When looking at sustainable material developments, one question often arises: How can businesses integrate effective, environmentally friendly materials? Zirconium silicate stands out as a key player in this field, offering a unique blend of performance, durability, and sustainability. Many professionals grapple with the challenge of finding materials that meet both performance standards and sustainability goals. Thankfully, the advantages of zirconium silicate provide a practical solution that can help bridge this gap. This article will guide you through the significance, applications, and the numerous benefits that this mineral offers to your operations, which is backed by proven data and industry insights.

With increasing global focus on sustainability, manufacturers must adapt to remain competitive. The search for materials that improve product longevity, performance, and eco-friendliness leads many to consider zirconium silicate. Understanding its properties and benefits can empower companies to make informed decisions, ensuring they not only meet industry standards but also contribute positively to the environment.

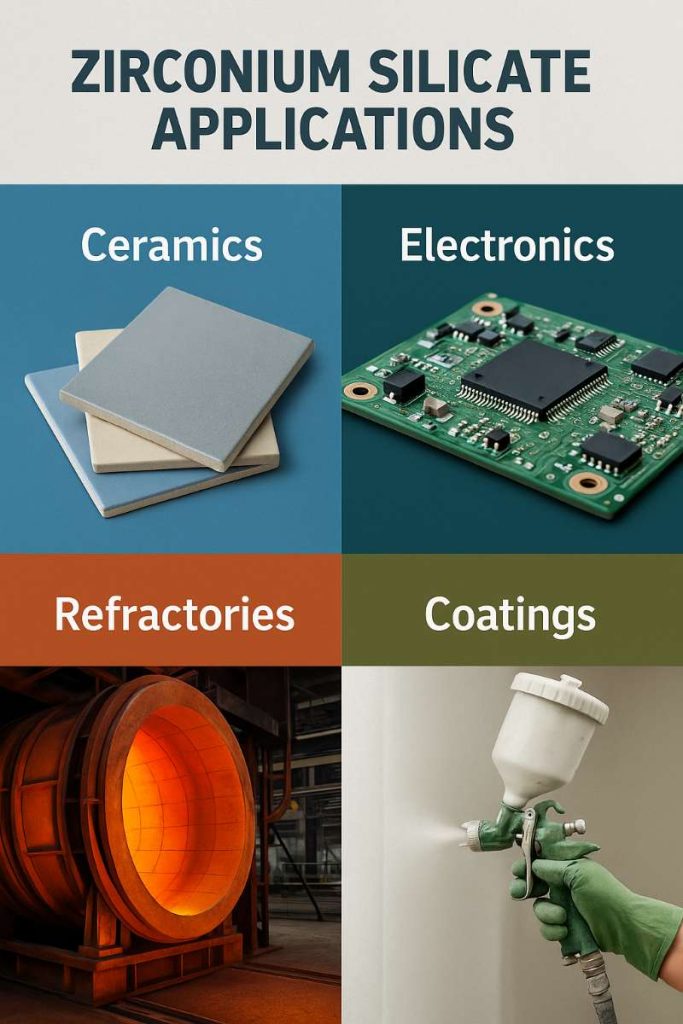

This image shows zirconium silicate used in various sustainable material applications.

Why Should Businesses Care About Zirconium Silicate?

Zirconium silicate is a mineral that plays a vital role in various industries, primarily due to its exceptional properties. Companies seeking sustainable alternatives recognize its potential as a game-changer. The growing emphasis on sustainability in manufacturing intensifies the need for materials like zirconium silicate, which can help firms achieve these objectives while maintaining exceptional quality.

As more industries start to prioritize eco-friendly products, the demand for alternative materials increases markedly. Zirconium silicate fits well into this shift. Different sectors such as ceramics, electronics, and construction benefit significantly from its use, providing businesses with versatile options that meet varied needs. For instance, manufacturers can utilize this mineral to create products that are not only durable but also environmentally responsible.

