Ceramic manufacturers frequently encounter inconsistent glaze application, leading to defects like crawling, pinholes, or uneven surfaces despite using standard formulations. These inconsistencies cause significant production downtime, high scrap rates, and wasted raw materials. The critical key to stabilizing flow and finish lies in optimizing the Particle Size Distribution (PSD) of Zircon Powder, ensuring superior rheology and flawless ceramic glazing.

Zircon Powder PSD Defines Glaze Fluidity

PSD directly dictates the suspension’s internal friction and fluidity by altering the total surface area and inter-particle spacing.

Understanding Rheology in Slurries

Rheology defines how your liquid glaze moves under pressure and responds to shear forces during application. Here is the deal: It is not just about thickness; it is about the thixotropic nature of the fluid where viscosity changes based on agitation speed. If you ignore the interaction between particle surface area and the liquid medium, achieving a consistent spray curtain becomes a guessing game.

Particle Packing and Flow

Tighter particle packing creates predictable flow channels by minimizing the void volume that the liquid medium must fill. You need a mix of sizes where small particles fit into the interstices between larger ones to create a “bearing effect.” This reduces void space and stabilizes the fluid dynamics of the slurry, preventing sudden viscosity spikes during pumping.

PSD Impact on Viscosity

A narrow PSD often leads to lower viscosity at higher solids loading because uniform particles slide over each other less efficiently than a graded mix. You might be wondering: How does this help? It allows you to apply a denser coating with higher specific gravity without the glaze running off vertical surfaces due to low yield stress.

| Distribution Type | Solids Loading Capability | Viscosity Characteristic | Application Result | |

|---|---|---|---|---|

| Broad Distribution | High (Max Packing) | Lower Viscosity | Dense, stable suspension with less water demand. | |

| Narrow Distribution | Low | Dilatant (Shear Thickening) | Prone to clogging; requires more water to flow. | |

| Gap Graded | Variable | Unpredictable | susceptible to segregation and uneven drying. |

Analysis: Controlling the distribution width (span) is as critical as the average particle size for maintaining a consistent yield stress in the spray booth.

Key Takeaway: Mastering the distribution curve allows you to maximize solid content while maintaining a fluid, sprayable consistency that resists sagging.

Unique Zircon Powder Traits Ensure Stability

Its chemical inertness and high density prevent unwanted reactions within the wet glaze matrix.

Stability of Zirconium Silicate

Zirconium Silicate (ZrSiO4) is remarkably resistant to chemical attack and has extremely low solubility in water and most glaze mediums. Here is the bottom line: You can store slurries for extended periods without pH drifts or ionic exchange that would alter the glaze’s flocculation state. This ensures your rheology remains constant from the mixing tank to the spray gun, regardless of storage time.

Thermal Resistance Roles

This material withstands extreme heat (melting point >2550°C) without decomposing or reacting prematurely in the kiln. You benefit because it maintains viscosity during the initial firing stages, acting as a refractory skeleton. This prevents the glaze from running off vertical surfaces or “curtaining” before the glassy phase fully matures.

Physical Shape Influence

Milled Zircon particles often retain an angular morphology which increases internal friction compared to spherical silica. But consider this: While angularity helps build the necessary yield stress to prevent settling, it can hinder high-speed flow. You must balance particle morphology through controlled milling to suit your specific high-pressure application equipment.

| Property | Value / Characteristic | Production Benefit | |

|---|---|---|---|

| Specific Gravity | ~4.6 g/cm³ | High density allows for compact, durable coatings. | |

| Mohs Hardness | 7.5 | Provides exceptional scratch resistance in the final product. | |

| Refractive Index | 1.93 – 1.98 | High light scattering for maximum whiteness and opacity. |

Analysis: The physical and chemical robustness of Zircon acts as a predictable anchor, stabilizing complex glaze formulations against thermal and chemical variance.

Key Takeaway: Leveraging the inherent stability of Zircon Powder minimizes process variables, leading to predictable firing results every time.

Measuring Zircon Powder Rheology Accurately

Rotational viscometry offers the most precise data on shear behavior and thixotropy.

