduce the weight of components without compromising strength or thermal stability. This could lead to fuel savings, higher payload capacities, and improved performance metrics, making these new materials attractive for manufacturers.

Chemical industries require materials that withstand corrosive environments effectively. Innovatively treated zirconia now meets these demands, offering reliability in processes where failure is not an option. As a result, businesses can depend on zirconia-coated equipment to enhance safety and longevity in their operations.

Additionally, several requirements are being met through these advancements:

- Cost-Effectiveness: By improving manufacturing processes, companies can produce zirconia at lower costs.

- Customization: The ability to tailor zirconia for specific applications allows for more specialized and varied uses across different sectors.

- Regulatory Compliance: New developments ensure that zirconia meets evolving industry standards, aiding businesses in maintaining compliance.

Therefore, these developments are aligning zirconia powder’s properties with the pressing needs of various industries, creating a win-win situation for manufacturers and consumers.

| Industry & Requirement | Zirconia’s Contribution |

|---|---|

| Dental (Aesthetic & Durability) | High strength with attractive appearance |

| Aerospace (Weight Reduction) | Lightweight yet strong components |

| Chemical Processing (Corrosion Resistance) | Reliable material under harsh conditions |

5. How Do New Zirconia Applications Improve Efficiency?

The latest applications of zirconia powder are leading to significant efficiency improvements across various sectors. Wondering how this could benefit your operations? Here are some key ways zirconia innovations enhance efficiency:

- Reduced Wear and Maintenance Costs: By incorporating advanced zirconia in components, industries experience decreased wear and tear. This durability translates to longer equipment lifespans and significantly lower maintenance costs, allowing companies to allocate resources to other essential areas.

- Enhanced Performance in Fuel Cells: In the energy sector, zirconia is increasingly used in fuel cells, which convert chemical energy into electricity. Innovations regarding its ionic conductivity have resulted in higher performance levels, making these fuel cells not only more efficient but also more cost-effective.

- Effective Thermal Management: Zirconia helps with thermal insulation or serves as thermal barriers, enhancing energy efficiency across applications. In automotive engines and industrial furnaces, for instance, its properties reduce energy loss, contributing to sustainable practices and operational savings.

- Streamlined Manufacturing Processes: With its enhanced mechanical properties, zirconia contributes to smoother manufacturing workflows. Companies can produce more reliable and consistent final products, minimizing defects and increasing throughput.

These advancements don’t just make zirconia powder more appealing as a material; they create a competitive edge for businesses that adopt these innovations.

| Application Area | Efficiency Improvement |

|---|---|

| Manufacturing | Reduced wear and longer lifespan |

| Energy (Fuel Cells) | Higher performance and electricity conversion |

| Thermal Management | Improved energy efficiency |

Overall, by investing in these new applications of zirconia powder, businesses can experience notable improvements in their operational efficiency, leading to increased productivity and profitability.

6. What Role Does Sustainability Play in R&D for Zirconia?

Sustainability is increasingly pivotal in the development of zirconia powder applications. Why should this concern you? Understanding this aspect can align your business with modern environmental standards and consumer expectations.

Recent R&D initiatives have focused on creating zirconia using more sustainable practices. This includes sourcing raw materials from environmentally friendly suppliers and reducing waste during production processes.

Furthermore, zirconia’s longevity and durability mean less frequent replacements. This leads to a reduced environmental footprint over the lifespan of products. As industries shift towards greener practices, materials like zirconia that promote sustainability will gain traction.

Additionally, the recycling potential of zirconia is significant. As applications grow, so does the interest in recycling zirconia components and powder, further enhancing its eco-friendly profile.

Consequently, aligning your operations with zirconia’s sustainable practices could provide competitive advantages in an increasingly eco-conscious market.

| Sustainability Aspect | Impact |

|---|---|

| Environmentally Friendly Sourcing | Reduced ecological impact of raw material extraction |

| Durability and Longevity | Less frequent replacements leading to waste reduction |

| Recycling Opportunities | Potential for closed-loop manufacturing systems |

This image highlights sustainable practices in zirconia production, emphasizing eco-friendly sourcing and recycling methods.

7. How Are Consumer Demands Shaping R&D Directions?

Collaborations between academic institutions, manufacturing companies, and research organizations play a pivotal role in advancing zirconia research. Curious about how these partnerships work? They can significantly accelerate innovation in this area, leading to better materials and applications.

Many universities nowadays partner with industries to conduct studies focusing on zirconia’s properties and potential. These collaborations provide essential resources such as funding, state-of-the-art laboratories, and access to expertise in material science. Additionally, researchers can gain insights into real-world challenges faced by manufacturers, fostering more relevant research outcomes.

For example, some companies are actively working alongside academic researchers to explore new doping strategies for zirconia formulations. These partnerships are often collaborative research projects where teams iterate on designs and share findings, enabling faster prototyping and market readiness.

Furthermore, international collaborations allow for the sharing of knowledge and best practices across borders. This exchange not only enhances the quality of research but also facilitates tackling complex challenges that require diverse expertise and perspective.

In summary, these collaborative efforts not only enhance the quality of zirconia research but also bring innovative solutions to market more quickly and effectively. Business can focus on several key areas in these partnerships:

- Technology Transfer: Sharing novel technologies and processes between academia and industry.

- Multidisciplinary Approaches: Combining expertise from various fields such as chemistry, engineering, and materials science.

- Joint Funding Opportunities: Pooling resources to access larger funding grants, which can lead to groundbreaking discoveries.

| Collaboration Type | Benefit |

|---|---|

| University-Industry Partnerships | Access to research funding and expertise |

| Joint Ventures | Faster development cycles and market readiness |

| International Collaborations | Sharing of knowledge and best practices |

8. What Collaborations Are Driving Zirconia Powder Research?

Collaborations between academic institutions, manufacturing companies, and research organizations play a pivotal role in advancing zirconia research. Curious about how these partnerships work? They can significantly accelerate innovation in this area.

