In today’s manufacturing landscape, companies often face significant challenges in sourcing materials that are both effective and environmentally friendly. Purchasing managers may grapple with selecting the right substances that meet industry demands while also fulfilling sustainability goals. The versatile mineral zirconium silicate is increasingly recognized as a key player in addressing these concerns, making it essential for modern material development. This article outlines why this compound stands out in sustainable material innovations, providing essential insights that help decision-makers understand its importance. Our analysis is grounded in current research and industry practices, ensuring credible information for informed decision-making. Readers will find practical advice on how to incorporate this valuable mineral into their operations effectively.

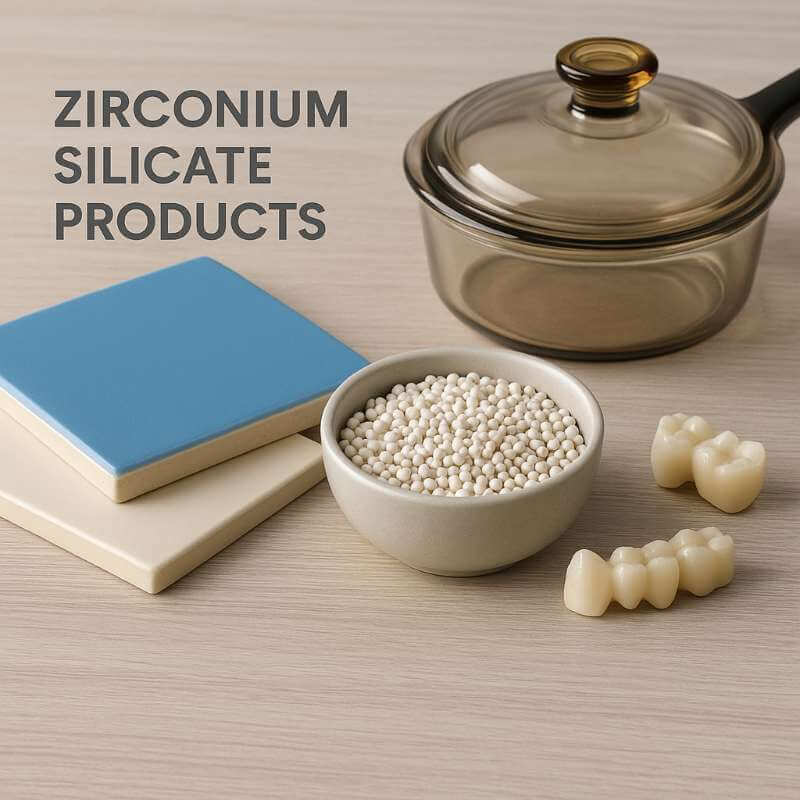

Zirconium silicate displayed in various applications, showcasing its versatility.

Why Is Zirconium Silicate Gaining Popularity?

Zirconium silicate has risen to prominence across various sectors due to its unique properties and versatility. So, what drives this growing interest? Various industries are becoming increasingly aware of the need for materials that not only deliver performance but also adhere to eco-friendly standards. The versatility of zirconium silicate allows it to be utilized in numerous applications ranging from ceramics to high-performance glass manufacturing. This mineral has a long history of use, but recent trends towards sustainability have led to a resurgence in its application.

Historically, this compound was primarily employed in ceramic processing, giving a distinctive advantage in producing robust and long-lasting products. However, with environmental concerns at the forefront of manufacturing practices, the focus has shifted to its role in sustainable applications. As industries face pressure to reduce their carbon footprints, materials like zirconium silicate that align with these goals become increasingly attractive.

Alternative materials often lack the same combination of durability, eco-friendliness, and cost-effectiveness. Many times, companies have to compromise between performance and sustainability. In contrast, zirconium silicate offers a reliable solution, making it an attractive option for companies looking to improve both their sustainability credibility and product quality. As a result, its market demand continues to grow, and it is now considered essential in multiple sectors.

What Are the Key Properties of Zirconium Silicate?

Zirconium silicate boasts several unique characteristics that contribute to its effectiveness and versatility. Here’s a breakdown of its key properties. Understanding these properties can help businesses leverage this material for a range of applications.

