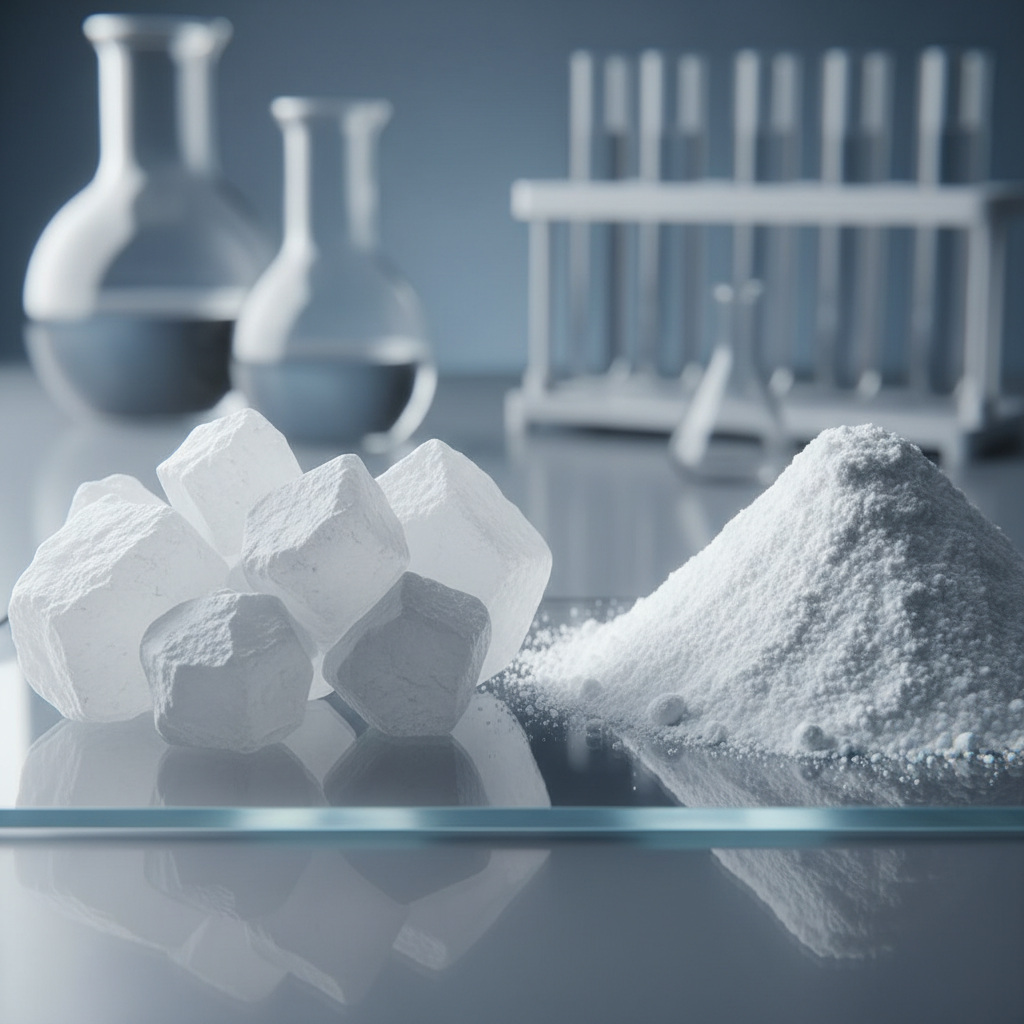

Zirconium silicate operates as a top-tier opacifier for ceramic glazes and functions as a high-performance refractory material in extreme thermal industrial environments.

You often face devastating production delays when ceramic finishes emerge brittle or furnace linings crumble under intense heat. These material failures drain your operational budget yet finding a consistent solution remains a constant struggle for many procurement officers. Implementing high-purity zirconium silicate provides the thermal resilience and chemical inertness required for high-stakes manufacturing applications across global markets. But here’s the kicker… this mineral does more than just resist heat as it bridges the gap between structural longevity and aesthetic perfection. By choosing this specialized powder, you eliminate the risk of substandard output while securing a reliable supply chain for your most demanding projects. This proven chemical compound ensures that every batch maintains uniform quality so your manufacturing facility avoids costly defects or unexpected maintenance shutdowns during peak production cycles.

What is zirconium silicate used for?

Zirconium silicate serves as a vital opacifier within ceramic glazes and functions as a stable refractory component for high-temperature furnace applications.