Using Rotational Viscometry

This method measures how the glaze reacts to different stirring speeds, generating a flow curve that reveals shear-thinning or shear-thickening behavior. Here is why it matters: You can see if the glaze thins out sufficiently when sprayed (high shear) but recovers viscosity quickly enough to stay on the tile (zero shear). It provides a full profile of the slurry’s behavior under the stress of industrial pumps.

The Flow Cup Method

Ford cups or Zahn cups are standard for quick production floor checks but only measure kinematic viscosity at a single point. You simply time how long a specific volume takes to drain through a calibrated orifice (e.g., 40-60 seconds). It is a fast, though less detailed, way to catch major shifts in batch consistency or water content.

Interpreting Viscosity Curves

Reading rheology curves helps you predict specific application issues like hysteresis (recovery time). Look at the data: A steep downward curve suggests strong shear-thinning, ideal for spraying, while a flat line indicates a Newtonian fluid that might drip. Understanding these graphs prevents defects before the glaze ever enters the spray booth.

| Measurement Tool | Primary Metric | Best Application | |

|---|---|---|---|

| Rotational Viscometer | Dynamic Viscosity (cP) | R&D, Formulation, Detailed Troubleshooting | |

| Ford/Zahn Cup | Efflux Time (Seconds) | Line-side QA, Consistency Checks | |

| Yield Stress Rheometer | Yield Point (Pa) | Determining anti-settling properties |

Analysis: Combining lab-grade viscometry for formulation with daily flow cup tests for process control ensures both accuracy and consistency.

Key Takeaway: Implementing a dual-measurement protocol protects you from drifting specifications and sudden application failures caused by unmonitored viscosity shifts.

Zircon Powder Size Metrics Dictate Finish

D50 and D90 values directly control surface smoothness, opacity, and melt integration.