The chemical structure of zirconium silicate consists of a complex arrangement of silicon and zirconium atoms, which endows it with a stable and inert nature. This stability translates into a remarkable resistance to acids, bases, and extreme temperatures, making it an ideal choice for a variety of industrial processes.

Among its many physical traits, several are particularly noteworthy:

| Property | Description |

|---|---|

| High thermal stability | Withstands extreme temperatures without degrading. |

| Low thermal conductivity | Ideal for applications requiring thermal insulation. |

| Excellent adhesion | Improves binding in composites and coatings. |

Because of these qualities, businesses operating in demanding environments prefer this mineral over many alternatives. For example, the aerospace and automotive sectors, where performance under high-stress conditions is crucial, have found zirconium silicate particularly useful.

Due to the unique combination of these properties, many industries prioritize this compound for both traditional and innovative applications. This trend is driven by its performance and the growing necessity to adopt more sustainable practices across the board.

How Does Zirconium Silicate Contribute to Sustainability?

Sustainability is more than a trend; it is now a core focus for many companies striving to operate responsibly in the modern business environment. So, how does this mineral fit into these sustainability efforts?

First and foremost, zirconium silicate is associated with a low environmental impact during its production. Extraction and processing techniques aim to minimize energy consumption, reducing the carbon footprint associated with material sourcing. Many companies have adopted practices that ensure waste is kept to a minimum, further underscoring its eco-friendly profile. The sustainable attributes of this mineral make it particularly appealing for organizations committed to improving their environmental footprint.

Another aspect of sustainability lies in its long lifecycle. Products made with zirconium silicate often have enhanced durability, meaning businesses can reduce the frequency of replacements and conserve resources. This longevity reduces the ongoing demand for raw materials, which is integral to sustainable operations.

Moreover, the mineral’s role in recycling initiatives cannot be overlooked. Zirconium silicate can often be collected and reused in various applications, aligning perfectly with the principles of a circular economy. For example, in ceramic production, off-cuts and rejected pieces can be reprocessed and turned back into usable materials, minimizing waste and resource consumption.

In concise terms, the sustainability benefits it offers include:

| Sustainability Benefit | Description |

|---|---|

| Minimal environmental footprint | Relatively low energy consumption during production. |

| Longevity and reduced need for replacements | High durability leads to longer-lasting products. |

| Opportunities for recycling and reuse | Can be collected and repurposed in various applications. |

When compared to many traditional materials, zirconium silicate emerges as a responsible and intelligent choice for manufacturers committed to a sustainable future.

What Industries Benefit the Most from Zirconium Silicate?

Understanding where zirconium silicate’s benefits apply can help businesses target their procurement efforts effectively. Which sectors gain the most from using this versatile material?

A variety of industries leverage the unique properties of zirconium silicate, including:

- Ceramics: This is one of the largest markets, where the mineral contributes to creating tiles, pottery, and dental applications. The added strength and aesthetic qualities enhance the finished products significantly.

- Glass Manufacturing: In this sector, zirconium silicate improves the thermal shock resistance of glass products, allowing them to be used in high-temperature situations without compromising performance.

- Electronics: For electronic components, this mineral serves as a critical ingredient in manufacturing specialized materials that require stability and performance under varying conditions.

Additional sectors like construction and automotive also see notable advantages from utilizing zirconium silicate, particularly in products that demand high-performance characteristics. As a result of its versatility, companies across different fields enhance product quality while aligning with their sustainability commitments.

The following table summarizes key applications of zirconium silicate:

| Industry | Application | Benefits |

|---|---|---|

| Ceramics | Tile and pottery production | Improved strength, durability, and aesthetic value |

| Glass Manufacturing | Specialty glass production | Enhanced thermal shock resistance and clarity |

| Electronics | Semiconductor manufacturing | Improved stability, thermal performance, and reliability |

| Automotive | Engine components | High heat resistance, enhancing longevity and performance |

Through these applications, businesses can achieve significant performance improvements without sacrificing their commitment to sustainability.

The image illustrates various ceramics and glass products that utilize zirconium silicate for enhanced performance.

How Can Purchasing Managers Leverage Zirconium Silicate?

Purchasing managers play a pivotal role in the seamless integration of effective materials into production systems. So, how can they leverage the advantages of this mineral effectively?