The primary industrial versatility of ZrSiO₄

Modern factories utilize this white powder for creating opaque finishes on porcelain tiles or sanitaryware products. This specific mineral allows you to achieve consistent whiteness without sacrificing the mechanical strength of your finished ceramic goods. This is where it gets interesting… beyond simple aesthetics, this compound provides resistance against chemical corrosion during heavy-duty industrial processing. You will find that adding this material to your production line reduces the frequency of product rejects while improving the surface hardness of every item manufactured.

- Achieving high-gloss glazes.

- Strengthening structural ceramics.

- Improving chemical inertness.

Is it the ultimate solution for high-heat environments?

Foundries rely on this mineral for creating molds that withstand molten metal temperatures without deforming or cracking. Its high melting point ensures that your precision casting remains accurate under conditions where lesser materials would surely fail. Ready for the good part? It also acts as an effective heat shield within glass melting furnaces and steel production facilities. You can depend on this stable compound for maintaining furnace integrity so your long-term maintenance costs remain manageable and predictable.

- Stabilizing furnace linings.

- Resisting thermal shock.

- Protecting structural steel.

Key Takeaway: Using zirconium silicate ensures high-level opacity and thermal stability across diverse manufacturing sectors.

| Industry Sector | Primary Application | Benefit | |

|---|---|---|---|

| Ceramics | Opacification | High Whiteness | |

| Metallurgy | Refractories | Heat Resistance | |

| Chemicals | Inert Filler | Corrosion Defense |

This data confirms why the mineral remains a staple for modern industrial procurement strategies.

What are zirconium silicate’s properties?

Zirconium silicate possesses a high refractive index of 1.93-2.01 along with a melting point exceeding 2500°C and exceptional chemical stability. High-purity zirconium silicate ensures these traits remain consistent across every production batch.

Does its 2500°C melting point define its utility?

This extreme temperature threshold allows you to deploy the material in the most punishing thermal zones of a factory. It remains solid and functional while other minerals liquefy or lose their structural bonds under intense heat. What’s the real story? This property alone makes it vital for space-age alloys and advanced ceramics that require absolute stability. You gain peace of mind knowing your components will not warp when temperatures soar beyond the limits of standard industrial materials.

- High thermal capacity.

- Zero deformation at heat.

- Structural bond strength.

Why is chemical stability a game-changer for durability?

Resistance to acids and alkalis ensures that your coatings do not degrade when exposed to harsh industrial cleaning agents. This inertness represents a shield that protects the underlying substrate from environmental damage or reactive chemical spills. Here is the kicker: even under saline conditions or high-humidity environments, this mineral maintains its original composition without oxidation. You can trust this stability for outdoor architectural projects where longevity and low maintenance are your primary goals.

- Acid-alkali resistance.

- Non-reactive surface.

- Weathering protection.

Key Takeaway: Superior melting points and chemical inertness make zirconium silicate an ideal choice for harsh environments.

| Physical Property | Value | Industrial Impact | |

|---|---|---|---|

| Melting Point | >2500°C | Extreme Heat Survival | |

| Refractive Index | 1.93 – 2.01 | Superior Opacity | |

| Hardness | 7.5 Mohs | Wear Resistance |

Analyzing these physical characteristics helps engineers select the right materials for demanding structural applications.

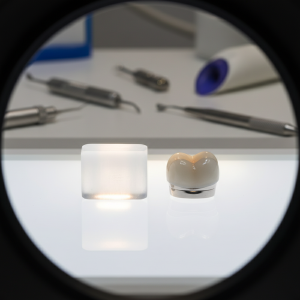

Why is it vital for the ceramic industry?

It provides the necessary opacity for glazes while increasing the mechanical strength and scratch resistance of tiles and sanitaryware. Every modern ceramic plant utilizes zirconium silicate to ensure their surface finishes meet high-quality international standards.

Can it achieve the perfect tile opacity and whiteness?

Achieving a brilliant white finish on porcelain requires a high refractive index that masks the underlying clay body effectively. This mineral scatters light so efficiently that you only need a small amount to produce a high-quality opaque glaze. Believe it or not: this efficiency directly translates to lower material costs for your factory since you achieve better results with less volume. You will notice that the resulting whiteness stays vibrant for decades without yellowing or fading from UV exposure.

- Maximum light scattering.

- Cost-efficient opacification.

- Long-term color stability.

Why is sanitaryware surface resistance non-negotiable?

Bathroom fixtures must withstand constant moisture and abrasive cleaning without losing their glossy, hygienic surface finish. This compound integrates into the glaze to create a dense barrier that prevents bacterial growth or deep staining. Wait, there is more… the increased surface hardness protects your products from scratches during shipping or installation in residential projects. You provide a superior product to your clients by ensuring that every washbasin or toilet remains pristine despite heavy daily usage.