Moreover, a transition towards using zirconium silicate can strengthen a company’s reputation as a leader in sustainability and innovation. Implementing sustainable practices not only aligns with current market trends but builds long-term customer loyalty because consumers are increasingly inclined to support companies that demonstrate a commitment to the planet. So, what does this mean for your business? Understanding the value of this mineral could position your operations ahead of competitors in terms of innovation and sustainability, thus contributing to a more responsible marketplace.

What Are the Environmental Benefits of Zirconium Silicate?

The material’s relevance extends well beyond its industrial applications, as it also contributes positively to environmental goals. For businesses, this means lowering their ecological footprints while enhancing their material offerings. However, achieving sustainability often requires a comprehensive rethinking of conventional practices. Fortunately, zirconium silicate can bridge that gap with its environmentally responsible profile.

First and foremost, zirconium silicate has a notably lower carbon footprint compared to many other materials. It can be sourced sustainably due to its abundance in nature. Here’s the deal: The extraction processes involved, when managed properly, minimize disruption to the environment, helping businesses meet their sustainability targets and adhere to environmental regulations effectively.

Additionally, the integration of zirconium silicate can enhance the properties of materials, which leads to reduced waste during manufacturing. For instance, when used in ceramics, it enhances not only the product’s durability but also its aesthetic appeal, making them more marketable. The innovative use of this mineral can lower economic costs associated with waste management and disposal, further contributing to sustainability.

To highlight the key environmental benefits, consider:

- Lower carbon footprint: Sourced sustainably, minimizing ecological disruption.

- Reduced waste: Enhanced durability leads to less material needed in production.

- Sustainable sourcing: Abundant natural resources can lessen reliance on synthetic alternatives.

- Improved lifecycle impact: Products designed with this mineral typically last longer, reducing overall consumption.

Companies integrating this mineral into their production will find that not only are they making strides toward environmental responsibility, but they are also enhancing profitability and operational efficiencies.

How Does Zirconium Silicate Enhance Product Performance?

The mineral stands out not only for its sustainability but also for its performance advantages, making it an even more appealing choice for manufacturers. Businesses require materials that not only meet eco-standards but also deliver on performance metrics. Zirconium silicate exhibits unique properties that significantly enhance the functional capabilities of various products.

One major performance benefit is heat resistance. This exceptional ability enables the mineral to withstand high temperatures, making it ideal for use in applications such as ceramic tiles and heat-resistant coatings. Products made from zirconium silicate can handle harsh conditions without deteriorating, thus extending their lifespan and reducing costs associated with replacements and repairs.

Furthermore, zirconium silicate possesses excellent chemical resistance. Many industries require materials that can withstand exposure to aggressive chemicals and solvents without deteriorating or losing their structural integrity. This characteristic allows for broader applications across sectors, facilitating the use of this mineral in environments where other materials might fail.

You might be curious: What does this mean for your product lineup? A more durable product translates to lower replacement costs and higher customer satisfaction. This, in turn, enhances your reputation as a manufacturer committed to quality and sustainability.

| Performance Enhancements | Explanation |

|---|---|

| High heat resistance | Suitable for ceramic tiles and heat-resistant coatings. |

| Excellent chemical resistance | Endures harsh chemicals, significantly extending product life. |

| Structural integrity | Improved strength reduces vulnerability to wear and tear. |

Incorporating zirconium silicate into your product designs can lead to these enhanced offerings, ensuring that your products stand out in competitive marketplaces while meeting growing customer demands for sustainability and durability.

What Are the Applications of Zirconium Silicate in Industry?

Zirconium silicate’s versatility leads to a wide range of applications across several industries, showcasing its adaptability and making it particularly attractive to businesses aiming to leverage sustainable material trends effectively.

In the ceramics industry, for example, zirconium silicate is a common ingredient in the formulation of tile and sanitary ware. The incorporation of this mineral not only strengthens the products but also enhances their aesthetic qualities, making them more appealing to consumers. Additionally, its role in the glass industry is equally noteworthy, where it can enhance clarity and strength in glass formulations, producing high-quality materials suitable for a range of applications.