Cost-effectiveness should be a fundamental consideration. While zirconium silicate may present a higher upfront cost compared to some alternatives, its long-term benefits, including reduced maintenance and replacement, often provide a favorable total cost of ownership.

Establishing reliable supplier partnerships is another critical effective strategy. Evaluating suppliers based on a range of criteria—including quality control systems, certifications, and track record—can yield better procurement outcomes. Moreover, negotiating contracts that include sustainability commitments can also protect against future cost volatility.

Here are some practical strategies for purchasing managers:

- Analyze total cost of ownership: This approach goes beyond just purchase price and takes into account longevity, performance, and maintenance costs associated with the material.

- Build relationships with trusted suppliers: Long-term partnerships often lead to better pricing and reliability of supply, making it easier to ensure stock availability.

- Negotiate sustainability clauses in contracts: This adds an essential layer of assurance, holding suppliers accountable for their environmental impact, which aligns with buyers’ organizational goals.

Taking these actions positions purchasing managers to make informed decisions that not only fulfill operational needs but also resonate with sustainability goals.

What Are the Challenges in Using Zirconium Silicate?

Though zirconium silicate offers many advantages, it is not without its challenges. What common issues should stakeholders be aware of?

One primary challenge is the misinformation regarding performance and applications. Some businesses may overlook or misunderstand its capabilities due to preconceived notions about alternative materials. Addressing these misconceptions through education and outreach can promote a broader understanding of its true potential.

Another challenge lies in environmental regulations. Navigating the complexities of compliance with differing sustainability guidelines can be daunting, particularly for organizations operating internationally. Companies must stay informed of local legislation to avoid fines and ensure smooth operations.

Finally, sourcing high-quality zirconium silicate can sometimes present difficulties. Not all suppliers maintain the same standards of quality control, requiring businesses to conduct diligent supplier assessments to ensure product reliability.

Some potential challenges include:

- Misconceptions about material performance: This can inhibit organizations from considering valuable options.

- Regulatory compliance complexities: Rapidly changing laws and guidelines require continuous monitoring to ensure adherence.

- Issues with supplier-quality consistency: Careful vetting of supplier capabilities is necessary to maintain product quality.

A proactive approach to these challenges can help businesses fully realize the benefits that zirconium silicate offers.

How to Evaluate Zirconium Silicate Suppliers?

Selecting the right supplier is critical in ensuring quality and consistency when integrating a new mineral into production processes. How can businesses evaluate their options effectively?

Start with assessing credentials and certifications. Reliable suppliers should comply with industry standards and be able to provide the necessary documentation to support their claims. This step is essential in establishing trust and accountability.

Next, customer feedback and case studies can offer valuable insights. Positive testimonials reflect reliability and quality, assisting in the decision-making process. Take the time to review case studies to understand how different suppliers have performed in real-world applications.

Finally, engage in direct communication with potential suppliers. Discussing specific needs and requirements and gauging their responsiveness and willingness to collaborate can provide insights into their professionalism and service levels.

Key factors to assess include:

| Evaluation Factor | Description |

|---|---|

| Certifications and compliance | Ensure the supplier meets necessary regulations for your industry. |

| Customer testimonials and case studies | Look for evidence of successful projects that showcase the supplier’s strengths. |

| Supplier responsiveness | Assess how willing and adaptable the supplier is to your needs. |

This thorough evaluation ensures that companies build strong partnerships with reputable suppliers capable of meeting their demands.

What Innovations Are Emerging in Zirconium Silicate Applications?

Innovation drives advancement in manufacturing processes and the adoption of new materials. What emerging trends should decision-makers consider?

Recent developments focus on improving production processes and widening application areas. Advances in technology are allowing for better extraction and processing methods, thereby making zirconium silicate more cost-effective and environmentally friendly. This continuous improvement plays a critical role in keeping products competitive in the market.

Research and development initiatives continue to explore new applications, highlighting its potential in fields that may have previously eschewed this mineral. For instance, innovations in coatings that utilize zirconium silicate are exhibiting enhanced durability in extreme conditions—this has potential applications in the aerospace industry where performance and safety are paramount.