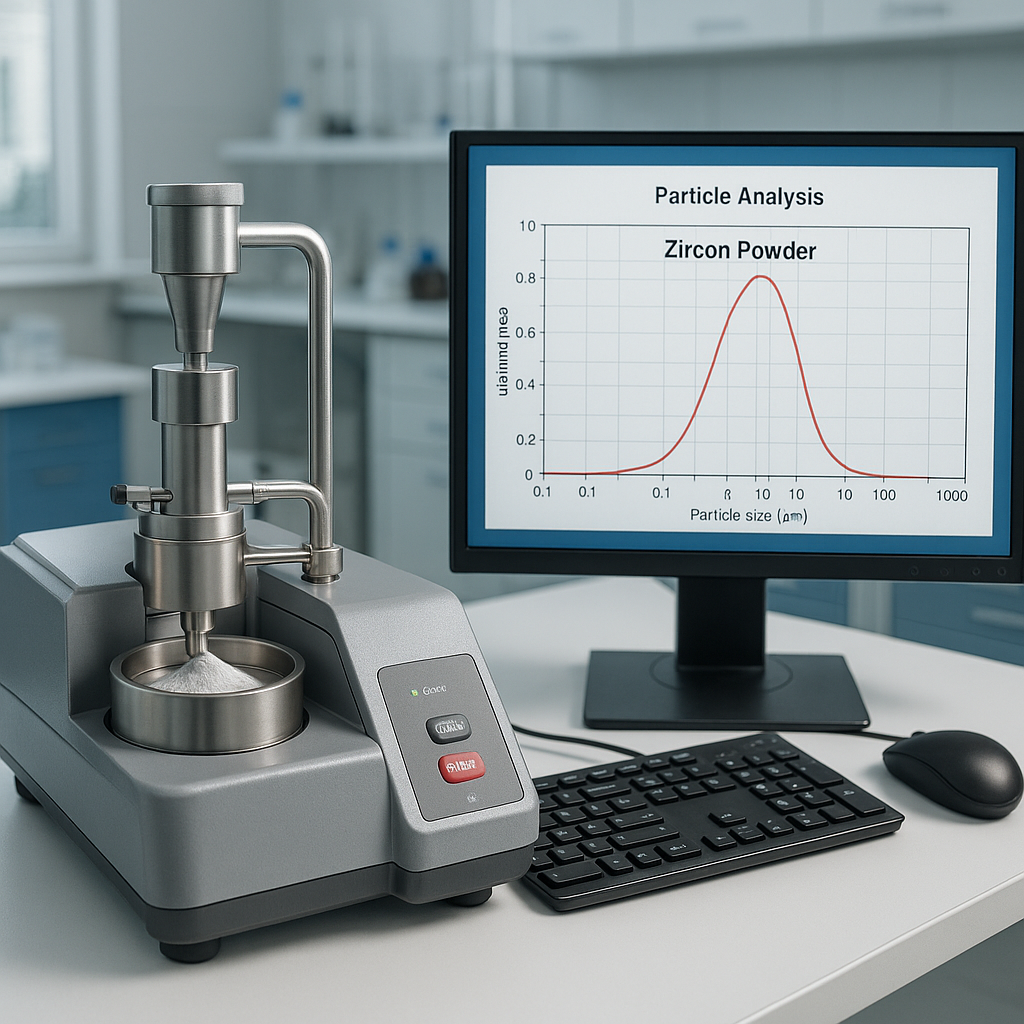

The Critical D50 Value

D50 represents the median particle size in your distribution, where 50% of the mass is finer and 50% is coarser. Why is this vital? It determines the specific surface area available for reaction; a lower D50 (e.g., 1.2 µm) generally means better coverage and higher opacity due to increased light scattering.

D90 and Surface Roughness

The D90 tells you the size of the coarsest particles in the distribution tail. If this value is too high (e.g., >15 µm), you will see protrusions and a rough texture in the fired glaze. Keeping the D90 strictly controlled is non-negotiable for achieving smooth, mirror-like glossy surfaces.

The Role of Fines

Ultrafine particles (<1 µm) act as a lubricant and suspension aid within the slurry matrix. It gets better: They help keep coarser particles afloat by increasing the density of the liquid phase. However, an excess of fines can lead to high drying shrinkage and surface cracking (crawling) before firing.

| Surface Finish Target | Recommended D50 | Recommended D90 | |

|---|---|---|---|

| High Gloss / Mirror | 0.8 – 1.2 µm | < 6.0 µm | |

| Satin / Semi-Matte | 1.5 – 2.0 µm | < 12.0 µm | |

| Rustic / Textured | 2.0 – 5.0 µm | < 25.0 µm |

Analysis: Balancing the coarse tail (D90) with the fines fraction is essential for a glaze that suspends well in the tank and fires smooth on the ware.

Key Takeaway: Tighter control over D50 and D90 specifications directly correlates to a reduction in tactile surface defects and visual imperfections.

