In the ceramics industry, achieving high-quality glaze smoothness and gloss is a top priority for manufacturers. Customers expect visually appealing products that reflect craftsmanship and attention to detail. However, many manufacturers struggle with selecting the right zircon silicate particle size, which can lead to significant issues such as surface roughness and dull finishes. Problems like roughness not only compromise the aesthetic quality of the final product but can also affect its marketability and acceptance.

This article directly addresses these challenges by explaining how different grades of zircon silicate — a widely used material in glazing — impact overall glaze performance. By understanding this critical relationship, you as a decision-maker can make informed purchasing decisions that ultimately enhance the quality of your final products. With years of expertise in the field, our company is well-positioned as a reliable source for consistent, well-defined zircon silicate materials tailored to your specific needs.

What is Particle Size and Its Importance?

Particle size plays a crucial role in determining various characteristics and performance metrics of glaze. Each particle within the glaze contributes to how it behaves during application, firing, and in the final aesthetic appeal of the product. Understanding particle size and why it matters can significantly improve glaze formulation.

To comprehend particle size, it’s essential to define a few key metrics that are commonly used in the industry:

- D50 (Median Particle Size): This metric represents the average size of the zircon silicate particles in a batch. It influences crucial properties such as opacity and whiteness, which are paramount in achieving a desirable glaze. A lower D50 value indicates smaller particles, thereby increasing the surface area, which aids in better light scattering and results in enhanced opacity.

- D90 (Coarse Fraction): The D90 value indicates the size of the largest 90% of particles in a sample. This is a critical figure since larger particles can cause surface imperfections. For instance, if the D90 value is too high, larger particles may protrude from the glaze surface, leading to a rough, uneven texture. This not only diminishes the gloss but can also result in a poor tactile experience for consumers.

- D10 (Fine Fraction): This metric identifies the smallest 10% of particles in a batch. Smaller particles often influence the rheological properties of the glaze, affecting how it flows and how easily it can be applied. Fine particles can lead to better suspension and uniformity in the glaze mixture but can also increase the viscosity, which poses its challenges in application.

Understanding these metrics leads to recognizing the core trade-off involved in selecting particle sizes. For example, finer particles with a D50 of less than 1.5µm can provide a greater opacifying power due to their increased surface area. This means that the glaze can hide underlying surfaces more effectively while also improving smoothness. However, the downside is that these finer particles might be more costly and may alter the glaze’s viscosity, which could complicate its application.

In contrast, choosing coarser particles yields a more economical option. These tend to have a D50 greater than 2.0µm, leading to reduced costs but often result in lower opacity and a rougher end product. Inadequate integration of these larger particles into the glaze mass can result in visible imperfections.

Thus, the initial choice of particle size is essential for achieving your desired glaze quality. It requires balancing both performance and cost considerations to achieve optimal results.

| Metric | Description | Impact on Glaze |

|---|---|---|

| D50 | Median Particle Size | Affects opacity and whiteness |

| D90 | Coarse Fraction | Main cause of roughness |

| D10 | Fine Fraction | Influences rheology and suspension stability |

How Does Particle Size Affect Glaze Properties?

Understanding how zircon silicate particle size specifically influences various glaze properties can guide manufacturers in selecting the right materials for their specific applications. Here are the key properties affected by particle size, explained in detail:

Glaze Smoothness (Surface Texture):

Surface roughness is a well-known issue when it comes to glaze quality. Larger D90 particles protruding from the glaze surface are often the primary culprits in creating an uneven texture. When these larger particles are present in excess, they can disrupt the uniformity of the glaze finish, making it look unrefined and unprofessional. To combat this, it is crucial to use zircon silicate with a controlled D90, ideally less than 5µm, for applications demanding a very smooth finish. High-end tiles and premium tableware are prime examples where smoothness is non-negotiable.