The following table outlines some recent innovations:

| Innovation | Description | Benefits |

|---|---|---|

| Advanced Coatings | Coatings for extreme conditions | Increased durability, corrosion resistance, and longevity |

| Sustainable Sourcing | Eco-friendly mining practices | Reduced environmental impact during extraction |

| Enhanced Processing | New techniques for material refinement | Cost reduction and improved quality assurance |

Companies should remain vigilant about these ongoing trends, as they may open new market avenues and lead to more sustainable manufacturing practices.

The image represents various innovative applications of zirconium silicate across different industries.

How to Integrate Zirconium Silicate Into Existing Systems?

Integrating new materials can be daunting, especially given the complexities of manufacturing processes. What strategic steps can ease this transition?

Begin by assessing existing systems to understand how this mineral will fit into current production setups. Identifying potential challenges and necessary adjustments prior to implementation can help mitigate disruptions.

Training staff on the properties and best practices associated with zirconium silicate is crucial. Ensuring that teams fully grasp how it differs from previously used materials will minimize the risk of errors in handling and application.

In addition, conducting pilot tests can provide valuable insights into product performance. Starting with small batches allows companies to gauge the effectiveness of zirconium silicate in real-world production conditions before making larger commitments. Once outcomes are well understood, scaling up becomes significantly easier.

Key actions for successful integration include:

- Assess current systems for compatibility: Understanding how existing processes will accommodate the new material is essential.

- Train teams on properties and best practices: Equip staff with the knowledge needed to work with zirconium silicate effectively.

- Conduct pilot tests: Collect data on performance before fully integrating into the production pipeline.

By undertaking these proactive steps, companies can achieve a smooth transition and successful outcomes with their material operations.

What Future Trends Should Decision-Makers Watch?

As manufacturing industries continue to evolve, so do material needs and consumer expectations. What future trends surrounding zirconium silicate should leaders monitor closely?

Market growth for this mineral is anticipated to increase substantially in the coming years. With a global shift toward sustainability, more companies are recognizing the value of incorporating eco-friendly materials in their supply chains. This trend is likely to enhance the demand for zirconium silicate as organizations seek to comply with environmental standards.

Moreover, advancements in technology that enhance the properties of zirconium silicate will likely lead to innovative applications. As research progresses, it is becoming increasingly plausible that this mineral may find a place in sectors not previously considered, driving new opportunities for growth and development.

Fostering collaboration between manufacturers and researchers will also prove vital. This partnership is essential for driving innovation, yielding tailored solutions that meet emerging challenges alongside significant advancements in material sciences.

Future considerations include:

- Increased demand for sustainable manufacturing practices: As cleaner production technologies gain traction, zirconium silicate’s role may expand.

- Expanding use in innovative applications: Continued advancements may lead to exciting new roles for this mineral across various fields.

- Collaboration with academia and industry: Partnerships could inspire innovative uses and propel new research initiatives.

Staying updated on these trends will equip organizations with the knowledge necessary to adapt to rapid changes in manufacturing dynamics.

Conclusion

In this comprehensive analysis, we explored the significant role of zirconium silicate in sustainable material solutions. By identifying its key properties, industry applications, and overall benefits, companies can enhance their understanding of its relevance in today’s market. The adoption of zirconium silicate fosters a responsible approach to sourcing materials, ultimately leading to significant efficiency gains and cost reductions. For expert guidance in sourcing high-quality zirconium silicate, connect with Global Industry today. With the right materials and partnerships, your business can meet sustainability goals effectively and unlock new avenues for growth.

FAQ Section

Q1: What makes zirconium silicate environmentally friendly? Zirconium silicate has a low environmental impact during production and promotes recycling efforts, making it a sustainable choice for manufacturers.

Q2: In which industries is zirconium silicate most commonly used? Key industries include ceramics, glass manufacturing, electronics, and automotive sectors, where its unique properties facilitate enhanced performance.

Q3: How can I find reliable suppliers for zirconium silicate? Look for suppliers with industry certifications, positive reviews from previous customers, and a solid track record of quality assurance in their products.

Q4: What challenges might arise when using zirconium silicate? Challenges include addressing misconceptions about its performance, navigating regulatory compliance complexities, and ensuring recipient quality throughout the supply chain.

Q5: What future developments could affect zirconium silicate usage? Emerging technologies alongside market demands for sustainability may expand innovative applications, and usage within various sectors could grow as awareness increases.