Overcoming Common Zircon Powder Obstacles

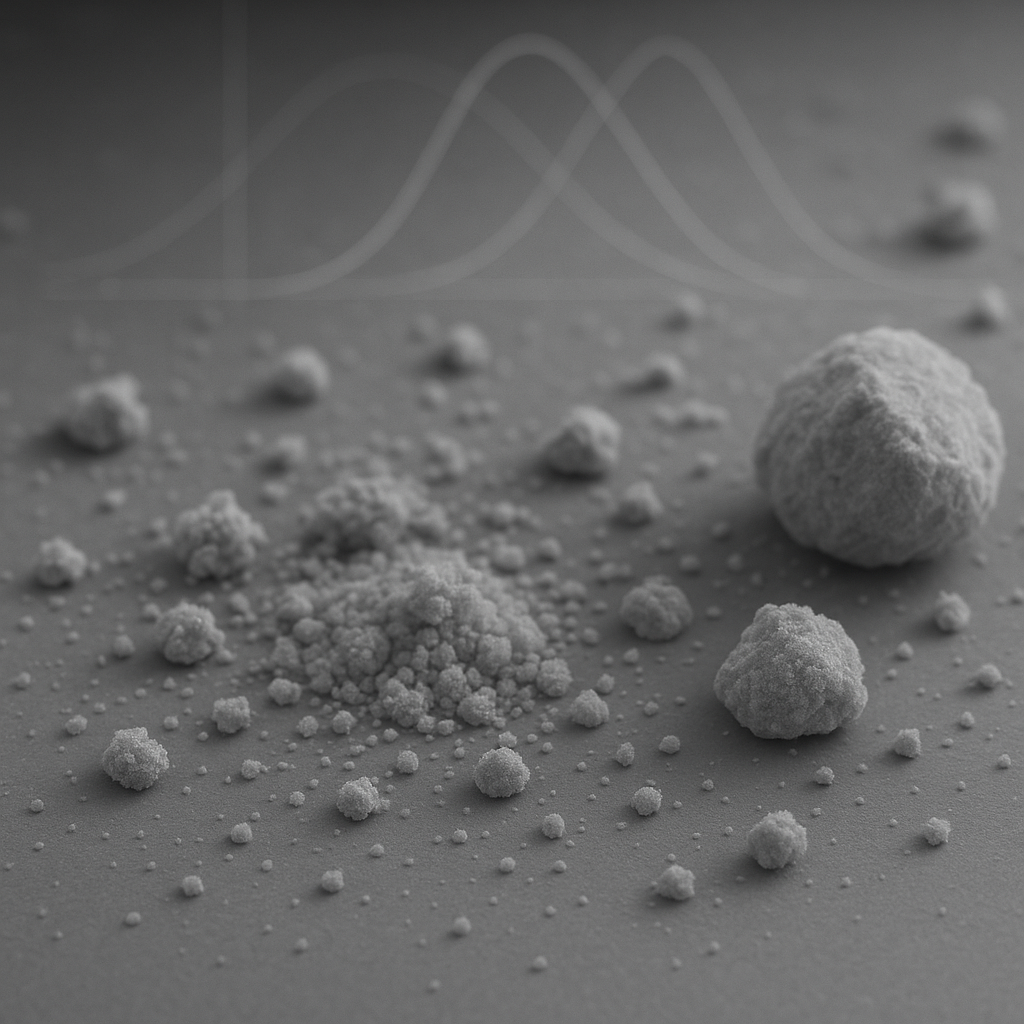

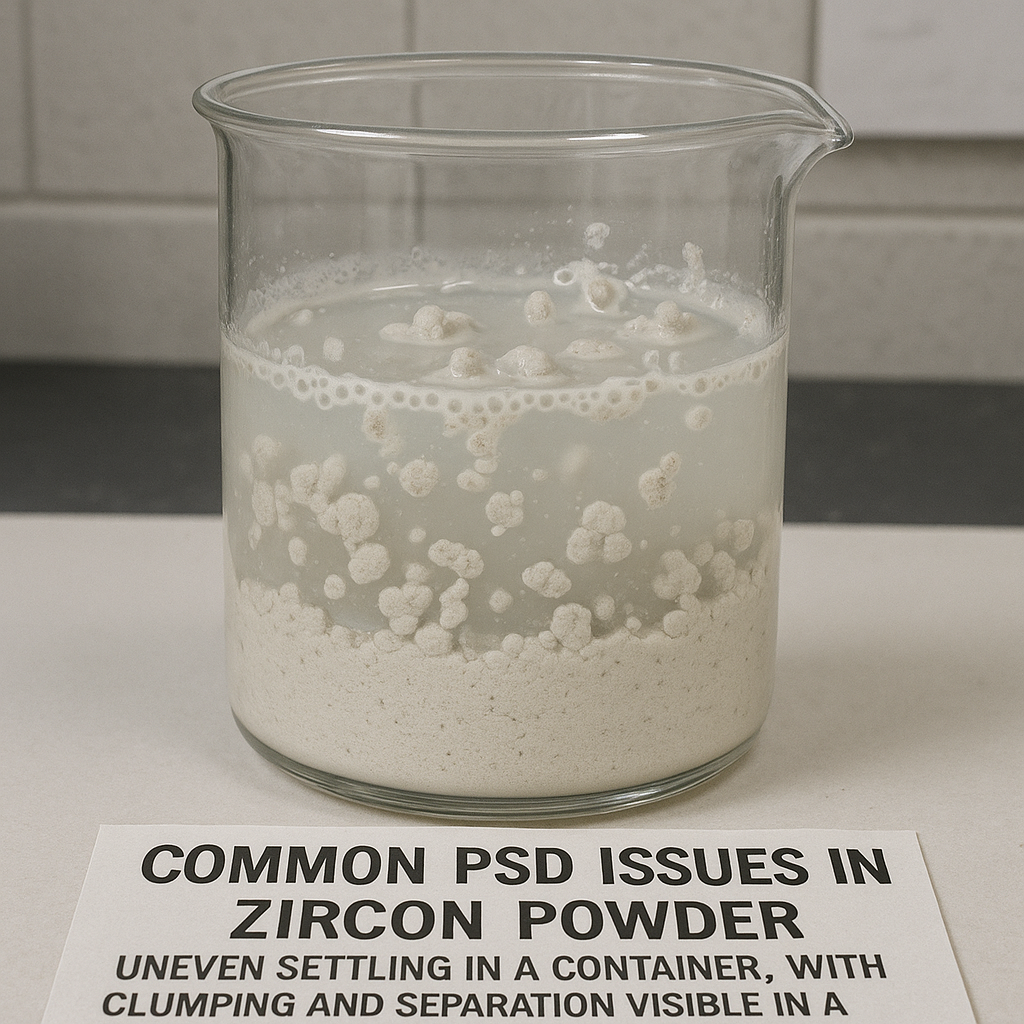

Hard sedimentation is the primary processing challenge due to Zircon’s high specific gravity.

Battling Sedimentation

Zircon is significantly denser than silica or feldspar, meaning it loves to settle to the tank bottom rapidly. Here is the kicker: Once it hard-packs, the angular particles interlock, making it nearly impossible to remix without high-shear agitation. You must maintain constant agitation or use rheological additives (like CMC or bentonite) to build a yield stress that supports the particles.

Inconsistency Risks

Variations in PSD batch-to-batch cause fluctuating glaze thickness and opacity levels. You might get transparent spots one day and heavy drips the next because the surface area of the powder changed. Sourcing pre-stabilized powder with a certified PSD curve is the only way to avoid this production nightmare.

Equipment and Nozzle Wear

Coarse Zircon particles are harder than steel and extremely abrasive. Think about this: They act like liquid sandpaper on your spray nozzles, check valves, and pump diaphragms. Monitoring PSD helps you remove the oversized particles (D99) that are responsible for the majority of erosive wear on expensive parts.

| Common Issue | Root Cause | Actionable Solution | |

|---|---|---|---|

| Hard Panning | Low yield stress in slurry | Add suspending agents (Bentonite/CMC). | |

| Nozzle Erosion | Excessive coarse particles | Screen glaze through 325 mesh (44µm). | |

| Pinholing | High viscosity / trapped air | Adjust deflocculant or reduce solid content. |

Analysis: Proactive management of particle sedimentation and abrasiveness extends equipment life and reduces maintenance intervals.