In the electronics sector, zirconium silicate is utilized in components such as capacitors and insulators. Its thermal stability and insulating properties make it ideal for these uses, ensuring reliable performance even under demanding conditions. The automotive industry is another significant sector where zirconium silicate is employed, particularly in braking systems and other components that require robust thermal resistance and durability.

The following table highlights key applications at a glance:

| Industry | Application |

|---|---|

| Ceramics | Tile and sanitary ware manufacturing |

| Glass | Enhanced clarity and resistance in glass products |

| Electronics | Components like capacitors and insulators |

| Automotive | Parts requiring high durability and thermal resistance |

This image illustrates zirconium silicate being used in ceramic tile manufacturing, showcasing its strength and aesthetic appeal.

For businesses, these diverse applications signal an opportunity to maintain a competitive edge by employing zirconium silicate in innovative ways, thus meeting diverse client needs while enhancing product offerings.

Why Is Zirconium Silicate Cost-Effective for Manufacturers?

Cost-effectiveness is a paramount factor for manufacturers when making material choices, and zirconium silicate presents a particularly favorable cost structure compared to many alternatives. Understanding these benefits can help businesses make informed decisions that positively impact their bottom line.

First, zirconium silicate often comes with lower sourcing and production costs than synthetic alternatives. Keep this in mind: Its natural abundance allows it to be sourced without the need for significant investment in extraction technology or complex processes. This directly influences the overall cost of finished products, giving manufacturers the ability to offer competitive pricing while maintaining quality.

Additionally, products made with zirconium silicate tend to exhibit lower replacement rates due to their enhanced durability and resistance to wear. This aspect can lead to long-term savings for consumers, ultimately resulting in higher customer satisfaction and repeat business.

Here’s a comparative breakdown of cost-effectiveness:

| Cost Factors | Zirconium Silicate | Alternatives |

|---|---|---|

| Sourcing Costs | Lower due to natural abundance | Higher due to extraction technology |

| Production Costs | Reduced due to efficiency | Higher with complex processes |

| Lifetime Costs | Lower replacement rates | Frequent replacements required |

Through understanding these financial factors, businesses can see why incorporating zirconium silicate is not only an economical choice but a strategic business decision for enhancing profitability and sustainability.

How Can Businesses Implement Zirconium Silicate Innovations?

Amidst the clear benefits, integrating zirconium silicate into existing production processes may seem daunting for some businesses. However, it can also present a powerful opportunity for innovation and operational improvement. Companies can follow several key steps to ensure a smooth transition.

First, conducting a thorough assessment of current material usage is vital. Take the time to identify specific areas where zirconium silicate could effectively replace existing materials without sacrificing quality. After pinpointing these opportunities, firms should engage with specialized suppliers of zirconium silicate. This collaboration can offer valuable insights and access to better practices that can enhance efficiency.

Training for staffs and stakeholders on the benefits and handling of this mineral is also essential. Educating teams about its properties and potential applications can lead to more informed choices during the production process, ensuring maximum efficiency and quality in the final products.

Here is a simple implementation path to consider:

| Implementation Steps | Description |

|---|---|

| Assessment of current materials | Identify areas to replace existing inputs. |

| Supplier engagement | Partner with specific zirconium silicate suppliers for optimal resources. |

| Staff training | Educate staff on proper handling, benefits, and production improvements. |

Taking these steps can help businesses efficiently adopt zirconium silicate in their production processes and reap the associated benefits, ultimately enhancing overall product quality and sustainability.

What Challenges Do Companies Face with Zirconium Silicate?

Despite its many benefits, companies face challenges associated with zirconium silicate that they must navigate effectively. Addressing these difficulties upfront is key to ensuring successful adoption and integration of the material.

A primary challenge is sourcing consistent quality zirconium silicate. Variations in material properties can impact product outcomes, leading to inconsistencies in production. Therefore, establishing trusted relationships with reliable suppliers is of utmost importance to ensure that the material’s quality remains high over time.