- Hygienic gloss finish.

- Stain-proof barrier.

- Abrasive wear defense.

Key Takeaway: Zirconium silicate is the gold standard for achieving high whiteness and durability in ceramic glazes.

| Ceramic Product | Use Case | Benefit | |

|---|---|---|---|

| Floor Tiles | Glaze Opacifier | Wear Resistance | |

| Wash Basins | Surface Coating | Stain Defense | |

| Tableware | Porcelain Additive | Chip Resistance |

This comparison highlights why global tile manufacturers depend on the mineral for consistent product aesthetics.

How does it perform in refractory materials?

Zirconium silicate prevents structural failure in furnace linings by offering superior thermal shock resistance and low thermal expansion. Utilizing high-grade zirconium silicate allows you to extend the operational life of expensive industrial kilns.

Are furnace linings protected by thermal shock resistance?

Rapid temperature fluctuations in industrial kilns can cause standard bricks to crack or explode due to uneven expansion. This mineral stabilizes the matrix of refractory shapes so they can expand and contract without losing their structural integrity. But here’s the kicker… this stability allows you to cycle your furnaces faster without risking a catastrophic lining collapse during production. You save valuable time during start-up and shut-down phases because your equipment can handle aggressive thermal transitions with ease.

- Thermal cycling stability.

- Crack prevention.

- Operational speed.

Can it reduce long-term operational maintenance costs?

Linings that last longer mean fewer shutdowns for repairs and lower expenses for replacement materials over the fiscal year. This compound resists the corrosive effects of molten glass and slag which typically eat away at less durable furnace components. This is where it gets interesting… by extending the lifespan of your kiln, you maximize your return on investment for heavy machinery. You will find that the reduced maintenance schedule allows your team to focus on production rather than constant emergency repairs.

- Corrosion resistance.

- Extended kiln life.

- Lower repair frequency.

Key Takeaway: Refractory durability hinges on the thermal stability provided by the inclusion of zirconium silicate.

| Material Type | Heat Limit | Primary Advantage | |

|---|---|---|---|

| Zircon Bricks | 1800°C | Chemical Resistance | |

| Zircon Cement | 1650°C | Thermal Shock Defense | |

| Glass Kiln Lining | 1600°C | Slag Protection |

Technical evaluation proves that adding this mineral significantly reduces the risk of structural failure in high-heat zones.

Can it enhance paints and coatings?

It acts as a functional filler that improves UV resistance, surface hardness, and weatherability in industrial and architectural coatings. Zirconium silicate ensures that your paint products maintain their protective qualities even when exposed to harsh environmental factors.

Does UV resistance extend industrial coating lifespans?

Outdoor machinery and pipelines face constant bombardment from solar radiation which typically causes paint to peel and crack. This mineral absorbs and scatters harmful rays so the polymer binder in your coating remains intact for much longer. Ready for the good part? You can market your paints as ultra-durable because they maintain their color and protective properties even in desert environments. This longevity reduces the repainting cycle for your clients and positions your brand as a leader in protective technology.

- Solar radiation shield.

- Color retention.

- Coating integrity.

Is it the secret to automotive scratch resistance?

Modern car finishes require a clear coat that can survive car washes and road debris without developing unsightly swirl marks. Integrating this fine powder into the coating matrix increases the surface hardness without affecting the transparency or gloss. What’s the real story? It creates a microscopic armor that deflects minor impacts and prevents micro-scratches from dulling the vehicle’s appearance. You provide a premium automotive finish that stays showroom-new for years so your customers remain satisfied with their investment.

- Micro-scratch defense.

- Gloss preservation.

- Impact resilience.

Key Takeaway: Coatings benefit from the mechanical reinforcement and light-scattering properties of zirconium silicate.

| Coating Type | Property Enhanced | Value Add | |

|---|---|---|---|

| Automotive | Hardness | Scratch Resistance | |

| Marine | Anti-Corrosion | Saltwater Defense | |

| Architectural | UV Shield | Weather Longevity |

The integration of this mineral into modern paint formulas provides a clear competitive edge for specialty coating manufacturers.

Is it effective in the foundry sector?

In the foundry industry, it is used for investment casting and mold coatings to ensure a smooth surface finish on metal parts. Applying zirconium silicate based washes to your molds prevents the liquid metal from bonding with the sand surface.

Does it minimize precision casting defects significantly?

Foundries often struggle with gas porosity or sand fusion when pouring molten steel into standard molds. Using coatings based on this mineral creates a smooth barrier that prevents the liquid metal from penetrating the mold surface. Believe it or not: this precision results in cast parts that require almost zero post-production grinding or finishing work. You save hours of labor and reduce material waste by getting the casting right on the first attempt every time.