Key Takeaway: Addressing sedimentation and abrasion through PSD control prevents costly downtime and extends the lifespan of application machinery.

Zircon Powder PSD Maximizes Glaze Opacity

Optimal sizing enhances light scattering efficiency for brighter, whiter glazes.

Light Scattering Mechanics

Opacity is generated when light bounces off Zircon particles that have a high refractive index difference from the glass matrix. Here is the secret: The particle size must match roughly half the wavelength of visible light (approx. 0.2 – 0.4 µm radius) for maximum scatter. If particles are too big, light passes through; if too small, they dissolve into the glass.

Whiteness and PSD

A tight PSD centered around 1 micron delivers the purest white because it maximizes the scattering cross-section per gram of material. You achieve higher brightness (L* value) without adding extra material, which is critical for cost savings. This is the most efficient way to improve aesthetic quality without changing the chemistry.

Enhancing Hiding Power

Good opacity effectively covers imperfections and the color of the underlying clay body. You need to know: A well-optimized Zircon glaze can hide dark red or brown clay bodies with a thinner layer than a coarse Zircon glaze. This allows you to use cheaper local raw materials for the tile body while maintaining a premium surface look.

| Opacity Grade | Average Particle Size | Application | |

|---|---|---|---|

| Super Opacifier | 0.8 – 1.0 µm | Premium Sanitaryware, Super White Tiles | |

| Standard Opacifier | 1.2 – 1.5 µm | Standard Wall Tiles, Tableware | |

| Coarse Flour | > 2.0 µm | Engobes, Matte Glazes, Frits |

Analysis: There is a direct geometric relationship between particle diameter and the refraction of light that determines visible quality and manufacturing cost.