Additionally, regulatory considerations often come into play, especially in heavily regulated sectors. Businesses need to ensure compliance with various environmental and safety standards when sourcing, using, or applying zirconium silicate. This requires staying informed about relevant regulations and adapting practices accordingly to avoid potential legal challenges.

Market competition frequently affects pricing and availability as well. Companies must remain vigilant, keeping abreast of market trends and engaging with multiple suppliers to cushion against potential pressures.

| Challenges | Solutions |

|---|---|

| Quality variability | Build strong supplier relationships to ensure consistency in quality. |

| Regulatory compliance | Stay up-to-date on governmental regulations and safety standards. |

| Market competition | Monitor market trends and engage multiple suppliers when necessary. |

Identifying and proactively addressing these challenges will set businesses on a successful path toward utilizing zirconium silicate effectively.

How Are Innovations in Zirconium Silicate Shaping the Future?

Innovations continue to emerge in the field of zirconium silicate, with research and development aimed at Innovations continue to emerge in the field of zirconium silicate, with research and development aimed at maximizing its potential. Understanding these trends will help businesses adapt and thrive in the ever-evolving market landscape.

Research into new applications of zirconium silicate is steadily increasing. Manufacturers are exploring new formulations that enhance performance while reducing environmental impact. This focus on sustainable innovation is crucial for maintaining compliance with stringent sustainability guidelines and attracting eco-conscious consumers.

Moreover, advancements in extraction and processing techniques are ongoing, refining the methods used to obtain this versatile mineral. These developments aim to enhance material quality while simultaneously minimizing negative environmental effects, creating a win-win situation for manufacturers and the environment alike.

Here’s a summary of upcoming trends:

- New formulations: Enhance performance while emphasizing sustainability.

- Advanced extraction: Improve methods yielding higher quality with reduced impacts.

Keeping a pulse on these innovations will undoubtedly help businesses leverage the benefits of zirconium silicate material now and in the exciting future ahead.

What Questions Should Decision-Makers Ask Suppliers?

When considering zirconium silicate as a material option, decision-makers must engage with suppliers effectively. Asking the right questions ensures a strong partnership and a steady supply of quality materials.

Key inquiries should revolve around the quality assurance processes suppliers utilize. It is essential to understand how quality is measured and maintained throughout production. Additionally, asking about environmental compliance will shed light on the supplier’s commitment to sustainable practices, ensuring alignment with a business’s sustainability goals.

Lastly, understanding supply chain reliability is crucial to avoid disruptions in production. Ensuring that suppliers can consistently meet demand will affirm long-term operational stability and financial health for your business.

Here’s a summary of critical questions to consider:

| Questions to Consider | Purpose |

|---|---|

| How do you measure quality? | Ensure consistency and reliability of material performance. |

| What are your compliance standards? | Assess supplier commitment to environmental and safety standards. |

| How do you manage supply chains? | Understand the reliability of suppliers to prevent potential disruptions in production. |

Asking these questions will foster a strong and informed partnership with those supplying zirconium silicate, ultimately benefiting both parties.