- Prevention of metal penetration.

- Reduced surface roughness.

- Lower finishing costs.

Why is investment casting mold stability crucial?

Aerospace and medical components require extreme dimensional accuracy that only high-quality mold materials can provide. This mineral ensures that the mold does not expand or warp during the cooling process of the molten alloy. Here is the kicker: the thermal stability of the mold allows for the creation of thin-walled parts that remain strong and accurate. You can tackle more complex engineering projects because your material selection supports the highest levels of casting precision available today.

- Dimensional accuracy.

- Complex geometry support.

- High cooling stability.

Key Takeaway: Foundry yields and part quality improve dramatically when zirconium silicate is utilized in mold preparation.

| Foundry Process | Mineral Role | Direct Result | |

|---|---|---|---|

| Sand Casting | Mold Wash | Surface Smoothness | |

| Precision Casting | Shell Building | Dimensional Accuracy | |

| Die Casting | Lubricant Filler | Thermal Resistance |

Analyzing foundry metrics shows that zirconium silicate is a primary factor in reducing scrap rates for precision metal parts.

How does it impact electronic applications?

Zirconium silicate provides excellent electrical insulation and is used in the production of multilayer ceramic capacitors and high-tech sensors. It allows for the miniaturization of modern devices while maintaining high thermal and electrical performance standards.

Is it the backbone of modern ceramic capacitors?

Electronic devices require capacitors that remain stable under varying voltages and temperatures to ensure reliable performance. This compound acts as a high-dielectric material that allows for the miniaturization of components in smartphones and laptops. Wait, there is more… its thermal stability prevents the capacitor from failing when the device heats up during heavy processing tasks. You can build more powerful and compact electronics because this mineral supports the density required for modern circuit designs.

- High dielectric constant.

- Thermal stability.

- Device miniaturization.

Can it optimize optical lens clarity and refraction?

Precision optics used in cameras and medical imaging require materials with a high refractive index to bend light accurately. This mineral is used in specialized glass formulations to improve clarity while reducing the weight of the lens. This is where it gets interesting… it allows for thinner lenses that still provide superior magnification and light transmission for high-end equipment. You gain a competitive advantage in the optics market by offering lighter and sharper products to professional photographers and doctors.

- Refractive index control.

- Lens weight reduction.

- Clarity optimization.

Key Takeaway: Electronics and optics rely on the unique insulation and refractive properties of zirconium silicate.

| Component | Mineral Benefit | Performance Impact | |

|---|---|---|---|

| MLCC Capacitors | Dielectric Stability | Higher Energy Density | |

| Precision Lenses | Refraction | Thinner Optics | |

| High-Heat Sensors | Insulation | Reliable Accuracy |

The high-tech manufacturing sector continues to find new ways to leverage the properties of this versatile compound.

What drives global demand trends?

Urbanization and industrialization in emerging markets are the primary drivers for the increased consumption of zirconium silicate globally. Sourcing high-grade zirconium silicate becomes more vital as construction projects expand in developing nations.

Is the Asia-Pacific region leading consumption growth?

Rapid construction in China and India has created a massive need for ceramic tiles and high-quality sanitaryware. These nations are investing heavily in infrastructure which requires durable refractory materials for steel and cement production. But here’s the kicker: the shift toward luxury housing in these regions has spiked the demand for premium white-glazed ceramics. You can see how global trade patterns are shifting toward these manufacturing hubs as they dominate the supply chain for building materials.

- Infrastructure expansion.

- Luxury ceramic demand.

- Manufacturing hub growth.

How does urbanization fuel construction mineral needs?

As more people move to cities, the demand for residential buildings and commercial spaces necessitates vast quantities of architectural coatings. Every new skyscraper or apartment complex requires protective paints and decorative tiles that use this mineral for durability. Ready for the good part? This trend shows no signs of slowing down as developing nations continue their path toward modern city living. You can expect a steady market for your products so long as the global population continues to centralize in urban areas.

- High-rise construction.

- Interior finishing needs.

- Market stability.

Key Takeaway: Rapid global urbanization and infrastructure growth are the engines driving consistent demand for zirconium silicate.

| Market Region | Major Driver | Demand Outlook | |

|---|---|---|---|

| Asia-Pacific | Infrastructure | Aggressive Growth | |

| Europe | High-Tech Coatings | Stable Demand | |

| North America | Electronics | Steady Increase |

Analyzing global market data shows that the construction and high-tech sectors will continue to require stable mineral supplies.

How to choose a high-purity supplier?