Key Takeaway: Optimizing for opacity allows you to achieve superior whiteness and coverage using significantly less Zircon loading.

Methods to Optimize Zircon Powder Blends

Jet milling produces the tightest particle curves required for high-end ceramic applications.

Jet vs. Ball Milling

Jet mills use compressed air to smash particles against each other at supersonic speeds, causing breakage along natural crystal planes. Here is the difference: This creates a narrower, cleaner curve with fewer superfines compared to ball milling, which relies on attrition. Ball mills are cheaper but leave a wider, less predictable distribution that affects rheology control.

Real-Time Laser Monitoring

Modern processing uses laser diffraction technology to check particle size instantly during production. You get real-time feedback during the milling process, allowing for immediate classifier adjustments. This ensures that every bag of powder meets the exact D50 and D90 spec you ordered, reducing lot-to-lot variance.

Blending for Balance

Sometimes you need a bimodal distribution to maximize packing density and reduce water demand. Try this: Blend a fine grade (1µm) with a medium grade (5µm) to create a slurry that packs tightly but flows easily. This strategy often improves rheology and reduces shrinkage better than a single-sized powder.

| Milling Method | PSD Characteristics | Typical Application | |

|---|---|---|---|

| Jet Milling | Steep curve, Narrow distribution | High-gloss glazes, Inkjet inks | |

| Ball Milling | Broad bell curve | Standard tiles, Engobes | |

| Vibration Milling | Very broad, high fines | Frits, Structural ceramics |

Analysis: Advanced milling technologies are the prerequisite for producing Zircon powders that meet modern automated glazing standards.

Key Takeaway: Investing in jet-milled or precision-blended powders eliminates the variability that plagues traditional ball-milled alternatives.

Zircon Powder Efficiency Lowers Production Costs

Better transfer efficiency and lower reject rates reduce total manufacturing costs.

Reducing Material Waste

Optimized rheology means more glaze sticks to the ware rather than bouncing off or turning into overspray mist. The result? Less glaze ends up in the waste water treatment plant or sludge reclamation system. You save money directly on the most expensive component in your glaze bucket: Zirconium Silicate.

Lowering Defect Rates

Consistent flow eliminates common application defects like pinholes, crawling, and orange peel. You process fewer re-fires and scrap fewer finished pieces, which is the biggest hidden cost in ceramics. This directly boosts your “First Time Quality” (FTQ) metrics and overall plant yield.

Extending Equipment Life

Removing coarse particles protects your pumps, screens, and spray guns from premature failure. Here is the deal: Less abrasion means fewer nozzle replacements and less production downtime for maintenance. Your maintenance budget drops significantly when the slurry is less aggressive and flows with lower pressure requirements.

| Cost Driver | Optimization Impact | Estimated Savings Potential | |

|---|---|---|---|

| Raw Material | Higher transfer efficiency | 5 – 10% reduction in glaze usage | |

| Quality / Yield | Reduced pinholes & crawling | 15 – 20% reduction in scrap | |

| Maintenance | Extended nozzle/pump life | 30% reduction in spare parts |

Analysis: The premium paid for optimized Zircon powder is recovered multiple times over through process efficiencies and scrap reduction.

Key Takeaway: High-quality PSD is an investment that pays dividends through higher yields, lower waste, and reduced equipment overhead.

Diverse Zircon Powder Applications in Industry

While critical for ceramics, Zircon’s properties are vital for metallurgy and glass manufacturing.

Sanitaryware and Tiles

These sectors consume the vast majority of Zircon production globally. You see it daily: Sinks, toilets, and floor tiles require that bright, clean white finish which implies hygiene. It provides the chemical resistance needed to withstand harsh daily cleaning agents without losing gloss.

Investment Casting Shells

Foundries use Zircon flour for the primary slurry coat in precision investment casting. You need it to prevent the molten metal from reacting with the mold wall at high temperatures. The high refractoriness and thermal stability ensure dimensionally accurate metal parts with superior surface finish.