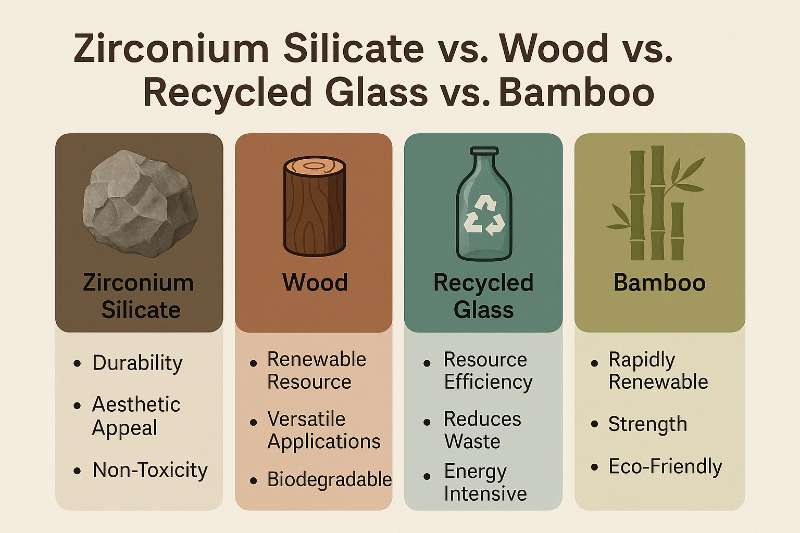

How Does Zirconium Silicate Compare to Other Sustainable Materials?

While various materials claim sustainability, zirconium silicate offers unique benefits that set it apart from many alternatives. Understanding what makes it special can help businesses make informed choices, ultimately benefiting both their operations and environmental initiatives.

For instance, traditional materials may provide some environmental advantages, but they often lack the versatility and performance characteristics exhibited by zirconium silicate. Comparatively, the durability and overall performance of zirconium silicate often exceed those of many synthetic options, granting it a significant advantage in numerous applications.

So, why does this matter? Companies utilizing zirconium silicate not only align with sustainability goals but also offer superior products to consumers seeking quality and accountability.

Here’s a quick overview comparing key sustainable materials and their attributes:

| Material | Benefits | Limitations |

|---|---|---|

| Zirconium Silicate | Durable, versatile, and eco-friendly | Sourcing quality can vary |

| Synthetic alternatives | Readily available, often lower cost | Typically less durable, higher environmental impact |

When seeking sustainable materials, zirconium silicate shines brightly as a superior choice, demonstrating that it can lead the charge toward achieving performance excellence alongside essential environmental goals.

This image illustrates a comparison between zirconium silicate and other sustainable materials.

Conclusion

In summary, zirconium silicate is integral to sustainable material developments. Its environmental benefits, exceptional performance metrics, and broad applications make it a valuable resource for industries aiming to improve sustainability practices. By adopting zirconium silicate, businesses can significantly enhance their product offerings while aligning with consumer expectations for quality and environmental responsibility. Global Industry invites you to consider how this mineral can transform your operations for the better. For further details and insights, connect with us today to explore potential partnerships and resources that can help elevate your business strategy and sustainability efforts.

FAQ Section

Q1: What is zirconium silicate?

Zirconium silicate is a naturally occurring mineral composed of zirconium and silicon. It is commonly used across various industries for its exceptional strength and durability, making it an essential component in products like ceramics and glass.

Q2: How does zirconium silicate contribute to sustainability?

This mineral plays a vital role in sustainability by offering a lower carbon footprint compared to many synthetic materials. Its natural abundance allows for sustainable sourcing, which minimizes environmental impacts during extraction and manufacturing while providing eco-friendly options for consumers.

Q3: In which industries is zirconium silicate most commonly used?

It finds extensive use in several sectors. The ceramics industry incorporates it in tiles and sanitary ware, while the glass sector utilizes it to enhance clarity and strength. Additionally, it is employed in electronics and automotive manufacturing, highlighting its versatile applications across different fields.

Q4: What are the advantages of using zirconium silicate over other materials?

This mineral stands out for its excellent heat and chemical resistance, which significantly enhances the durability of products made from it. Compared to traditional alternatives, it often provides superior performance and longevity, making it a cost-effective choice for manufacturers aiming for high-quality outputs.

Q5: What trends are influencing the future of zirconium silicate?

Recent trends include increased research into innovative applications and formulations that leverage this mineral’s unique properties. Additionally, advancements in sustainable production methods are shaping its future, reflecting a growing demand for eco-friendly materials that meet stringent environmental standards in various industries. with reduced ecological footprints. Additionally, the rise of smart manufacturing and the demand for sustainable materials are propelling research and investment in zirconium silicate. These trends underline its importance as both a raw material and a component of innovative products aimed at sustainability and performance optimization.