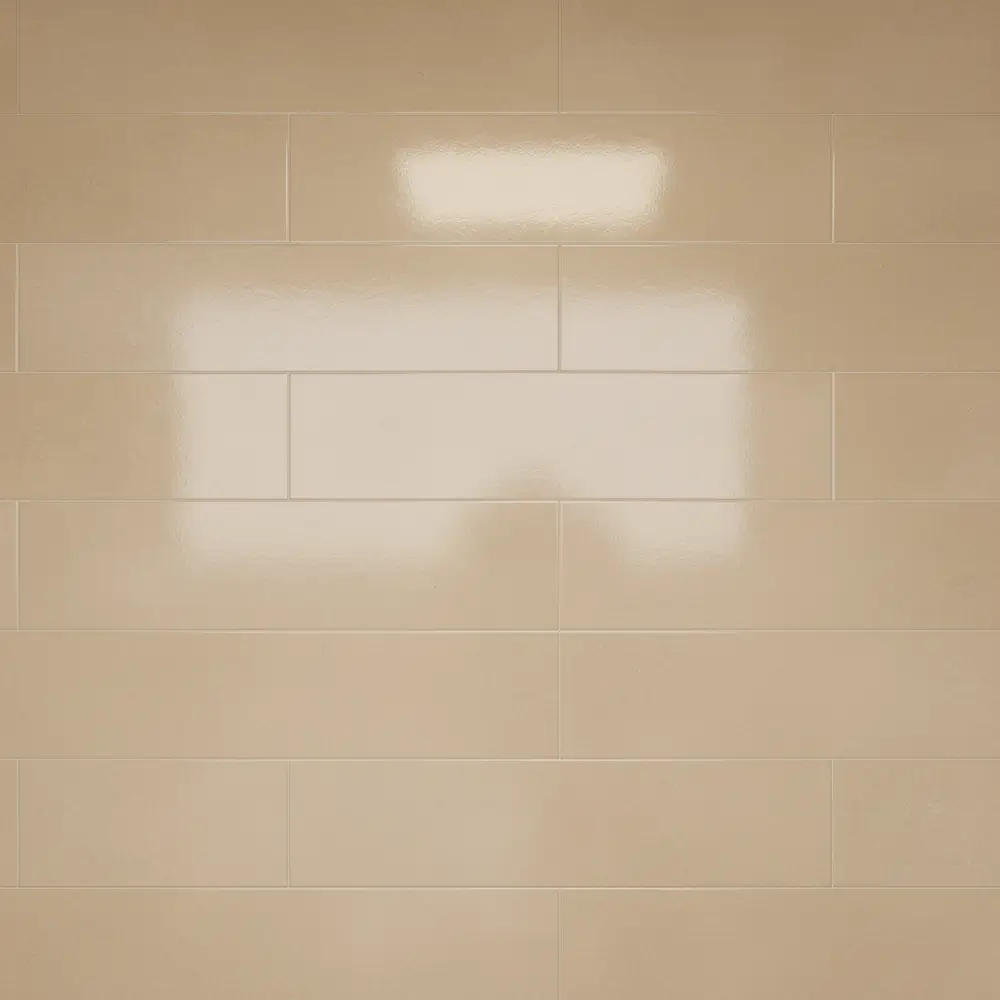

This image illustrates smooth ceramic tiles with a glossy glaze finish, showcasing the end result of proper particle size selection.

Gloss Level:

Gloss is another attribute significantly impacted by particle size. The way light interacts with the surface of the glaze is directly related to its texture. A smooth, flawless surface reflects light specularly, akin to a mirror, yielding high gloss. On the other hand, a rough surface diffuses light, resulting in a lackluster appearance. Therefore, controlling the coarse fraction (D90) becomes essential not only for achieving the desired aesthetic but also for maintaining high gloss levels, which can make or break a product’s market appeal.

Opacity and Whiteness:

Opacity is fundamentally influenced by the number and size of particles in the glaze. More particles mean greater light scattering, which results in higher opacity. Therefore, by incorporating finer zircon silicate, manufacturers can achieve the same level of opacity with a reduced quantity — effectively making it a more efficient and cost-effective option. The relationship here is clear: utilizing a high-quality, finer product can yield significant cost savings without compromising on performance.