Refractory and Glass

Specialized Zircon adds durability to glass melting furnaces and refractory blocks. Think about the heat: It lines the tanks that melt glass, resisting corrosion from the molten glass itself. In glass batch formulations, it modifies viscosity and improves alkali resistance, extending the lifespan of the glass product.

| Industry Sector | Function of Zircon | Critical Requirement | |

|---|---|---|---|

| Sanitaryware | Opacifier | High Whiteness & Chem Resistance | |

| Investment Casting | Mold Interface | High Refractoriness (>2500°C) | |

| Glass Production | Component / Liner | Corrosion Resistance |

Analysis: While ceramics dominate consumption, the unique thermal properties of Zircon make it indispensable in metallurgy and glass production.

Key Takeaway: The versatility of Zircon powder spans multiple high-temperature industries, driven by its unmatchable thermal and chemical stability.

Future Trends in Zircon Powder Technology

Nano-grade sizing and digital integration are driving the next evolution in surface coatings.

Shift to Nano-Sizing

The industry is moving toward sub-micron and nano-scale particles to maximize efficiency. What is the future? Nano-zircon offers higher opacity with ultra-thin layers, essential for modern lightweight tiles. This reduces total material consumption while enhancing surface properties like scratch resistance and antibacterial potential.

Eco-Friendly Processing

Energy-efficient milling and dry grinding technologies are becoming a priority to reduce carbon footprints. You will see more suppliers switching to dry grinding methods that eliminate the need for drying energy. This reduces the environmental impact of preparing ceramic raw materials and conserves water resources.

Digital Glazing Formulations

Inkjet printing requires ultra-fine, narrow PSDs to prevent nozzle clogging in printheads. Get ready: As digital glazing expands to cover full-surface application, demand for specialized Zircon inks will skyrocket. Standard powders simply clog these microscopic printheads (often <50 µm openings), necessitating highly engineered dispersions.

| Technological Trend | Driver | Production Implication | |

|---|---|---|---|

| Digital / Inkjet | Customization | Requires colloidal/nano Zircon (<0.5 µm) | |

| Thin-Body Tiles | Material Savings | Higher opacity required per micron of glaze | |

| Green Manufacturing | Carbon Regulations | Shift to dry milling & lower firing temps |

Analysis: The trajectory of Zircon technology is clearly headed toward finer sizing and tighter distributions to support digital manufacturing and sustainability.

Key Takeaway: Embracing nano-technologies and digital-ready formulations places manufacturers at the forefront of the next generation of ceramic production.

Conclusion

Controlling Particle Size Distribution eliminates rheological defects and stabilizes production. High-purity, optimized Zircon Powder delivers the consistent results necessary for modern manufacturing. Precise material science is the future of zero-defect ceramic manufacturing. Contact our technical team to analyze your current glaze challenges and find the perfect Zircon solution.

FAQ Section

Q1: Can I use any Zircon Powder for my glazes?No, it is risky. Using generic powder without a specific PSD curve often leads to unpredictable viscosity and settling. You must select a grade (e.g., 325 mesh vs. 5 micron) tailored to your specific application method (spray, dip, or bell) to ensure proper flow.

Q2: What is the best way to prevent hard settling?The most effective method is controlling the “fines” content or using rheological additives. Ensuring a balanced distribution of fine particles creates a structural network (yield stress) that supports coarser particles, preventing them from forming a hard, non-redispersible cake at the bottom.

Q3: How does Zircon Powder PSD affect firing temperature?Finer particles react faster due to higher surface area. A finer PSD increases the reactivity of the Zircon, potentially lowering the required maturation temperature or altering how the glaze melts and seals the surface, which can be beneficial for fast-firing cycles.

Q4: Can Zircon Powder improve glaze durability?Yes, significantly. Beyond opacity, a well-dispersed Zircon network adds mechanical strength (hardness) and chemical resistance to the fired glaze, making it more resistant to cutlery scratches and chemical attack over time.

Q5: What is the ideal D50 for glossy glazes?Generally, a D50 between 1.0 to 2.0 microns is preferred. This range offers the best balance between high opacity (maximum light scattering) and smooth surface leveling for a high-gloss finish without trapping bubbles.