Many universities now partner with industries to conduct studies focusing on zirconia’s properties and applications. These collaborations provide access to funding, expertise, and cutting-edge technology.

For example, some companies work alongside research institutions to develop doped zirconia formulations. These partnerships allow for a faster iteration of designs and prototypes, speeding up time to market.

Additionally, international collaborations enable knowledge and best practices to be shared across borders. By combining resources and insights, involved parties can tackle more complex challenges related to zirconia applications.

In summary, these partnerships not only enhance the quality of research but also bring innovative zirconia solutions to market more quickly.

| Collaboration Type | Benefit |

|---|---|

| University-Industry Partnerships | Access to research funding and expertise |

| Joint Ventures | Faster development cycles and market readiness |

| International Collaborations | Sharing of knowledge and best practices |

9. What Challenges Exist in Advancing Zirconia Technologies?

Despite its many advantages, advancing zirconia technologies comes with challenges. What should you be aware of? Understanding these obstacles can help you better prepare for market changes and make informed decisions regarding investments and material choices.

One significant challenge is the cost of producing high-quality zirconia. While advancements have been made, ensuring consistent quality while reducing costs can be tough. New processes must also be economically viable to compete with alternative materials on the market.

In addition to production costs, the complexity of tailoring zirconia for specific applications presents technical hurdles. This often involves extensive research and development efforts, which can slow down the innovation cycle. Not every development will meet industry expectations, requiring ongoing testing and validation to ensure reliability.

Regulatory challenges can also impact research. As industries evolve, compliance with safety and environmental regulations becomes increasingly important. Businesses must navigate these regulations carefully to avoid potential setbacks in their R&D timelines.

In addition to the aforementioned challenges, companies face the following common issues:

- Market Competition: Staying relevant amidst numerous competitors can drive up the race for innovation.

- Supply Chain Disruptions: Fluctuations in raw material availability may impact production schedules.

- Knowledge Gaps: There may be a lack of skilled professionals who specialize in zirconia applications.

This understanding of challenges is essential for making informed decisions. Awareness and preparation can lead to better strategies for meeting these hurdles, ensuring that companies remain competitive in a fast-evolving market landscape.

| Challenge | Impact |

|---|---|

| Production Costs | High-quality zirconia can be expensive to produce |

| Technical Complexity | Tailoring properties requires extensive testing |

| Regulatory Compliance | Adherence to evolving safety and environmental standards |

10. How Can Businesses Benefit from Investing in Zirconia Innovations?

Investing in zirconia innovations can yield numerous benefits for businesses. What can you gain from this investment?

First, implementing advanced zirconia materials can lead to improved product performance. Enhanced durability reduces the frequency of replacements, lowering lifetime costs.

Second, companies that adopt innovative zirconia products can achieve competitive advantages. By offering superior materials, businesses can attract larger clients or better markets, eventually increasing profitability.

Finally, as sustainability becomes crucial, businesses that prioritize eco-friendly zirconia solutions will enhance their corporate reputation. This aligns their operations with current market trends, satisfying both consumer demand and regulatory requirements.

Investing in zirconia innovations isn’t just about upgrading materials; it’s a strategic move towards future growth and sustainability for your business.

| Investment Benefit | Outcome |

|---|---|

| Improved Product Performance | Lower replacement costs and enhanced reliability |

| Competitive Advantage | Attraction of larger clients and improved profitability |

| Enhanced Corporate Reputation | Alignment with sustainability trends |

Conclusion

In summary, recent research and development breakthroughs are transforming zirconia powder applications, benefiting various industries. These innovations enhance properties, improve efficiency, and meet the growing demands for sustainability. By utilizing zirconia, companies can achieve not only cost savings but also align with modern consumer expectations.

For businesses looking to stay competitive, engaging with Global Industry for tailored zirconia solutions is a strategic next step. This partnership can empower you to capitalize on the latest advancements, positioning your company for success in the evolving market landscape.

FAQ Section

Q1: What are the primary benefits of zirconia powder?

Zirconia powder offers exceptional mechanical strength, thermal stability, and resistance to wear and corrosion. These properties make it an ideal choice for critical applications in industries such as dental, aerospace, and ceramics. Its versatility allows for a wide range of uses, enhancing product performance and durability.

Q2: How often do breakthroughs in zirconia research occur?

Breakthroughs in zirconia research occur regularly, driven by advancements in material sciences and technology. Researchers are constantly exploring new formulations and processing techniques, leading to improved properties and expanded applications. Staying updated on these advancements can significantly impact industry practices and product offerings.

Q3: Are there any safety concerns with using zirconia?

Generally, zirconia is considered safe for industrial use and applications. However, like any material, safety precautions should be followed during handling to avoid inhalation of fine particles, particularly in powder form. Employers should implement proper ventilation and personal protective equipment (PPE) protocols in work environments.

Q4: What industries most significantly utilize zirconia powder?

Zirconia powder is primarily used in the dental industry for making crowns and bridges, in aerospace for high-temperature components, and in electronic devices for insulators and sensors. Its applications extend to ceramics and coating technologies, highlighting its adaptability across diverse sectors.

Q5: How can businesses stay updated on zirconia developments?

Businesses can stay informed about zirconia developments by subscribing to industry journals, participating in trade shows, and attending conferences focused on materials science. Engaging with research institutions and following related news can also provide valuable insights into the latest innovations and trends in zirconia technology.