Rheology and Suspension:

Moreover, the rheological properties of the glaze should not be overlooked. Fine particles can enhance the viscosity of the glaze slurry. This increased viscosity, while beneficial in maintaining suspension, may necessitate adjustments to the glaze formulation. Manufacturers may need to add deflocculants or other additives to ensure proper flow and application characteristics, complicating the formulation process but ultimately allowing for better glaze performance.

A comprehensive understanding of these properties allows manufacturers to tailor their selections according to the specific needs of their products, leading to superior outcomes.

| Property | Impact of Particle Size |

|---|---|

| Smoothness | Larger particles lead to roughness and defects. |

| Gloss Level | Smooth surfaces reflect more light for higher gloss. |

| Opacity | Smaller particles enhance light scattering for opacity. |

| Rheology | Fine particles can increase viscosity requiring formulation adjustments. |

What Are Application-Specific Recommendations?

When selecting zircon silicate grades, it is essential to tailor your choice to the specific needs of each application. Below are detailed recommendations categorized by usage type:

For Wall Tiles & General Industrial Ceramics:

- Goal: Achieve good opacity without incurring excessive costs. Wall tiles generally require a balance between performance and economic efficiency.

- Recommendation: A standard-grade zircon silicate with a D50 around 1.8-2.5µm is recommended, as this range typically provides the best balance of performance and cost. It allows for adequate coverage and aesthetic appeal while remaining budget-friendly.

For Floor Tiles & Sanitaryware:

- Goal: Attain high opacity, good smoothness, and excellent durability in products that will withstand wear and tear.

- Recommendation: A finer grade with a D50 between 1.3-1.8µm is ideal for these applications. This range not only ensures high opacity but also improves the smoothness of the glaze, catering to durability requirements that floor tiles and sanitaryware often need.

For High-Gloss Polished Tiles & Premium Tableware:

- Goal: Maximum gloss, perfect smoothness, and brilliant whiteness are crucial for these high-end products, as customers expect nothing less than perfection.

- Recommendation: An ultra-fine or micronized grade zircon silicate with a D50 of around 0.9-1.2µm is necessary for these applications. Consistency in particle distribution is critical here, as even slight variations can lead to imperfections that detract from the overall quality.

The image showcases a variety of ceramic products, each demonstrating different glaze finishes influenced by particle size.

This comprehensive table summarizes these recommendations, offering a quick reference for manufacturers seeking to optimize their glaze choices based on specific applications.

| Application Type | Goal | Recommended Particle Size (D50) |

|---|---|---|

| Wall Tiles & General Industrial Ceramics | Good opacity at a competitive cost | 1.8-2.5µm |

| Floor Tiles & Sanitaryware | High opacity and good durability | 1.3-1.8µm |

| High-Gloss Polished Tiles & Premium Tableware | Maximum gloss and smoothness | 0.9-1.2µm |

What Common Mistakes Should You Avoid?

Understanding common pitfalls can help manufacturers make better decisions and avoid challenges that can arise from poor material selection. Here are the primary mistakes to avoid when working with zircon silicate:

Miscalculating Particle Sizes:

A frequent error is not accurately assessing the particle sizes required for specific applications. Ensure you utilize the correct metrics, particularly assessing both D50 and D90 accurately. This means regularly consulting specifications for each batch of material used. For raw materials like Zircon Sand, accurate assessment is the first step.

Neglecting Test Results:

If you rely solely on product specifications without conducting your tests, you risks ending up with poor glaze performance. Regular testing and monitoring of results are essential to optimizing glaze characteristics, ensuring that they meet your desired quality standards.

Overlooking Process Variability:

Recognize that every production run can have slight differences in particle behavior. Factors such as humidity, temperature, and mixing methods can all affect how particles perform. Constant monitoring, combined with adjustments, can help maintain quality and consistency.

By being aware of these common mistakes and taking proactive measures to avoid them, you can enhance the performance and quality of your glaze products, leading to superior end results that will satisfy market standards.

| Common Mistake | Description |

|---|---|

| Miscalculating Particle Sizes | Failing to utilize the correct metrics can lead to inferior results. |

| Neglecting Test Results | Not conducting tests can result in subpar performance. |

| Overlooking Variability | Ignoring process differences may harm consistency. |

How Can You Make Informed Choices?