Selecting a supplier requires verifying product purity levels, technical support capabilities, and the reliability of their global logistics network. You must ensure your partner provides consistent materials to avoid unexpected variations in your manufacturing output.

Is 99.9% purity essential for your specific operations?

Lower grade minerals often contain iron or titanium impurities that can discolor your glazes or ruin the thermal properties of your refractories. Using high-purity minerals ensures that your finished products meet the highest quality standards without variations. What’s the real story? A slight impurity can lead to a batch of tiles being rejected which costs you far more than the price of premium raw materials. You protect your profit margins by insisting on rigorous lab testing and certification for every shipment you receive.

- Impurity control.

- Batch consistency.

- Profit protection.

Why does technical support matter more than price?

Industrial processes are complex and you may need guidance on particle size distribution or mineral blending for your specific kiln. A supplier that offers engineering expertise can help you optimize your formula to reduce waste and improve output quality. Believe it or not: the cheapest supplier often lacks the knowledge to help you when a production crisis occurs in your facility. You should prioritize partners who provide a full range of services from data sheets to on-site troubleshooting for your team.

- Application guidance.

- Formula optimization.

- Problem-solving partnership.

Key Takeaway: Supplier selection should be based on purity standards and technical depth rather than just initial cost.

| Supplier Criteria | Priority Level | Business Impact | |

|---|---|---|---|

| Chemical Purity | High | Product Quality | |

| Logistics Network | Medium | Supply Chain Safety | |

| Engineering Support | High | Process Optimization |

Choosing a partner with a proven track record ensures your production line remains efficient and competitive in the global market.

Is zirconium silicate an eco-friendly choice?

It is considered a non-toxic mineral that helps industries meet strict environmental regulations and sustainability goals in modern manufacturing. Switching to high-purity zirconium silicate allows your company to align with modern ESG requirements.

Does non-toxicity make it a sustainable mineral choice?

Unlike some lead-based opacifiers or heavy metal pigments, this mineral is safe for workers and the environment throughout its lifecycle. It does not leach harmful chemicals into the groundwater when products are eventually disposed of in landfills. Here is the kicker: this safety profile simplifies your compliance with health and safety laws in both the domestic and international markets. You can build a brand reputation based on environmental responsibility by choosing materials that do not harm the planet.

- Worker safety.

- Zero leaching.

- Regulatory compliance.

Can it help industries meet strict ESG regulations?

Investors and governments are increasingly pressuring manufacturers to adopt sustainable sourcing practices and reduce their carbon footprint. Utilizing durable minerals that extend product lifespans reduces the overall waste generated by industrial sectors. This is where it gets interesting… the high efficiency of the mineral means you use less energy to achieve the desired results in your manufacturing process. You align your company with the future of green industry by integrating these sustainable practices into your core operations today.

- Waste reduction.

- Energy efficiency.

- ESG alignment.

Key Takeaway: Environmental safety and long-term sustainability are core advantages of using zirconium silicate in modern industry.

| Sustainability Goal | Mineral Contribution | Metric | |

|---|---|---|---|

| Waste Reduction | Extended Life | Lower Replacement Rate | |

| Non-Toxicity | Safe Disposal | Zero Hazardous Runoff | |

| Energy Saving | Process Efficiency | Lower Carbon Output |

Adopting this mineral supports the global transition toward cleaner and more responsible industrial manufacturing practices.

Conclusion

Zirconium silicate represents the backbone of high-performance ceramics and heavy-duty industrial applications. By prioritizing material purity and thermal stability, you can eliminate the manufacturing defects that currently stall your production lines. We encourage you to evaluate your current raw material supply and consider the long-term benefits of a higher grade mineral solution. For personalized technical guidance or to request a detailed quote, please contact us to discuss your specific industrial requirements.

FAQ

Can I use zirconium silicate for high-gloss automotive finishes?Yes, you can integrate this mineral into clear coats to improve scratch resistance and maintain a showroom shine over many years of road exposure.

What’s the best way to determine purity levels for industrial refractories?You should always request a Certificate of Analysis (COA) from your supplier to verify that iron and titanium impurities remain below critical thresholds.

How do I know if my current milling process requires different bead sizes?If your output particles are inconsistent or your grinding time is increasing, you may need to consult with a technician about optimizing your grinding media.

Can I replace alumina with this mineral in my furnace lining?It depends on your specific operating temperature and chemical environment but this mineral often provides better thermal shock resistance in certain applications.

What’s the best storage method for maintaining powder consistency?You must store the powder in a dry, temperature-controlled environment to prevent moisture absorption which can lead to clumping and processing issues.