Making informed choices regarding zircon silicate particle size means recognizing the implications of your decisions on glaze performance. Key insights into particle selection include:

- Understanding the Role of D90 and D50: Recognizing that the coarse fraction (D90) directly impacts smoothness and gloss will help you make informed decisions that reflect the quality you wish to achieve.

- Evaluating Performance Over Price: By shifting your focus from merely comparing price to evaluating zircon silicate based on its performance and ability to yield high-quality finishes, you’ll likely discover more effective and suitable options.

- Prioritizing Regular Testing: Regular testing and adjustments according to the specific requirements of your products can greatly improve the glaze characteristics, ensuring consistency and ultimately enhancing customer satisfaction.

With these considerations in mind, you can significantly improve the overall quality and appeal of your products. Trustworthy suppliers will provide you with the necessary resources to ensure your selections yield optimal results.

Conclusion

Understanding the critical role that zircon silicate particle size plays in glaze quality is essential for manufacturers seeking to enhance their products. The coarse fraction significantly impacts both smoothness and gloss, while the median particle size drives opacity. By grasping these factors, you can improve your production process and product quality effectively.

Achieving a consistent high-quality finish enhances the overall value of your ceramics and positions your products favorably in the market. For expert assistance tailored to your specific glazing needs, reach out to Global Industry. Our skilled team stands ready to help you analyze your requirements and recommend the most effective zircon silicate solutions to boost your product quality.

FAQ Section

Q1: Why is zircon silicate preferred for glazing?

Zircon silicate is preferred for glazing due to its excellent opacifying properties and ability to enhance the whiteness of ceramic products. Its unique crystal structure helps to scatter light effectively, improving the aesthetics of the final glaze. This makes it an essential component for producing high-quality ceramics that require a bright, opaque finish. Additionally, zircon silicate is chemically stable and resistant to high temperatures, ensuring that it performs well even under rigorous firing conditions.

Q2: What is the impact of particle size on glaze smoothness?

Particle size plays a significant role in determining glaze smoothness. Smaller particles tend to create a more uniform glaze surface, which is essential for achieving a smooth finish. In contrast, larger particles may protrude from the surface, leading to a rough texture that detracts from both the appearance and feel of the final product. A smaller D90 value allows for better integration of the particles within the glaze matrix, reducing the risk of surface imperfections. This is particularly important in applications where aesthetic quality is paramount, such as high-end tiles and dinnerware.

Q3: How does particle size influence glaze costs?

The choice of particle size can significantly influence overall glaze costs. Generally, finer particles may be more expensive due to their complex production processes. However, they often require less material to achieve the same level of opacity and aesthetic quality. This means that while the upfront cost might be higher, the total cost can actually be lower when accounting for material efficiency. Manufacturers can achieve superior results with smaller quantities, which leads to savings in both material use and potential rework or defects in the finished product.

Q4: What are the best practices when selecting particle size?

Best practices for selecting particle size include understanding the specific requirements of your application, such as desired gloss, opacity, and smoothness. Conducting thorough testing with different particle sizes can help determine the most effective option for your specific glaze formulation. It is also crucial to collaborate closely with suppliers who can provide detailed technical specifications and guidance based on your unique production conditions. Additionally, maintaining consistent monitoring during production runs ensures that any variability in materials or processes can be addressed promptly.

Q5: How can I get technical assistance with my glaze formulation?

For technical assistance with glaze formulations, manufacturers are encouraged to reach out to suppliers directly. Our technical team is available to provide expert consultations, helping you analyze your specific requirements and suggesting the most suitable zircon silicate products for your needs. Additionally, many suppliers offer resources such as product catalogs or technical datasheets, which can help guide your decisions. Whether you need assistance with formulation adjustments, testing methodologies, or material selections, professional support is essential for achieving optimal results in your glazing operations.